• The UPS is supplied in complete package from factory in the

best way for its transport and shipment till you receive is. It is

recommended to remain it packaged until it arrives to its final

location.

• When serious damages are observed in the package, or its level

of damages can be sensed in the contents and/or the shock

indicator is in RED, handle the product according to the

instructions stated in the own label of transport control.

Keep the affected equipment isolated from other received

equipment, and wait the further inspection by qualified staff.

In case it has to be returned to the factory or your distributor

but the same package is in poor conditions, contact with the

appropriate person in order to agree the way and conditions for

its return.

• Respect the unpacking instructions, as well as the established

mode to remove the equipment from the pallet.

These operations require the manpower of at least two

persons.

• The equipment has to be always in vertical position.

When moving the equipment, consider the slope of the

ground or surface and the risk of tipping.

• Be careful not to lift heavy loads without other people’s help.

Please refer to the following recommendations:

, < 18 kg.

, 18 - 32 kg.

, 32 - 55 kg.

, > 55 kg.

• To avoid accidentally dropping equipment or any

damaged enclosure, do not start it up under any concept. This

kind of fault can cause fire or electrical discharge. Contact

with our (S.T.S.).

• Some models include casters to move it till its location. They

are not designed for long distances or constant movements.

The equipment shall be guided by two persons as minimum,

which will be placed on either side and oriented to the walking

direction.

• UPSs are electronic equipment. Avoid jolting or bouncing like

those produced by moving the equipment over an uneven or

wavy surface.

• When moving an equipment from a cold to a warm environment

and vice versa, condensation (small water drops) might occur on

the external and internal surfaces. Before installing a moving

equipment from another place or even package, the

equipment should be placed in the new location for a minimum

of two hours before making any action, with the purpose of

adapting it to the new environmental conditions and avoid

possible condensations.

The UPS has to be completely dry before starting any

installation task.

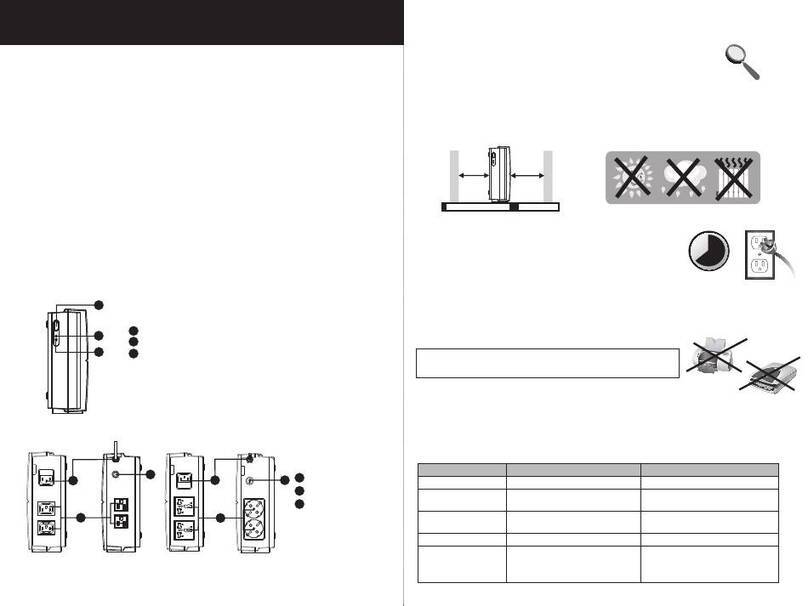

• Do not store, install or expose the equipment in corrosive,

wets, warm, dusty environments or with conductive parts and

never outdoors.

The best location for installation should be cool, dry and far

from heat sources and easy to access. If possible, place it in

an environment with temperature control.

• Avoid locating, installing or storing the equipment in places

with direct sunlight or high temperatures. Batteries might

damage and/or shorten its lifetime.

In the exceptional and long exposure of intense heat, batteries

can cause filtrations, overheating or explosions, which can

cause fires, burn or other injuries. High temperatures can also

make deformation in the plastic enclosure.

• Do not obstruct the cooling grids by inserting an y objects

through themselves or other orifices.

• Locate the equipment to the power supply outlet and supplied

loads as close as possible , leaving an easy access in case of

an urgent disconnection.

• All models with casters have four leveling feet at each corner of

the base, with the purpose of locking and level the unit.

Loosen them until they can be lifted from the ground.

With the help of a spanner, act on each one and loosen

them half round more against the ground.

For slightly uneven grounds, immobilize the equipment with

these leveling parts.

Check if the equipment is completely immobilized.

Fortuitously pulling out the connection cables from the

equipment will indirectly be avoided so unexpected

movements will not happen.

• Regarding any interventions inside the equipment, battery

cabinet and battery manipulation is a task reserved to

personnel with specific or qualified knowledge only and in

particular to (S.S.T.). It is mandatory to immobilize the

equipment with the leveling feet- stated in the previous point,

before doing any action.

Attention! Risk of tipping may happen when the

battery trays are moved without stabilizing the unit first.

Do not remove more than one tray at the same time. High risk

of injury may take place over the operators due to accident

shock of the possible equipment falling down and/or

entrapment.

• Leave a minimum of free space to cool the unit of:

25 cm at both sides.

50 cm at the rear side.

100 cm at the top side.

150 cm at the front side.

• It is recommended to leave an additional 75cm at both sides,

for possible interventions of the (S.T.S.) or the requisite

clearance of the connected cables to facilitate the movement

of the equipment.

• Do not cut, deteriorate or manipulate the electrical cables, or do

not put heavy objects on them. Any of these actions could

cause a short-circuit, fire or electrical discharge.

Check if the connected electrical cables, plugs and outlets are in

good conditions.