ERL AQUAMIST HFS-5 User manual

Instruction manual v3w1

FIDC tracking water injection system

GETTING TO KNOW THE AQUAMIST HFS-5

Over the last few years, demand for great engine power output is increasing. Cubic inches option is

no longer the norm. Squeezing out 200-300hp per litre is within the reach of the ordinary folks on the

street. The tuning industry has grown to embrace new tuning technique as well as readily affordable

components to produce powerful and reliable engines.

We, at Aquamist has also coming to terms with the inevitable, meeting the demands of the market

and offering new systems capable of supporting engine power output up to 1000+ BHP.

The HFS-5 reads the duty cycle of a fuel injector and delivers water proportional to fuel flow. Wate

r

quantity is metered by a High speed inline valve and flow is monitored by a turbine flow sensor.

For clogged jet and severed hose. A number of options are available for the user to limit engine

power in the absence of water flow.

We believe the HFS-5 meets all the requirement of a high-end water injection system for achieving

fast engine transient and responses with absolute precision. Tracking the fuel delivery is the most

reliable method to deliver your fluid flow under the whole engine operating cycle. Anything short o

f

this means having to tailor your fuel map to compensate the irregular fluid quantity ingested by the

engine.

Page 3

Contents:

System overview Page

3 Checking the contents of the box

4 Getting started on installation

J

unction Box

5 Junction box pin-out description

6 Flow Sensor

HFS/DDS3

7-8 HFS-5/DDS3 Dash Gauge Functions

9 Powering the system up for the first time

10 Failsfe with a number of options

Failsafe:

11 Boost control / MAP switch

Wiring: 12 Jet sizes & Advanced delivery management

13 Final check-up and setting up the failsafe

14-16 Generic wiring for PWM and MPS mode

Appendix:

17 Electrical / Mechanical specifications

18 Wiring details Guarantee and Warranty

This is a “must do” immediately

after unpacking ....

Water pump

Unpack the corrugated sheet carefully. The pump

should be labelled with the original custom Shurflo/

Aquamist part #8030 912 239 .

The white box

♦6M of 6mm OD nylon hose (806-261)

♦2M of 4mm OD nylon hose (806-266)

♦15A Fused water pump harness with 40A relay

♦75mm stainless hose clip and support bracket

♦HSV with 6/4 mm hose connector and clips and

2-way sealed plug and socket set (806-244)

♦0.8 mm water jet (806-323) in plastic bag

♦0.9 mm water jet (806-324) in plastic bag

♦1.0 mm water jet (806-325) in plastic bag

♦1x 4mm Y-piece (806-362) in plastic bag

♦2x M8 x 1/8 BSP jet adaptor with plug (806-357)

♦FIA2 (806-441) module with HFS-5 harness -3A

FUSE

♦1x water tank adapter 1/8 BSP (806-270) + 6mm

qck-fit elbow (806-376)

♦100 micron inline water filter (806-257)

♦4x M5x 40mm, nuts, washers and fasteners for

pump

♦1x M6 grounding stud with washed and nuts

and 6mm eyelet for pump ground

♦5-port brass manifold with 3/8BSP adapter. 3x

blanking plugs, 1x 3/8 BSP-M to 1/8BSP-F adap-

tor 2x 6mm 1/8BSP-M elbow.

♦1x 22cc surge arrestor/accumulator (806-409)

♦1x Pump label

DDS3v8 fluid monitoring system box

♦Assortment of 22 AWG coloured hook-up wires

♦1x DDS3 Dash Gauge with 1.5 M x 8-way cable

♦1x Version 8 Junction box

♦1x water level switch with connector (806-280c)

♦1x Digital flow sensor (806-428)

♦A set of wires for inter-connection

Note: Please contact your supplier immediately should yo

u

discover any missing parts.

Checking the contents of the box carefully

Page 2

Page 4

Page 5

Before installations guidelines

♦The pump and water tank is designed to be fitted

in the trunk. Install the water pump and inline

filter below the water tank.

♦Ensure all fittings are tighten and leak proof

before filling up with methanol, test it with water

first. If high concentration of methanol is used,

please vent the tank’s breather hole externally.

Methanol is poisonous at high concentrations.

Assembling the pump in steps

♦Gently assemble the two 3/8 BSP adapters into

the pump without crossing the threads. The

female one going into the inlet of the pump.

Flow direction is moulded onto the plastic pump

head. Ensure o-ring is properly seated.

♦Ensure the accumulator lies horizontally after

final tightening.

♦Assemble the accumulator supporting bracket

with the metal band supplied.

♦Assemble the rest of the 1/8 BSP elbow fittings

and blanking plugs. Ensure all o-ring type fittings

are not overly tightened.

♦Mark (dyes smeared on the bottom of the

pump’s rubber feet) and drill four holes for the

pump.

Water tank components

♦

Ensure the outlet is facing the rear or the side of

the tank. Drill/bore a burr-free 7/8“hole. Clear up

all the burred edges and wash the tank thor-

oughly. No debris or plastic shaving should re-

mained in the delivery system. 1-2 inch from the

bottom of the tank is ideal.

♦

Same size hole for the water level sensor. Do not

place the sensor near the washer pump, it will

not operate properly. The float should swing up-

wards. Tank venting hole must be re-directly

externally if high alcohol concentration is used.

