Voith BTS-Ex User manual

Installation and Operating Manual

(Translation of the original installation and operating manual)

BTS-Ex

Non-contacting Thermal Switch Unit

for limiting the maximum surface

temperature on Voith Turbo Couplings

Version 7, 2020-07-15

3626-019600ex en, Protection Class 0: public

Installation and Operating Manual / Version 7 / 3626-019600ex

en / Protection class

0: public / 2020-07-15

2

BTS

-Ex, non-contacting thermal switch unit

Contact

Contact

Voith Group

St. Pöltener Str. 43

89522 Heidenheim, GERMANY

Telefon: + 49 7951 32 1666

E

-Mail: Industry.Service@voith.com

Internet

: www.voith.com/fluid-couplings

If you have questions regarding the

product, please contact the Voith

Service

stating the serial number (see

nameplate).

3626

-019600ex en

This document describes the state of de-

sign of the product at the time of the

editorial deadline on 2020

-07-15.

Copyright © by

J.M. Voith SE & Co. KG

This document is protected by

copy

right.

It must not be translated, duplicated

(mechanically or elec

tron

ically) in whole

or in part, nor passed on to third parties

without the publisher's written approval.

Installation and Operating Manual / Version 7 / 3626-019600ex

en / Protection class

0: public / 2020-07-15

3

BTS-Ex, non-contacting thermal switch unit

Contents

Contents

1Possible Applications, BTS-Ex Characteristics 5

1.1 Use as safety device in potentially explosive atmospheres 5

1.2 Special conditions for the use in potentially explosive

atmospheres and as safety device in potentially explosive

atmospheres 7

1.3 Declaration of conformity 8

2Function of BTS-Ex 9

2.1 Switching element 10

2.2 Initiator 10

2.3 Evaluator 10

2.4 Interaction of BTS-Ex components 11

3Technical Data 13

3.1 Switching element 13

3.2 Initiator, mounting flange 14

3.3 Evaluator 14

4User Information 15

5Safety 17

5.1 Safety information 17

5.1.1 Structure of safety information 17

5.1.2 Definition of safety symbols 18

5.2 Intended use 18

5.3 Unintended use 18

5.4 General information as to dangerous situations 19

5.5 Remaining risks 22

5.6 What to do in case of accidents 22

5.7 Information with regard to operation 22

5.8 Qualification of staff 23

5.9 Product monitoring 24

5.10 Nameplate 24

Installation and Operating Manual / Version 7 / 3626-019600ex

en / Protection class

0: public / 2020-07-15

BTS

-Ex, non-contacting thermal switch unit

Contents

4

6Installation 25

6.1 As delivered condition 25

6.2 Scope of supply 26

6.3 Mounting - switching element and initiator 26

6.4 Mounting, connection - evaluator 29

7Display and Setting of Evaluator 31

7.1 Design 31

7.2 Setting of DIP switches S1 and S2 (cutoff frequency) 31

7.3 Setting the S3 DIP switch - (start-up bypass) 32

7.4 Setting of start-up bypass time 32

8Commissioning 34

9Maintenance, Servicing 35

9.1 Outside cleaning 37

10 Disposal 38

11 Malfunctions - Remedial Actions, Troubleshooting 39

12 Queries, Orders Placed for Field Service Engineers and

Spare Parts 42

13 Spare Parts Information 43

13.1 Switching elements 43

13.2 Initiator, mounting flange 44

13.3 Evaluator 44

14 Annex 45

14.1 EU Declaration of Conformity 45

14.2 Initiator NJ10-22-N-E93-Y106925 46

14.3 Initiator NJ10-22-N-E93-Y30627 47

14.4 Initiator NJ10-22-N-E93-Y30629 48

14.5 Initiator NJ10-22-N-E93-Y245590 49

14.6 Initiator NJ10-22-N-E93-Y246868 50

14.7 Initiator NJ10-22-N-E93-Y246869 51

14.8 Evaluator KFD2-SR2-Ex2.W.SM 52

BTS-Ex, non-contacting thermal switch unit

Possible Applications, BTS-Ex Characteristics

Installation and Operating Manual / Version 7 / 3626-019600ex

en / Protection class

0: public / 2020-07-15

5

1 Possible Applications, BTS-Ex

Characteristics

The non-contacting thermal switch unit (BTS-Ex) is a monitoring system for Voith

turbo couplings.

– The BTS-Ex provides easy monitoring of the turbo coupling temperature.

– In case of excess temperature, dependent on the application,

- the operator can be warned,

- the drive motor shutdown can be initiated,

- the load on the driven machine can be reduced.

– If excess temperature is identified in time, the discharge or loss of coupling filling

through the fusible plugs can be avoided.

Downtimes are reduced.

– After the turbo coupling has cooled down, the BTS-Ex resets automatically.

– The BTS-Ex can be used for Voith turbo couplings from size 366.

1.1 Use as safety device in potentially explosive

atmospheres

The BTS-Ex can be used in potentially explosive atmospheres as safety device to limit

the maximum permissible surface temperature of the turbo coupling. An ignition

protection level IPL1 (SIL 1) is reached in a low requirement rate.

WARNING

Explosion hazard

When the permissible surface temperature is exceeded, there is the risk of

explosion.

•

In case of excess

temperature, the drive motor has to be switched off within

the specified time (installation and operating manual of turbo coupling).

The following electrical equipment belongs to the whole system:

– Switching element (will be fixed to the turbo coupling)

– Initiator to evaluate the switching element

– Evaluator with safety-related function.

