Voith WSR-D80112-S User manual

Installation and Operating Manual

Way Valve

WSR-D80112-S

Version 1.5, 2016-02-26

91800271810, Protection Class: 0: Offen (public)

Installation and Operating Manual / Version 1.5/ 91800271810, Protection Class

EN / Protection Class 0: Offen

(p

ublic

)

/ 2014-09-03

WSR-D80112-S

Contact

2

Contact

Voith Turbo GmbH & Co. KG

Voithstraße 1

74555 Crailsheim, GERMANY

Phone: + 49 7951 32-0

Fax + 49 7951 32-500

E-mail

www.voith.com

Voith Turbo GmbH & Co. KG

After-Sales Service of Business Unit

Electronic Drive Systems

Voithstraße 1

74555 Crailsheim, GERMANY

Phone: + 49 7951 32-470

Fax + 49 7951 32-605

E-mail

Please indicate type and serial number

(see nameplate).

This document describes the state of

design of the product at the time of the

editorial deadline on 2016-02-26.

Copyright © by

Voith Turbo GmbH & Co. KG

This document is protected by

copyright. It must not be translated,

duplicated (mechanically or electron-

ically) in whole or in part, or passed on

to third parties without the publisher's

written approval.

Installation and Operating Manual / Version 1.5/ 91800271810, Protection Class

EN / Protection Class 0: Offen

(p

ublic

)

/ 2014-09-03

3

WSR-D80112-S

Contents

Contents

1User Information 5

1.1Identification of text function 5

1.2Safety information 6

1.3Field of application 7

1.4General information 7

1.5Health and safety at work 8

1.5.1Accident prevention 9

1.5.2Environment 10

1.6General description of the way valve 10

1.7Proper use 10

2Technical Data 11

2.1Way Valve 11

3Packing, Storage, and Transportation 14

3.1Packaging 14

3.2Storage and preservation 14

3.3Transport 15

4Design and Functioning 16

4.1Design 16

4.2Function 17

5Installation 19

5.1Notes 19

5.2Mounting 20

5.3Hydraulic connection 21

5.4Electrical connection 22

6Commissioning 23

Installation and Operating Manual / Version 1.5/ 91800271810, Protection Class

EN / Protection Class 0: Offen

(p

ublic

)

/ 2014-09-03

4

WSR-D80112-S

Contents

6.1Test run 23

6.2Parameter settings 25

6.2.1Potentiometer effect 26

6.2.2Setting of X0 and X1 potentiometers 27

6.2.3Setting of proportional gains 29

6.2.4Adjustment of operating frequency SF 31

6.2.5Adjustment of the hydraulic center position 31

6.2.6Factory setting 31

7Operation 32

7.1Operation with manual operation knob 32

7.2Normal operation 33

7.3Troubleshooting 33

8Maintenance, Servicing and Inspection 35

8.1Maintenance and Servicing 35

8.2Inspection 36

8.3Spare parts information 37

8.4Seal replacement 37

8.5Replacing the control magnet 38

8.5.1Disassembly 38

8.5.2Mounting 40

8.6Replacement of the hydraulic part 41

8.6.1Disassembly 41

8.6.2Mounting 42

9Decommissioning 43

10Annex 44

Installation and Operating Manual / Version 1.5/ 91800271810, Protection Class

EN / Protection Class 0: Offen

(p

ublic

)

/ 2014-09-03

5

WSR-D80112-S

User Information

1 User Information

1.1 Identification of text function

Texts in this installation and operating manual are differentiated as to their function

and are identified accordingly. The following text functions are possible:

Text type Function

A

ction instruction

1st level

1., 2., etc. Prompts an action

A

ction instruction

1st level

a), b), etc. Denotes a section in a sequence of

actions

List

Indicates individual elements of the list

Highlighting

Identifies important comments

Cross-reference Refers the reader to another chapter or

document

Note For useful additional information for

proper handling of the product only

i

Installation and Operating Manual / Version 1.5/

91800271810, Protection Class

EN / Protection Class 0: Offen

(p

ublic

)

/ 2014-09-03

6

WSR-D80112-S

User Information

1.2 Safety information

Safety information is classified as follows:

DANGER

DANGER indicates an immediate threat to a person's life or health. Failure to

observe this note will result in death or most serious injury.