♦A tall and slim water tank is ideal for this type of

application. Minimise delivery surge problems at

low water level.

Getting started on installation

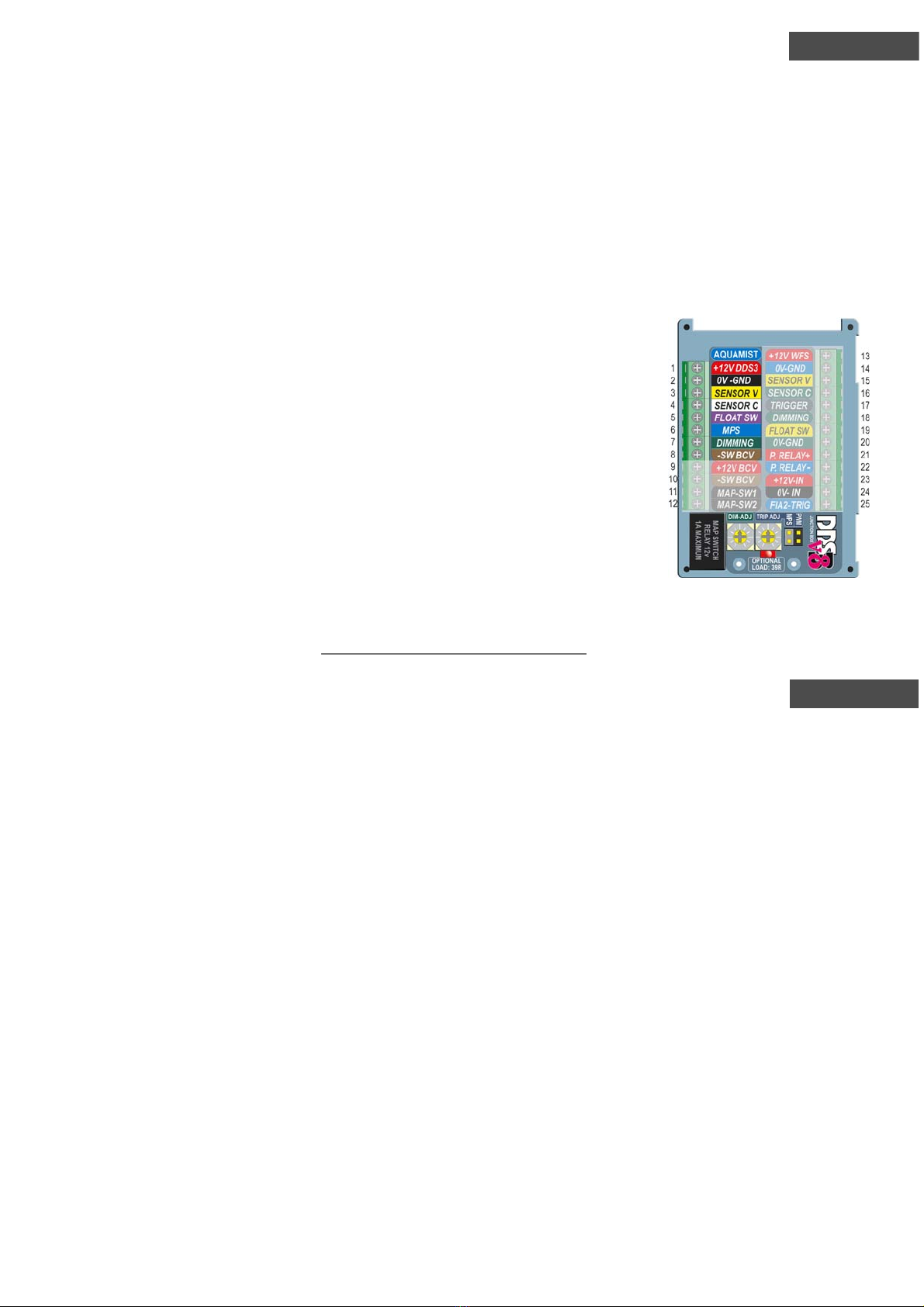

Pin1-8

Legends are colour matched and

connects directly to DDS3 Gauge

via a 8-core cable.

Pin 9-10

It will activate a wastegate sole-

noid valve directly when correct

water flow is detected (system

on). Pin 9 is a fused +12Vand

Pin10 Switches to ground.

Pin 11-12

This relay output can be used to

disconnect the OE boost control

valve and switch to a “Dummy

load resistor” to prevent “engine

check lamp” activation. “Dummy

Load Resistor” is supplied can be

soldered in. It can also be used to

switch pre-defined MAP on a third party EMS, if

available. Open circuits under fault or “DDS3-OFF”.

Pin 13-16

Flow Sensor connections, colour matched.

Pin 17

Failsafe triggering input. PWM or MPS (mode) -

section by jumper link at the bottom of the board.

Pin 18

To car’s +ve of parking lamp circuit to enable “DIM-

ADJ” potentiometer on the DDS3 junction board

Pin 19-22

To water level switch and priming pump

relay (up to 0.2A). Pin 22 switches to

ground on activation when pin 17 is

triggered.

Pin 23

Main +12V power supply to the DDS3.

