4

2 WARNINGS AND SAFETY PRECAUTIONS

■This appliance can be used by children

aged from 8 years and above and persons with

reduced physical, sensory or mental capabili-

ties or lack of experience and knowledge if they

have been given supervision or instruction con-

cerning use of the appliance in a safe way and

understand the hazards involved.

■This product is designed for home use.

■Usage voltage of your product is 220-240

Volt~50 Hz.

■ Power cord of your product is tted with a

grounded plug. That cable must denitely be

connected to a grounded socket.

■The whole electrical wiring must be installed

by a qualied electrician.

■Installation by unauthorized persons could

lead to poor operation performance, damage to

the product, and accidents.

■Feeder cable of the appliance mustn’t be

exposed to jamming or crashing during as-

sembly. Feeder cable mustn’t be placed near

the cooker. In such cases, it might melt down

and lead to re.

■Do not plug in the appliance before the ins-

tallation.

■Make sure that the installation place allows

the user to easily unplug the power cable in

case of any danger.

■Do not touch your product’s lamps when

they work for a long time. Since they would be

hot, they could burn your hand.

■Kitchen cooker hoods are designed for nor-

mal cooking and home use. For uses other than

specied, there is the risk of failure and the app-

liance becomes out of warranty.

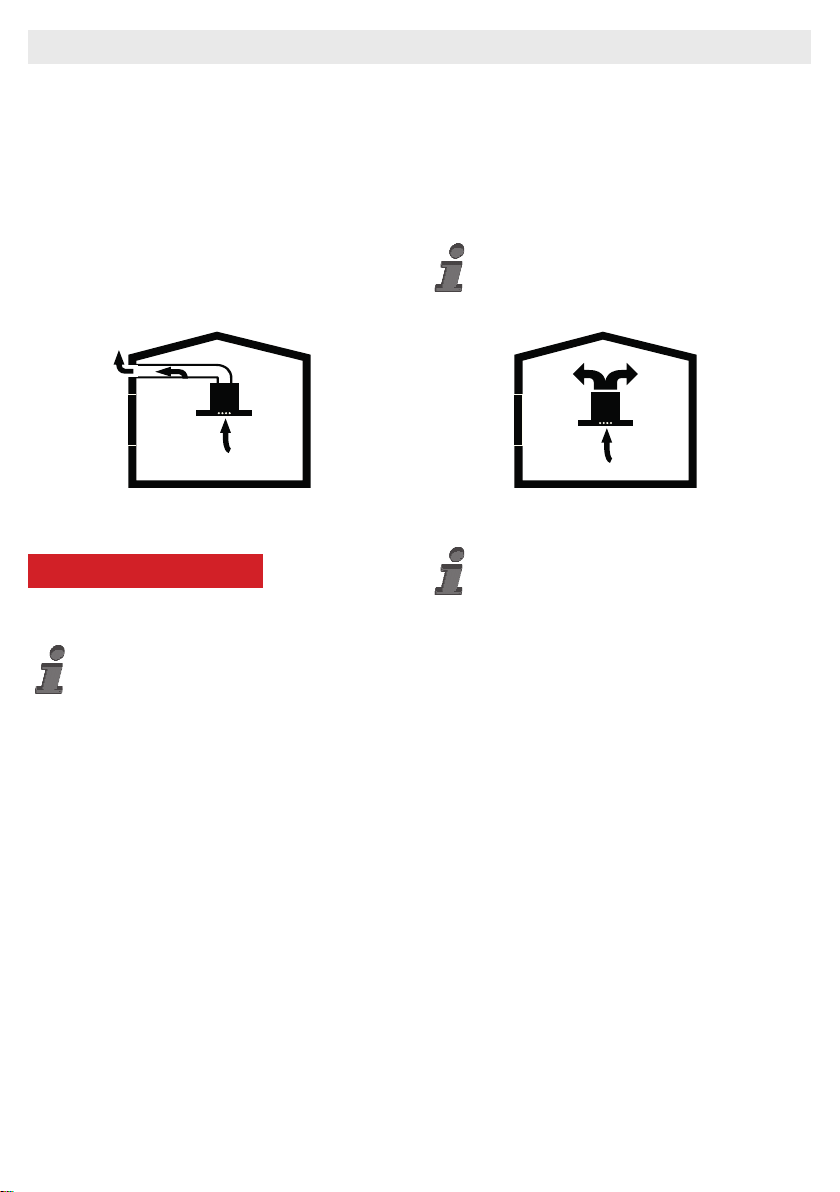

■Comply with the rules and instructions re-

garding discharge of outgoing air, stipulated by

the relevant authorities. (This warning does not

apply to uses without ue.)

