INS00110-A

1Introduction ...........................................................................................................................................................................................................3

2Safety ....................................................................................................................................................................................................................4

3Information ............................................................................................................................................................................................................5

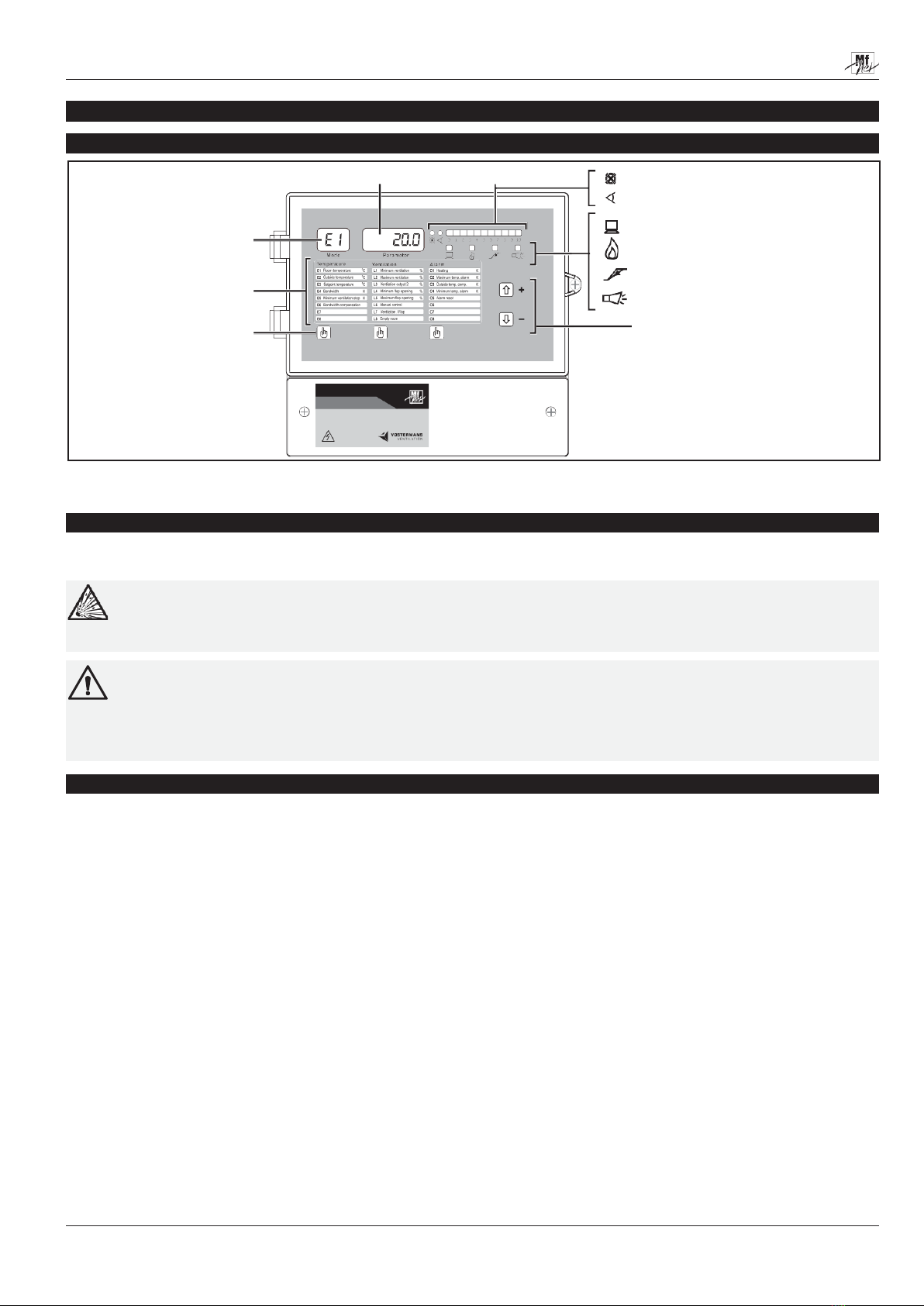

3.1 Overview.......................................................................................................................................................................................................5

3.2 Intended use .................................................................................................................................................................................................5

3.3 Technical Information .....................................................................................................................................................................................5

4Installation .............................................................................................................................................................................................................6

4.1 Mechanical....................................................................................................................................................................................................6