Wired to the Fuel injector’s +ve supply.

Pin24

To 0V, Battery negative or chassis

ground with good electrical contact.

Pin25

FIA2 Fuel injector amplifier trigger in the

absence of manifold pressure switch or

FIDC (fuel injection duty cycle) trigger is

preferred. (for Aquamist use only)

TRIP ADJ potentiometer

Setting failsafe tripping range between 25 to 75% full

scale of the signal seen at pin 17.

DIM ADJ potentiometer

Adjust display/backlit intensity on the gauge for night

driving conditions.

MPS/PWM jumper link.

Selecting mode of operation: the WI system can be

triggered by either Manifold pressure sensor (MPS)

or fuel injector’s Duty cycle (PWM). Adjustable be-

tween 12% to 72% via “TRIP ADJ”

Junction box pin-out description

Page 6

Page 7

Flow Sensor

The standard sensor has a 1/8BSP (parallel

thread) female port on each end. Do not use 1/8

NPT fitting male thread as the tapped thread may

crack the ports. Use a 1/8BSP(M) to 1/8NPT(F)

adaptor to convert the fitting if the hose you are

using is not the same as the Aquamist type

(4mm and 6mm OD). The sensor is bi-directional

but do not change flow direction after long period

of usage unless the two internal disc filters are

properly cleaned. The sensor is suitable for use

with water or methanol at any concentration.

Sensor is fitted with 1/8BSP 4mm qck-fit hose

connectors from factory.

The DDS3 junction board supplied all the neces-

sary electrical power and signals to and from the

sensor via a 4-core cable. Length can be extended up

to 20 feet without any loss of accuracy.

Diagram below show the pin-out and functions of the

DDS3 terminals. Sensor V refers to the actual flow

signal from the sensor. Sensor C is for internal

reference use only. If you need to data-log the flow

rate, take the signal form the Sensor V terminal.

Do not install the

sensor near any mag-

netic radiated de-

vices such as ignition

coil, motors or sole-

noids because it in-

terferes with the hall

effect sensor that

reads the turbine

speed. Avoid areas

with high heat and

vibrations. A cool and

dry location is ideal.

Never reverse the

polarity of the power

feed to the sensor or

permanent damage may occur.

1. 8-element Bargraph Display (80-1200ml/min)

Each segment is equivalent to 50ml/min. of flow if the

sensor is calibrated for absolute mode.

Depends on user preference, the display can be scaled

to suit the liquid flow up to 1 litre per minute. (see 5)

2. “S” indicates the presence of sensor.

The letter “S” (sensor) must be lit after power up and

stay on to show the sensor is functioning correctly.

3. Water injection ON led

This led comes on the when the dash button is de-

pressed, showing the water injection system is enabled.

.

It will switch to full brightness when the DDS3

is triggered. (Pin 17)

4. Water Level Sensor led (yellow)

When the water level in the tank is below the

sensor, this led will light up and disables the

water injection as well as any other related

functions such as high boost, priming pump

and main pump.

5. SC (Sensor Calibration)

20-stepped potentiometer allow user to scale

the flow sensor to give an ideal visual indication

of a given flow rate. Ideally set the full scale of

the sensor about two/three segments below

maximum so a problem is easier to identify. It

can also be used to trim the sensor to show a

absolute or relative values for a particular set up.

6. Backlit flow legend

Fixed scale to indicate absolute flow rate.

Sensor must be calibrated for each application

for accuracy - scale will be updated .

7. “B” Boost Enabled led

This led lights up to show the “extended

boost” over wastegate is triggered. Provided

the following conditions are met: “Water Injec-

tion On” button is depressed, flow-rate is in-

side the set window and water tank is above

the set level.

1

2

3

5

7

10

9

8

6

4

HFS-5/DDS3 Dash Gauge Functions

Page 9

Page 8

8. Water injection enable button

Due to extra power level achieved under WI, user

want may want to reduce the power to the wheels

in less than ideal driving conditions. Disabling the WI

will reduce boost to wastegate bleed valve setting (if

fitted) as well as switching to a less aggressive MAP

on custom engine management.

9. Over-range setting potentiometer

It is just as important to monitor over-range condi-

tions as well as under-range flow conditions. If a leak

develops close to the water jet and starves the

engine of the water, the user must know this condi-

tion. A 20-stepped potentiometer allows accurate

and repeatable adjustment range.

10. Under-range setting potentiometer

This setting can indicate partial blockage and trapped

air inside a delivery hose. Again a 20-stepped poten-

tiometer is employed.

NOTE: The two range potentiometers “9”and“10”

form the basis of a SOA (Safe Operating Area) that

allow users to tune their car more safely.

Please note that methanol has only 80% mass of

water and 50% latent heat of water. If water and

alcohol mix is injected, allow a bigger jet to compen-

sate this. This is a common mistake often made.

Every 25% of methanol added should allow a 0.1mm

Increase of jet size diameter.

Installation

The gauge will fit into any 52mm gauge pod and a

two-prong bracket is provided. Do not over-tighten

the thumb-wheel since it has an embedded o-ring to

create high friction between the surfaces thus pre-

venting loosening due to vibrations.