BTS

-Ex, non-contacting thermal switch unit

Possible Applications, BTS-Ex Characteristics

Installation and Operating Manual / Version 7 / 3626-019600ex

en / Protection class

0: public / 2020-07-15

6

The safety devices will be installed into/fixed to a master machine. Depending on the

ingress protection level (IP), the interval for cleaning the operational equipment (dust

deposits) has to be defined.

Switching element and initiator may be used as follows:

– In Zone 2 (gas-Ex, Category 3G, EPL Gc) in Explosion Groups IIA and IIB

(initiator also IIC)

– In Zone 22 (dust-Ex, Category 3D, EPL DC) in Explosion Groups IIIA, IIIB and IIIC

– In Zone 1 (gas-Ex, Category 2 G, EPL Gb) in Explosion Groups IIA and IIB

(initiator also IIC)

– In Zone 21 (dust-Ex, Category 2D, EPL Db) in Explosion Groups IIIA, IIIB and IIIC

WARNING

Explosion hazard

In case of non

-compliance

with the conditions for use, there is the risk of

explosion.

•

In case of explosive dust atmospheres of Explosion Group IIIC, the product

may be used with organic dusts only.

It is only allowed to install the evaluator beyond potentially explosive atmospheres in

housings that comply with the IP category of environmental requirements or in

housings with own approval.

Qualification with regard to surface temperature depends on the ambient conditions; it

applies to T4...T3: T4 means that for all gases, vapors, mists with an ignition

temperature of > 135 °C, the equipment is not an ignition source.

In explosive dust atmospheres, the reference temperature T***°C (from 85 °C to 190

°C) is relevant for the further considerations with regard to safety distance to the

smoldering temperature.

Installation and Operating Manual / Version 7 / 3626-019600ex

en / Protection class

0: public / 2020-07-15

7

BTS-Ex, non-contacting thermal switch unit

Possible Applications, BTS-Ex Characteristics

1.2 Special conditions for the use in potentially explosive

atmospheres and as safety device in potentially

explosive atmospheres

The devices are only approved for proper and intended use in accordance with the

instructions. Contravention excludes any warranty and responsibility on the part of the

manufacturer!

– Only use accessories in potentially explosive atmospheres which satisfy all

requirements of European directives and national legislation.

– In case of explosive dust atmospheres of Explosion Group IIIC, the product may

be used with organic dusts only.

– It is imperative to comply with the ambient conditions as specified in this operating

manual.

– The provision of lightning protection measures have to be ensured by the

operator.

– Ensure that the fusible plugs required in addition are used on each turbo coupling

which is operated with this safety device.

– If the maximal permissible surface temperature of the turbo coupling is ensured by

this safety device, the type of protection "Protection by ignition source monitoring"

also applies to the turbo coupling.

– Voith Turbo has to determine the response temperature.

– The ambient temperatures of individual elements must not exceed the respective

limiting temperatures.

– Mechanical damage caused by ice formation must be reliably excluded.

– Locks need to be re-attached after opening and closing.

– Operation of the safety device is only allowed with undamaged housings and

lines.

– Make sure to satisfy electromagnetic compatibility when installing the system.

– On installation, it is vital to observe the nationally applicable provisions governing

installation of equipment, such as EN 60079-14, EN 1127-1 and EN 1127-2.

– It is mandatory to provide an equipotential bonding. Compliance with provisions

governing the installations into plants in the country of use must to be ensured

(e.g. VDE 0100, part 540, IEC 364-5-54).

– Avoid electrostatic charging.

– To ensure the discharge of electrostatic charging, please observe the national

regulations.

•Non-conductive parts must not exceed a surface of 100 cm² in IIB.

•It is not allowed to use the BTS-Ex in equipment with electrical corrosion

protection, or after consultation with the manufacturer and by taking special

measures only. It is not permitted to route compensation currents through the

construction.

– The evaluator is designed for use in Contamination Level 2, as per DIN EN 50178.

Protect the switching element and initiator against the ingress of liquids and/or

impurities, if required. This depends on the operating conditions, e.g. heavy dust

contamination or chemically aggressive fluids.

– For temperatures below -20 °C, install the initiators with mechanical protection.

Operating manual

of turbo coupling

BTS

-Ex, non-contacting thermal switch unit

Possible Applications, BTS-Ex Characteristics

Installation and Operating Manual / Version 7 / 3626-019600ex

en / Protection class

0: public / 2020-07-15

8

– Keep a minimum distance of 3 mm between switching element and initiator (

Chapter 6.3).

– After switching off, it is mandatory to eliminate all errors/faults before re-starting or

switching on again the BTS-Ex.

– It is recommended designing the monitoring devices and monitoring circuits of the

shutdown chain at least as per PL c according to EN ISO 13849-1 or SIL 1

according to EN 61508 or EN 62061.

– In case of existing explosive atmosphere, it is not permitted so loosen seized parts

(caused e.g. by frost or corrosion) forcefully. Icing-up has to be avoided.

– The operator has to provide protective measures according to the explosion

protection document, e.g. protection against external impact energy.

– In order to ensure explosion protection, electrical equipment and mechanical

devices mounted in addition have to comply with the requirements of the zones

applying on the jobsite and shall be inspected separately by the person installing

the machine.

– Coatings / paintings are permissible up to a thickness of 0.2 mm in Explosion

Group IIC. In IIB / I, it is never allowed to exceed a thickness of 2 mm; if

necessary, a reduction of e.g. 0.5 to 1 mm has to be made dependent on the

quality of the coating / painting. Operators are not allowed to perform any

paintings.

