BUILDING REGULATIONS

This appliance must be installed and serviced

only by a competent person in accordance with

the current: IEE Regulations,

Building Regulation, Building Standards

(Scotland) (Consolidation), Building Regulations

(Northern Ireland), local water by-laws,

Health & Safety Document 63S (The Electricity at

Work Regulations 1989), IS 813 (Eire) and other

local requirements.

The relevant Standards should be followed,

including:

BS EN 15450: Heating systems in buildings –

Design of heat pump heating systems.

BS EN:12828 : Central heating for domestic

premises.

BS EN 7593 : Treatment of water in domestic hot

water central heating systems.

BS EN 14511 : Requirements heat pumps for

space heating and cooling.

BS EN 378 : Safety and environmental

requirements for heat pumps.

The Health and Safety at Work Act 1974.

The Management of Health and Safety at Work

Regulations 1999.

The Construction (Health, Safety and Welfare)

Regulations 1996.

The Construction (Design and Management)

Regulations 1994.

The Lifting Operations and Lifting Equipment

Regulations 1998.

Where no specific instruction is given, reference

should be made to the relevant codes of Practice.

There have been no banned substances

used in the manufacture of these

appliances.

________________________________________________________________

INDEX

1 GENERAL

.....................................................5

1.1 GENERAL PRECAUTIONS

....................................... 5

1.2 FUNDAMENTAL SAFETY RULES

............................ 5

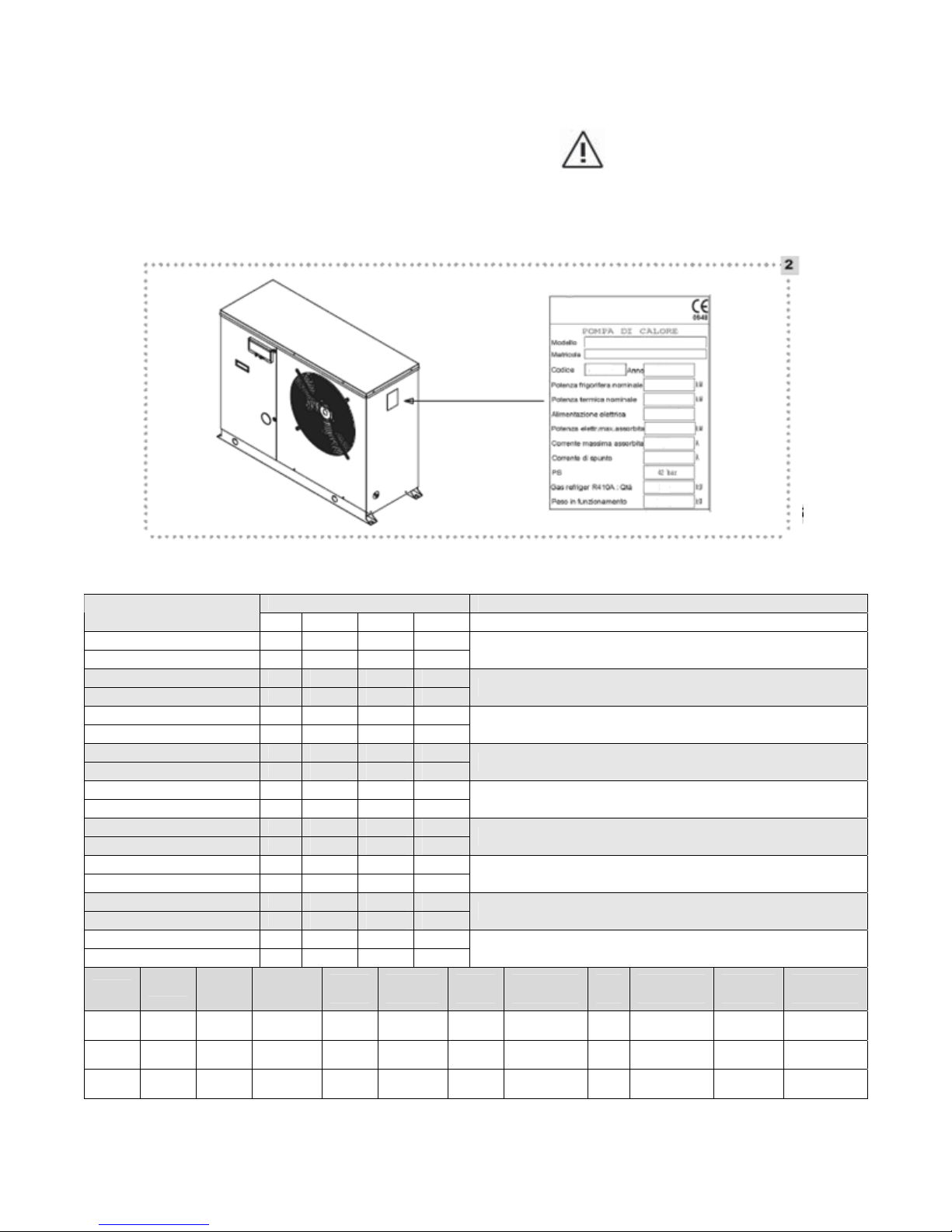

1.3 DESCRIPTION OF THE APPLIANCE

....................... 6

1.4 IDENTIFICATION