An open ended 8-core cable is provided for connect-

ing the gauge to the junction box where all the other

sensors and peripheral devices are terminated. We

avoid using plug/socket termination because it is

difficult to thread them through the firewall between

the engine bay and pas-

senger compartment

All the core colours are

coded and matched to

the legends in front of

the terminal block, this

helps to avoid any acci-

dental termination er-

rors. The wires should

be stripped and twisted

before inserting into the

terminal blocks. The

eight top left terminals

are reserved for the

DDS3 gauge.

Powering the system up for the first time

The HFS-5 is setup as PWM-triggered mode

from factory, ie, when the fuel duty cycle has

reached a preset %, the water injection com-

mences. Please check the DDS3 junction box set to

“PWM” on the jumper link.

Step 1: Powering up the system

Disconnect the hose from the water jet and locate

it into a container, Ignition key on #1 & 2, the pump

should remain idle. Switch the DDS3 on via the

dash gauge button, again the system should remain

idle, Two leds should illuminate - “S” and “water

injection” Start the engine,

Step 2: FIA2

If the FIA2 is wiring and reading the fuel duty cycle

correctly, the green led should illuminate after the

engine is fired up and not before. You should see a

faint pulse following the engine RPM. The red led

should not illuminate at this stage.

Step 2: Manually triggering the DDS3 J.Box

Locate the “TRIP ADJ” potentiometer and turn it

fully counter-clockwise. At 12% injector duty cycle

(IDC) the WI should commence.

Blip the throttle to induce more IDC, you should see

the red led below the potentiometer lights up.

Repeat it several times to confirm this.

Step 3: Check the rest of the system.

Upon the triggered period, you should check the

following peripherals are receiving the correct signal

from the DDS3 Junction board.

1. The red led on the FIA2 illuminates

2. The “water injection” led on the gauge should get

brighter.

3. The HSV should click and buzz.

4. The water pump should turn on,

All above conditions should revert back after trig-

gered period is over.

5. The DDS3 bargraph should register flow.

Make a note of anyone of the item/items did not meet the

above conditions,contact Aquamist or your Supplier.

Step 4: Final check-up before going for a drive

Repeat the throttle blipping until all the air is purged

out of the system. You should see a continuous

stream of water coming out of the hose every time

you blip the throttle, purging is now completed.

Adjust the “TRIP ADJ” to mid way, reconnect the

hose to the jet take the system for a test drive.

You have successfully installed the system. The

system can also be triggered by manifold pressure

by relocating pin 17 to a map sensor and set

to“MPS”.

Page 10

Page 11

Failsfe with a number of options

Assuming the system is running reliably and

worked properly without any issues. Implementing

the failsafe option is the next step. The DDS can

offer a number of options to be integrated into an

existing set up so that the engine can receive ade-

quate protection when water injection flow is inter-

rupted. Pin 9 to 12 is dedicated for this purpose

Standard factory car with boost controller:

Most turbo cars from the factory runs rich under

boost conditions. With the help of a boost controller,

you can utilise those excess fuel for power by rais-

ing the boost pressure. Water will be injected to

replacing those excessive fuel. This is a very cost

effective power enhancement modification. Wiring

schematics for such a usage. (See page 16)

Standard factory car with light modifications:

Boost pressure is raised, Ignition and fuel map is

modified by either of a off-the-shelf Rom chip re-

placement or a reflash. Water injection is used to

assist in-cylinder intercooling and knock suppression.

On those set up, cutting boost to wastegate pres-

sure is ideal, in the event of water flow being inter-

rupted. (see page 14)

Standard factory cars with piggyback modifications:

Piggyback ECU is another tuning option. In general,

Signal from a load sensor is intercepted and modi-

fied before pass it to the existing engine manage-

ment. These modification can be quite involved at

times. For those applications, dropping the boost is

the simplest option. Some high-end system offer

several user selectable octane-compensated maps

but it is rare switch-able “on the fly”.

Factory EMS replacement with third party EMS:

This can possible be the most ideal set up for water

injection. A dedicated input switch allow instant pag-

ing of alternative map in the event of water flow fault.

Boost control / MAP Switch

The DDS3 can perform a few useful functions

to enable the engine to run leaner and more timing

advance with minimum of risk to the engine. In

return for some extra power and torque. Details of

how this can be achieved are listed below.

Equipped with two outputs from the junction box,

the DDS3 is able to alter boost or switch an alterna-

tive fuel/ignition

MAP in the ab-

sence of water

(when available).

The first output can

drive boost control

bleed valve directly

to increase boost in

the “presence” of

water (Pin 9/10),

The second output

(Pin 11/12) is in the

form of “circuit break” relay output in the “ab-

sence” of water during high boost or high fuel duty

cycle,

Both outputs revert the car back to standard setting

when the DDS3 dash switch is turned off or the

water tank level is low or water flow is not within

the preset “flow-window”

Pin 9 and Pin 10:

Pin 9 is a steady +12V supply and Pin 10 switches

to ground when the water flow is within the set

limits. It is designed to activate a solenoid valve (not

supplied) to raise boost. It can also be used to

activate a MAP sensor clamp to trim fuel and ad-

vance ignition timing. This function is disabled when

the DDS3 is turned off.