1.3 Declaration of conformity

Annex (see declaration of conformity)

Installation and Operating Manual / Version 7 / 3626-019600ex

en / Protection class

0: public / 2020-07-15

9

BTS-Ex, non-contacting thermal switch unit

Function of BTS-Ex

2 Function of BTS-Ex

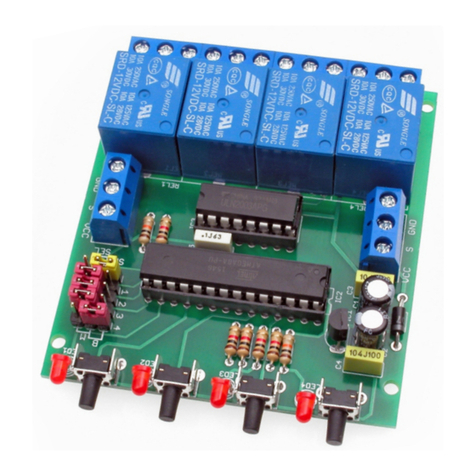

The non-contacting thermal switch unit (BTS-Ex) consists of three components:

– Switching element

– Initiator with mounting flange

– Evaluator

Fig. 1

Evaluator

a = 4 ± 1 mm

Turbo coupling

Initiator

Mounting flange

Switching element

a

BTS

-Ex, non-contacting thermal switch unit

Function of BTS-Ex

Installation and Operating Manual / Version 7 / 3626-019600ex

en / Protection class

0: public / 2020-07-15

10

2.1 Switching element

The switching element is a passive component (ordinary electrical equipment). It is

inserted into the outer wheel or into the turbo coupling shell. The result is a thermal

contact between the switching element and the turbo coupling with the operating fluid.

A coil and a thermostatic switch are integrated in the switching element. The switching

point of the thermostatic switch corresponds to the response temperature of the

switching element.

Below the nominal response temperature, the thermostatic switch is closed and

bridges the coil. Above the nominal response temperature, the thermostatic switch

opens and interrupts the circuit. When the temperature decreases, the thermostatic

switch connects again the circuit. The BTS-Ex is again ready for service (it resets

automatically).

2.2 Initiator

The initiator has been designed as intrinsically safe, polarized two-wire sensor. It

works to the inductive sensor principle.

An electric oscillator is integrated in the initiator which produces a high-frequency

oscillation. The oscillator has an oscillating circuit as element determining the

frequency, comprising a coil and a capacitor.

The oscillating circuit coil is located in the sensor head. An electromagnetic alternating

field leaves the sensor head via this coil.

2.3 Evaluator

The evaluator is an electronic unit recording the electric pulses and evaluating the

period between the pulses (appropriate equipment with intrinsically safe circuit to the

explosive atmosphere).

The evaluation starts by switching on the supply voltage.

After starting the evaluation, monitoring of pulses must be interrupted for an

adjustable period of time (start-up bypass time).

A relay with changeover contact will be released if the number of pulses per unit of

time drops below a certain value.

Nominal response

temperature

Chapter 3.1

Installation and Operating Manual / Version 7 / 3626-019600ex

en / Protection class

0: public / 2020-07-15

11

BTS-Ex, non-contacting thermal switch unit

Function of BTS-Ex

2.4 Interaction of BTS-Ex components

Instead of a blind screw, the switching element is screwed into the turbo coupling. The

initiator with mounting flange is mounted parallel with the turbo coupling axis and is

connected to the evaluator.

The coil inside the switching element is coupled inductively with the coil inside the

initiator if the switching element is located in front of the initiator head. When the

thermostatic switch is closed, energy is transmitted from the initiator to the switching

element. The oscillator is attenuated and has a lower current consumption.

If the coupling temperature exceeds the response temperature of switching element,

the thermostatic switch will interrupt the circuit in the switching element. The switching

element can no longer attenuate the oscillator in the initiator.

The evaluator recognizes the attenuation of initiator due to the initiator current con-

sumption.

If the turbo coupling with screwed in switching element rotates, then the switching ele-

ment will permanently pass the initiator, thus permanently creating attenuation pulses.

Thus, permanently attenuation pulses are generated. The output relay in the evaluator

is energized.

In case of excess temperature, these attenuation pulses are not given, i.e. the cutoff

frequency set on the evaluator is not reached. The evaluator recognizes the missing

pulses, the output relay is de-energized.

Installation, position

Chapter 6.3

Cutoff frequency

Chapter 3.3

BTS

-Ex, non-contacting thermal switch unit

Function of BTS-Ex

Installation and Operating Manual / Version 7 / 3626-019600ex

en / Protection class

0: public / 2020-07-15

12

On startup of the turbo coupling, a start-up bypass time is set at the evaluator. As long

as the start-up bypass is active, the output relay remains energized.

After this set time, the speed of the turbo coupling with the switching element must

have exceeded the set cutoff frequency.

WARNING

Risk of personal injuries and damage to property

Following the shutdown, the control system has to be locked in a way that

prevents automatic re

-start.

•

Switch

off the unit in which the turbo coupling is installed and secure the

switch against inadvertent switch-on.

•

For all work performed on the turbo coupling and BTS-

Ex ensure that both

the drive motor and the driven machine have stopped running and that

unintended starting is absolutely impossible!

WARNING

Explosion hazard

In case of non

-

compliance with the maximum permissible temperature, there is

the risk of explosion.

•

The coupling

may only be restarted if the turbo coupling temperature is below

the maximum permissible temperature allowed when switching on the motor!

