Clipper head

Problem Cause Solution

Upper blade does not move · defective reduction drive · have it replaced by a specialist workshop

Upper blade does not move

over the entire running

surface

· eccentric knocked out

· eccentric shaft defective

· have it replaced by a specialist workshop

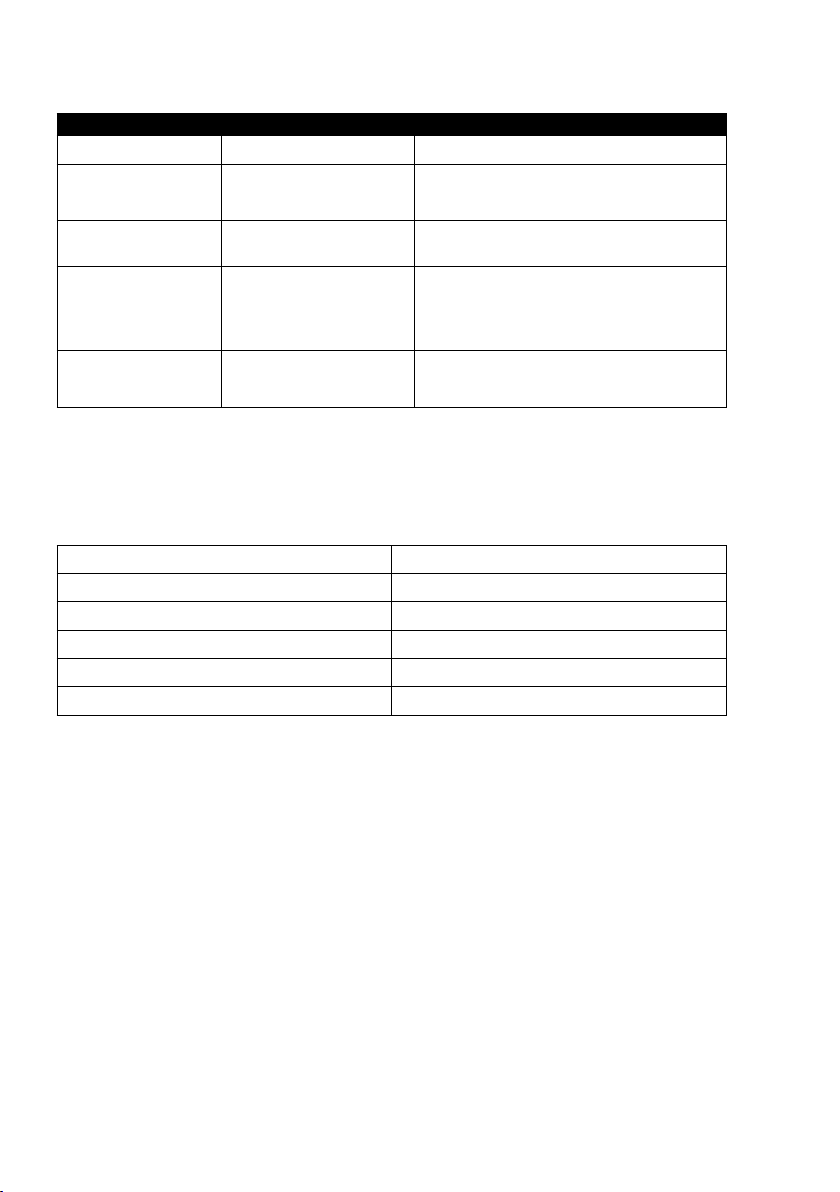

Clipper head gets very hot · blade tension too high

· blades and/or eccentric run dry

· have it replaced by a specialist workshop

Blades cut badly · blades are blunt

· blades are badly sharpened

· blade tension too low

· blades have rust

· have blades sharpened by a specialist workshop

· have blades sharpened by a specialist workshop

· increase tension by tightening the tensioning nut

· have blades sharpened by a specialist workshop or if

too much rust replace the blades

Blades do not cut · eccentric defective

· defective reduction drive

· clipper head knocked out

· have it replaced by a specialist workshop

If your problem is not listed here, or continues to exist, please feel free to contact our

customer service.

