49-109J F533 2 Legend Brands, Inc.

are properly grounded. Do not modify the plugs pro-

vided with the appliance – if the plugs do not fit the

outlets, have proper outlets installed by a qualified

electrician.

This equipment is for use on circuits with a nominal rat-

ing of no more than 120V.

Handle the unit carefully

Always operate the unit on a stable, level surface. Do

not drop, throw, or place where it could fall. Rough treat-

ment can damage the unit, and may create a hazardous

condition or void the warranty.

This unit intended for household and commercial use.

BEFORE FIRST USE

The unit is shipped with two duct rings and an adaptor kit

packed inside the storage compartment. A 3 mm Allen

wrench is required for installation of these components.

Required: Install Reactivation Air Outlet duct ring

Install the Reactivation Duct Ring, See Fig. B.

Optional: Install Air Inlet duct ring

Attach to inlet with the thumbscrews provided. See Fig.

B.

Optional: Install Process Air Outlet offset screws

The Process Air Outlet Adaptor Kit may be installed us-

ing the offset screws provided. See Fig. B.

CONTROLS AND OPERATING

INSTRUCTIONS

Positioning the Dehumidifier

For best results, operate your dehumidifier in an en-

closed area. Close all doors and windows that open to

the outside to maximize water removal efficiency. Place

your dehumidifier away from any obstructions that could

block airflow into and out of the unit. Duct reactivation

outlet outdoors through window adapter or dryer vent.

Plug in electrical cords

Always plug the cords firmly into the sockets in the

top compartment first, then into the wall outlets. En-

sure that the cords are routed properly through the

cord cutout notch before closing the storage com-

partment lid.

NOTICE: The power cords of the DriTec must be

plugged into separate GFCI-protected 120V outlets rated

for at least 15A.

CONTROL PANEL

Press the ON/OFF to turn the unit on.

Fig. A: Parts Identification

Air filter

Power sockets inside

compartment. Stor-

age for power cords,

react ducting.

Air inlet

Reactivation

Air Outlet

(installation

of duct re-

quired)

Control panel

Process Air Out-

let (optional duct

attachment kit

provided)

For maximum efficiency, use both circuits while ensuring that the green light illuminates.

However, the dehumidifier may run on one power cord if the second circuit is not

available. Plug into Circuit 1. When using a single power cable, the dehumidifier

operates at half the rated performance.

Positioning the Dehumidifier

When connecting the dehumidifier to power for the first time, the control panel briefly cycles

through various readouts. This is a regular self-diagnosis procedure for the unit; thus,

no intervention by the user is required.

Ducting Setup

Note, the unit is designed for indoor use only. The equipment should not be exposed to snow or rain.

If any electrical component becomes wet, allow for thorough drying before operating the unit.

Reactivation Outlet Ducting

To attach the ducting on the duct ring, use the provided duct clamp. Ensure that the reactivation air is ducted

to the outside.

NOTICE

During operation, condensate may collect inside the reactivation duct. Water should not run back into the unit;

this could damage the unit. Or lead to a shock hazard.

Note: The temperatures in the React Out ducting may reach 66°C (150°F).

Only use the heat-rated ducting provided.

Process Outlet Ducting

The out air should be ducted, where more drying is required. It should only be used with a lay-flat ducting.

Maximum Ducting length

For maximum performance, ducting should not exceed these lengths:

Reactivation air: 20 feet |. 6m

Inlet air: 30 feet |. 9.1m

Process air: 10feet | 3 m

For additional ducting options, see figure C

5 6

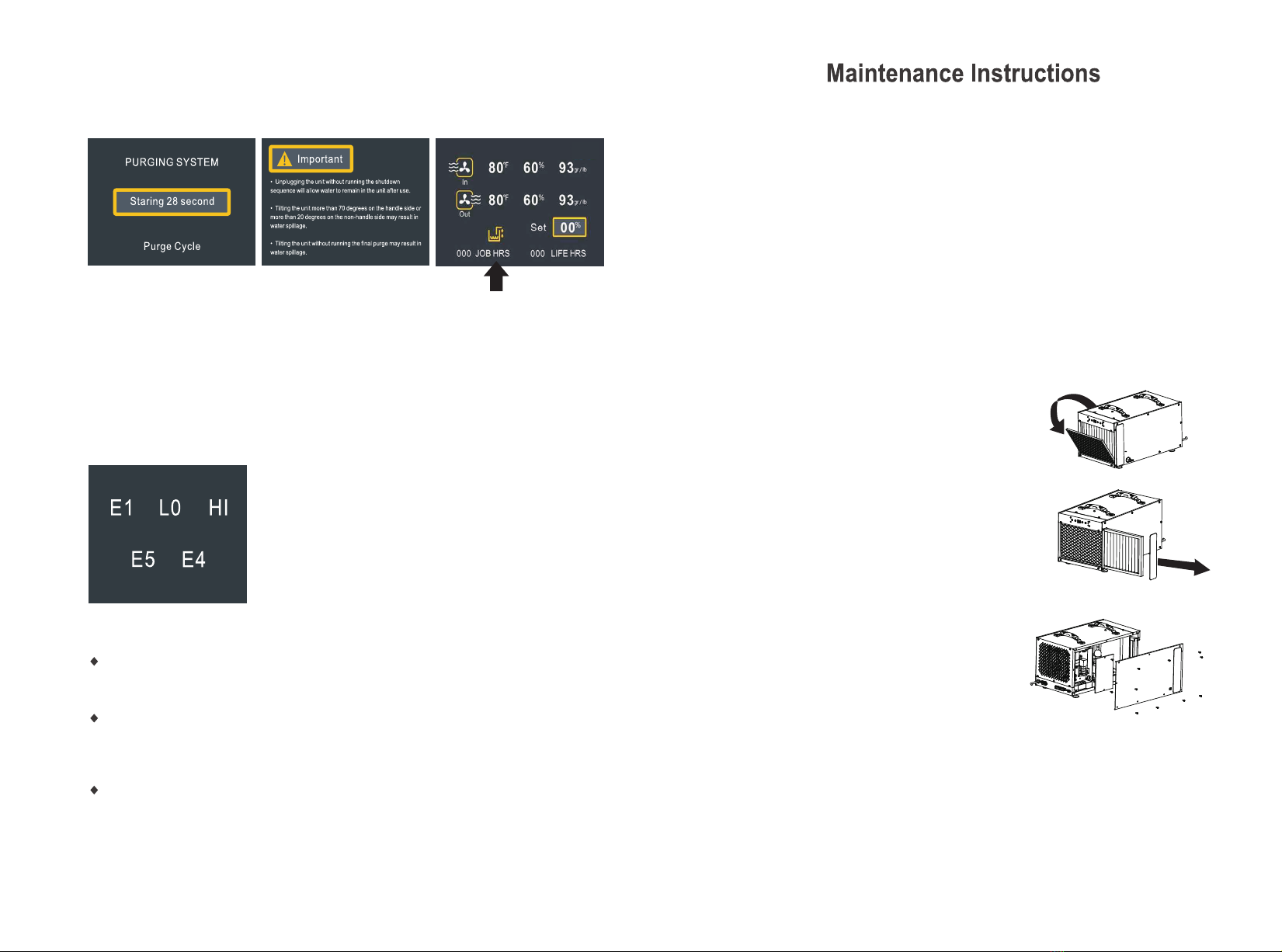

LCD Display Instructions

The machine displays when it is not

working. (Power off state but have

electricity)

PURGE

PURGE

PURGE

PURGE

PURGE

PURGE

1. When the machine is powered on but not working:

Boot display: The LOGO interface

will disappear after 2 seconds. Enter

the following interface

2. Main interface display of dehumidification state:

The following information is displayed when the machine is working:

Refers to the working time, which is defined as the time from

starting up to shutting down,including the defrost time during

the period, and the standby time after the humidity. The

submenu has a reset function. If not, the working time shall

be accumulated.

Total time 9999 hours, the largest cumulative to the largest

automatically reset after restart, and display units for hours.

(round off).

000 JOB HRS:

(after power on, the buzzer makes a sound)

3.1

Device name displayed on the screen

“Indicates”:Do I need to clear out this time?",

press ">"if you need to clear. When the operation

is completed, the working time of the main

interface and the working time of this interface

will be reset and started to be instant again.

After accumulation (9999), clean up and round.

3.2

3.3

“Coil Temp 000℃ ”: Used to display the current

temperature of the coil.When it is below zero,

the "-" symbol is displayed in front. "-" is not

required on zero.

Only applicable to app-controlled dehumidifier.

000 LIFE HRS:

Refers to the total working time, i.e. the total working time (hours), which is in hours.(press the mode key +

select the confirmation key, and the total working time will be cleaned after 3 seconds.

IN/OUT 00℉ 00% 00 gr / lb:

Indicates the temperature, humidity and moisture content of the air inlet and outlet

{GPP - grain per pound (gr/lb)}.

Indicates set humidity.

Set 00%:

If the main interface does not operate for 10 minutes, the screen will go out.Press any key to

wake up.

Other icons light up or flicker when opened

The total working time is the accumulation of each working time (hours) in hours. (Press the

mode key + select to confirmation key, and the total working time will be cleaned after 3 seconds.

3.Dehumidification status submenu interface display