Maximum allowable

temperature

Operating manual

of turbo coupling

Installation and Operating Manual / Version 7 / 3626-019600ex

en / Protection class

0: public / 2020-07-15

13

BTS-Ex, non-contacting thermal switch unit

Technical Data

3 Technical Data

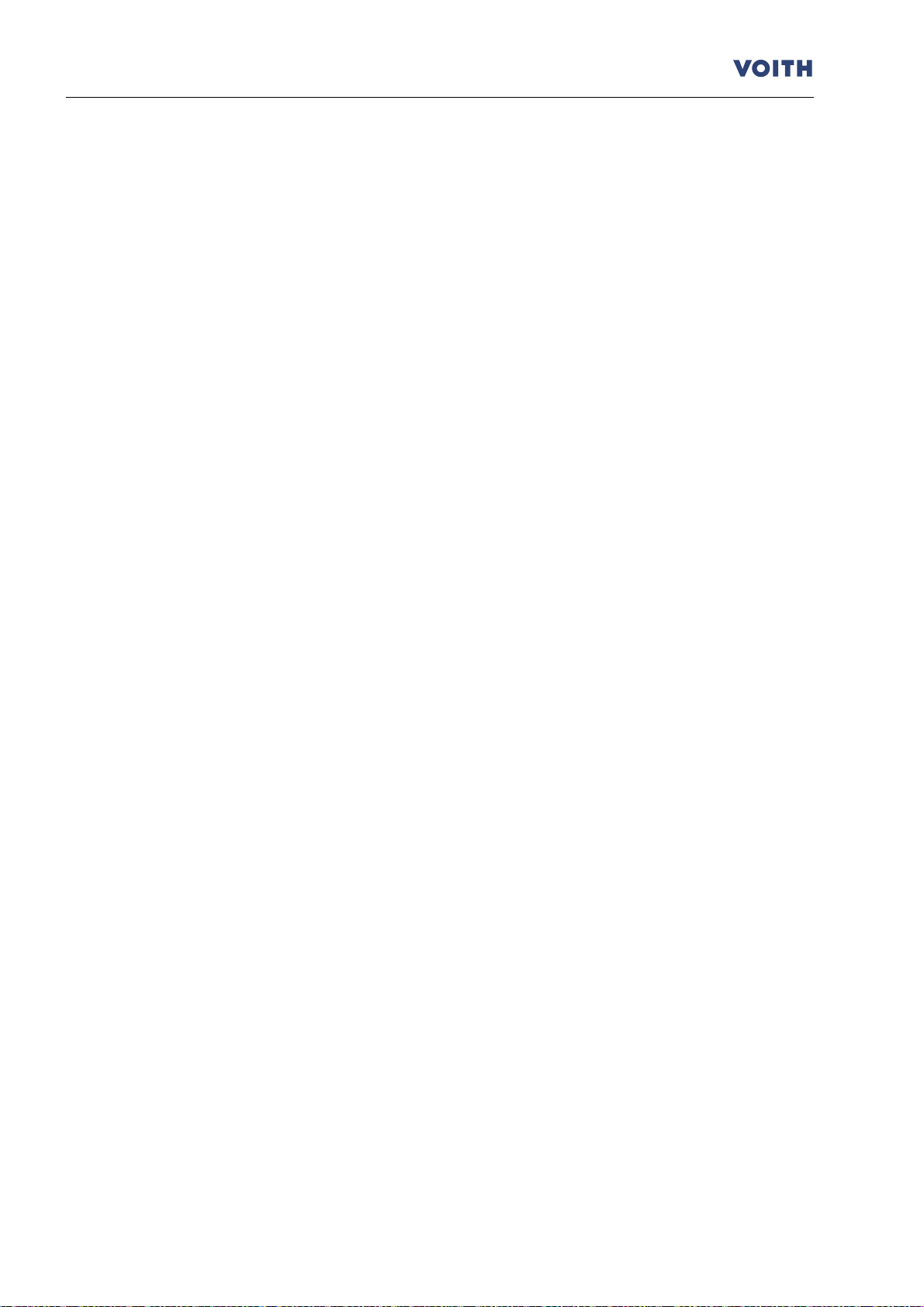

3.1 Switching element

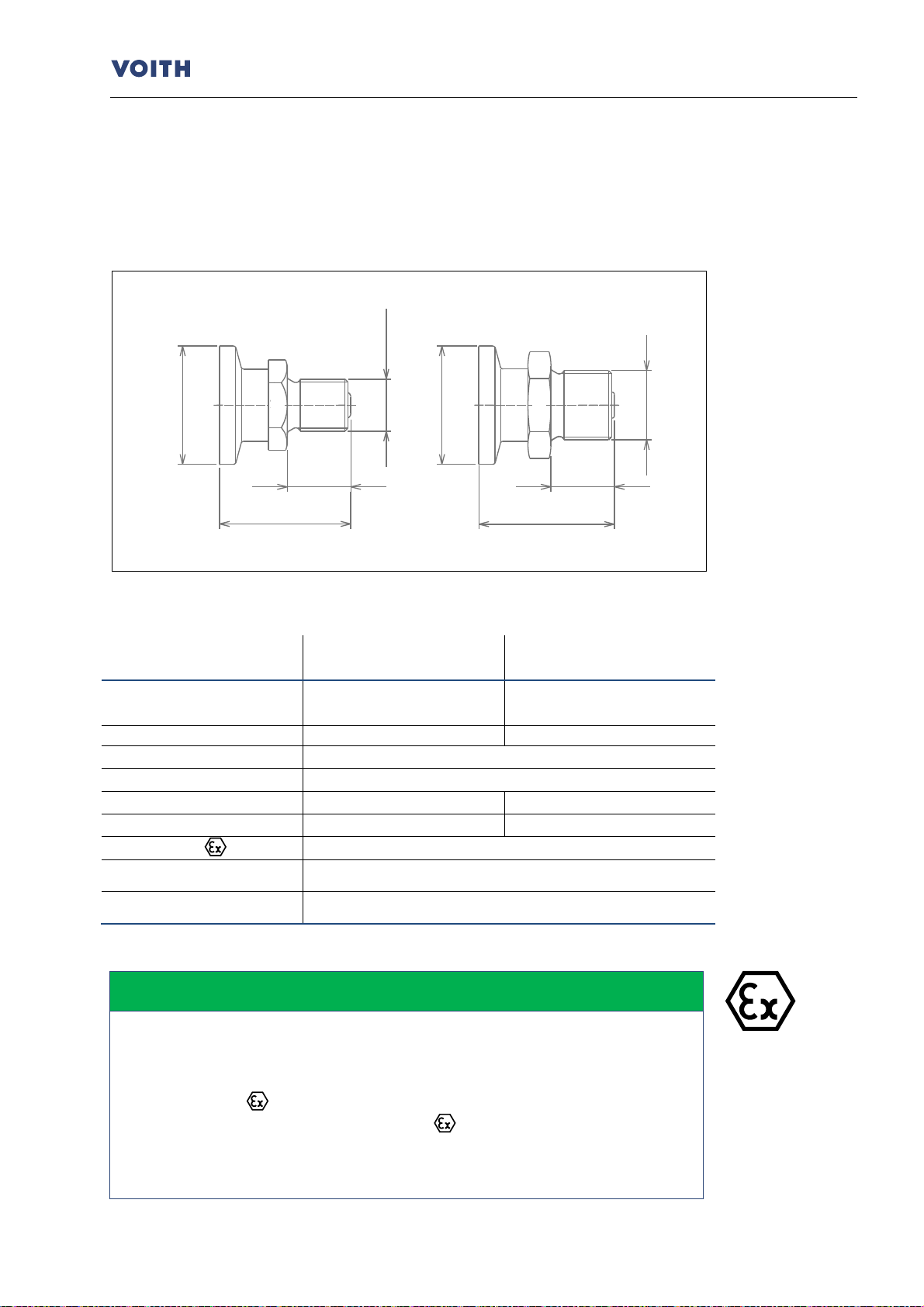

Fig. 2

The following switching elements are available for the different turbo coupling sizes:

Dimension of thread M18x1.5 M24x1.5

Nominal response temperature 85 / 90 / 100 / 110 /

125 / 140 /160 / 180 °C 85 / 125 / 140 /

160 / 180 °C

suitable for coupling size 366 – 650 750 – 1150

Response tolerance ± 5 °C

Trip temperature approx. 40 K below the response temperature

Width across flats 27 32

Tightening torque 60 Nm 144 Nm

Classification is II 2GD

Ui = 10 V Ii = 50 mA Pi = 50 mW

Service temperature in the coil

area

-40 °C to +120 °C

Service temperature in the

area of the thermostatic switch

to 90 °C (T5), to 125 °C (T4), to 190 °C (T3)

Table 1

SAFETY INFORMATION

•

The type of switching element is stamped in on the housing indicating:

- Voith

- Nominal response temperature

- Ex marking II Ex i X

- Serial number (example: Voith 140 °C II Ex i X 1234 5678)

•

The nominal response temperature of the switching element is determined in

connection with the the coupling design.