WARNING

WARNING indicates a potentially hazardous situation to the life and health o

f

persons. Failure to observe this note could result in death or most serious

injury.

CAUTION

CAUTION indicates a potential threat to a person's health. Failure to observe

this note may result in minor injuries.

NOTICE

NOTICE indicates potentially imminent damages to property. Failure to

observe this note may result in damage to the product or to other objects.

Installation and Operating Manual / Version 1.5/ 91800271810, Protection Class

EN / Protection Class 0: Offen

(p

ublic

)

/ 2014-09-03

7

WSR-D80112-S

User Information

1.3 Field of application

This installation and operating manual applies to the current state of design of the way

valve (see page 2). Subject to design modifications.

The version of this installation and operating manual is shown on the front page, for

the initial document it reads version 1. The version number is always increased by 1

throughout the entire installation and operating manual when the contents are revised.

The following table shows which chapters have been revised.

Version Revision in chapter Remarks

1.1 6.2.5 Adjustment of the hydr.

center position

Description for PI-controller

removed

1.2 10 Annex Outline drawing changed

1.3 Chapter 2.1 Add. installation dir. horizontal

1.4 all revised

1.5 all French speech added

1.4 General information

Installation and Operating Manual

The installation and operating manual contains important information regarding proper

handling of the way valve. Prior to installation and commissioning of the way valve,

carefully read the entire installation and operating manual and make sure you fully

understand its content.

Keep this installation and operating manual in a place that is accessible to the

operator's staff at all times.

In addition to this installation and operating manual, hold the rules governing accident

prevention and environmental protection available and observe the same.

Please keep for later reference.

Warranty

The terms and conditions stated in the General Terms and Conditions of Sale for

Industrial Engineering of Voith Turbo GmbH & Co. KG, Crailsheim shall apply.

Warranty claims are excluded, if these are due to one or several of the following

causes:

Improper transportation, storage, installation, connection, commissioning,

operation, maintenance and repair of the way valve.

Non-observance of the information contained in the installation and operating

manual with regard to safety at work and of the product.

Use of spare parts not approved by Voith Turbo, Crailsheim.

Installation and Operating Manual / Version 1.5/

91800271810, Protection Class

EN / Protection Class 0: Offen

(p

ublic

)

/ 2014-09-03

8

WSR-D80112-S

User Information

NOTICE

During the warranty period, repair work on the way valve may be performed

only with the approval of Voith Turbo GmbH & Co. KG, Crailsheim.

Constructional modifications

Mounting work and structural modifications are not permitted.

The threaded joint of the cable gland on the control magnet (VRM) and the position

pickup is secured against distortion. Do not distort or slacken the threaded joint.

1.5 Health and safety at work

DANGER

For reasons of safety it is not allowed to perform any modifications,

attachments or conversions on the way valve without prior approval by Voith

Turbo GmbH & Co. KG, Crailsheim.

WARNING

Only trained and instructed staff is allowed to work on the way valve. This

staff must be sufficiently trained, instructed and authorized to properly mount,

operate and maintain the way valve in accordance with the safety standards.

The following notes apply to the entire manual and are to be observed in addition to

the individual instructions.

Installation and Operating Manual / Version 1.5/

91800271810, Protection Class

EN / Protection Class 0: Offen

(p

ublic

)

/ 2014-09-03

9

WSR-D80112-S

User Information

1.5.1 Accident prevention

WARNING

Operating medium leaving/leaking out of the way valve may get in contac

t

with hot machine parts, posing a risk of fire.

The way valve is under pressure!

On operation with manual operation knob, uncontrolled piston rod movements

may result posing a risk to persons and property. This movement may pose a

risk to both individuals and objects.