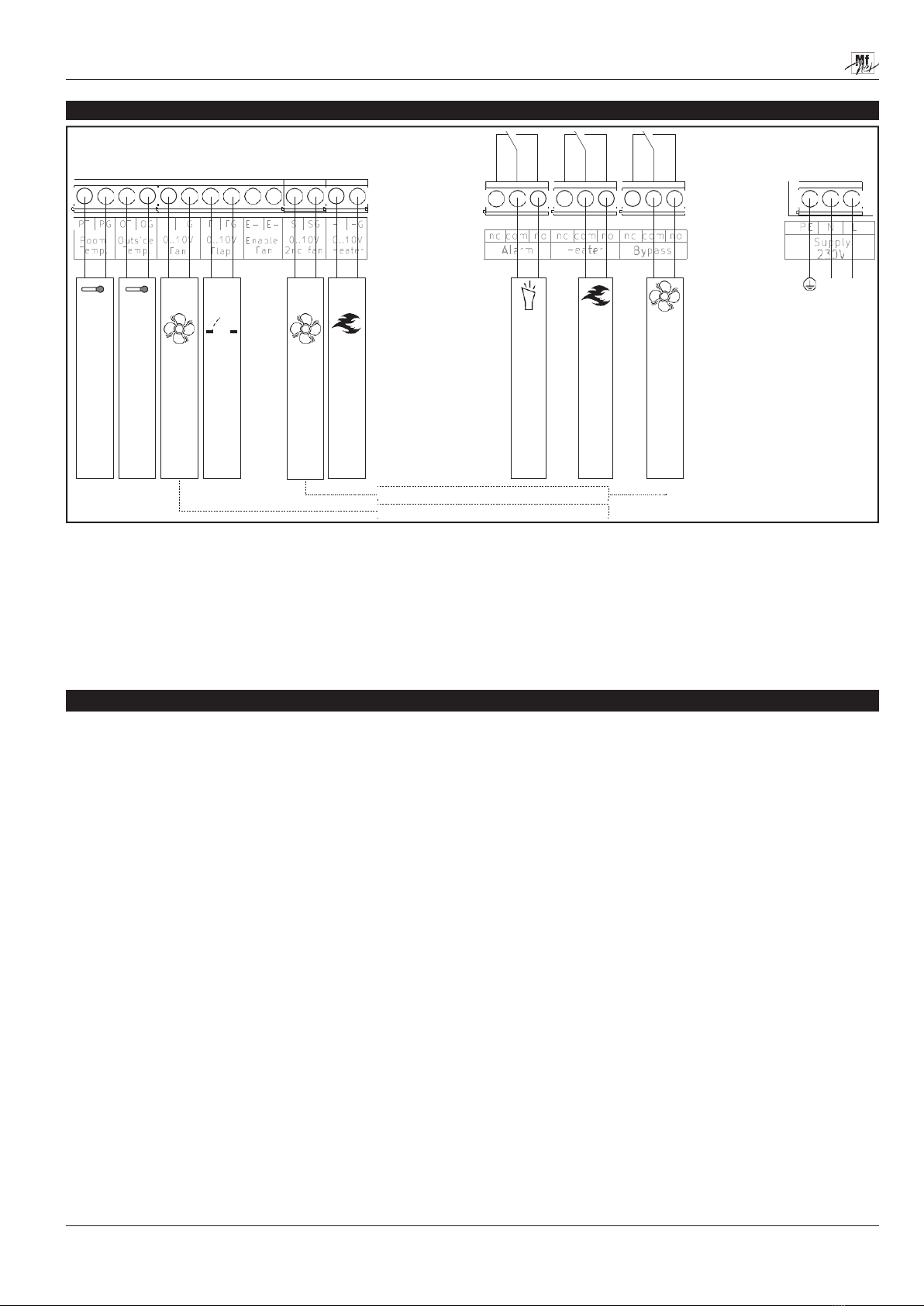

4.2 Electrical .......................................................................................................................................................................................................6

4.3 Wiring diagram ..............................................................................................................................................................................................7

5Settings .................................................................................................................................................................................................................7

5.1 General settings list........................................................................................................................................................................................8

5.2 Advanced settings list.....................................................................................................................................................................................8

