5 (6) 0-003-2060-1 (EN)

SETTINGS

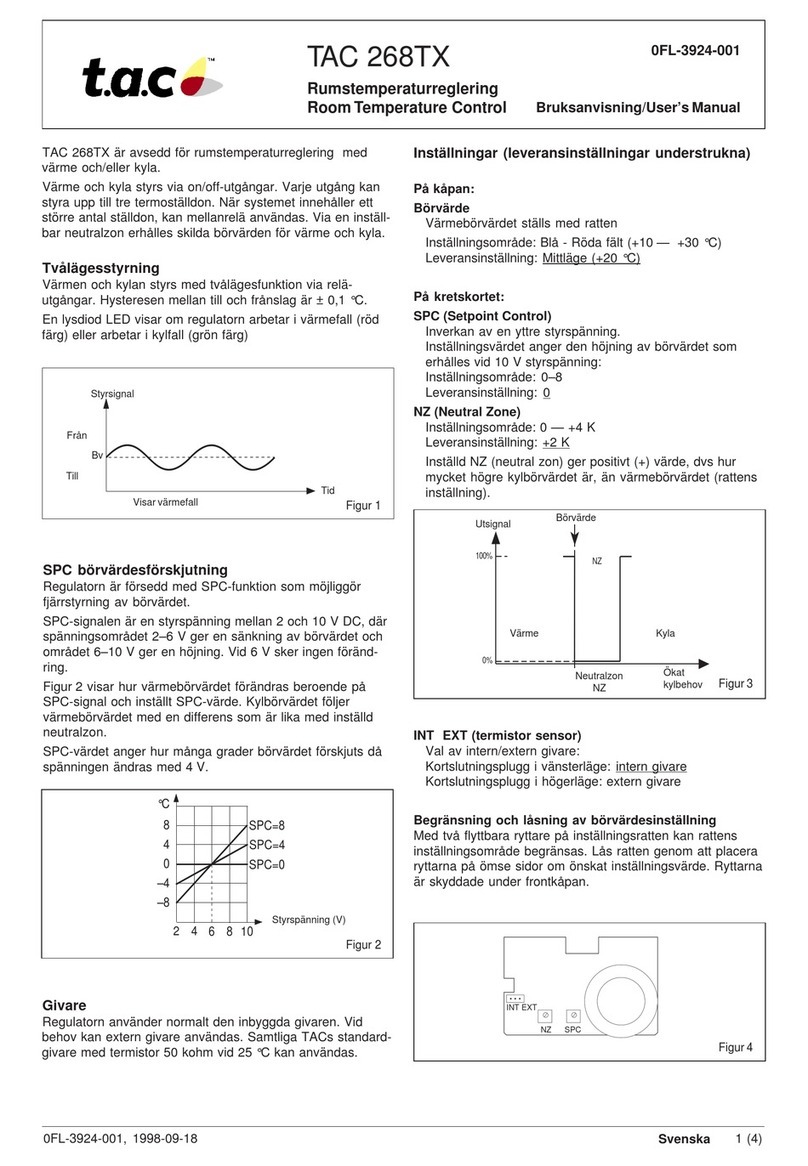

Function in the Description

“OFF” position “ON” position

Modulating Increase/decrease Control

– Sequence Control

2-10 V 0-10 V Voltage range

6-10 V, 5-10 V 2-6 V, 0-5 V Part of voltage range

60 s, 0% 300 s, 50% Running time (Security function)

Normal Inverted Direction of movement

Normal Linear/Logarithmic Valve characteristic

Operation End position adjustment Operation/End position adjustment

INC

6-10, 5-10

ADJ

LIN/LG

INV

300 s / 50%

0-10

2-6, 0-5

SEQ

OP

NORM

NORM

% / 60 s

2-10

– – –

MOD

12345678

O

N

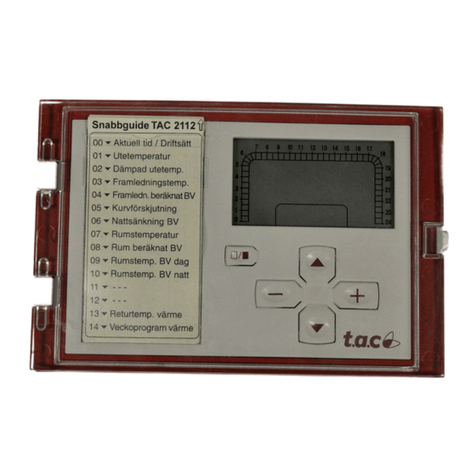

There are eight switches in a row on the

circuit board, see figure 6.

Note! Switch 0% / 60 s, 300 s / 50%

has a double function, see below!

M400: On delivery, all switches are in

the “OFF” position except for the third

one.

Control signal—MOD/INC

M400 can either be controlled by an

increase/decrease signal or by a

variable direct voltage, a so called

modulating signal, so a certain voltage

level corresponds to a certain position.

Sequence or parallel control—

– – –/SEQ

With sequence or parallel control, two

actuators can be controlled by only one

control signal.

You can choose which part of a voltage

range to use, the upper one 6-10 V

(5-10 V) or the lower one 2-6 V (0-5 V).

If the switch »NORM/INV« is in the

NORM position, the higher voltage

corresponds to 0% flow and the lower

one to 100%. To achieve the opposite

function, the switch »NORM/INV«

should be put in the INV position.

Note! If sequence or parallel control is

not used, the switch »– – –/SEQ« must

be in the left position, as the switch for

modulating or increase/decrease

control »MOD/INC« is not valid during

sequence or parallel control.

Voltage range—2-10/0-10

You can choose whether to use the

control signal voltage range 2-10 V or

0-10 V.

Part of voltage range—

6-10, 5-10/2-6, 0-5

You can choose which part of a voltage

range to use, the upper one 6-10 V

(5-10 V) or the lower one 2-6 V

(0-5 V). If the switch is in the NORM

position, the higher voltage corresponds

to 0% and the lower one to 100%. To

achieve the opposite function, the

switch should be put in its INV position.

Running time—60 s/300 s

During increase/decrease control, you

can choose between 60 s or 300 s

running time. During modulating control,

the running time is always 15 s/20 s.

Security function—0% / 50%

At 2–10 V control signal you can select

which security function you want the

actuator to have.

If the actuator is used for heating

control and switch 5 is ON (50%), the

actuator will open the valve halfway if

the control signal disappears, e.g. if the

X1 connection is unplugged.

If, instead, you want the valve closed,

set switch 5 to OFF (0%).

Note! The direction of movement is also

significant. See Installation Instruction

0FL-4006.

Direction of movement—NORM/INV

When normal direction of movement is

used, the screw of the actuator moves

inwards when the control voltage

decreases or if the actuator gets an

increase signal. With the switch

»NORM/INV«, the direction of

movement can be changed.

Linearization—NORM/LIN/LG

It is possible to choose whether the

motorized valve characteristics should

be affected or remain unchanged. If

you wish for the characteristics to be

affected, the choice »LIN/LG« will make

the characteristics of an equally

modified percentage (EQM) valve

almost linear. A motorized valve

equipped with a linear valve will operate

with “Quick open characteristics”, i.e.

when the control signal is only

increased a little, the valve will be

almost completely open.

Note! For the actuator to register new

settings of the switches, the supply

voltage must be cut or the manual

operation handle lowered when the

settings are done, and then it must be

raised again. (This does not apply to

the switch »OP/ADJ«.)

End position adjustment—OP/ADJ

The switch is used to adjust the end

positions when the actuator is in

operation.

Figure 6