Pressurization Module with

Plenum Installation, Operation

and Maintenance Manual

VoltAire Systems, LLC

Specifications are subject to change without notice

Page 3 of 20

VoltAire Doc. # DA0322A

Published: June 13, 2023

1. IMPORTANT INFORMATION TO REVIEW PRIOR TO INSTALLATION,

OPERATION AND MAINTENANCE

READ THE ENTIRE MANUAL PRIOR TO INSTALLING, OPERATING AND MAINTAINING the VoltAire Systems

Pressurization Module. Do not install or perform maintenance on the equipment if you do not understand all of the

instructions. Contact VoltAire Systems at (407) 378-7482 with any questions or concerns.

The pressurization module should be fully inspected on initial delivery. Open the packaging completely at the time of

initial delivery and verify there is no hidden or concealed damage. Shipping damage, including concealed damage, is

not covered under warranty. Reject the shipment if any damageis found.

WARNING: IMPROPER INSTALLATION AND OPERATION MAY CAUSE PROPERTY DAMAGE, PERSONAL

INJURY OR LOSS OF LIFE. The pressurization module shall only be installed andserviced by a certified professional in

strict accordance with the requirements within this manual,in accordance with all local/state/federal codes, and per

industry standards. Remove power from the unit during maintenanceand installation, as linevoltage may be dangerous,

hazardous and lethal.

In the event of a conflict, code requirements shall take precedence over the instructions provided within this manual. The

installer shall be aware of allcode requirements and shall comply fully.

Use care when transporting and lifting the pressurization module.

WARNING: WEAR PROPER PERSONAL PROTECTION EQUIPMENT, INCLUDING BUT NOT LIMITED TO SAFETY

GLASSES, GOGGLES, AND GLOVES. EDGES MAY BE SHARP.

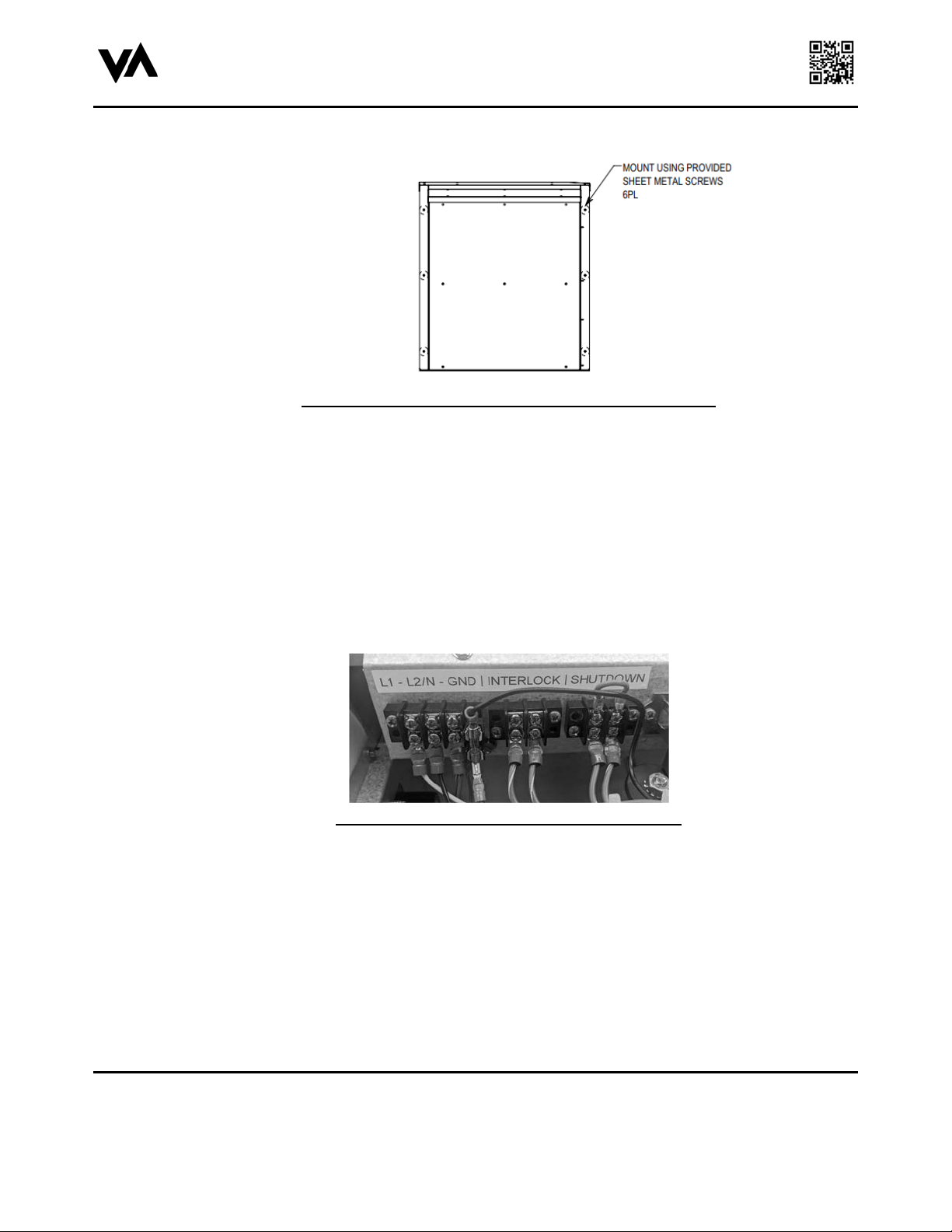

A field provided disconnect must be provided by the installer with the power supply circuit serving thepressurization

module. The installer shall size the electrical wire and disconnect in accordance with all applicable codes. Verify wire

terminals and voltageprior to starting the pressurization module, otherwise you may damage the electrical components.