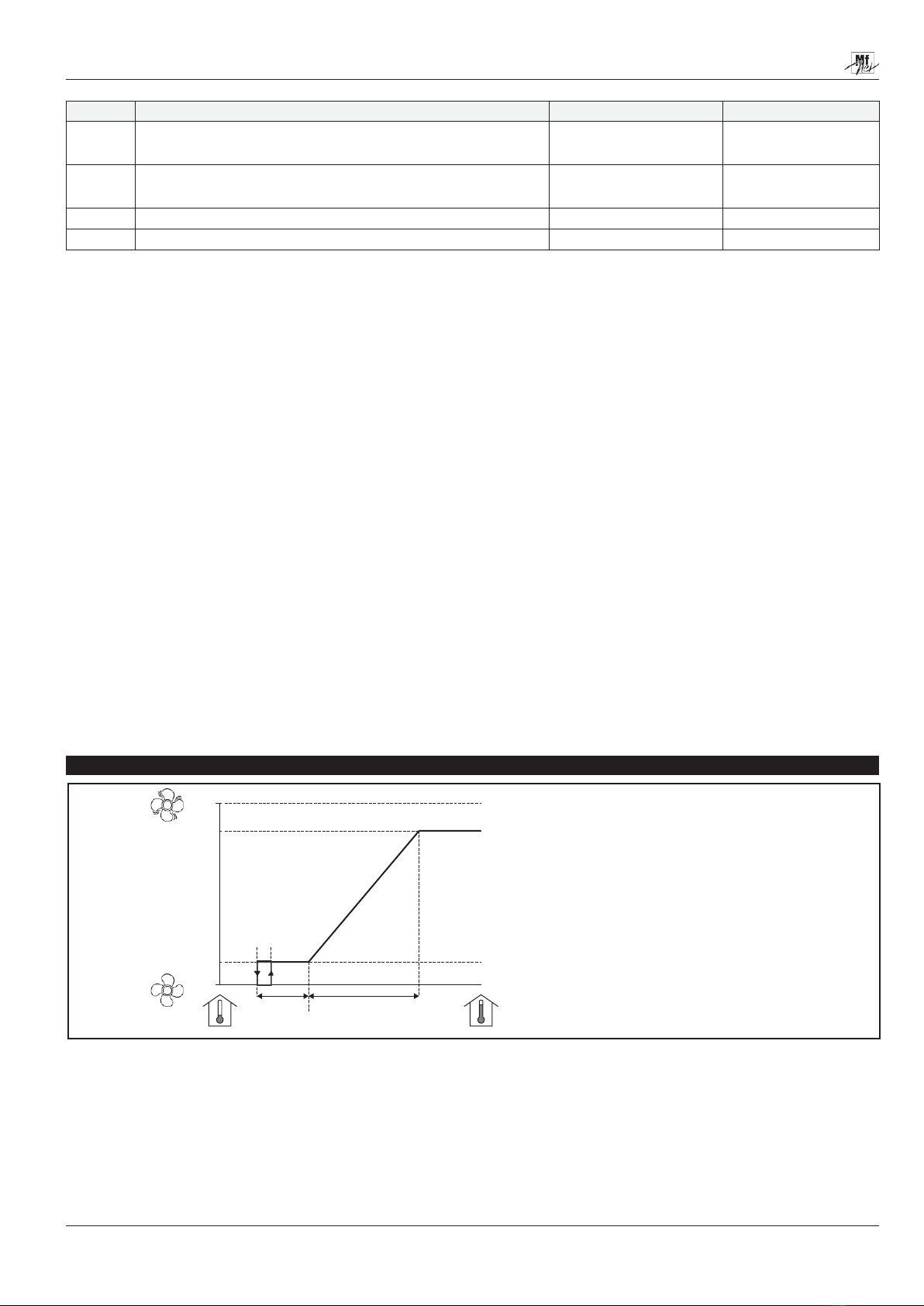

5.3 Ventilation level .............................................................................................................................................................................................9

5.4 Bandwidth compensation ..............................................................................................................................................................................11

5.5 Air inlet flap .................................................................................................................................................................................................12

5.6 Heating.......................................................................................................................................................................................................12

5.7 Manual control.............................................................................................................................................................................................12

5.8 Empty room.................................................................................................................................................................................................12

5.9 Temperature alarms.....................................................................................................................................................................................13

6Operation.............................................................................................................................................................................................................13

6.1 Alarm..........................................................................................................................................................................................................13

7Maintenance.........................................................................................................................................................................................................14

8Troubleshooting...................................................................................................................................................................................................14

9End of life ............................................................................................................................................................................................................14

Glossary ..............................................................................................................................................................................................................15

IMPORTANT: READ THESE INSTRUCTIONS CAREFULLY BEFORE USE

KEEP THESE INSTRUCTIONS FOR FUTURE REFERENCE

These instructions are a part of this product and must be passed on to any subsequent owner and/or user.

Contact your supplier if there are parts of these instructions that you do not understand. Compliance with these instructions will ensure a safe and correct use of

this product.

Legal notice / Disclaimer

The scope of delivery may vary from product images shown. This document was created with all due care. The information, instructions and parts listed are

current on the date this document was issued.

Improper use

No liability is accepted for damages resulting from improper use.

Packaging

If packaging materials are no longer required, dispose of them in accordance with regulations that apply in your area.

NOTICE

This product is for professional use only.