During operation of the way valve, the output pressure may vary severely in

case of a failure of the electric energy or of malfunctions of the control

electronics integrated in the way valve. The piston rod of a hydraulic cylinder,

for example, may move uncontrolled posing a risk to persons or objects.

WARNING

The way valve is a hydraulic unit. In case of improper use, operating medium

being under pressure may leak out. The operating medium poses a risk to the

health and life of the operating staff. Prior to performing any work on the way

valve, switch off the hydraulic supply system.

In case of improper use, operating medium being under pressure may leak

out on the sealing surfaces.

On commissioning or operation of the way valve, spraying hydraulic oil ma

y

get into the eyes causing blindness. Wear safety goggles for all work

performed on the way valve.

During operation, the outer surfaces of the way valve and the hydraulic

connecting lines may become hot due to the operating medium. Any contac

t

may cause injuries by burning. Prior to performing any work on the way valve,

let the way valve cool down.

CAUTION

Prior to performing any work, switch off the hydraulic supply system.

On commissioning or operation of the way valve, the end of the piston rod

directly or indirectly driven by the way valve may move uncontrolled in case o

f

a failure of the hydraulic or electric energy, due to malfunctions in the maste

r

control or on the way valve. This movement may pose a risk to both

individuals and objects. Prior to performing any work on the way valve, switch

off the hydraulic and electric auxiliary energy.

Installation and Operating Manual / Version 1.5/ 91800271810, Protection Class

EN / Protection Class 0: Offen

(p

ublic

)

/ 2014-09-03

10

WSR-D80112-S

User Information

NOTICE

Electrical components are integrated in the way valve. These components

may be destroyed, e.g. when performing electric welding work near the way

valve. Prior to performing any electric welding work near the way valve,

remove all electric connecting lines.

1.5.2 Environment

NOTICE

On assembly, disassembly or improper use of the way valve, operating

medium may leak out. Operating medium getting into the sewage system o

r

open soil causes severe environmental damages. Collect any leaking

operating medium and dispose of it in accordance with the national statutory

provisions.

1.6 General description of the way valve

In hydraulics, a "Voith way valve" serves to release, block or change the flow direction

of the hydraulic fluid by converting a setpoint signal, 4mA to 20mA, into a linear

movement of the control piston.

The way valves differ according to the following main features:

1. Number of positions

2. Number of flow routes

3. Number, size and kind of connections, e.g. nominal diameter, thread, ...

'Voith way valves' are suitable for fixing to hydraulic cylinders or to adapter plates and

4-way blocks.

1.7 Proper use

The way valve serves to transform an electric set signal, e.g. 4 - 20 mA into a flow rate

variable in direction and size. This allows, for example, remote-controlled, infinitely

variable adjustment of a hydraulic positioning cylinder with spring resetting for the

positioning of control valves on turbo machinery.

The maximum pressure indicated in the installation and operating manual must not be

exceeded.

Proper use also includes observing this installation and operating manual and

complying with the inspection and maintenance instructions.

Installation and Operating Manual / Version 1.5/ 91800271810, Protection Class

EN / Protection Class 0: Offen

(p

ublic

)

