Vortec 901 Series Use and care manual

Please read all instructions BEFORE attempting to use this product

IMPORTANT

ROUND AIR FLOW

AMPLIFIERS

OPERATION & SAFETY

INSTRUCTIONS

Models 901 series, 902, 903, 904, 909A

(Includes all BSP versions of models listed above)

Pelmar Engineering Ltd.

Tel. (888) 754-6329, (416) 288-1736

E-mail: [email protected]

Web site: www.pelmareng.com

WARNING: COMPRESSED AIR COULD CAUSE DEATH,

BLINDNESS OR INJURY

1. Do not operate air ow ampliers at compressed air pressures above 150 psig (10.3 Bar).

2. Do not operate airow ampliers at line temperatures above 110°F (43°C).

3. Avoid direct contact with compressed air.

4. Do not direct compressed air at any person.

5. When using compressed air, wear safety glasses with side shields.

Introduction

An air ow amplier uses a small amount of compressed air to move a much larger air volume.

Amplication ratios may meet or exceed 20:1. For more details on airow of a specic unit, visit

www.vortec.com, or contact your local distributor or Vortec.

Compressed Air Supply

The compressed air supply must be ltered to remove water and dirt using a 5 micron or smaller lter.

Failure to use a lter may cause clogging of the compressed air paths inside the Vortec product. Filter

recommendations are given in Table 1.

Filter elements must be changed on a regular basis. Frequency of change is determined by the

condition of the compressed air supply. Filters should be installed in the compressed air supply line

as close as possible to the Vortec product.

The appropriate size of the compressed air supply line should be selected to ensure optimal

performance of the Vortec product. Please refer to Table 2 to determine what supply line size is

recommended for your application. Contact Vortec at 1-800-441-7475 for further assistance.

Operation

In order to vary the volume of airow from the air ow amplier, an appropriately sized pressure

regulator can be used to control the compressed air pressure, (less pressure = less airow). (Pressure

regulator recommendations are given in Table 1.)

The output airow volume can also be adjusted by varying the internal air gap. For models with

shims (901A, 901BA, 901DA, 901HA, 902, 903, 904), this is accomplished by adding or removing gap

shims (see Table 1). In adjustable model 909A, this can be accomplished by rotating the outlet barrel

(counter-clockwise will increase airow, clockwise will decrease airow).

GENERAL SAFETY CONSIDERATIONS

Installation and Maintenance

Air ow ampliers can be installed by directly plumbing to the appropriately-sized, hard piped,

compressed air source that does not exceed 150 psig (10.3 Bar), see Table 2.

When using air ow ampliers for ducting fumes or smoke, the duct must be sized, and routed to

prevent back pressure totaling more than 2” of water column. Back pressure in ducted airow will

substantially affect performance.

It is critical to the performance of the air ow amplier that the internal air passages remain clean.

If the air ow amplier’s performance suddenly drops, carefully disassemble the unit and inspect for

debris. If debris is found, it may be necessary to change your lter element. Clean the debris from

the unit and reassemble. Use caution during reassembly to ensure that the shim (where applicable)

remains centered and does not become lodged in the air passage. For detailed instructions on

cleaning or reassembly, contact your authorized distributor or Vortec.

Troubleshooting

Insucient airow may be caused by the following:

1. Undersized compressed air line size.

2. Compressed air pressure too low.

3. Partial or complete blockage of internal air path, due to dirt. See Maintenance section for cleaning

instructions; and Compressed Air Supply section for lter recommendations.

4. Insucient compressed air volume.

If trouble persists, please contact Vortec at 1-800-441-7475.

Limited Warranty

Vortec compressed air products manufactured by ITW Air Management will be replaced or repaired

if found to be defective due to manufacture defect within ten years from the date of invoice. Refer to

our website www.vortec.com for full warranty details and limitations. ITW Air Management makes no

specic warranty merchantability or warrant of tness to a particular purpose.

Exploded Views

(Drawings shown below are not to scale)

0.79”

I.D.

1.75”

O.D.

1.25”

O.D.

O-Ring

1/4”-18 NPT Inlet

Shim

Mounting Holes 2.5”

1.57”

I.D.

2.75”

O.D.

2”

O.D.

O-Ring

3/8”-18 NPT Inlet

Shim

Mounting Holes 3.56”

5”

O.D.

3”

I.D.

Shim 1/2”-14 NPT Inlet

Mounting Holes 6.5”

Ground Connection

Screw

O-Ring

4”

O.D.

