3

ENGLISH

OperatOr’sManual

The installation of this appliance must conform with local codes,

or in the absence of local codes, with the National Fuel Gas Code,

International Fuel Gas Code, ANSI Z223.1/NFPA 54, or the Natural Gas

and Propane Installation Code, CSA B149.1, as applicable.

The appliance and its individual shutoff valve must be disconnected from

the gas supply piping system during any pressure testing of that system

at test pressures in excess of ½ psi (3.5 kPa).

The appliance must be isolated from the gas supply piping system by

closing its individual manual shutoff valve during any pressure testing

of the gas supply piping system at test pressures equal to or less than

½ psi (3.5 kPa).

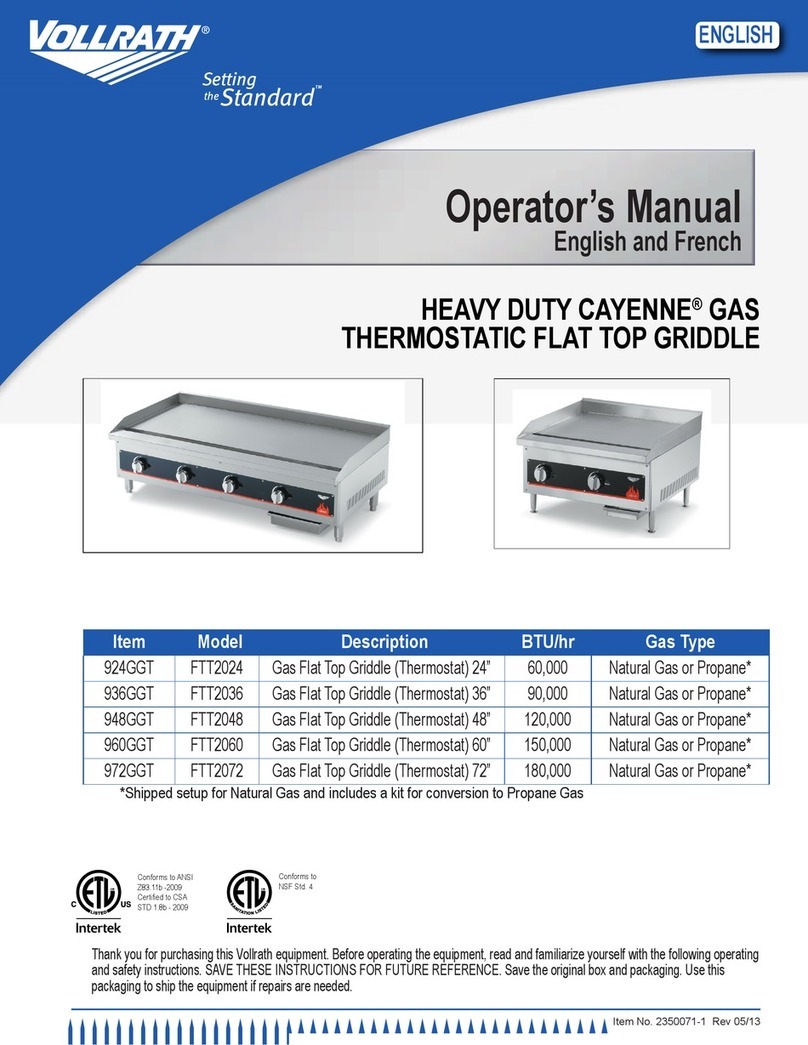

Clearance and positioning around the appliance: This appliance

must be installed adjacent to non-combustible surfaces only with a minimum

spacing of 6” from all sides. This appliance must be a minimum distance of

6” from another appliance. The appliance must have the supplied 4” legs

installed and be placed on a non-combustible surface.

Air supply and ventilation: The area in front and around the appliances

must be kept clear to avoid any obstruction of the ow of combustion and

ventilation air. Adequate clearance must be maintained at all times in front of

and at the sides of the appliance for servicing and proper ventilation.

Orice sizing: Equipment is manufactured for 1000 BTU per cubic feet

heat value of natural gas. Installer is responsible for correct orice sizing.

Refer to the International Fuel Gas Code for proper orice sizing.