/ 2014-09-03

11

WSR-D80112-S

Technical Data

2 Technical Data

2.1 Way Valve

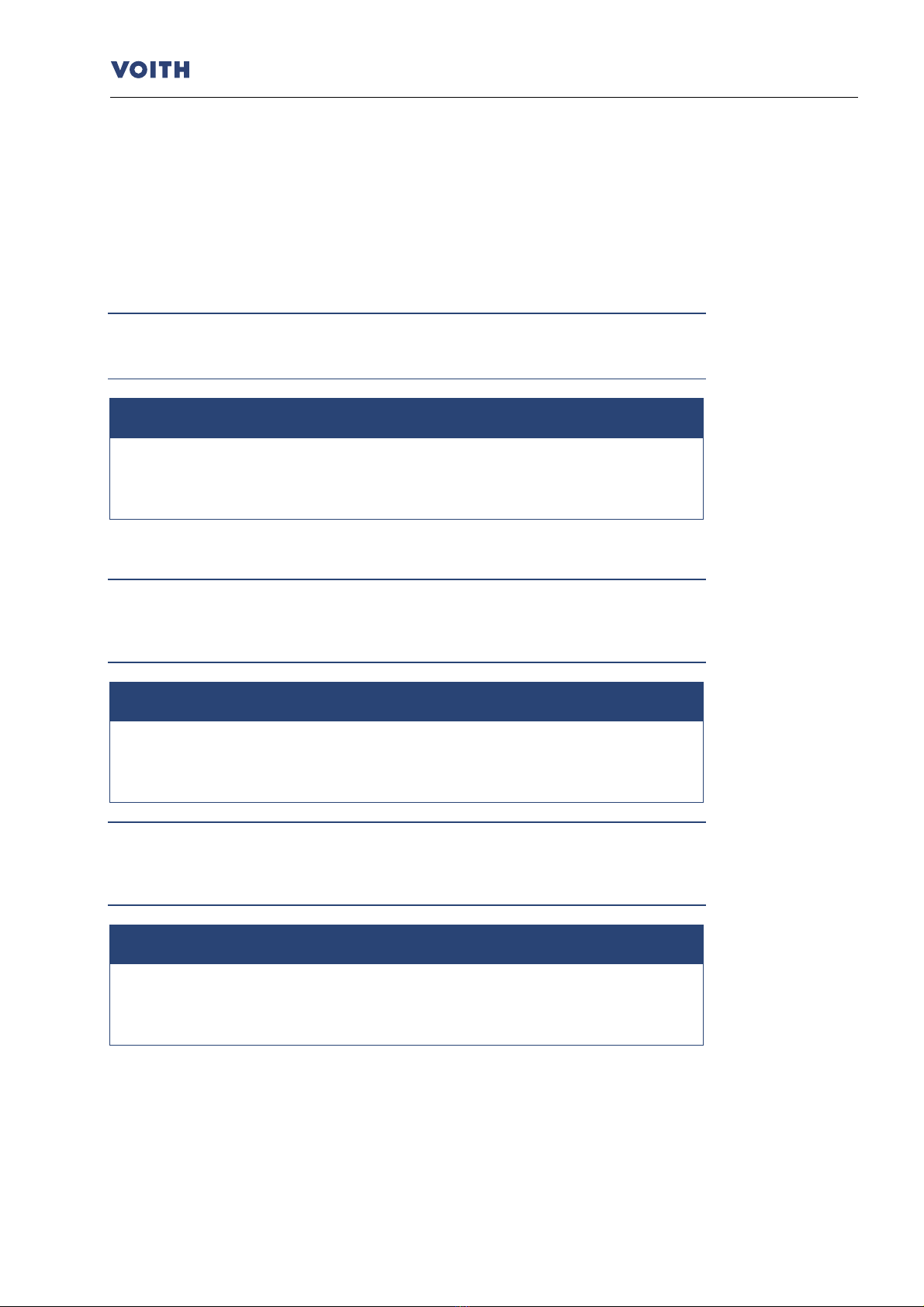

General data

Way valve type WSR-D80112-S

Article number 22000106810

Operating Manual No. 91800271810

Product identification See nameplate

Ingress

protection IP 65 as per EN 60529

Ambient temperature for operation TA -20 ... +70 °C

Ambient temperature (storage) -20 ... +80 °C

Installation conditions Indoor installation

Outdoor installation

Offshore

Industrial

atmosphere

Hydraulic Data

Supply pressure P

permissible pressure range 1 … 25 bar

Maximum pressure 25 bar

Return pressure T -0.05 … 0.2 bar

Flow rate P A,B at p = 4 bar 290 l/min

Flow rate A,B T at p = 4 bar 290 l/min

Operating medium

Type Hydraulic oil as per DIN 51524

Turbine oil as per DIN 51515

High-flash point fluid1)

Oil temperature during operation +10 … +70 °C

Cleanliness grade (ISO VG 4406) - / 16 / 13

Viscosity (DIN 51519) ISO VG 32 … ISO VG 46

Leakage (Toil = 50 °C at 10 bar) < 10 l/min

a) Important note:

The above-mentioned unit with -S marking is a SIL-certified version. Please refer to the nameplate on the

unit as to which type you are using. An additional safety manual is provided for SIL-certified way valves as

well as a Proof Test manual.