~ 47

~ 22

~ 45.5

~ 22

M24x1.5

M18x1.5

Ø 41

M24x1.5

Ø 41

M18x1.5

BTS

-Ex, non-contacting thermal switch unit

Technical Data

Installation and Operating Manual / Version 7 / 3626-019600ex

en / Protection class

0: public / 2020-07-15

14

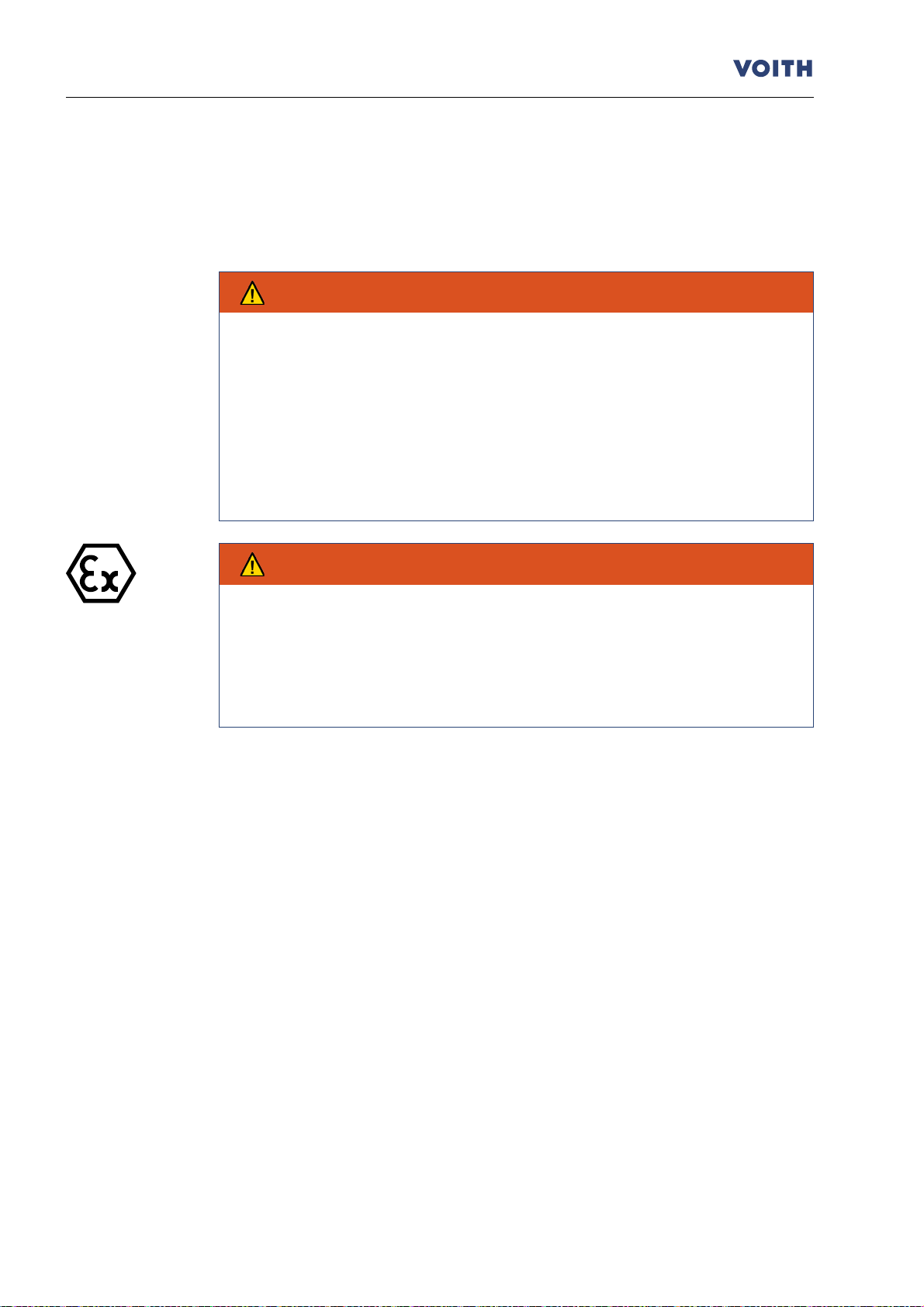

3.2 Initiator, mounting flange

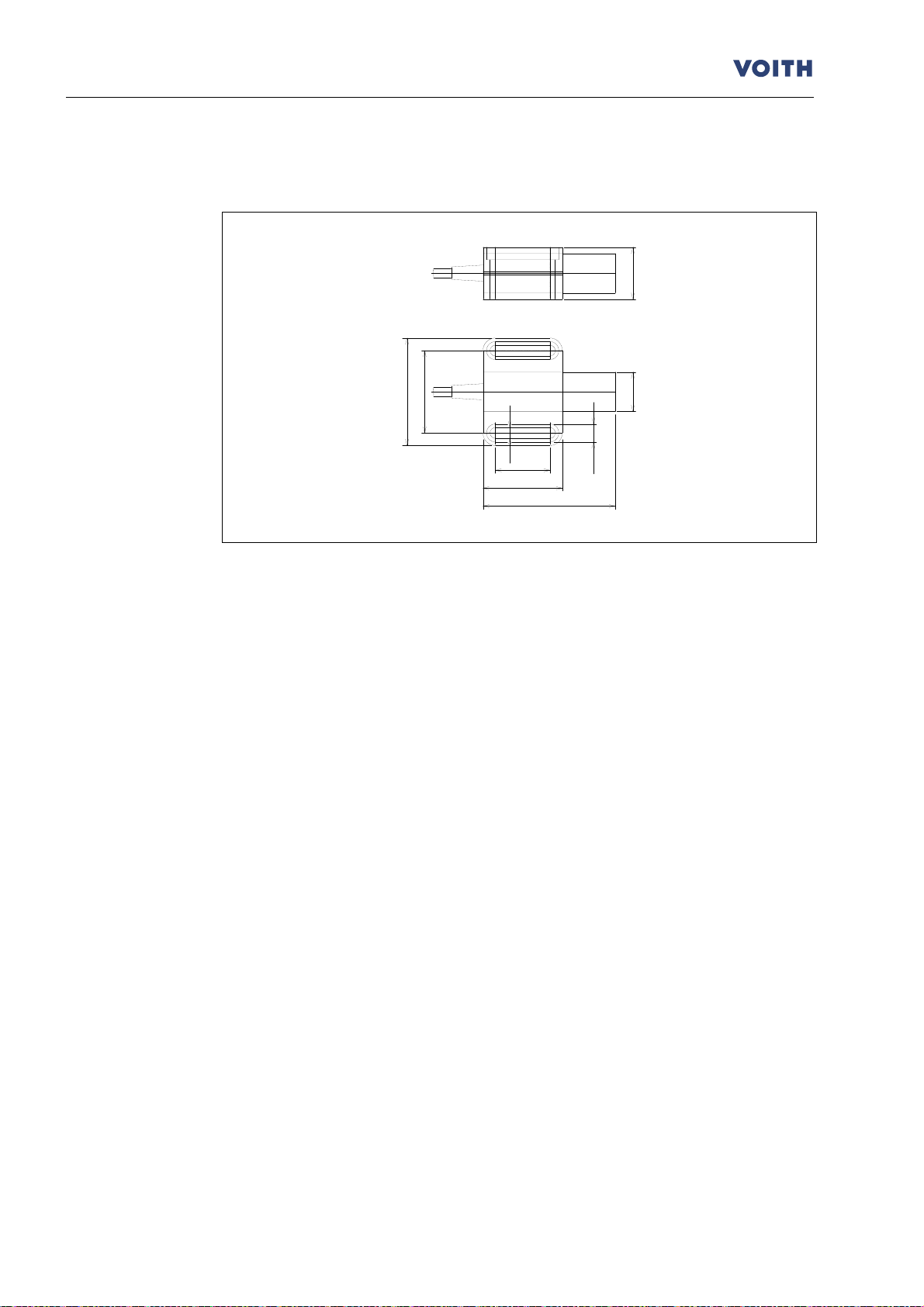

Fig. 3

Annex Type: NJ 10-22-N-E93-Y106925

NJ 10-22-N-E93-Y30627

NJ 10-22-N-E93-Y30629

NJ 10-22-N-E93-Y245590 (new design, cable length 2 m)

NJ 10-22-N-E93-Y246868 (new design, cable length 5 m)

NJ 10-22-N-E93-Y246869 (new design, cable length 10 m)

3.3 Evaluator

Annex Type: KFD2-SR2-Ex2.W.SM

31

Ø 22

29

~ 12

~ 6

46

60

Initiator shown with mounting flange

45

75

Installation and Operating Manual / Version 7 / 3626-019600ex

en / Protection class

0: public / 2020-07-15

15

BTS-Ex, non-contacting thermal switch unit

User Information

4 User Information

This manual will support you in using the non-contacting thermal switch unit (BTS-Ex)

in a safe, proper and economical way.

