EN | 76 |EN

the appliance immediately. Do

not pull the plug out of the elec-

trical outlet, as this can become

a source of ignition.

• Operate the appliance only

in well ventilated areas. Keep

ventilation openings clear of

obstruction. Without adequate

ventilation there is a danger of

explosive gas mixtures.

• A drinking water cooler having

ammable refrigerant shall not

be intended for use in lobbies

or locations of egress, such as

a hallway or public corridor.

Danger of injury from sharp

corners and edges!

In the area of ventilation slits,

there is the danger of injury from

sharp corners and edges.

• Always carry out work in this

area with caution.

Danger to life from improper

installation and initial commis-

sioning!

Errors in the installation or ini-

tial commissioning can lead to

life-threatening situations and

cause substantial property dam-

age.

• All wiring and plumbing must

conform to national, state, and

local codes. Failure to comply

could result in serious injury,

death or equipment damage.

Water pipe connections and

xtures directly connected to a

potable water supply shall be

sized, installed, and maintained

in accordance with federal,

state, and local codes.

• Only trained and certied elec-

trical, plumbing and refrigera-

tion technicians should service

this unit. Always have installa-

tion and initial commissioning

carried out exclusively by per-

sons qualied by the manufac-

turer or a qualied dealer.

• Disconnect power to the unit be-

fore servicing. Follow all LOCK-

OUT/TAGOUT procedures.

Verify power to the unit is OFF

and disconnected before any

work is performed. Failure to do

so could result in serious injury,

death or equipment damage.

• Refrain from unauthorized instal-

lation and changes of location.

• The Electrical LOCKOUT/

TAGOUT Procedure is used to

protect personnel working on

an electrical unit. Before per-

forming any maintenance or

service that requires exposure

to electrical components, follow

these steps:

• In Electrical Box, place unit Cir-

cuit Breaker into OFF position.

• Place a lock or other device

on the Electrical Box Cover to

prevent someone from plac-

ing Circuit Breaker in the ON

position.

• Place a tag on Electrical Box

Cover to indicate that unit has

been disconnected for service

and power should not be re-

stored until tag is removed by

maintenance personnel.

• Disconnect the unit’s Power

Cord from Electrical Outlet.

• Place a tag on the Power Cord

to indicate that the unit has

been disconnected for service

and power should not be re-

stored until tag is removed by

maintenance personnel.

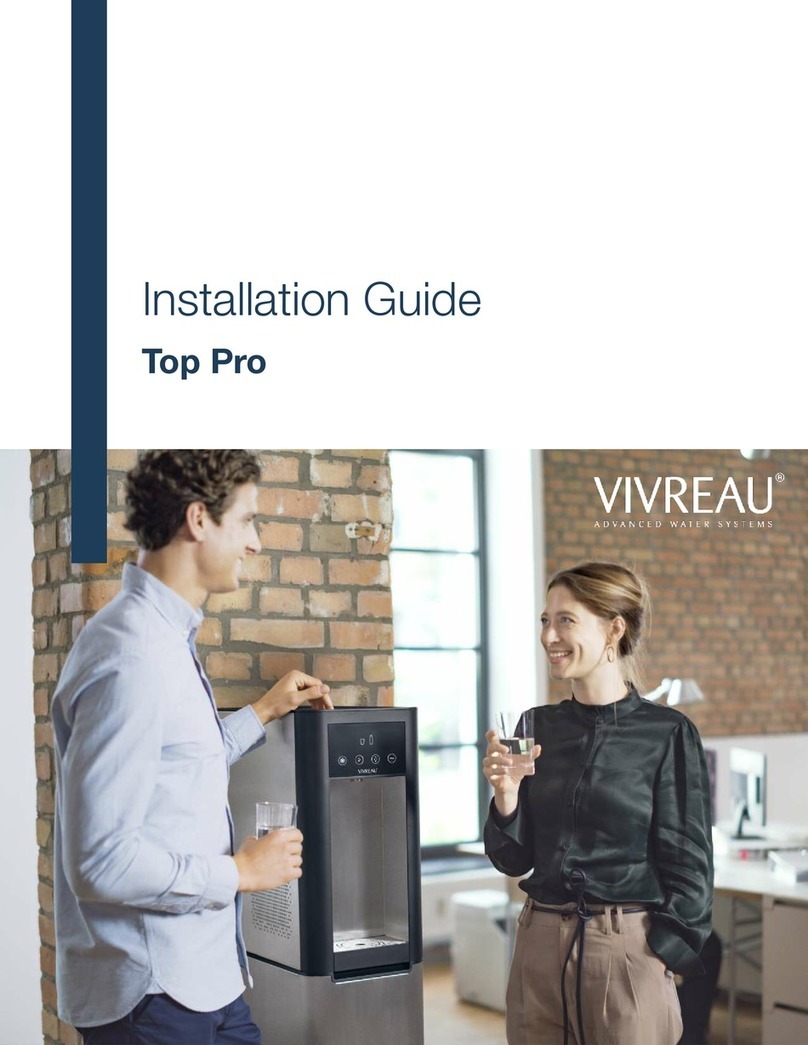

• The water dispenser may not

be installed near direct or

indirect heat sources (such as

ovens, radiators, heaters, dish-

washers, washing machines

and so forth). Likewise, hoses

and cables must not come into

contact with heat sources.

• The water dispenser must be

placed on a level surface that

can bear the weight and is re-

sistant to liquids and heat.

• The water dispenser may not

be installed at locations where

there is a possibility of sprayed

water or jets of water.

• No objects may be placed on

the water dispenser.

• The water dispenser should not

be cleaned with a water jet.

• There must be no explosive,

corrosive or abrasive environ-

ment condition. Keep the water

dispenser away from amma-

ble objects.

• The water dispenser must not

be subject to agitations and

vibrations.

• The water dispenser is not suit-

ed for outdoor use.

• Never cover or block ventilation

slits and cooling ns.

• The water dispenser is to be

installed in locations which have

free access and can be moni-

tored by trained personnel.

• Consult the manufacturer even in

the case of a change of location.

Danger to health from contam-

ination!

Not following the hygiene guide-

lines can lead to contamination

of the end product and could be

harmful for the consumer.

• Observe all statutory regula-

tions and hygiene guidelines.

• Always be aware of hygiene at

the installation location.

• Ensure that the operating envi-

ronment of the water dispens-

ers corresponds to the stated

specications.

• Always maintain the cleaning

intervals.

• Always maintain the disinfec-

tion intervals.

• Always maintain the intervals

for replacing lters.

• Flush the water dispenser after

a standstill of 24 hours.

• Flush the water dispenser

after more than 120 minutes of

being disconnected from the

power supply (see ‘After longer

periods of inactivity’ on page

28).

• Always avoid contact with the

outlet tap.

Danger of injury through slip-

ping in puddles of water!

Slipping in puddles of water on

the oor could cause a fall. A fall

could result in injuries.

• Wipe up puddles of water using

a cloth immediately.

• Check the drip tray regularly

and empty it if necessary.

SAFETY INSTRUCTIONS