...................................................... 7

1.5 TECHNICAL DATA

................................................... 8

1.6 HYDRAULIC DATA

.................................................. 9

1.7 ACCESSORIES

....................................................... 9

1.7.1 Electric heater

............................................... 9

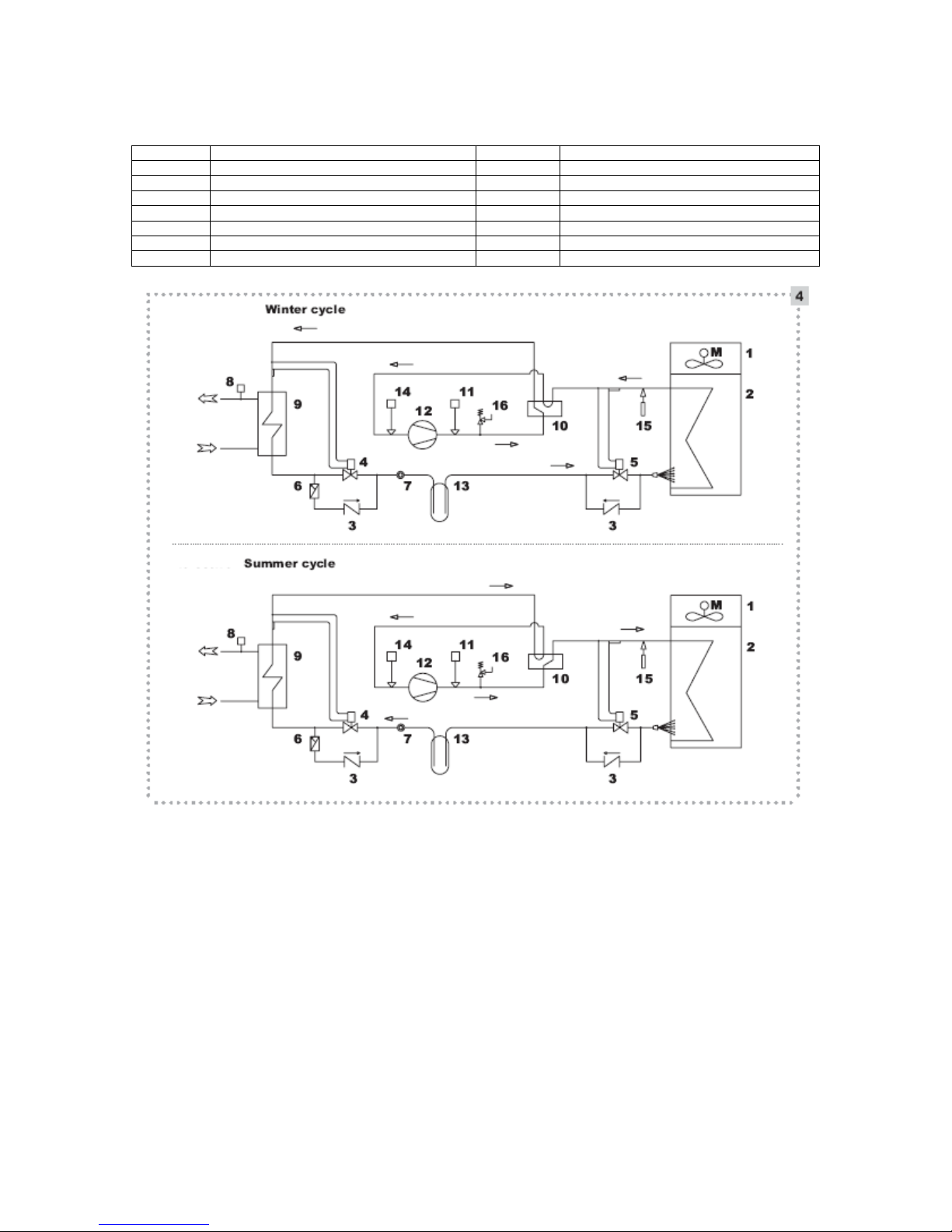

1.8 HEAT PUMP COOLING CIRCUIT

........................... 10

1.9 ELECTRICAL PANEL AND WIRING

DIAGRAM ...... 10

1.9.1 ARIA 6HP / 8HP Models ............ 10

1.9.2 ARIA 11HP Model ........................... 12

2 INSTALLER

................................................ 13

2.1 CONTROL PANEL

................................................... 13

2.2 ACTIVATION & DEACTIVATION

............................. 15

2.2.1 Heating / Cooling activation

......................... 15

2.2.2 Heating / Cooling deactivation

..................... 16

2.3 OPERATIONS PERFORMED WITH

THE REMOTE ON-OFF “SO” and

SUMMER-WINTER “SEI” SWITCHES

..................................................... 17

2.3.1 Cooling function

............................................ 17

2.3.2 Heating function

............................................ 17

2.4 SHUTDOWN FOR LONG PERIODS

....................... 17

2.5 CLEANING

.............................................................. 17

2.6 MAINTENANCE

....................................................... 17

2.7 USEFUL INFORMATION

......................................... 18

2.8 RECEIVING THE PRODUCT

.................................. 18

2.9 DIMENSIONS WITH PACKAGING

.......................... 18

2.10 DIMENSIONS WITHOUT PACKAGING

.................. 19