VOH Wheeltest I User manual

Wheeltest I

USER’S MANUAL

TRANSLATED FROM FRENCH

Mecatronic solution

EN_Wheeltest1_guid

e

Created 24.02.2010

Page 2

User’s manual

S.G

1General information....................................................................................................................................3

1.1 Warranty....................................................................................................................................................3

1.2 Safety information .....................................................................................................................................4

1.3 Transportation...........................................................................................................................................4

1.4 Storage......................................................................................................................................................4

2Parts of the machine ..................................................................................................................................5

3Use ...............................................................................................................................................................6

3.1 Start-up......................................................................................................................................................6

3.2 Use............................................................................................................................................................6

3.2.1 Placing the component on the Wheeltest 1.......................................................................................... 6

3.2.2 Adjustments.......................................................................................................................................... 6

4Resolution of common problem................................................................................................................9

5Exclusion of responsibility/warranty........................................................................................................9

6Maintenance and care ................................................................................................................................9

7Technical data.............................................................................................................................................9

8Representation/distribution.....................................................................................................................10

Mecatronic solution

EN_Wheeltest1_guid

e

Created 24.02.2010

Page 3

User’s manual

S.G

1 General information

1.1 Warranty

VOH Ltd guarantees this product against faulty manufacture or material in normal conditions of use and service,

for one year from the commissioning at the client’s place of business. If at any time during the length of the

warranty, the product shall be deemed faulty or break down, VOH Ltd. shall repair or replace it (choice to be

made by VOH Ltd.).

If the product is defective, please call the customer service of VOH on +41(32) 945 17 45.

Said warranty shall not apply if VOH Ltd proves that the fault or failure arises from damages which occurred while

the product was in the possession of a buyer.

VOH Ltd.’s responsibility is limited to the repair or replacement of the product under the conditions listed

hereabove.

VOH LTD. SHALL NOT BE RESPONSIBLE FOR LOSS OR ANY DAMAGES WHATSOEVER, INCLUDING

CONSECUTIVE OR ACCESSORY DAMAGES, ARISING DIRECTLY OR INDIRECTLY FROM AN EXPLICIT OR

IMPLICIT VIOLATION OF THE WARRANTY, OR FROM ANY OTHER FAULT OF THIS PRODUCT. THIS

WARRANTY IS THE ONLY EXPLICIT WARRANTY THAT VOH GRANTS ON THIS PRODUCT.

This warranty only covers the initial buyer and is not transferable.

Should you have questions concerning this warranty, please write to VOH Ltd.:

VOH Ltd.

La Praye 5a

CH-2608 Courtelary

Phone : +41(32) 945 17 45

Fax : +41(32) 945 17 55

Internet : http://www.voh.ch

Mecatronic solution

EN_Wheeltest1_guid

e

Created 24.02.2010

Page 4

User’s manual

S.G

1.2 Safety information

Warning

Do not use the Wheeltest 1 if it is damaged. Before using the Wheeltest 1, inspect its casing and its

electrical connections.

The Wheeltest 1 must be used in the way specified by the manufacturer.

Do not use the Wheeltest 1 near dust.

The Wheeltest 1 must only be used by people who have been trained to do so.

Beware!!!

Please read the information included in this manual before using this apparatus. Incorrect use may

damage the system or cause measurement errors.

Before connecting the machine for the first time, verify that the supply voltage of the power grid

corresponds to that required by the machine.

In case of prolonged non-use, disconnect the electrical supply cable.

Do not dismantle the machine. Only the manufacturer is entitled to replace or repair a faulty component.

Use this machine at a temperature between 10°C and 40°C (140 °F)

Never place objects other than watch wheels in the device.

1.3 Transportation

If the apparatus is moved, take care not to cause any shocks that could damage its mechanisms. In case of

transport over a long distance, it is preferable to use anti-shock packaging.