Pin 11 and Pin 12:

The remaining two connections Pin 11 and Pin 12

are “normally opened” voltage free contacts. When

the DDS3 is first switched on, the contacts closes

and stay closed until a “flow fault” is detected.

It is an ideal output to switch an aggressive fuel

/

ignition MAP off when water flow is interrupted. The

same pair of contact can also be used to reduce

boost by cutting the feed to a solenoid-type boost

control valve,

Pin 4 (sensor calibration comparator input):

The pin is normally used for scaling the flow sensor

but it can also be used to form a “real-time” close

loop flow comparator, against a known flow curve.

Please contact Aquamist for this advanced usage of

this input.

+12V BCV

-SW BCV

MAP-SW1

MAP-SW2 0

RESISTOR

DIM-ADJ

OPTIONAL

LOAD: 39R

MAP SWITCH

RELAY 12v

1AMAXIMUM

9

10

11

12

12V

-SW

GROUND SWITCH OUTPUT

WHEN WATER FLOW RATE

IS INSIDE THE SAFE-WINDOW

AREA. SWITCH CURRENT IS

LIMITED TO 1A

"VOLTAGE FREE" CONTACTS

FOR "MAP SWITCHING" USAGE.

CONTACTS ARE MADE WHEN

THE DDS3 IS SWITCHED ON

AND WHEN CORRECT WATER

FLOW IS DETECTED.

Page 13

Pa

g

e 12

The HFS-5 is supplied with a set of high-flow

water jets, sized at 0.8, 0.9 and 1mm jet (see

chart for flow rate). A Y-piece is supplied with

the kit for twin jet applications. The two nickel

plated brass jet adapters. Three pre-HSV in-

hose restrictors are supplied for duty cycle/

flow matching, should

good linearity is required.

We recommend running

between 10-15% water to

fuel for increase safety

purposes. This can be

done by adding all your

fuel injectors, multiply the

required water percent-

age and then pick the

nearest jet size to suit.

For more demanding ap-

plications, one can run up

to 15 to 25% of water to

fuel ratio. Up to 50% of

methanol can be added to

the mix to promote extra charge air cooling

and octane enhancement.

Applications involving methanol mix beyond 50%:

Great care and attention must be taken to ensure the fluid

tank is capable of handling methanol and designed for this

type of application. These tanks are normally termed as Fuel

cell. Available from most reputable racing parts suppliers.

Anti-surge foam should be used for circuit racing. Follow

the maker’s guidelines carefully.

The breather hole must be vented externally with

a suitable hose. All fluid delivery hose and fittings

must be free of all leaks. Ensure the area is well

ventilated and isolated from the driver’s compart-

ment. Take whatever measures to avoid any

methanol fume building up in trunk area.

Methanol is highly flammable. The main delivery

hose to the engine bay should be routed under-

neath the car. Ensure it is securely clipped and

fastened. Avoid kinks, close proximity of moving

parts and heat producing components. Please

treat this recommendation seriously. If in doubt,

ask advice from professional person familiar with

this kind of application. DO NOT take any undue

risks. It is recommend that a suitable fire extin-

guisher is placed within easy reach of the driver.

All electrical connections must be properly tightened to

avoid spark production.

Jet sizes and Advanced delivery management

Final checkup and setting up the failsafe.

Final check-up before going for a drive

Clip the water jet on the windshield and take it for a

drive. Observe the jet pattern is cone shaped during

spray and no splatter due to trapped air. Reconnect

the hose to the manifold jet . You have now success-

fully installed the system.

Setting the DDS3 to perform fail-safe:

This can be regarded as the most important part of

the entire system especially your car is tuned to work

with high percentage of water/methanol.

Setting up the DDS3 in five easy steps:

It should be relative straight forward if you following

the procedures as set out below:

1. Manually trigger the system with the jet/jets you

intend to use. It will be better if you can do this jet

spraying externally.

2. Adjust SC (sensor calibrate potentiometer) whilst

spraying to register around 6 bars on the gauge.

3. Temporarily set the “WL” (window low potenti-

ometer) fully counter-clockwise and the “WH”(win-

dow high potentiometer) fully clockwise.

4. Trigger the system and turn the WL clockwise

until the “B” led distinguishes. Wind back 2-3 clicks

after the “B” led comes back on and leave.

5. Wind the “WH” counter-clockwise until the “B”

led distinguishes. Wind back 2-3 clicks further after

the “B” comes back on and leave.

You have now set the fail-safe window properly. The

system is now ready to perform full-time flow moni-

toring tasks. You may need to fine tune the window

after the jet/jets are spraying against manifold pres-

sure as flow will be slightly lower. Perhaps a click or

two clockwise (more gain) on the “SC” potentiome-

ter will do the trick.

+12V BCV

-SW BCV

MAP-SW1

MAP-SW2 0

RESISTOR

DIM-ADJ

OPTIONAL

LOAD: 39R

M

A

PSWITCH

RELA

Y

12v

1

A

M

A

XIMUM

9

10

11

12

12V

-SW

GROUND SWITCH OUTPUT

WHEN WATER FLOW RATE

IS INSIDE THE SAFE-WINDOW

AREA. SWITCH CURRENT IS

LIMITED TO 1A

"VOLTAGE FREE" CONTACTS

FOR "MAP SWITCHING" USAGE.