Model

902

Model

903

Model

904

LIT0125

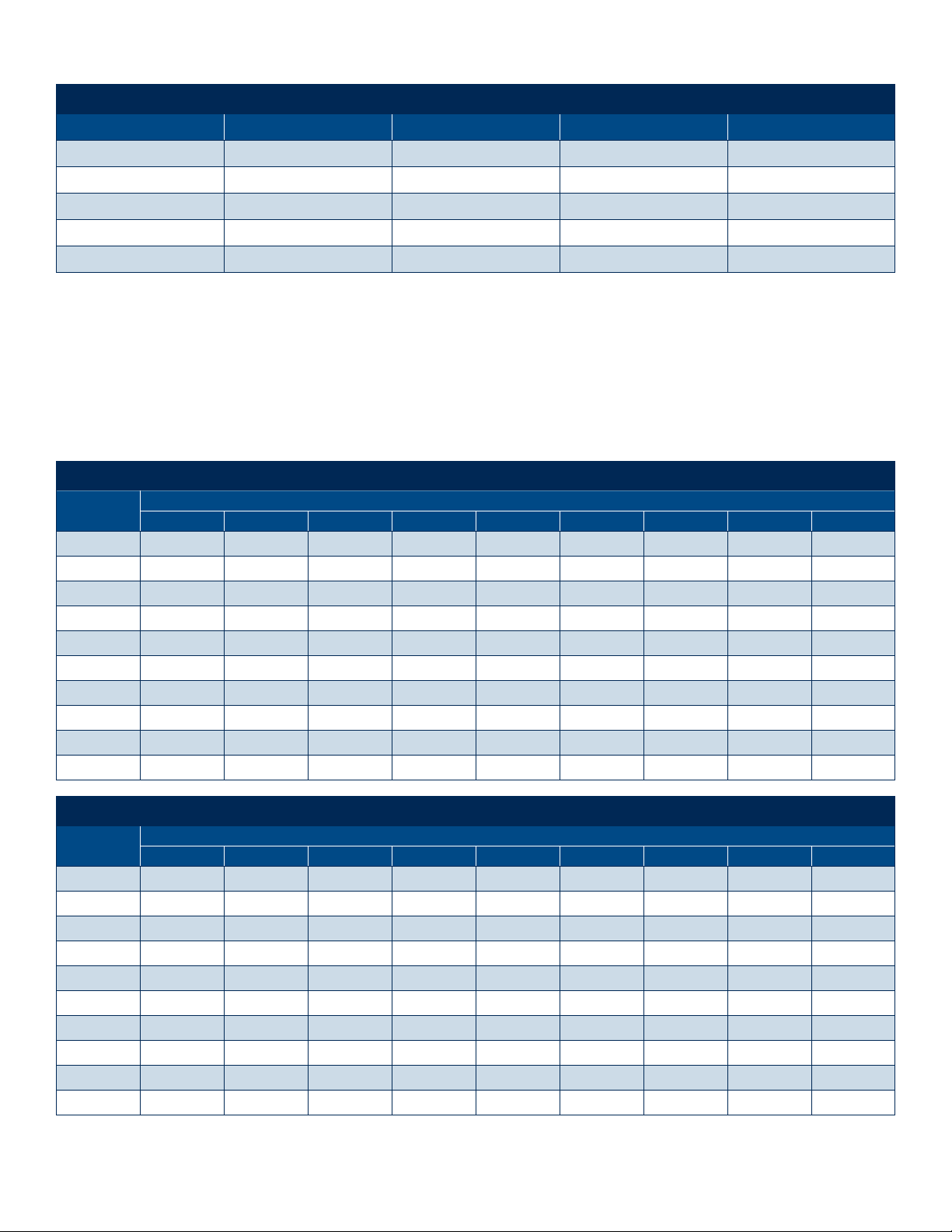

FILTER AND REPLACEMENT PART ITEM NUMBERS

Vortec Model 5 micron Air Filter Oil Removal Filter Pressure Regulator .002" or .003" shims

901 series 701S-24A 701S-48 208R 901-002, 901-003

902A 701S-24A 701S-48 208R -

902 701S-24A 701S-48 208R 902-002, 902-003

903 701S-36A 701S-48 208RX 903-002, 903-003

904 701S-40A 701S-54 208RX 904-002, 904-003

Table 1: Filter Recommendations

Table 2: Determining Compressed Air Line Size

1. Calculate total product compressed air consumption (SCFM, SLPM).

2. Determine length of compressed air line required for connection to main supply.

3. Locate pipe length in left column and read to the right to nd the compressed air requirements.

4. Locate pipe size at top of column.

MAXIMUM AIRFLOW (SCFM) THROUGH PIPE AT 5 PSIG PRESSURE DROP (100 PSIG AND 70OF)

Pipe Length

(Feet)

Pipe Size (Nominal) - Schedule 40

1/4 3/8 1/2 3/4 1 1-1/4 1-1/2 2 2-1/2

10 29 65 120 254 480 978 1483 2863 4536

20 21 46 85 180 340 692 1049 2024 3208

30 17 37 70 147 277 565 856 1653 2619

40 15 32 60 127 240 489 792 1431 2268

50 13 29 54 114 215 437 663 1280 2029

60 12 26 49 104 196 399 606 1169 1852

70 11 25 46 96 181 370 561 1082 1715

80 10 23 43 90 170 346 524 1012 1604

90 10 22 40 85 160 326 494 954 1512

100 9 21 38 80 152 309 469 905 1435

MAXIMUM AIRFLOW (SLPM) THROUGH PIPE AT 0.3 BAR PRESSURE DROP (6.9 BAR AND 21OC)

Pipe Length

(Meters)

Pipe Size (Nominal) - Schedule 40

1/4 3/8 1/2 3/4 1 1-1/4 1-1/2 2 2-1/2

3 821 1840 3396 7188 13584 27677 42117 81023 128369

6 594 1302 2406 5094 9622 19584 29687 57279 90786

9 481 1047 1981 4160 7839 15990 24225 46780 74188

12 425 906 1698 3594 6792 13839 20999 40497 64184

15 368 821 1528 3226 6085 12367 18763 36224 57421

18 340 736 1387 2943 5547 11292 17150 33083 52412

21 311 708 1302 2717 5122 10471 15877 30621 48535

24 283 651 1217 2547 4811 9792 14829 28640 45393

27 269 623 1132 2406 4528 9226 13980 26998 42790

31 255 594 1075 2264 4302 8745 13273 25612 40611

Rubber hose maximum airow rating: 1/2” I.D. rubber hose = 3/8” pipe; 3/4” I.D. rubber hose = 1/2” pipe

This manual suits for next models

4

Table of contents

Other Vortec Amplifier manuals