Voith IPH Series User manual

This manual suits for next models

48

Table of contents

Popular Water Pump manuals by other brands

Armstrong

Armstrong ASTRO 220SSU Installation and operating instructions

Ingersoll-Rand

Ingersoll-Rand ARO 66610 C Series Operator's manual

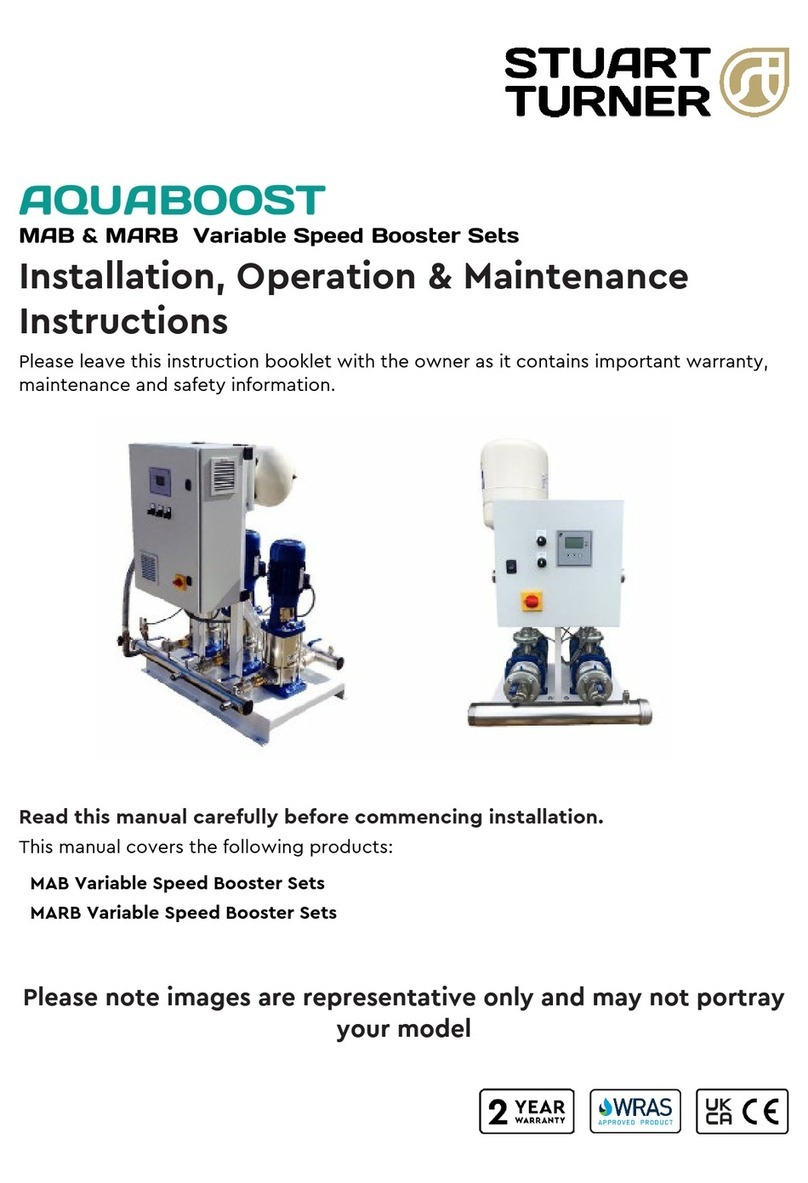

Stuart Turner

Stuart Turner AQUABOOST MAB Installation, operation & maintenance instructions

T.I.P.

T.I.P. DRAIN 6000/36 operating instructions

YAMADA

YAMADA NDP-20 series Maintenance manual

F.F. Group

F.F. Group CWSP 400 Original instructions

GORMAN-RUPP

GORMAN-RUPP 86B3-B Installation, operation, and maintenance manual with parts list

