Contents

00 - Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Safety precautions during work on fuel system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Safety measures when working on vehicles with a start/stop system . . . . . . . . . . . . . . . . 1

1.3 Safety precautions when using testers and measuring instruments during a road test . . . . 2

1.4 Safety precautions when working on the cooling system . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.5 Safety precautions for working on vehicles with auxiliary heater . . . . . . . . . . . . . . . . . . . . 2

2 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

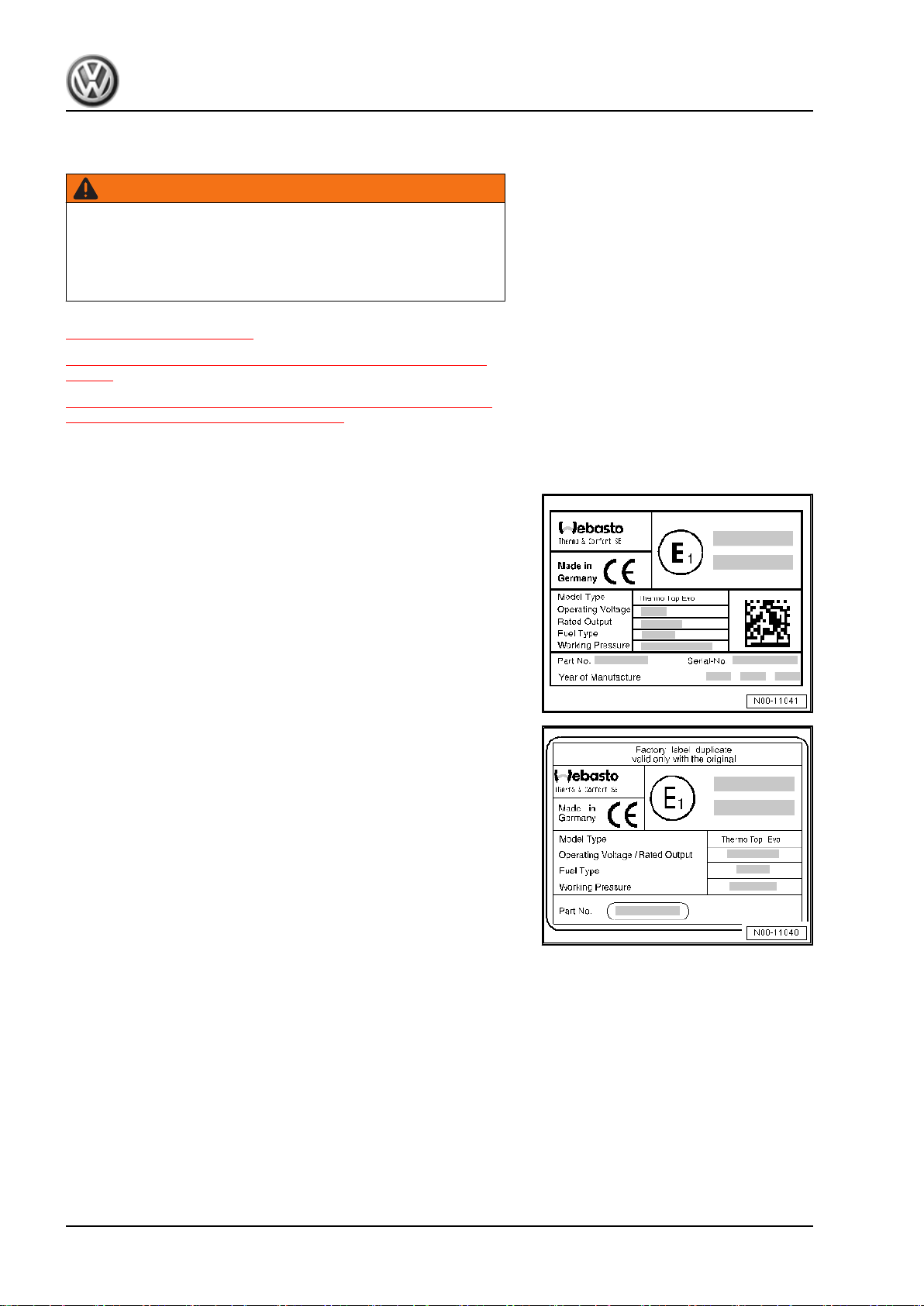

2.1 Type plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Starting conditions for auxiliary/supplementary heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 Rules for cleanliness when working on auxiliary/supplementary heater and fuel system . . 5

3 Repair instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1 Rules for cleanliness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.3 General repair instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.4 Contact corrosion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.5 Nuts and bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.6 Pipe/wire routing and attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4 Hazard classification of high-voltage system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

82 - Supplementary heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1 Overview of fitting locations - auxiliary/supplementary heater . . . . . . . . . . . . . . . . . . . . . . 9

1.1 Overview of fitting locations - components not located in passenger compartment . . . . . . 9

2 Auxiliary/supplementary heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1 Overview of fitting locations - auxiliary/supplementary heater . . . . . . . . . . . . . . . . . . . . . . 10

2.2 Assembly overview - auxiliary/supplementary heater, internal . . . . . . . . . . . . . . . . . . . . . . 12

2.3 Assembly overview - auxiliary/supplementary heater attachments . . . . . . . . . . . . . . . . . . 13

2.4 Removing and installing auxiliary/supplementary heater . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.5 Removing and installing air intake silencer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.6 Removing and installing circulation pump V55 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.7 Removing and installing exhaust system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.8 Removing and installing cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.9 Dismantling and assembling heater unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.10 Removing and installing glow plug with flame monitor Q8 . . . . . . . . . . . . . . . . . . . . . . . . 21

2.11 Removing and installing temperature sensor G18 and overheating sensor G189 . . . . . . 22

2.12 Removing and installing auxiliary heater control unit J364 . . . . . . . . . . . . . . . . . . . . . . . . 23

2.13 Removing and installing combustion air blower V6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.14 Connector pin assignment for auxiliary/supplementary heater . . . . . . . . . . . . . . . . . . . . . . 23

3 Coolant circuit with auxiliary/supplementary heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.1 Connection diagram - coolant hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.2 Removing and installing heater coolant shut-off valve N279 . . . . . . . . . . . . . . . . . . . . . . 25

4 Fuel supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.1 Checking fuel delivery rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.2 Removing and installing metering pump V54 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5 Regulation of auxiliary/supplementary heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.1 Function description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.2 Heating mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.3 Switching off auxiliary/supplementary heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6 Other controlling and regulating components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.1 Removing and installing ambient temperature sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.2 Removing and installing remote control receiver for auxiliary coolant heater R149 . . . . . . 32

6.3 Functional description of remote control for auxiliary/supplementary heater . . . . . . . . . . . . 32

Transporter 2016 ➤

Auxiliary heater - Edition 04.2020

Contents i