Installation and Operating Manual / Version 1.5/

91800271810, Protection Class

EN / Protection Class 0: Offen

(p

ublic

)

/ 2014-09-03

12

WSR-D80112-S

Technical Data

Mechanical data

Way valve design 3/3 4/3

Installation positions

VRM…Voith control magnet

Recommended installation position:

Preferably vertically, control magnet at the bottom

Sealing material FPM2)

Special design4)

NBR

3)

Dimensions, fastening See Chapter 10

Hydraulic connection See Chapter 10

Weight approx. 21

kg

1) According to customer's request or especially for high-flash point fluids

2) Fluor-caoutchouc

3) Acrylnitril-Butadien-caoutchouc

4) According to the customer's specification and consultation with Voith Turbo GmbH & Co.KG

Installation and Operating Manual / Version 1.5/ 91800271810, Protection Class

EN / Protection Class 0: Offen

(p

ublic

)

/ 2014-09-03

13

WSR-D80112-S

Technical Data

Electrical data

Supply voltage (power) including residual ripple 24 (+10% / -15%) V DC

Current consumption 1 A, max. 3 A for t < 1 sec

Supply voltage (control) 24 (+10% / -15%) V DC

Current consumption 0.2 A

Control Parameters

Setpoint w for stroke 0% … 100% w = 4.0 … 20.0 mA

Actual value input for stroke 0% ... 100% 20…4 mA

Actual value remote indication for stroke

0% … 100% 4…20 (load 400 max.) mA

Magnetic force switch-off at w < 3 mA

Magnetic force switch-on at w 4 mA

Setpoint limitation

E506 Electronics

E524 Electronics

E530 Electronics

w > 20.2

w > 90

w > 21

mA

mA

mA

Input configuration

E506 Electronics

E524 / E530 Electronics

Applied, related to GND

Isolated (500 k)

Please see the outline drawing in Chapter 10 for further technical data.

Installation and Operating Manual / Version 1.5/ 91800271810, Protection Class

EN / Protection Class 0: Offen

(p

ublic

)

/ 2014-09-03

14

WSR-D80112-S

Packin

g

, Stora

g

e, and Trans

p

ortation

3 Packing, Storage, and

Transportation

3.1 Packaging

The way valve is supplied in special packaging. All hydraulic connections are

sealed with protective plugs.

NOTICE

Keep all protective plugs and covers for a possible repacking, furthe

r

transportation, or storage.

3.2 Storage and preservation

The outer surfaces of the way valve are electro-plated. On delivery, the surfaces

of the way valve which are not surface-coated are moistened with preservation

oil.

NOTICE

Within Europe, this preservation is sufficient as corrosion protection for about

8 months. A precondition is that the way valve is stored in a dry location.

If it is intended to store the way valve for a longer period of time, special

precautions have to be taken. Coordinate such precautions for each individual

case with Voith Turbo GmbH & Co. KG, Crailsheim.

NOTICE

The ambient conditions for storage must be within the limits indicated in

Chapter 2.

Installation and Operating Manual / Version 1.5/

91800271810, Protection Class

EN / Protection Class 0: Offen

(p

ublic

)

/ 2014-09-03

15

WSR-D80112-S

Packin

g

, Stora

g

e, and Trans

p

ortation

3.3 Transport

CAUTION

Improper transportation or lifting of the way valve may cause damage to

property and personal injuries.

Ensure, in particular, that no constraining forces act on the cable gland of the

control magnet.

Only use suitable lifting appliances that are in accordance with the safety

regulations to lift the way valve.