■Flammable foods must not be cooked under

the appliance.

■Turn on the appliance after placing a sau-

cepan, pan, etc. on the cooker. Otherwise, high

temperature might lead to deformation on some

components of your product.

■Turn off the cooker’s burner before taking

the saucepan, pan, etc. off the cooker.

■Do not leave hot oil on your cooker. Pots

that contain hot oil might lead to inammation.

■ Since oils could catch re when you cook

fried foods in particular, be careful about your

curtains and tablecloths.

■ Ensure timely replacement of the lters. Fil-

ters not replaced in a timely manner pose risk

of re due to accumulated grease deposits on

them.

■ Do not use non-re-resistant ltering materi-

als instead of the lter.

■ Do not operate your product without lter,

and do not remove the lters when the product

is in use.

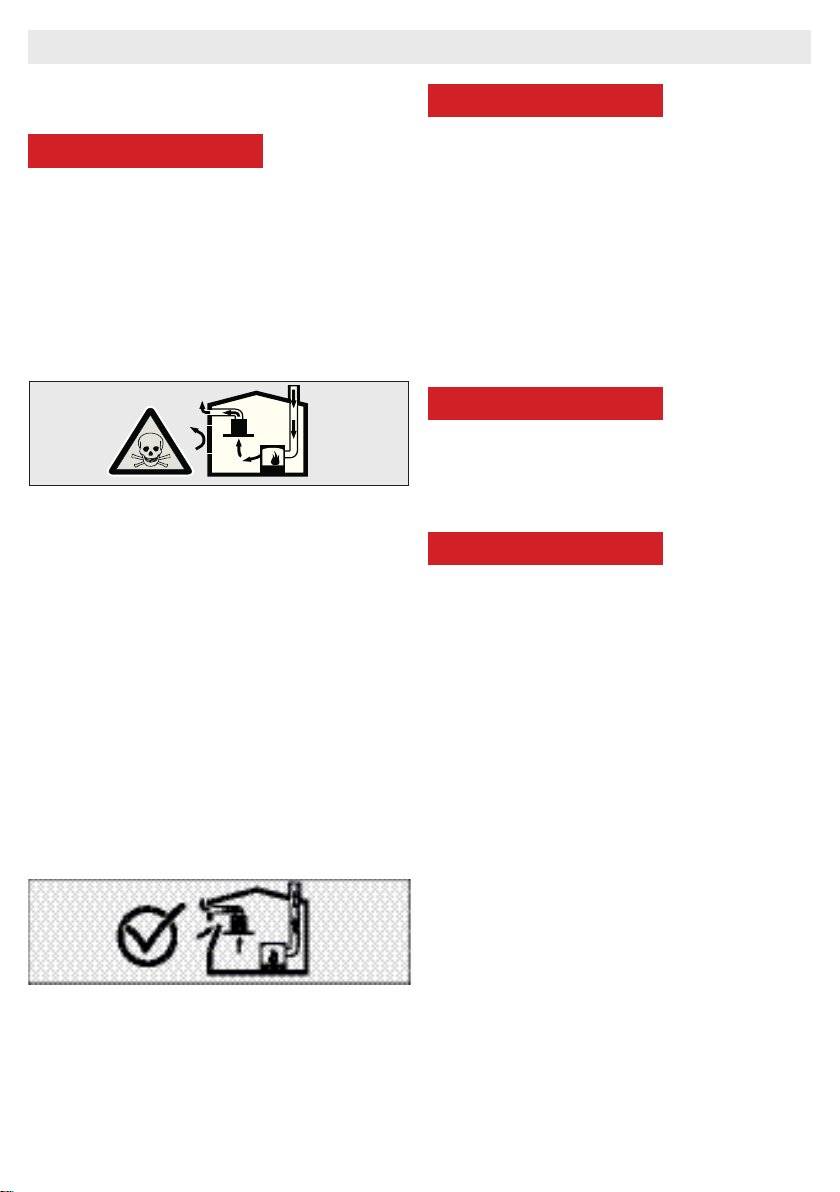

■ In case of any deagration, de-energize the

cooker hood and cooking appliances. (Plug off

the appliance or turn off the main switch).

■If your product’s periodic cleaning is not

made in a timely manner, it could pose risk of

re.

■De-energize the appliance before any ma-

intenance operations. (Plug off the appliance or

turn off the main switch.)

■When electric cooker hood and devices

fed with energies other than electricity opera-

te simultaneously, the negative pressure in the

room must not exceed 4 Pa ( 4 X 10 bar ).

■Gas or fuel oil burning appliances, such as

room heaters, which share the same environ-

WARNINGS AND SAFETY PRECAUTIONS