CONTACTS ARE MADE WHEN

THE DDS3 IS SWITCHED ON

AND WHEN CORRECT WATER

FLOW IS DETECTED.

Page 15

Page 14

+12V DDS3

SENSOR V

0V -GND

FLOAT SW

MPS

DIMMING

-SW BCV

+12V BCV

-SW BCV

MAP-SW1

MAP-SW2 0V- IN

+12V-IN

P. RELAY

-

FIA2-TRIG

P. RELAY+

0V-GND

DIMMING

SENSOR C

SENSOR V

0V-GND

+12V WFS

TRIGGER

SENSOR C

RESISTOR

DIM-ADJ

OPTIONAL

LOAD: 39R

MAP SWITCH

RELAY 12v

1AMAXIMUM

AQUAMIST

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

FiA2

806-441 Made in England by ERL Ltd.

FLOW SENSOR

Part No. 806- 428

Serial No: 22100

Flowrange: 100-450ml/min

Output range: 0.5-4.5VDC

Made by ERL Ltd. Sussex England

806-244

7

124

5

3

+

-

SET TO

PWM

806-431

806-441 806-428

87

86 85

806-276

40A

RELAY

30

806-409

150W pump with 125 PSI

Internal b

y

pass valve fitted

V

oltage: 12VDC Current: 12A max

Flow rate: Upto 3.0 LPM max

Media: Water and Methanol

ERL reference: 8/125/3D0S

WARNING:

Over 50% Water/Methanol mixture is FLAMMABLE

RED

+12V TO

ENABLE DIM

86

9

3A FUSE

BLK

BATTERY

FLOW

ml/m

100 200 300 400

Aquamist

WL WHSC

WATER LEVEL

M

a

d

e

in

E

n

g

la

n

d

W. INJECTION

39R

AQUAMIST HFS-5 SYSTEM GENERIC WIRING DIAGRAM

pwm

TRIGGER MODE: PWM :: FAILSAFE: BOOST CUT

DDS3v8 JUNCTION BOARD

12AWG (6M)

6mm 4mm 4mm

DUMMY LOAD

TO AVOID CEL

WATER TANK

806-270

806-281

SYSTEM

ACTIVE

12% TO

60% DC

ENGINE

MANAGEMENT

SYSTEM

+12V

FIDC

"VOLTAGE FREE" CONTACTS

FOR "MAP SWITCHING" USAGE.

CONTACTS ARE MADE WHEN

THE DDS3IS SWITCHED ON

AND WHEN CORRECT WATER

FLOW IS DETECTED.

12V

-SW

GROUND SWITCH OUTPUT

WHEN WATER FLOW RATE

IS INSIDE THE SAFE-WINDOW

AREA. SWITCH CURRENT IS

LIMITED TO 1A

+12V DDS3

SENSOR V

0V -GND

FLOAT SW

MPS

DIMMING

-SW BCV

+12V BCV

-SW BCV

MAP-SW1

MAP-SW2

0V- IN

+12V-IN

P. RELAY

-

FIA2-TRIG

P. RELAY+

0V-GND

DIMMING

SENSOR C

SENSOR V

0V-GND

+12V WFS

TRIGGER

SENSOR C

RESISTOR

DIM-ADJ

OPTIONAL

LOAD: 39R

M

A

PSWITCH

REL

A

Y

12v

1

A

M

A

XIMUM

AQUAMIST

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

FiA2

806-441 Made in England by ERL Ltd.

FLOW SENSOR

Part No. 806-428

Serial No: 22100

Flowrange: 100-450ml/min

Output range: 0.5-4.5VDC

Made by ERL Ltd. Sussex England

806-244

7

124

5

3

+

-

SET TO

MPS

806-431

806-441 806-428

87

86 85

806-276

40A

RELAY

30

806-409

150W pump with 125 PSI

Internal b

y

pass valve fitted

V

oltage: 12VDC Current:12A max

Flow rate: Upto 3.0 LPM max

Media: Water and Metha nol

ERL reference: 8/125/3D0S

WARNING:

Over 50% Water/Meth anol mixture i s FLAMMABLE

RED

+12V TO

ENABLE DIM

68

9

3A FUSE

BLK

BATTERY

FLOW

ml/m

100 200 300 400

Aquamist

WL WHSC

WATE R L EV EL

M

a

d

e

in

E

n

g

la

n

d

W. INJECTION

39R

AQUAMIST HFS-5 SYSTEM GENERIC WIRING DIAGRAM

G1

TRIGGER MODE: MPS :: FAILSAFE: BOOST CUT

DDS3v8 JUNCTION BOARD

12AWG (6M)

6mm 4mm 4mm

DUMMY LOAD

TO AVOID CEL

WATER TANK

806-270

806-281

SYSTEM

ACTIVE

0.6v TO

3.6VDC

ENGINE

MANAGEMENT

SYSTEM

+12V

FIDC

MAP

SENSOR

0-5V

NC

"VOLTAGE FREE" CONTACTS

FOR "MAP SWITCHING" USAGE.

CONTACTSARE MADE WHEN

THE DDS3 IS SWITCHED ON

AND WHEN CORRECT WATER

FLOW IS DETECTED.

