VA41620/VA41630 Evaluation Board User’s Manual

V1.0

1

Contents

1 Introduction ........................................................................................................................... 2

1.1 Purpose of Document .................................................................................................... 2

1.2 Overview of Hardware and Software components ........................................................ 2

1.3 Key components included on the PEB1 evaluation kit (subject to change depending on

availability). ................................................................................................................................ 2

1.4 PEB1 MCU board component placement diagram ........................................................ 5

1.5 Connector pin assignment table for MCU board ........................................................... 6

1.6 Materials List .................................................................................................................. 7

1.7 Board connectivity ......................................................................................................... 7

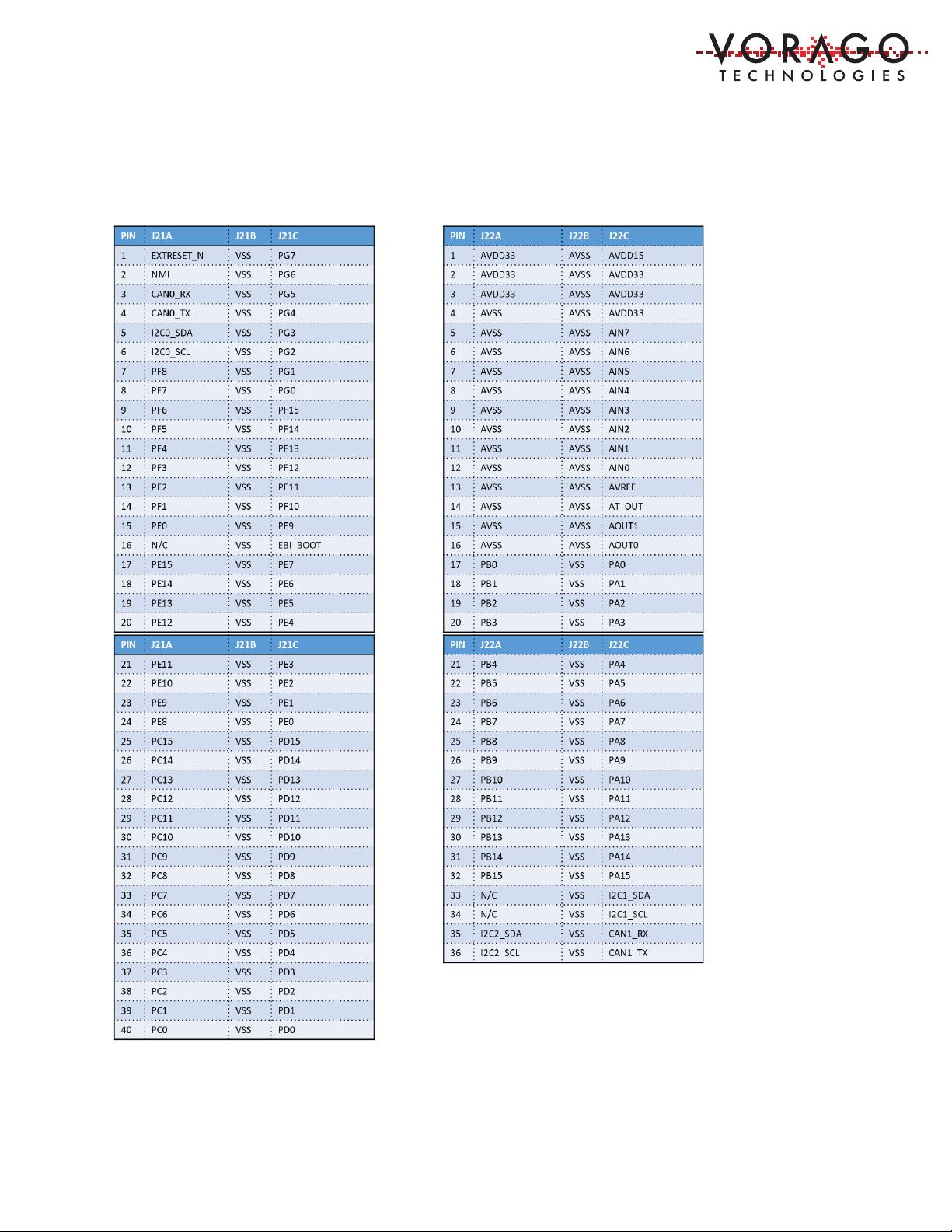

1.8 Connector pin assignment table for GPIO board ........................................................... 8

1.9 Support ......................................................................................................................... 13

2 Software Setup ..................................................................................................................... 13

2.1 Required Downloads .................................................................................................... 14

3 Hardware check ................................................................................................................... 17

3.1 Powering up the board ................................................................................................. 17

4 Command line control of the EVK ........................................................................................ 17

4.1 J-Link OB and RTT (Real Time Terminal) ....................................................................... 20

5 Starting an IDE and building a program ............................................................................... 23

5.1 Keil IDE – ....................................................................................................................... 23

5.2 Programming procedure (Keil Specific) ........................................................................ 31

6 Software Development Kit ................................................................................................... 33

6.1 Project organization ..................................................................................................... 33

6.2 CMSIS compatible driver .............................................................................................. 34

6.3 Preprocessor directives ................................................................................................ 34

7 Commonly asked questions ................................................................................................. 35

8 Other resources for VA416x0 code ...................................................................................... 36

9 Revision history .................................................................................................................... 36