1.4 Storage

The Wheeltest 1 must be stored in a dry and dust-free place. The storage temperature must be between 10°C

and 40°C. It is advisable to wrap up the machine to protect it from dust and humidity.

Mecatronic solution

EN_Wheeltest1_guid

e

Created 24.02.2010

Page 5

User’s manual

S.G

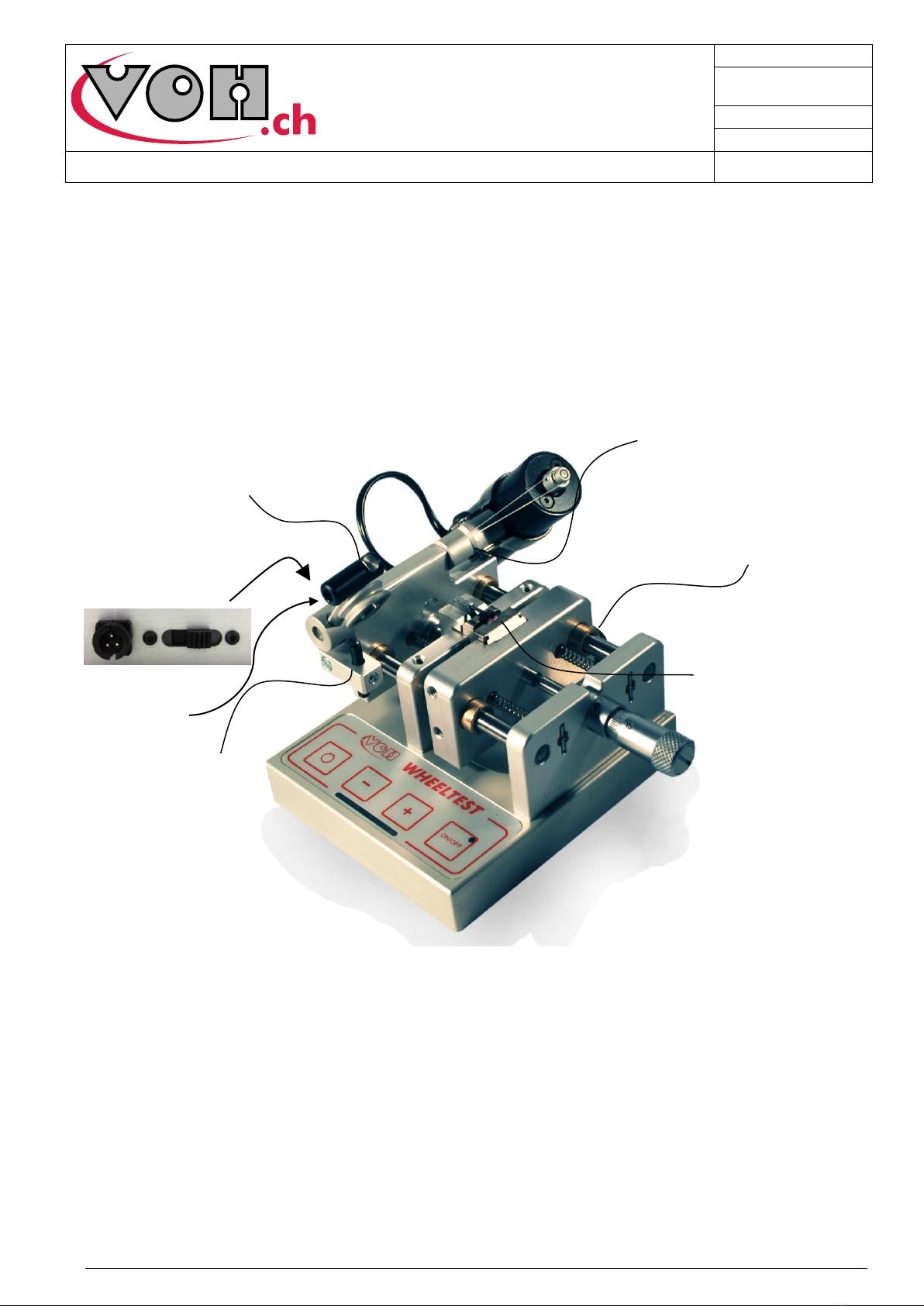

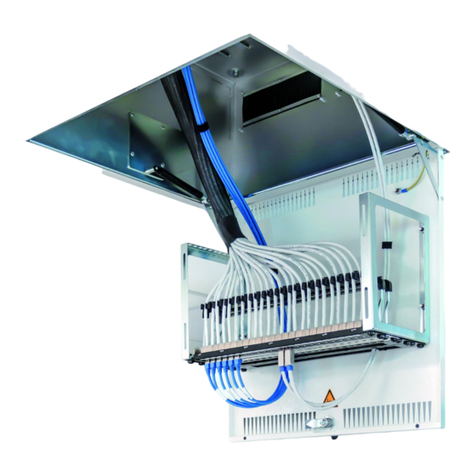

2 Parts of the machine

A wheel is positioned between the ruby Vs and set to revolve by a belt. The Wheeltest 1 comprises a series of

control knobs for the motor, and four screws to adjust the position of the Vs and of the drive.

Figure 1: General view of the Wheeltest 1

Control panel

Motor

Micrometric screw to adjust the

distance between Vs

Micrometric screw to adjust the

position of the bow

Space between Vs

« V » height

adjustment

5V connection and

switch

Belt

Bow buffer

Bow

Mecatronic solution

EN_Wheeltest1_guid

e

Created 24.02.2010

Page 6

User’s manual

S.G

3 Use

3.1 Start-up

The machine is started by the slide switch next to the power connection. When it is turned on, the motor will not

turn, but the last parameters used (speed and direction of rotation) will be restored.

3.2 Use

3.2.1Placing the component on the Wheeltest 1

The component to be measured must be placed between the two Vs of the Wheeltest.

3.2.2 Adjustments

1. Adjust the spacing of the two Vs by means of the micrometric buffer, in order for the wheel to be held in

the manner closest to its function once mounted in a watch.

2. The height adjustment of the V closest to the user is made by means of the black knob placed on the

right of the Wheeltest. The precise adjustment may be visualised by checking that the part displayed on

the screen is seen exclusively from above.

Mecatronic solution

EN_Wheeltest1_guid

e

Created 24.02.2010