12V

-SW

GROUND SWITCH OUTPUT

WHEN WATER FLOW RATE

IS INSIDE THE SAFE-WINDOW

AREA. SWITCH CURRENT IS

LIMITED TO 1A

Page 16

Page 17

Electrical / Mechanical Specifications

DDS3-gauge

Input voltage: ........................................................... 11.5 - 14.5VDC

Input current:

Standby ............................................................... 25mA DC

Full Brightness ................................................. 250mA DC

Flow Sensor input voltage:

Presence .............................................................. 0.5V DC

Flow ............................................................. 0.55 - 4.5V DC

Manifold Pressure switch: ........................... Ground “off” activation

Float Sensor Threshold: ............................................... Ground active

Sensor Calibrating Voltage: ................................................. 5-0V DC

Detection Window range:

Low ............................................................ 0.5v to 2.5V DC

High .............................................................. 2.5V to 5V DC

Boost valve drive ................................................................... 1A max

Water on led:

Standby ................................................................ 5mA DC

WI active ............................................................. 15mA DC

Water level led: ................................................................. 15mA DC

Boost enable led: .............................................................. 8mA max

Bargraph led: ................................................ 8mA per segment max

Bargraph type:

Red ......................................................... Super Bright Red

Blue ............................................................ High efficiency

Dimensions ......................................................... 52mm x 45mm (H)

Operating temperature range: ................................................ 0-50C

Flow sensor

Input voltage: ............................................................... 10-15V DC

Input current: .................................................................. 25mA DC

Output Voltage: .................................................................. 0-5V DC

Output current: ............................................................... 5mA max

Dimensions: ....................................................... 40x 75 x 20mm(H)

Water level switch

Input voltage: ............................................................... 50VDC max

Switch current: ........................................................... 100mA max

Panel hole dimension: ......................................................... 22mm

Junction box

Input voltage: ............................................................ 11.5-15V DC

Input current:

Standby: ........................................................... 30mA DC

Output currents:

Priming .Pump: ............................................... 1A DC max

Boost valve: .................................................... 1A DC max

Boost cut relay ............................................... 2A DC max

Flow sensor ..................................................... 50mA max

In circuit Fuse links:

DDS3 gauge: ............................................................ 0.5A

Priming pump: ......................................................... .0.5A

Boost valve: ............................................................... 1A

Flow sensor: ............................................................0.2A

Dimensions: .................................................... 75 x 57 x 17mm(H)

Water pump

Input voltage: ............................................................ 11.5-15V DC

Input current: ............................................................... 12A max DC

Flow: ....................................................................... 2 litre per min

Dimensions: ................................................ 240 x102 x 104mm(H)

FIA2

Input voltage: ............................................................ 11.5-15V DC

Input current: ................................................................ 2A max DC

Fuse: ................................................................ 3A quick blow type

Dimensions: ...................................................... 68 x39 x 21mm(H)

+12V DDS3

SENSOR V

0V -GND

FLOAT SW

MPS

DIMMING

-SW BCV

+12V BCV

-SW BCV

MAP-SW1

MAP-SW2

0V- IN

+12V-IN

P. RELAY

-

FIA2-TRIG

P. RELAY+

0V-GND

DIMMING

SENSOR C

SENSOR V

0V-GND

+12V WFS

TRIGGER

SENSOR C

RESISTOR

DIM-ADJ

OPTIONAL

LOAD: 39R

MAP SWITCH

RELAY 12v

1A MAXIMUM

AQUAMIST

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

FiA2

806-441 Made in En gland by ERL Ltd.

FLOW SENSOR

Part No. 806- 428

Serial No: 22100

Flow range: 100-450ml/min

Output range: 0.5-4.5VDC

Made by ERL L td. Sussex England

806-244

7

124

5

3

+

-

SET TO

PWM

806-431

806-441 806-428

87

86 85

806-276

40A

RELAY

30

806-409

150W pump with 125 PSI

Internal bypass valve fitted

V

oltage: 12VDC Current: 12A max

Flow rate: Upto 3.0 LPM max

Media: Water and Methanol

ERL reference: 8/125/3D0S

WARNING:

Over 50% Water/Methanol mixture is FLAMMABLE

RED

OE BOOST

CONTROL

VALVE

+12V TO

ENABLE DIM

86

9

3A FUSE

BLK

BATTERY

FLOW

ml/m

100 200 300 400

Aquamist

WL WHSC

WATER LEVEL

M

a

d

e

in

E

n

g

la

n

d

W. INJECTION

+12V SW

39R

AQUAMIST HFS-5 SYSTEM GENERIC WIRING DIAGRAM

G1-PWM-BC

TRIGGER MODE: PWM :: FAILSAFE: BOOST CUT

DDS3v8 JUNCTION BOARD

12AWG (6M)

6mm 4mm 4mm

DUMMY LOAD

TO AVOID CEL

WATER TANK

806-270

806-281

ECU BOOST

CONTROL

CUT &

SPLICE

SYSTEM

ACTIVE

12% TO

60% DC

ENGINE

MANAGEMENT

SYSTEM

+12V

FIDC

Page 19

Appendix Page 18

GUARANTEE

ERL guarantees, at our option, to replace faulty goods sup-

plied or repair the same, subject to the claim made in writing

to us within 12 months after the sale by us, or for such other

period as may be indicated by us for specific products in lieu

of any warranty or condition implied by law as to the quality

or fitness for any particular purpose of the goods.

