Instructions for use_RPE4-10_14039_1en_05/2023

Page 15

www.argo-hytos.com

CAUTION

Switching off the pressure source and relieving the circuit

In the event of an emergency, switch the power source off (pump) and relieve all parts of the hydraulic circuit,

including the hydraulic accumulators, by connecting them to the tank. Before any work on the circuit, such as

removing a valve ensure that the circuit is depressurized. Otherwise there is a risk of leakage of the working

fluid and contamination of personnel.

CAUTION

Disconnecting the electrical supply

Disconnect the electrical parts of the valve from the power supply. On the one hand, there is a risk of electric

shock, and on the other hand, unintended activation of the valve can lead to serious situations.

ENVIRONMENTAL PROTECTION

Spilled working fluid must be removed immediately, e.g. with suitable absorbents, contaminated parts of the perimeter cleaned,

contaminated objects in the vicinity cleaned or disposed of. Contaminated objects and residues of leaked working fluid must be

disposed of in accordance with the applicable environmental regulations.

FIRST AID

Contamination by hydraulic working fluid

If contamination of persons occurs, contaminated parts of clothing must be removed immediately and the skin thoroughly washed

with soap or treated with a suitable cream.

If the eyes are contaminated, flush them with clean water and seek medical attention. Seek medical attention also in case of

accidental ingestion of working fluid or skin allergic reaction to splashes of working fluid.

Electric shock

In the event of an electric shock, immediately turn off the power source, call emergency medical help and, if possible, start resuscita-

tion of the victim if they are unconscious and not breathing (cardiac massage, use of a defibrillator, etc.)

