1.1. INTRODUCTION

Thank you for your purchasing of a Vortex engine. This manual contains information on how to

help you with getting the best results from your new engine. Furthermore, it will explain you how

to operate your Vortex engine safely and in a proper manner.

Vortex update this manual constantly. All the information in this manual is based on the latest

experience and product information available at the time of writing.

Vortex reserve the right to make any kind of changes to this manual at anytime without notice and

without incurring in any obligation.

This manual shall be considered part of the Vortex engine and should remain with the engine itself

if resold.

1.2. SYMBOLS

Personal injury Mechanical Danger Caution

Pay attention to the symbols of this manual. They alert you of dangerous situations for you or for

your engine.

1.3. SAFETY INFORMATION

- Do not start the engine indoor as garages, trailers, etc. Start the engine in a well-ventilated area

only. Exhaust emissions are hazardous to your health.

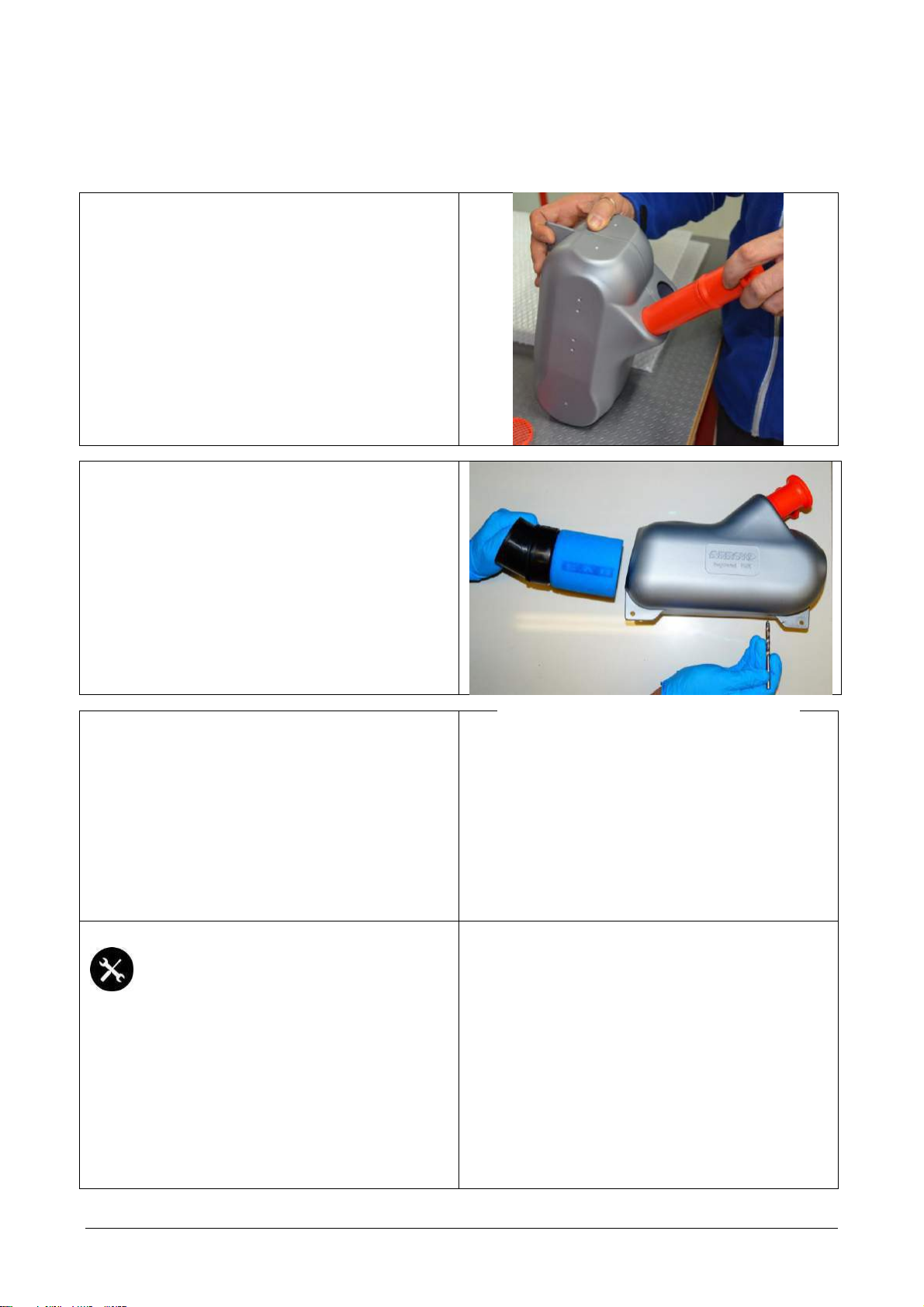

- Always wear gloves and proper clothing when working on your engine.

- Use caution when handling fuel. Gasoline is flammable and explosive. When working with fuel,

do not smoke or use it near fire or flames. Avoid any skin contact and inhaling fuel vapors.

- Never touch moving parts when the engine is running.

- During operation both engine and muffler, become very hot. Do not touch them and do not place

anything on them after operation.

- Do not touch the spark plug or cable. It may provoke electrical shocks.

- Understand the operation of all controls and learn how to stop the engine quickly in case of

emergency.

- Do not use the engine without clutch cover and chain protection.