Page 7

User’s manual

S.G

3. The wheel is now correctly placed, and must now be driven. The wheel should rotate at a maximum

speed of a one or two revolutions per second, or three teeth per second for slightly toothed wheels.

With buffer option:

The buffer allows the spindle of the wheel to be supported.

The buffer support pin is adjusted by means of the adjustment screw placed on the side of the buffer.

Drive adjustment is thus made by lowering the belt on a part of the wheel without visual measurement. The

position of the belt is adjustable, as to depth, by the screw placed at the back of the apparatus; it should be

placed on the spindle of the wheel or any other part of the wheel outside of the part to be measured. A height

buffer allows the bow to be positioned with a repeatable pressure.

V height adjustment

Adjustment screw

buffer

Mecatronic solution

EN_Wheeltest1_guid

e

Created 24.02.2010

Page 8

User’s manual

S.G

Figure 2 : height buffer bow

Rotation speed is adjusted by the « + » and « - » buttons on the control panel; a lighted bar comprising 8 LEDs

allows the speed chosen to be visualised. Rotation is launched by pressing on the « on/ off » for 2 seconds; the

LED will turn on at the top of the button. Brief pressure on the « on/ off » button allows step-by-step rotations.

The wheel rotation direction is alternated by pressing the button at the far left.

Figure 3 : control panel

Change of

direction

Mecatronic solution

EN_Wheeltest1_guid

e

Created 24.02.2010

Page 9

User’s manual

S.G

4 Resolution of common problems

Type of error

Cause

Resolution

No LED turns on

when powered up

Speed was set at minimum during

last use

Increase speed to confirm that the

Wheeltest 1 is being supplied with

power

The wheel is not

driven

The bow is badly placed or damaged.