These instructions should be retained by the owner and/or with the unit.

2. PARTS SHIPPED LOOSE AND TOOLS/MATERIALS PROVIDED BY THE

INSTALLER

Materials shipped loose in addition to this manual are as follows:

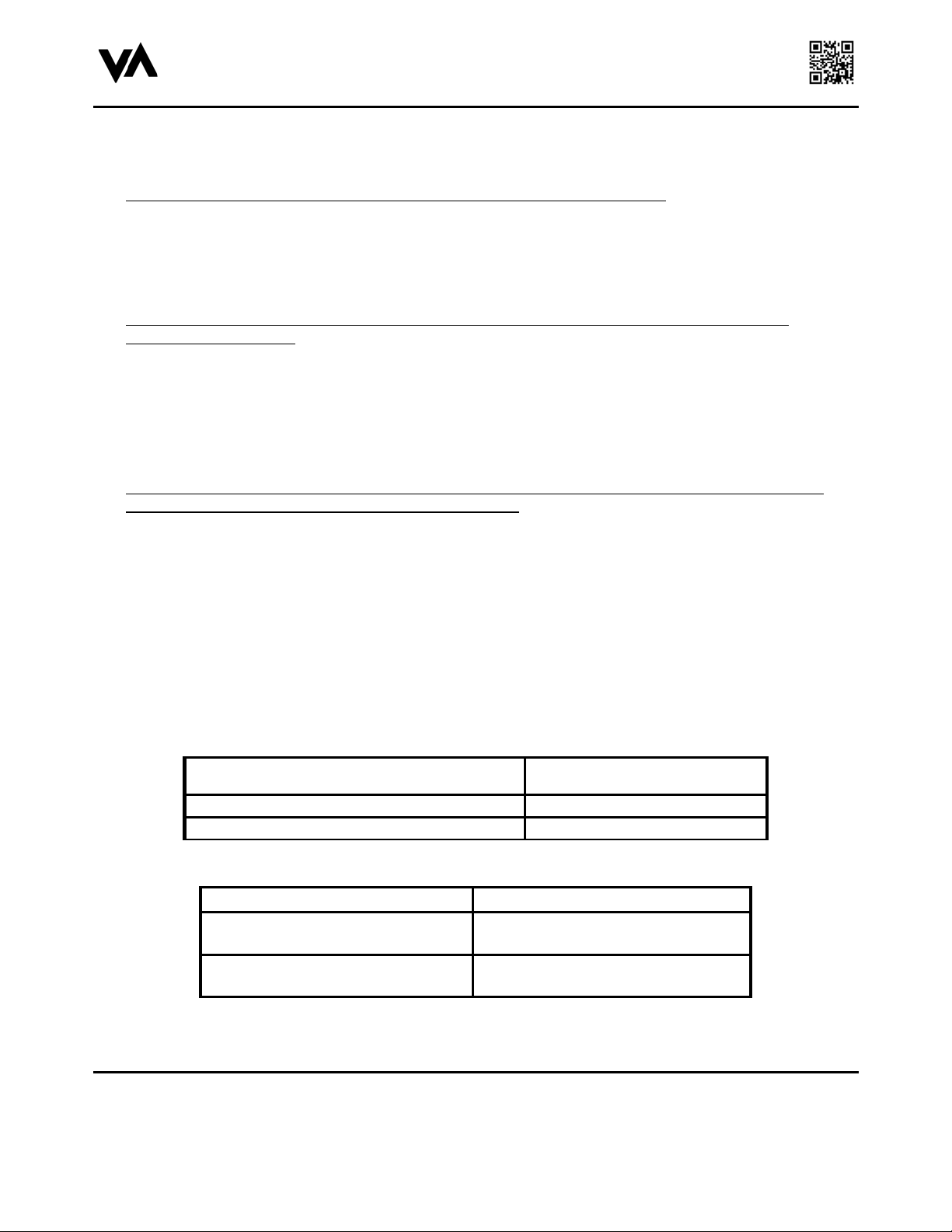

a) Ship Loose Kit

DESCRIPTION PART NUMBER

Pressurization Module Ship Loose Kit D0Z0007VAA

Pressurization Module Plenum Ship Loose Kit D0Z0008VAA

b) Bard Economizer Exhaust Modification Kit (Optional, Sold Separately)

DESCRIPTION PART NUMBER

W18-W24 Economizer Exhaust Mod

Field Kit

Bard Models W18-W24

W18-W24ECONMODKIT

W30-W36 Economizer Exhaust Mod

Field Kit (Bard Models W18-W24) W30-W36ECONMODKIT