For transportation purposes, it is not allowed to keep the way valve connected

to the connecting line.

Never lift or carry the way valve on the cable gland or on the open cable end

of the control magnet.

WARNING

Do not stay below suspended loads.

When transporting the way valve, it may swing or tilt due to fast movements o

f

the lifting appliance or due to eccentricities of center of gravity.

When lifting or while transporting the way valve by means of a lifting

appliance, secure it against swinging and tilting.

NOTICE

Be careful with mounted pipes when lifting the way valve.

Using chains to lift the way valve is not recommended. Chains may damage

the painting or individual parts.

From a weight of 15kg, it is recommended no longer carrying the way valve by

hand.

Fig. 1: Illustration for the lifting

Installation and Operating Manual / Version 1.5/

91800271810, Protection Class

EN / Protection Class 0: Offen

(p

ublic

)

/ 2014-09-03

16

WSR-D80112-S

Desi

g

n and Functionin

g

4 Design and Functioning

4.1 Design

The way valve comprises the main functional units:

Voith Control Magnet VRM

Manual operation knob

Retaining clip

Cable gland

Control housing

Control piston

Tappet for power transmission

Control spring

Cover

Fig. 2: Illustration of the way valve

Legend

P = Input pressre

A = Outlet A

B = Outlet B

T = Tank return line

FMag = Magnetic force

Fspring = Spring force

(1)

(1a)(1a)

(1b)

(1c)

(2)

(3)

(4)

(5)

(6)

Fmag

FFed

Installation and Operating Manual / Version 1.5/ 91800271810, Protection Class

EN / Protection Class 0: Offen

(p

ublic

)

/ 2014-09-03

17

WSR-D80112-S

Desi

g

n and Functionin

g

4.2 Function

The way valve is an electro-hydraulic positioner with permanently activated way valve.

This enables variable and basically hysteresis-free positioning of a hydraulic cylinder

equipped with a position transmitter and spring resetting.

For way valve operation, an electric and a hydraulic auxiliary energy are required. All

electric controllers and connections necessary for the way valve operation are

integrated in the Voith control magnet (VRM). The control loop parameters and the

parameters to scale the position of the piston rod are set via potentiometers on the

VRM.

Block diagram - way valve

Fig. 3: Block diagram of way valve

Position control

The way valve is controlled by the control system with an electric signal (4 mA to 20

mA) as position setpoint (w) 0% to 100% for a piston rod. In the VRM position control

loop, this setpoint (w) is compared to the actual position (x) of the piston rod

measured by the position pick-up resulting in a change of the magnetic force (FMag)

of the VRM via the magnetic force controller. This magnetic force moves the control

piston of the gate valve against a control spring, thus changing the magnitude and

direction of the flow rate (Q) to the hydraulic cylinder working chamber. The hydraulic

force resulting from the flow rate effects a movement of the piston rod position (x) in

connection with the compression spring. The piston rod moves into or out of the

actuator with a velocity dependent on the flow rate.

The main control parameters can be adjusted at the VRM from the outside via

potentiometers, thus allowing optimum adjustment of the control for various cylinders

and allocation of the required stroke range to setpoint w.

Function of manual operation knob

Instead of the magnetic force FMag, a force can be set with the manual operation

knob that is transmitted to the tappet and thus to the control piston via the magnet

armature. This permits a movement of the control piston without electrical connection

to thus connect outlet A with P or T. Thus, the piston rod on a cylinder connected on

outlet A can be moved to a corresponding final position. However, it is not possible to

adjust any desired position.

Installation and Operating Manual / Version 1.5/ 91800271810, Protection Class

EN / Protection Class 0: Offen

(p

ublic

)

/ 2014-09-03

18

WSR-D80112-S

Desi

g

n and Functionin

g

Limitation of maximum value

In case of incorrect connection of the setpoint, e.g. by unintentional connection of 24

VDC to the plus-port of the setpoint input, the setpoint current is limited to an uncritical

value by means of an overload protector integrated in the VRM, thus protecting the

way valve control against damage.