6.6 Repairs carried out by skilled persons

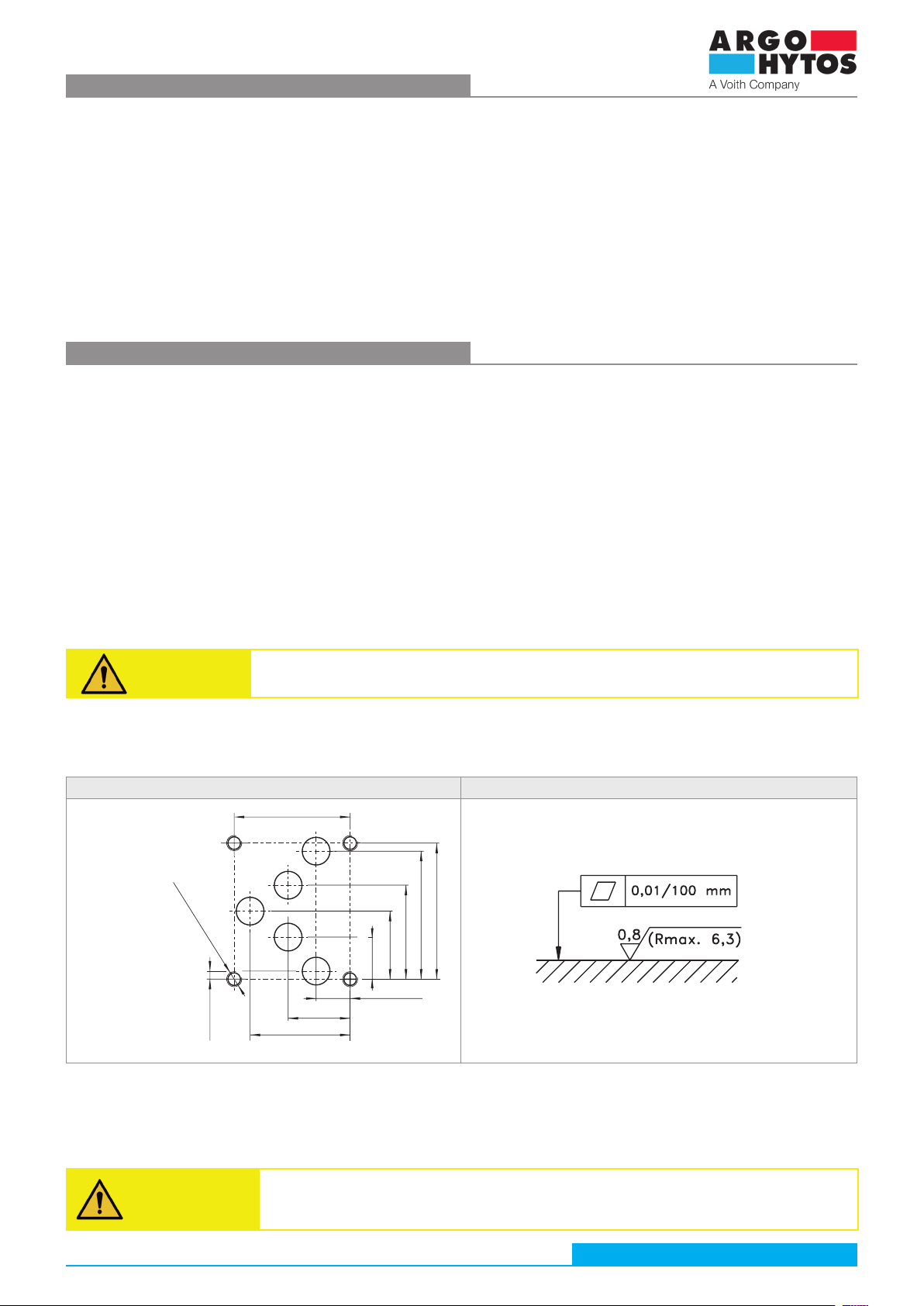

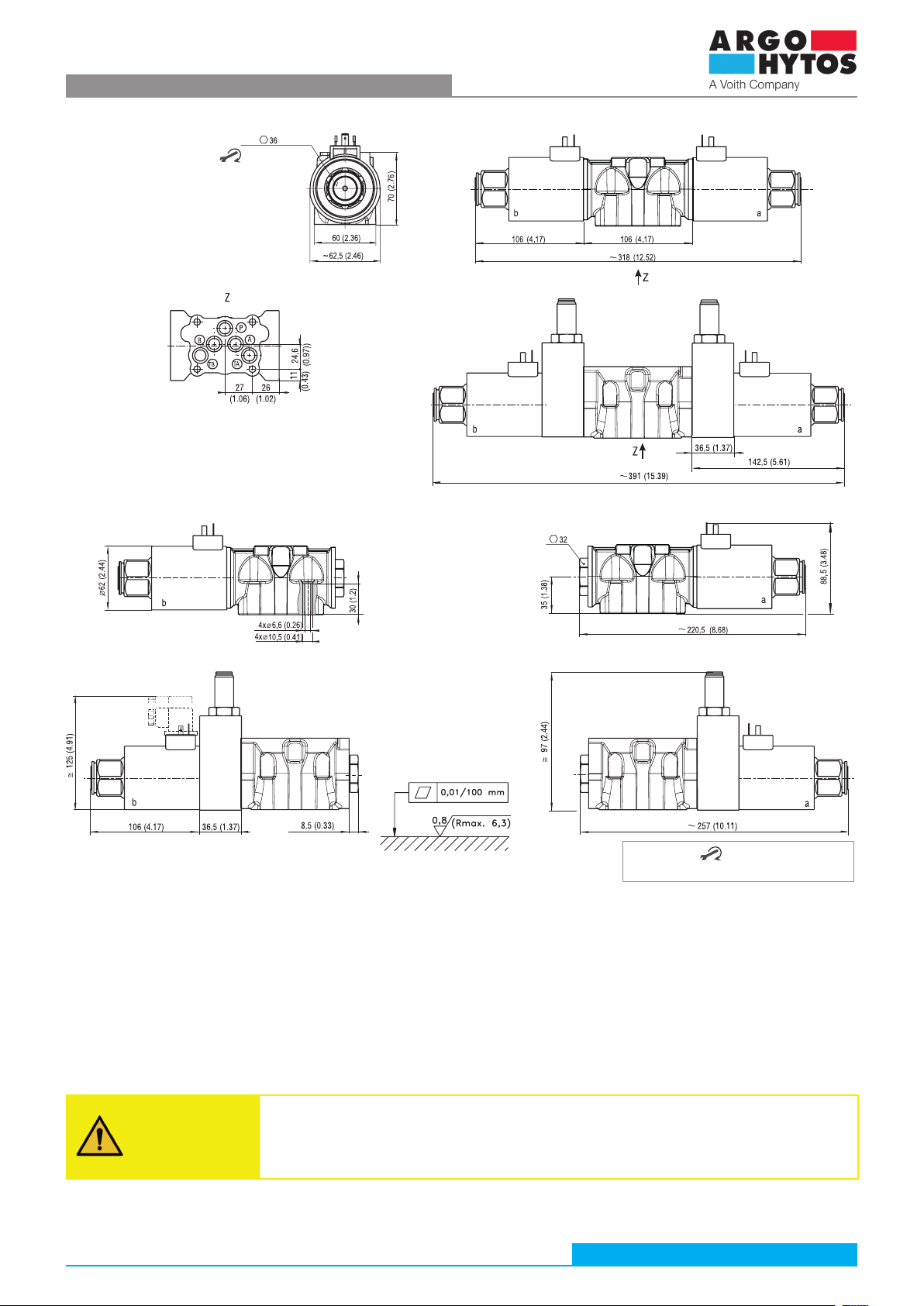

6.6.1 Dismantling the valve and replacing the seal on the valve connection surface

The user is entitled to replace the defective valve with a new one, replace the seal on the valve base and replace the electromagnet coil. A set of seals

and coils is supplied as spare parts.

› Make sure the circuit is depressurized and the power supply to the electrical parts is turned off.

› If the equipment has been in operation, it is necessary to let the circuit cool down to avoid burning from the circuit parts.

› Disconnect the coil connector socket and, for a valve with a sensor, also the position sensor connector socket. Make sure that particularly the inner

space of the sockets with contracts are not dirty and contaminated with working fluid.

› Using a size 5 inbus wrench, loosen all four M6x45 valve fastening screws one by one and remove the valve from the connection plate. Take into

account that the inside of the valve contains a residual amount of working fluid which will start to leak out after removal. We recommend that you

immediately place the valve in a prepared suitable container, e.g. a smaller plastic box, to avoid contamination of the machine and the floor.

› For example, use a small screwdriver to remove the five sealing rings from the recesses at the base of the valve body. Clean the valve connection

surface and the plate, check for damage to the surfaces and insert new, undamaged sealing rings. Reinstall the valve and connect the electrical

connectors (see chapter 6.2 Product installation).

› Verify the correct operation of the valve and its tightness in the safe mode of operation of the device. It is recommended to start the test at low

circuit pressure.

6.6.2 Replacing the electromagnet coil

If the function of the electromagnet coil is lost, or if the coil type (connector type, control voltage) needs to be changed, remove the coil and replace