Any claim against us must be made to us in writing within

the period of 12 months after the sale by us , or our agents,

or our distributors of goods in question (or such other period

as may be indicated by us) and any goods to which the claim

relates must be returned to us within that period suitably

packaged and cleaned and, with any particular instructions

which we may have notified to you at the time of supply.

Original invoice, the nature of any claimed defect must ac-

company the goods in question prior to despatch to us.

If these requirements are not complied with our Guarantee

shall not apply and we shall be discharged from all liability

arising from the supply of defective goods.

LIABILITY

We shall not be under any liability whether in contract, or

tort or otherwise and whether or not resulting from our neg-

ligence or that of our employees, in respect of defects in

goods supplied or for any damage or loss resulting from

such defects.

We shall not be under any liability for damage, loss of ex-

pense resulting from failures to give advice or information

or giving the incorrect advice or information whether or not

due to our negligence or that of our employees.

In no event shall any breach of contract on our part or tort

(including negligence) or failure of any time on our part that

of our employee give rise to liability for loss of revenue or

consequentiallossor damagesarisingfromanycause what-

soever.

Note: ERL reserves the right to make changes to our prod-

ucts without notice in order to improve design performance

and reliability.

In Car Dash Gauge (8-core cable)

Pin Colour Size Description Electrical parameter

1 Red 24awg +12V power supply to gauge 50mA @12v

2 Black 24awg 0V power supply to gauge 50mA @12v

3 Yellow 24awg Flow Sensor input voltage 0-5 VDC @10mA

4 White 24awg Flow Sensor calibration output voltage 5-0 VDC @1mA

5 Purple 24awg Float Sensor from water tank Ground active

6 Blue 24awg Manifold Pressure Switch (806-157) Normally closed

7 Green 24awg Night driving dimming connection +12V active

8 Brown 24awg Watergate bleed valve option (SW-) 1A @12V max.

Flow Sensor (4-core cable)

Pin Colour Size Description Electrical parameter

1 Red 24awg +12V power supply of Flow Sensor 30mA @ 12v

2 Blue 24awg 0V power supply of Flow Sensor 0V Ground

3 Yellow 24awg Flow Sensor output voltage 0-5VDC@10mA

4 Green 24awg Flow Sensor calibration input voltage 5-0VDC@1mA

DDS3 Junction Box (25-ways - Pin 1= top left corner. Pin 25 bottom right corner)

Pin Colour Size Description Electrical parameter

1-8 ------ 8-core Same as Dash Gauge Above ------

9 Red 22awg +12V power supply to bleed valve +12V, 1A fused

10 Brown 22awg Switching to ground for Bleed valve 1A maximum

11 D.Grey 22awg Map Switch/Boost cut (EMS side) 1A maximum

12 D,Grey 22awg Map Switch/Boost cut (BCV side) 1A maximum

13-16 ------ 4-core Same as Flow Sensor as above ------

17 D.Blue 22awg FIDC detect or MAP senson 0 to 5V input

18 Green 22awg Night driving dimming connection +12V active

19 Yellow 22awg To ground when tank is empty 0.25A maximum

20 Green 22awg Common ground 0.25A maximum

21 Red 22awg Priming P. relay +12V supply (0.5A FUSED) 0.5A maximum

22 Blue 22awg Priming pump relay ground switch (active) 1A maximum

23 Red 18awg +12V switched power supply for all 3A maximum

24 Black 18awg 0V ground supply for all 3A maximum

25 Blue 22awg FIA2 trigger 0.1A Maximum

FIA2 harness (green cable shell)

Pin Colour Size Description Electrical parameter

1 Black 22awg Ground power supply (0v) 2A @ 12v

3 Blue 22awg WI control input (0v=disable) 20ma

6 Red 22awg +12V power input (via injector +) Fused +12VDC@3A

6 Red 22awg +12V to High Speed Valve +12V 1A max

8 Green 22awg FIDC signal pickup input (-ve switched) -PWM @10mA

8 Green 22awg FlDC trigger input for the DDS3v8 JB -PWM @1mA

4 Brown 22awg PWM drive to High Speed Valve 1A PWM drive

ERL ltd Iroko House Bolney Ave Peacehaven East Sussex BN10 8HF England

THE END

Other ERL Water System manuals

Popular Water System manuals by other brands

4eco

4eco immerSUN Installation and user guide

AmeriWater

AmeriWater V125DTH Operation & maintenance manual

Grizzly

Grizzly HWW 3819 InoxInox Translation of the original instructions for use

HYDROLAB

HYDROLAB R Series user manual

Culligan

Culligan Platinum Plus Series owner's guide

Technische Alternative

Technische Alternative FRISTAR operating manual

Water Control

Water Control WHRO-700 installation manual

Armstrong

Armstrong E.2 Series Installation and operating instructions

BWT

BWT BWTDWFK-TRIFLO manual

Beko

Beko BEKOMAT 16i CO Translation of original installation and operation manual

Intewa

Intewa Rainmaster Favorit-SC 40 Installation and user manual

Culligan

Culligan MEDALLIST SERIES Service manual