24V Control and 24V Power function

During normal operation, both 24V connections have to be connected to the 24V

supply. To switch off the way valve, both 24V connections can be simultaneously

disconnected from the 24V supply.

However, if only the hydraulic part is to be switched into its preferential position with

the way valve and its actual value remote indication remaining active, it is sufficient to

switch off the 24V power; the 24V control may remain connected with the 24V supply.

Thus, a remote indication is available even in a switched-off condition, e.g. for

observation purposes.

Magnetic force switch-off

At setpoint w < 3 mA (wmin) the magnetic force FMag = 0 N and the control piston of

the slide valve are moved uncontrolled into the appropriate end position by the spring

tension FF. This connects outlet A with T and, for example, a valve that is coupled to

the actuator is kept safely in its closed position.

Installation and Operating Manual / Version 1.5/

91800271810, Protection Class

EN / Protection Class 0: Offen

(p

ublic

)

/ 2014-09-03

19

WSR-D80112-S

Installation

5 Installation

5.1 Notes

WARNING

Only staff satisfying the qualifications according to Chapter 1.5 is allowed to

work on the way valve.

Work performed improperly could result in severe injuries.

CAUTION

Electric lines, cable glands, cable entries and electric connections must not be

damaged.

NOTICE

Improper installation of the way valve may cause malfunctioning and

premature failure of the way valve.

Cleanliness is imperative during both installation and connection. Prevent any

impurities (dust, metal chips, etc.) from getting into the interior of the wa

y

valve or into the piping system. Any such impurities may cause damage to the

way valve.

During the installation period, cover and protect the way valve and, in

particular, the electric and hydraulic connections.

Prior to the installation, check the way valve for possible damages.

Hydraulic connections and flange surfaces must not be damaged.

Installation according to the latest design standard.

For dimensions of the way valve, the flange arrangement, and the positions of the

hydraulic connections, please see the outline drawing in Chapter 10.

Please observe, among others, Standard EN ISO 4413 "General rules and safety

requirements for hydraulic systems and their components".

Installation and Operating Manual / Version 1.5/

91800271810, Protection Class

EN / Protection Class 0: Offen

(p

ublic

)

/ 2014-09-03

20

WSR-D80112-S

Installation

5.2 Mounting

DANGER

Any work on the way valve may only be performed in de-energized condition

and with the oil supply system switched off. During installation, the oil and

power supply for the way valve has to be secured against unintentional

switching-on.

WARNING

During mounting, always secure the way valve against tilting, swinging, o

r

falling down!

CAUTION

Wear safety goggles when mounting the way valve.

NOTICE

Mount the way valve in accordance with the permissible installation position

described in Chapter 2.

Flange on the way valve to a hydraulic consumer via the connecting bores

being at the way valve bottom. Use O-rings to the flange surface for sealing.

For position and dimensions of the connecting bores, please see Chapter 10.

Mounting procedure

Unpack and transport the way valve (see Chapter 3).

Transport the way valve as described in Chapter 3.

Observe the installation position (see Chapter 2).

Remove the plug.

Position the way valve on the suitable wiring diagram. Use O-rings on the way

valve for sealing. The customer's connecting surface has to correspond to Ra

1.6µm and Rmax 6.3µm.

Tighten the fastening bolts. (Observe the tightening torque!)

NOTICE

When mounting ensure that the flange surfaces are clean and the sealing

rings are at their proper position.

This manual suits for next models

1

Table of contents

Other Voith Control Unit manuals

Popular Control Unit manuals by other brands

Tekmar

Tekmar Universal Reset Module 422 Data brochure

Asco

Asco 8030 Series Installation & maintenance instructions

Weir

Weir SPM EXL Operation Instruction and Service Manual

Beckhoff

Beckhoff KM6551 Documentation

Motorline professional

Motorline professional MC61SE installer and user manual

UNICORECOMM

UNICORECOMM UM220-IV M0 user manual