it with a new one.

› Make sure the circuit is depressurized and the power supply to the electrical parts is turned off.

› If the equipment has been in operation, it is necessary to let the circuit cool down to avoid burning from the circuit parts.

› Disconnect the coil connector socket. Make sure that particularly the inner space of the socket with the contacts is not dirty and contaminated

with the working fluid.

› Remove the plastic / aluminium clamping nut at the end of the control system.

› Remove the coil.

› Take a new coil and verify that it is the correct type according to the description on the casing.

› Place the new coil on the control system with the connector closer to the valve body.

› Rotate the coil so that the connector is in the desired position and secure the coil position by tightening the nut with a torque of 6+1 Nm using a

size 36 wrench.

› Check that the connector socket is clean and undamaged and insert it into the connector on the coil.

An insufficiently fastened connector can cause unreliable operation of the electromagnet, especially when subjected to vibrations.

› Check the function of the electromagnet in a safe mode of operation of the device, for example, at low pressure in the circuit.

Repairs to a defective valve are carried out only by the manufacturer. Remove the residual working fluid from the disassembled defective valve and

pack it in such a way that there is no mechanical damage and contamination outside the packaging during transportation. Send the packaged valve

with a description of the defect to the manufacturer's address. The manufacturer provides a 1-year warranty for the new valve. However, the claim

may not be recognized by the manufacturer if the valve is mechanically damaged, the seal material is damaged by an aggressive fluid, or the valve

has been used improperly, which is not in accordance with these instructions for use.