10. Technical data

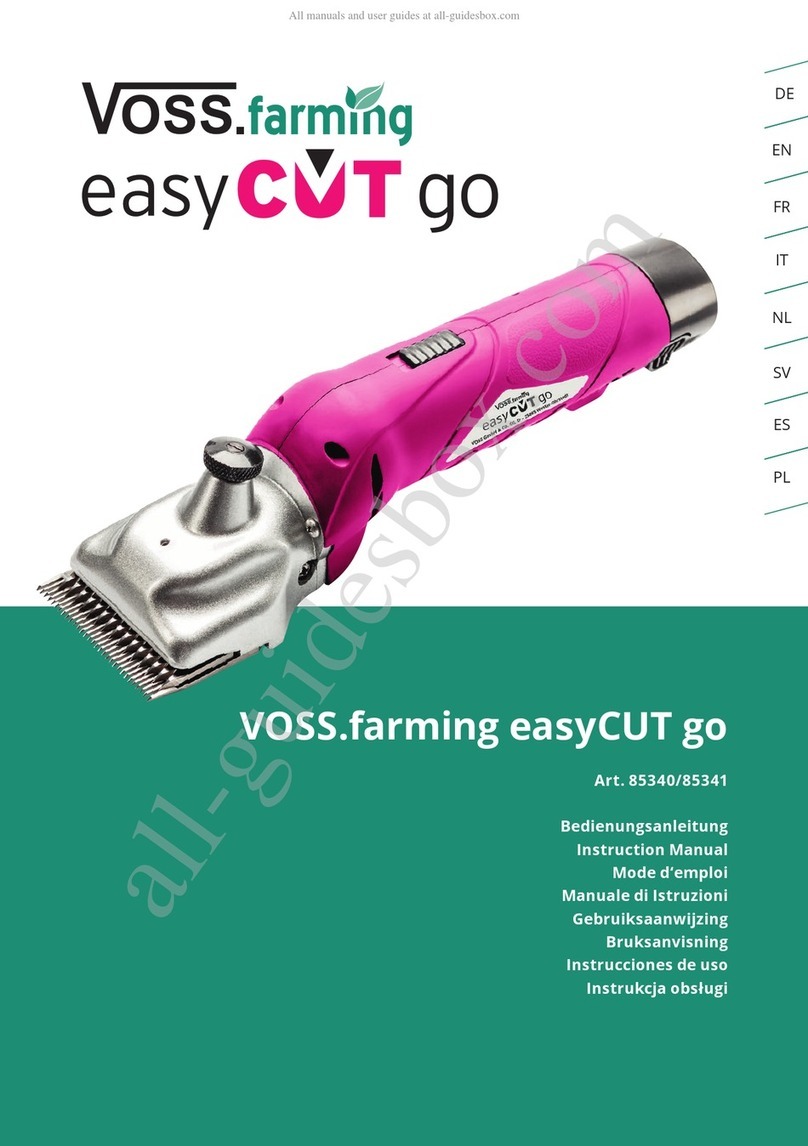

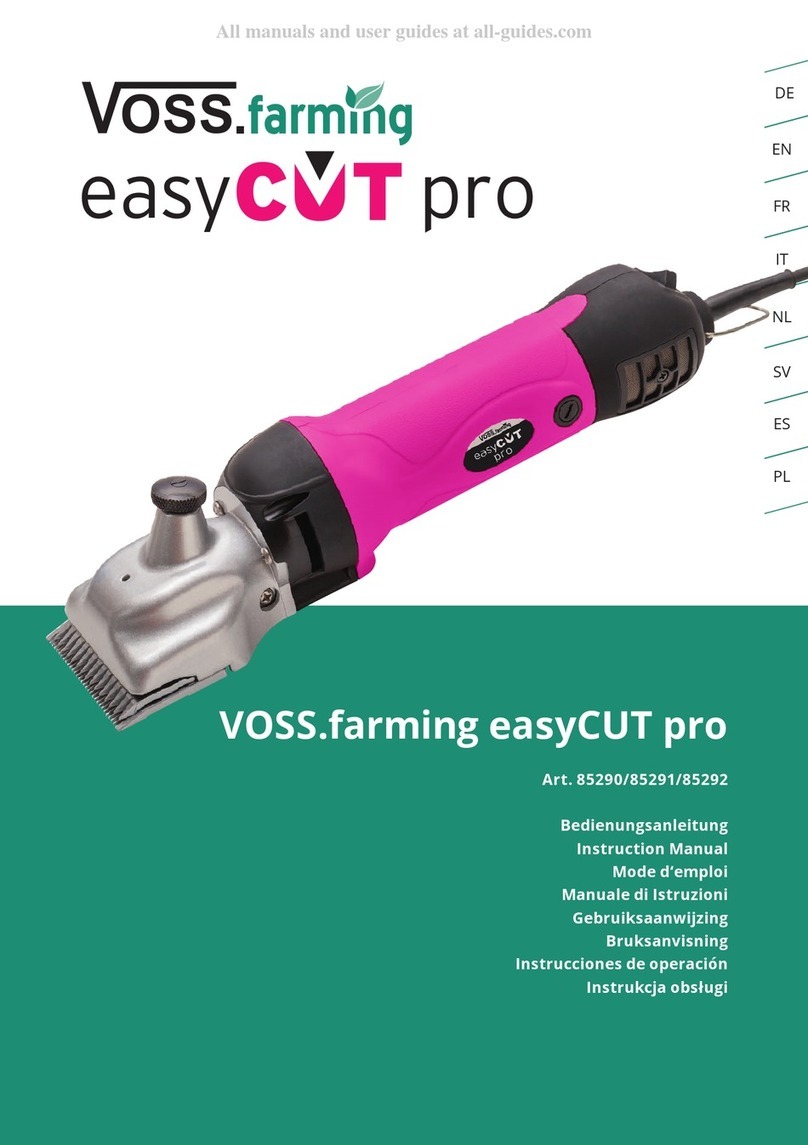

Device type/Model VOSS.farming easyCUT Horse Clipper

Supply voltage 230-240 V/AC

Motor power 150 W

Strokes: Power level 1 / 2 1 = ca. 2200/min, 2 = ca. 2600/min

Max. ambient temperature 0° - 40° C

Max. air humidity 10% - 90% (relative)

Spare parts

Only spare parts expressly approved or oered by the manufacturer may be used.

If necessary, please contact your specialist dealer.

Attention:

Unauthorized modications or alterations to the clipper are not permitted!

Disposal

The user is responsible for the proper disposal of the clipping blades and the clipping

machine at the end of their service lives. Observe the relevant regulations in your coun-

try. Do not dispose of the clipper in household waste. Proper disposal preserves the

environment and prevents possible harmful eects. In accordance with the EU directi-

ves 2012/19/EU on disposal of electrical and electronic equipment, your device will be