The wheel is squeezed against the

two Vs

Reposition, or replace the belt

Increase space between Vs

The wheel has an

abnormal axial beat

Too-wide space between the Vs

Tighten the Vs

5 Exclusion of responsibility/warranty

Damages caused by use, transportation or storage that do not comply with those described in this manual are

not taken care of by the manufacturer. Modifications to the machine and opening the casing are forbidden and

entail an exclusion of responsibility. The right to a warranty expires when these are demonstrated or if the faults

noted cannot be original. Consumables (belts) are not subject to warranty.

6 Maintenance and care

No special care is necessary for the Wheeltest 1, if it is used in a laboratory, except classic cleaning with a dry

cloth. The belt is a consumable to be replaced when the user deems necessary.

7 Technical data

Parameter

Value

Supply voltage

5V DC

Power

850 mW

Dimensions

Depth : 80 mm

Width : 70 mm

Height : 60 mm

Mecatronic solution

EN_Wheeltest1_guid

e

Created 24.02.2010

Page 10

User’s manual

S.G

8 Representation/distribution

Table of contents

Popular Industrial Equipment manuals by other brands

PCB Piezotronics

PCB Piezotronics J353B32 Installation and operating manual

Preferred Instruments

Preferred Instruments JC-FWC-ND-OIT quick start guide

ABB

ABB HT570285 Operation manual

Rexel

Rexel CONNECTIS GIGAMEDIA GGM CBOX installation guide

Reflex

Reflex Servitec 35-95 operating manual

Meler

Meler Micron PUR LC instruction manual

PHD

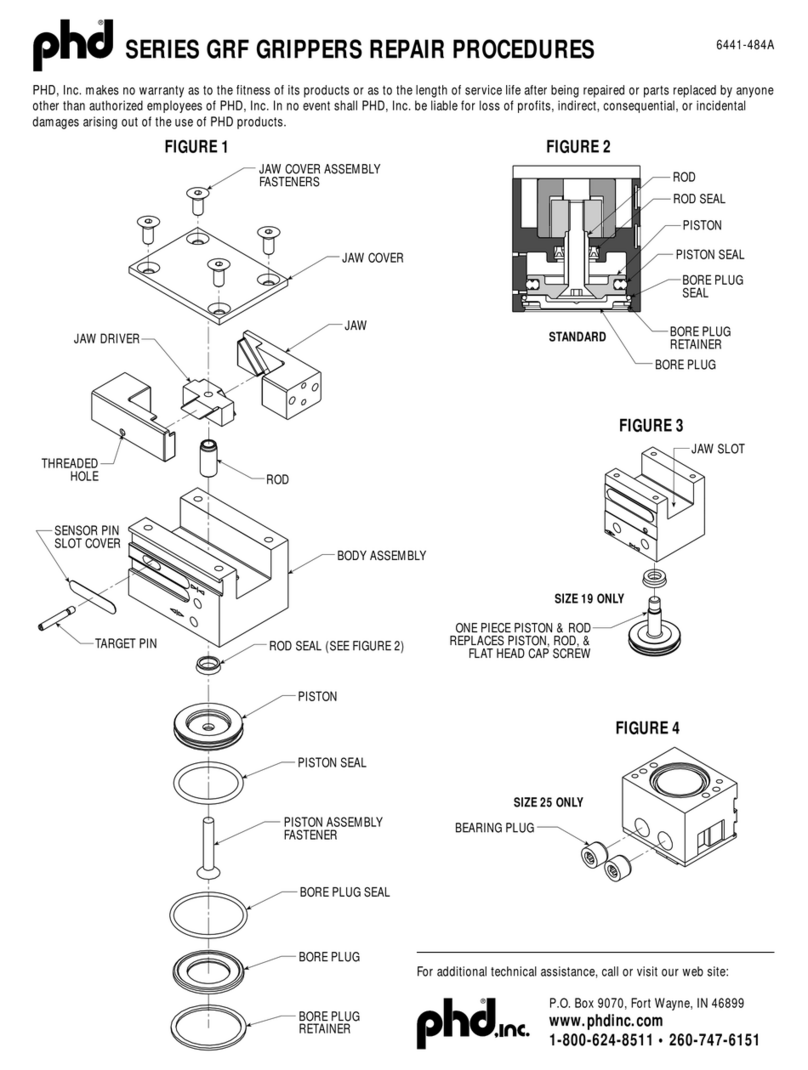

PHD GRF Series REPAIR PROCEDURES

SkyAzúl

SkyAzúl 210 Installation & operation manual

ConSenses

ConSenses Accelerometer BA Series Assembly instructions

Eaton

Eaton Power XL SmartWire-DT DX-NET-SWD3 Instruction leaflet

Bosch

Bosch Rexroth HQ 2/C-H Assembly instructions

Siemens

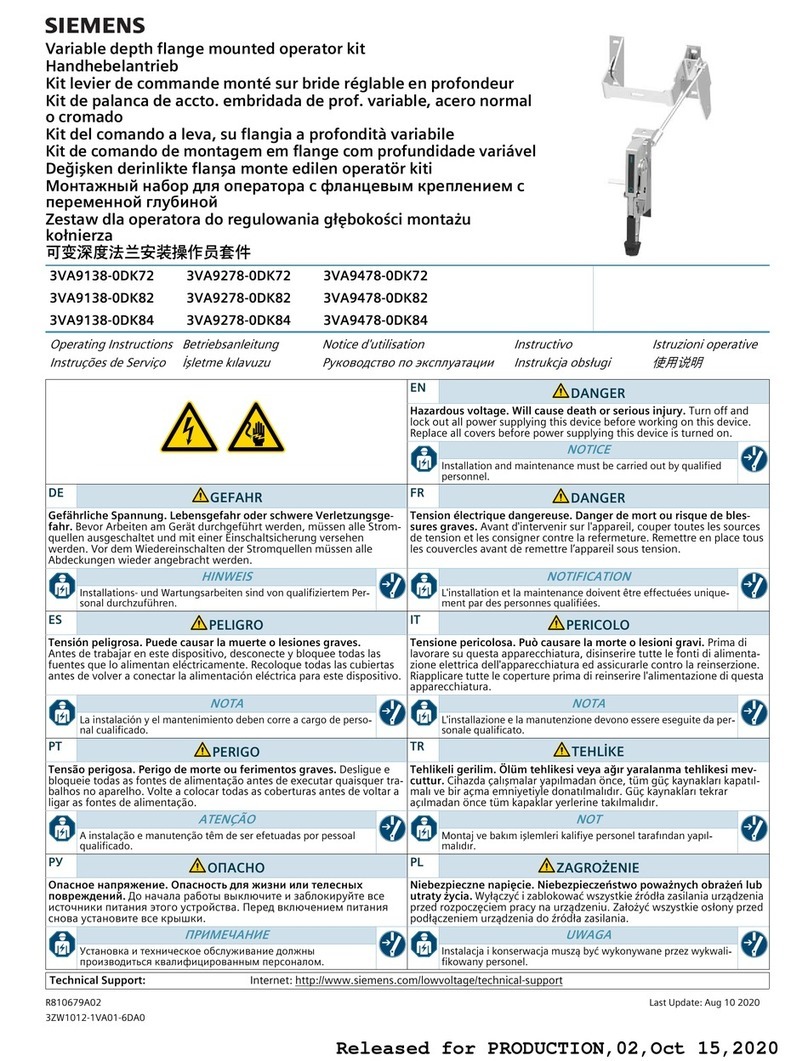

Siemens 3VA9138-0DK72 operating instructions