If you observe the information contained in this manual, you will

– increase the reliability and lifetime of the unit,

– avoid any risks

– reduce repairs and downtimes.

This manual must

– always be available at the BTS-Ex place of use,

– be read and used by every person who works on the unit or commissions the

same.

You will find further documents which have to be regarded at any rate, in the

annex.

The non-contacting thermal switch unit has been manufactured to the latest design

standard and approved safety regulations. Nevertheless, the user's or third party's life

may be endangered or the unit or other property impaired in case of improper

handling or unintended use.

Spare parts:

Spare parts must comply with the technical requirements stipulated by Voith. This is

ensured by using original spare parts.

Installation and/or use of non-original spare parts may negatively change the mecha-

nical properties of the BTS-Ex and may thus impair safety.

Voith is not liable for any damages resulting from the use of non-original spare parts.

Use only appropriate workshop equipment for maintenance. Professional

maintenance and/or repair can only be guaranteed by the manufacturer or an

authorized specialist workshop.

BTS

-Ex, non-contacting thermal switch unit

User Information

Installation and Operating Manual / Version 7 / 3626-019600ex

en / Protection class

0: public / 2020-07-15

16

This manual has been issued with utmost care. However, should you need any further

information, please contact:

Voith Group

St. Pöltener Str. 43

89522 Heidenheim, GERMANY

Telefon: + 49 7951 32 1666

E-Mail: Industry.Service@voith.com

Internet: www.voith.com/fluid-couplings

© Voith 2020.

Distribution as well as the reproduction of this document and the utilization and

communication of its contents are prohibited unless expressly permitted. Offenders

will be held liable for the payment of damages. All rights reserved in case a patent is

granted, or a utility model or design is registered.

Voith reserves the right for modifications.

Installation and Operating Manual / Version 7 / 3626-019600ex

en / Protection class

0: public / 2020-07-15

17

BTS-Ex, non-contacting thermal switch unit

Safety

5 Safety

5.1 Safety information

Safety information indicating the descriptions and symbols as described in the

following are used in the operating manual.