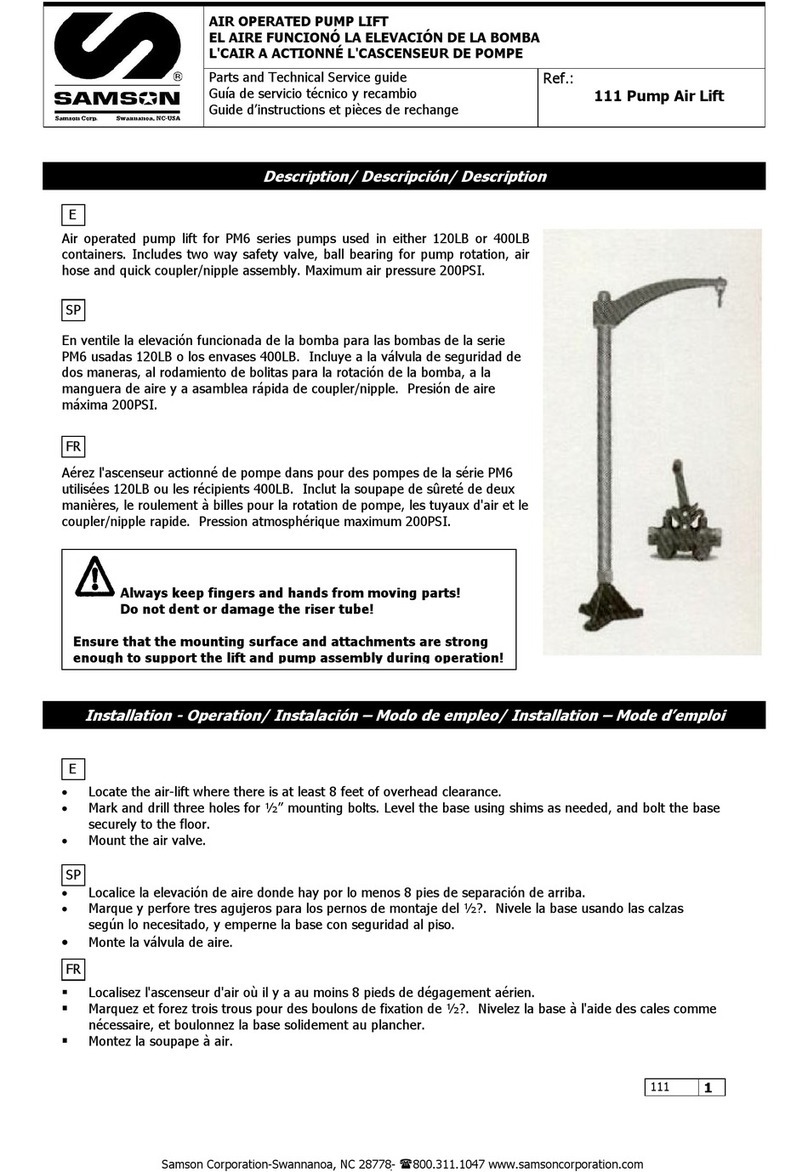

Samson

Samson 111 Parts and technical service guide

Clarke

Clarke TAM100 7230035 Operating & maintenance instructions

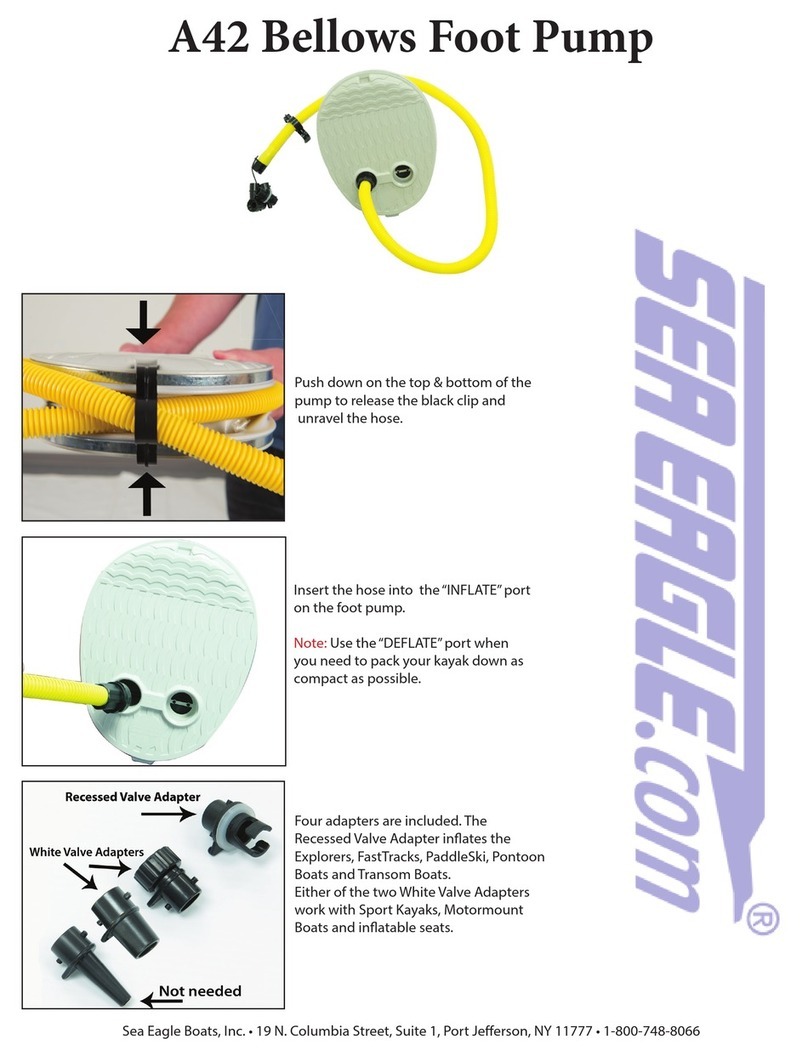

Sea Eagle

Sea Eagle A42 quick start guide

Mesto

Mesto SAUGFIX 3253 Series Instructions for use

Laing

Laing Ecocirc E1 Series Installation & operating manual

airbox

airbox Variflow 8 user manual

Grundfos

Grundfos JP Series Installation and operating instructions

Sealey

Sealey TP6918 quick start guide

Xylem

Xylem LOWARA Micro 10 Installation and Maintenance

Pentax

Pentax CA Instructions for installing and operating

Woosung Automa

Woosung Automa W2V40 User instruction