Pressure regulator: All commercial cooking equipment must have

a pressure regulator on the incoming service line for safe and efcient

operation. The regulator provided for this appliance is adaptable for both

Natural gas and LP gas. A conversion kit with separate instructions is

included explaining this procedure in detail.

Regulator information: ¾” NPT inlet and outlet; factory adjusted for 4” w.c.

Natural Gas standard and may be converted by qualied personnel to be

used for Propane at 10” w.c.

Vent

Tee

Nipple of

any legth

Cap

To gas supply if branch

connects to appliance

or to appliance if branch

connects to gas supply

Connection Diagram

Supplied

regulator

Prior to connecting the regulator, check the incoming line pressure. The

regulator can only withstand a maximum pressure of ½ PSI (14” w.c.).

If the line pressure is beyond this limit, a step down regulator before the

regulator provided will be required. The arrow forged into the bottom of the

regulator body shows gas ow direction, and should point downstream to the

appliance.

Gas conversion: Conversion from Natural Gas to Liquid Propane (LP) or

vice versa may only be performed by a qualied technician or service agent

per the International Fuel Gas Code.

NOTE: Refer to the International Fuel Gas Code for proper orice sizing.

NOTE: The orice size is marked on the orice/spud.

Gas connection: The appliance comes tted with a ¾” N.P.T male adapter

for connection to the pressure regulator.

Maintenance: A qualied service company should check the unit for safe

and efcient operation on an annual basis. Contact the factory representative

or local service company to perform maintenance and repairs.

Gas piping : Gas piping shall be of such size and so installed as to provide

a supply of gas sufcient to meet the full gas input of the appliance. If the

appliance is to be connected to existing piping, it shall be checked to determine

if it has adequate capacity. Joint compound (pipe dope) shall be used sparingly

and only on the male threads of the pipe joints. Such compounds must be

resistant to the action of LP gases.

CAUTION

Any loose dirt or metal particles, which are allowed to enter the gas lines

on this appliance, will damage the valve and affect its operation. When

installing this appliance, all pipe and ttings must be free from any internal

contaminates. It is recommended that a sediment trap be installed in-line

before the regulator.

Manual shut off valve: A manual shut off valve should be installed in an

accessible location within 6 ft. (1.8 m) of the appliance.

Checking for gas leaks: Using a gas leak detector or a leak detection

solution is recommended for locating gas leaks. Matches, candle ame or

other sources of ignition shall not be used for this purpose. Check entire piping

system for leaks.

Exhaust canopy: Cooking appliances inherently create a good deal of heat

and smoke and should be installed under an efcient exhaust hood with ame

proof lters. A vertical distance of not less than 4 ft. (1.2m) shall be provided

between the top of the appliance and lters or any other combustible material.

WARNING

FIRE DEATH HAZARD

If you smell gas follow the instructions provided by the gas

supplier.

Do not touch any electrical switch; do not try to light the

burner; do not use a telephone within close proximity.

Lighting the pilot: The manifold units are equipped with standing pilots, and

each should be lit immediately after the gas is supplied to the appliance.

1. Before attempting to light pilots, turn off the main gas valve to the appliance

and wait 5 minutes to clear the gas.

2. Turn off all gas control knobs (E). See Figure 1.

3. Turn on control valve and light all pilots.

4. The pilot burner must be lit at the end of the tube. Hold an ignition source

through the pilot light hole (D) in the front panel at the pilot tube. When the

ame is established remove ignition source.

5. To shut down the appliance turn off the main gas valve to the appliance.

NOTE: Smoke appearing on initial use of the appliance is normal. This is as a

result of the rust preventative coating burning off. Allow the appliance to ‘burn

in’ for at least 15 minutes before the rst use.

Pilot ame regulation: The pilot ame on the appliance has been factory

adjusted. When adjustment is necessary, adjust the pilot ames as small as

possible, but high enough to light the burner immediately when burner valve

is turned to the ‘High’ setting. Access to the pilot ame adjustment screw is

obtained by removing the front panel.

Burner adjustment: Remove the front panel to gain access. Turn burner

valve knob to ‘High’ position. Slowly decrease mixing ring aperture to give a

soft blue ame having luminous tips, then slowly increase opening to a point

where the yellow tips disappear and a stable blue ame is obtained.