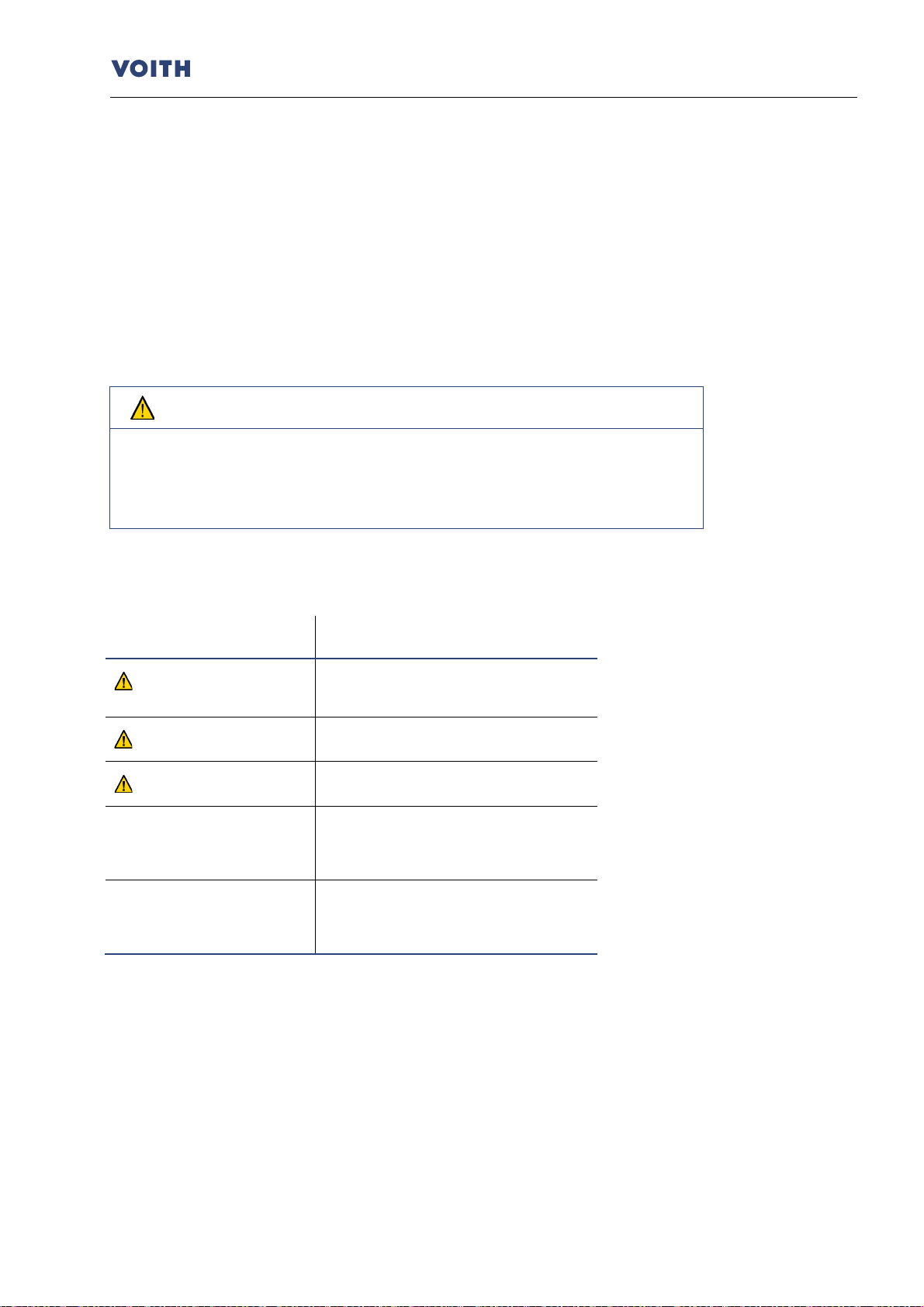

5.1.1 Structure of safety information

DANGER WORD

Results of a hazardous situation

Source of hazard

•

Warding off of danger

Danger word

The danger word divides the severity of the danger in several levels:

Danger word

Severity of danger

DANGER

Death or serious injury (irreversible personal

injury)

WARNING

Death or serious injury possible

CAUTION

Minor or moderate injury possible

NOTICE

Possibly damage to property of

- the product

- its environment

SAFETY INFORMATION

General applications details, useful

information, safe job procedure and proper

safety measures

Table 2

Results of a hazardous situation

Hazard consequences indicate the kind of hazard.

Source of hazard

The source of hazard indicates the cause of hazard.

Warding off of danger

Warding off of danger describes the measures to be taken to ward off a danger.

BTS

-Ex, non-contacting thermal switch unit

Safety

Installation and Operating Manual / Version 7 / 3626-019600ex

en / Protection class

0: public / 2020-07-15

18

5.1.2 Definition of safety symbols

Symbol

Definition

Explosion hazard

Marking with the Ex-symbol indicates possible hazards which have to be

observed for the use in potentially explosive atmospheres.

Table 3

5.2 Intended use

– The non-contacting thermal switch unit (BTS-Ex) serves for the non-contacting

temperature monitoring of Voith turbo couplings and has been designed for

industrial applications. Any use beyond that described herein, e.g. for operating or

application conditions that have not been agreed upon, is deemed unintended.

– Intended use also includes observing this installation and operating manual.

– The manufacturer is not liable for any damages resulting from unintended use.

The risk has to be borne solely by the user.

5.3 Unintended use

– Design range is not met.

– Any use beyond that described herein, e.g. for higher powers, higher speeds, or

operating conditions that have not been agreed upon, is deemed unintended.

– Moreover, it is not permitted to use BTS-Ex non-contacting thermal switch units or

spare parts from third parties.

Design range

Operating manual

of turbo coupling

Installation and Operating Manual / Version 7 / 3626-019600ex

en / Protection class

0: public / 2020-07-15

19

BTS-Ex, non-contacting thermal switch unit

Safety

5.4 General information as to dangerous situations

For all work performed on the non-contacting thermal switch unit, please ob-

serve the local regulations for the prevention of accidents as well as the regula-

tions for installation of electrical equipment!

WARNING

Explosion hazard

In case of non

-compliance with the regulations or impermissible change, there

is

the risk of explosion.

•

When using the non-

contacting thermal switch unit in potentially explosive

atmospheres, observe the local regulations applicable to electrical equipment

in potentially explosive atmospheres! Changes on electrical equipment for

pot

entially explosive atmospheres, including connecting lines, are not

permitted.

Hazards while working on the non-contacting thermal switch unit:

DANGER

Electric shock

On account of incorrectly mounted or incorrectly connected electrical

components, and disconnected electric connections, persons could get an

electric shock and be severely injured, possibly with fatal consequences.

Incorrectly mounted or incorrectly connected electrical components and dis

con

-

nected ele

ctric connections may cause damages to the machinery.

•

A qualified electrician has to properly carry out the connection to the electric

supply network considering the system voltage and the maximum power con-

sumption!

•

The system voltage has to be in confor

mity with the system voltage indicated

on the nameplate!

•

There has to be a corresponding electrical protection by a fuse on the

network side.

BTS

-Ex, non-contacting thermal switch unit

Safety

Installation and Operating Manual / Version 7 / 3626-019600ex

en / Protection class

0: public / 2020-07-15

20

Electric shock:

DANGER

Electrostatic processes

Electrostatic charging may injure persons by an

electric shock.

•

Allow only a qualified electrician to install the equipment into which the turbo

coupling is installed.

•

The unit and the electrical installation are provided with ground connections.

Working on the turbo coupling:

WARNING

Risk of

injury

While working on the turbo coupling, there is the risk of injury through cutting,

crushing, burns and cold burns in case of minus degrees.

•

Please observe the installation and operating manual of the turbo coupling!

•

Never touch the turbo coupling without wearing protective gloves.

•

Start to work on the turbo coupling only after it has cooled down.

•

Ensure that there is sufficient light, a sufficiently large working space and

good ventilation when working on the turbo coupling.

•

Switch off the unit in

which the turbo coupling is installed and secure the

switch against inadvertent switch-on.

•

For all work performed on the turbo coupling ensure that both the drive motor

and the driven machine have stopped running and that unintended starting is

absolutely impossible!

Noise:

WARNING

Hearing loss, permanent impairment of hearing

The turbo coupling generates noise during operation. If

the A-

classified

equivalent sound pressure level L

PA, 1m

exceeds 80 dB(A), this may cause

impairment of hearing!

•

Wear ear protection.

Sound pressure

level

cover sheet of

operating manual of

turbo coupling

Table of contents

Other Voith Switch manuals