3. Safety Instructions

3.1. Intended Use

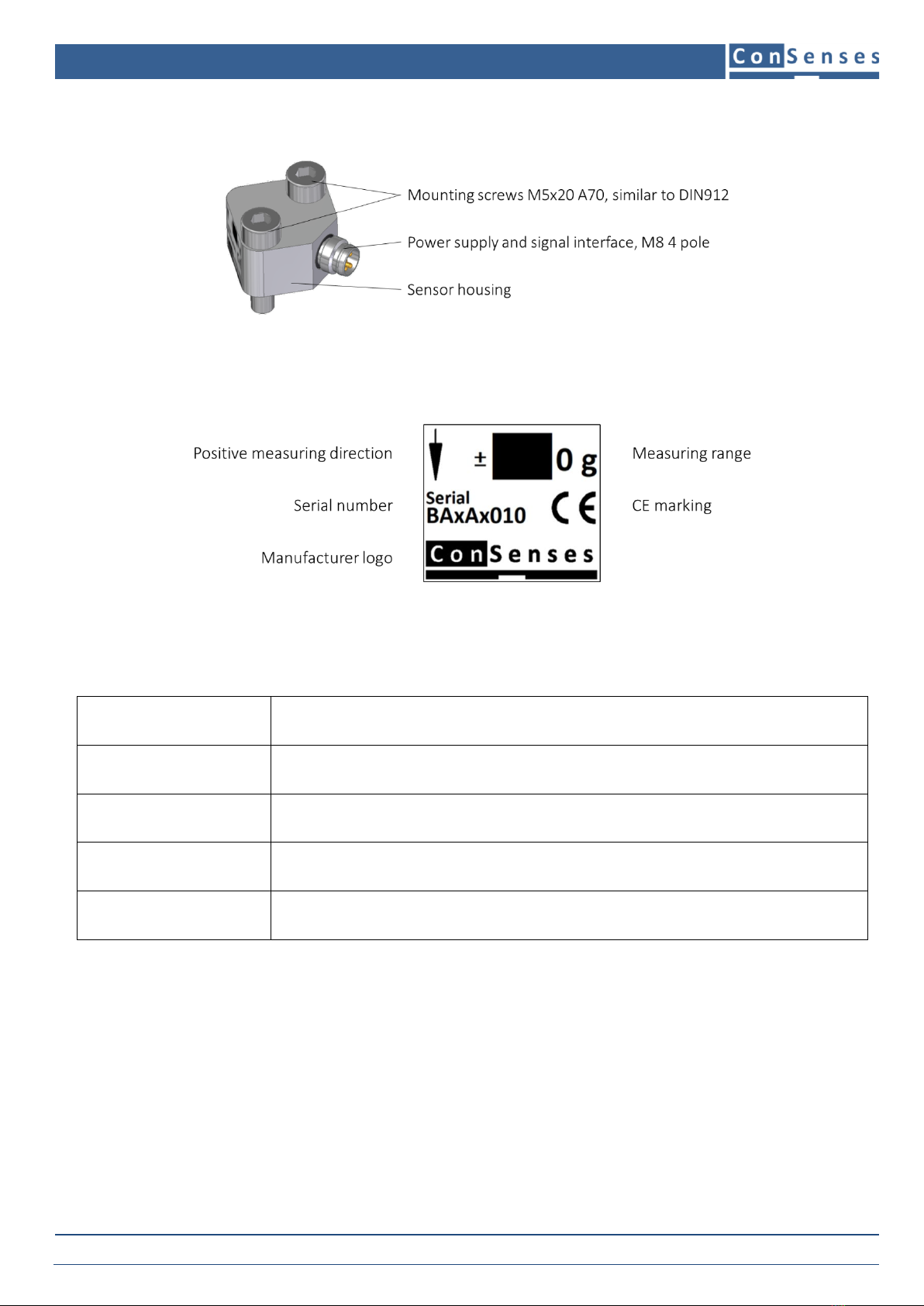

The accelerometers BA are sensors for the metrological detection of vibrations on components or machine

elements within the operating limits of the sensor.

Any other use is not in accordance with the intended use.

To ensure safe operation, the product may only be used in accordance with the information in these assembly

instructions and in compliance with the following safety regulations and the technical data provided. During

use, the legal and safety regulations required for the respective application must also be observed. This also

applies analogously to the use of accessories.

The accelerometers are not intended for use as safety components. Proper transport, professional storage and

assembly as well as careful operation and maintenance are prerequisites for faultless and safe operation of

the accelerometers.

3.2. Operating Personnel

This product must be installed and operated exclusively by qualified personnel in accordance with the tech-

nical data in connection with the safety provisions and regulations set out below.

Qualified personnel include persons who, as operators of the equipment under investigation, have been in-

structed in its handling and safety concepts and are familiar with the operation of the product described in

this documentation. They must have read and understood the assembly instructions and the safety instruc-

tions carefully.

When using the accelerators, the legal and safety regulations required for the respective application must also

be observed. This also applies analogously to the use of accessories.

Ensure that work is carried out in a safety-conscious manner and compliance with the relevant accident pre-

vention regulations, e.g., those of the employers’ liability insurance associations.

3.3. Safety Regulations and Load Limits

For safe operation of the product, it is essential to observe the assembly instructions and load limits. The max-

imum loads specified in the technical data sheets must not be exceeded under any circumstances. This con-

cerns:

▪Maximum shock acceleration

▪Temperature limits

Signal cables of the sensors must be installed in such a way that electromagnetic emissions do not impair the

sensor function.

Prior to each commissioning, project planning and risk analysis must be carried out, considering all safety

aspects of the surrounding technology. In particular, this concerns personal and plant protection. Supplemen-

tary safety precautions must be taken to prevent defects or faults in equipment that could result in personal

injury, equipment damage, or loss of data.