- 2 -

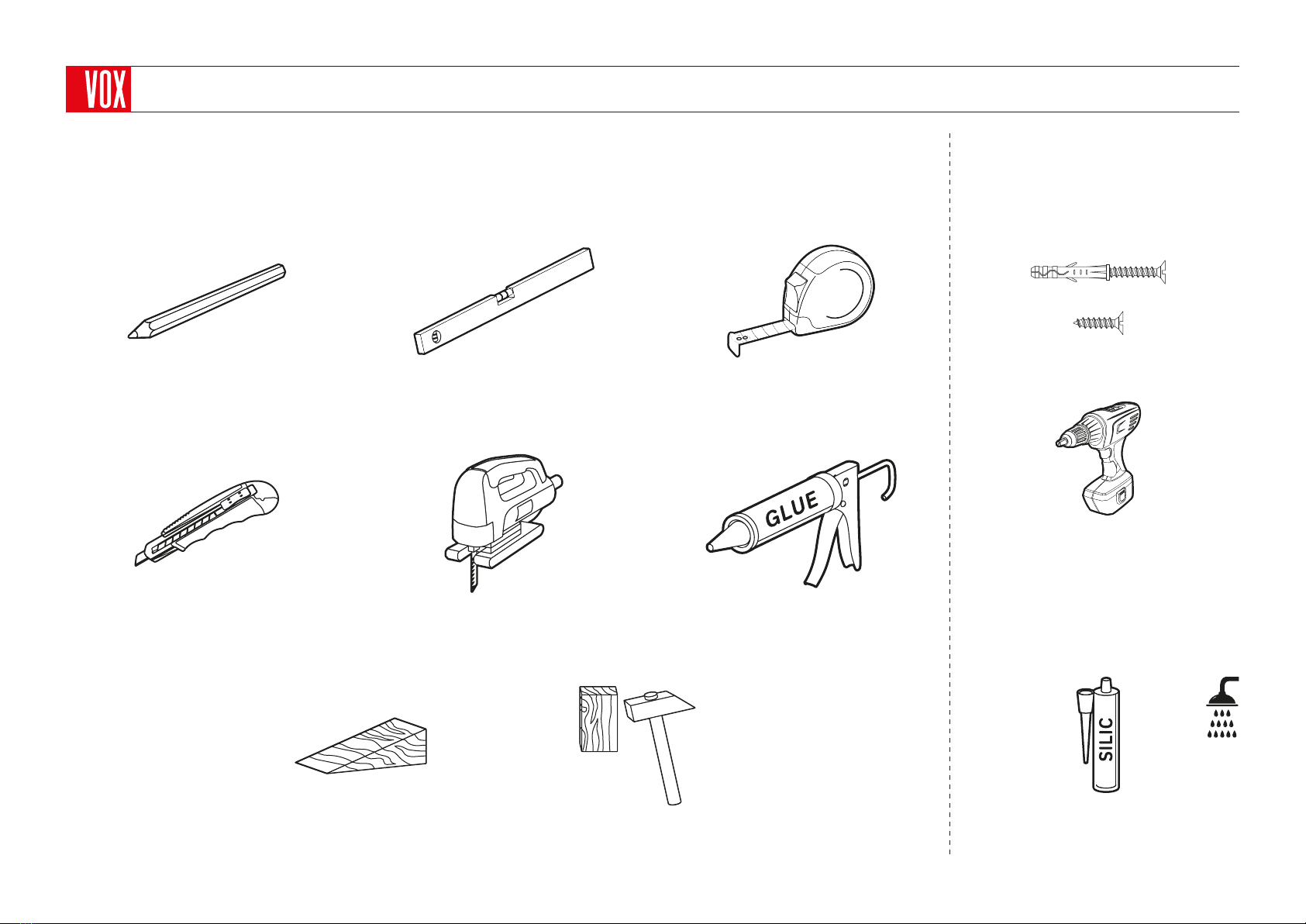

General guidelines

1. General information about the product and installation

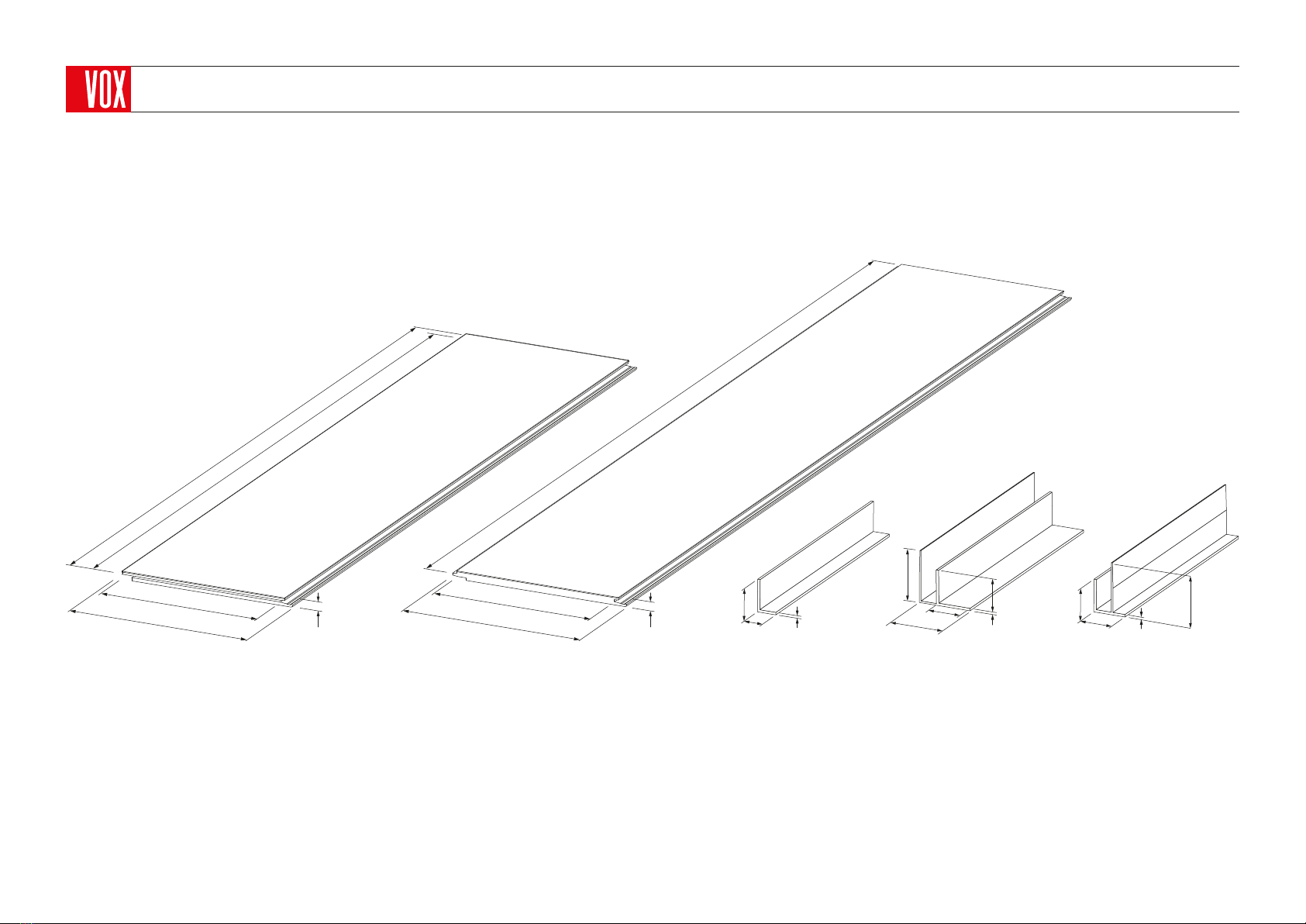

• KERRADECO panels may be installed on a wooden frame or using a glue

• the panels can be installed horizontally or vertically, depending on the decor

• the person installing the panels should have basic technical knowledge and be familiar with safety

precautions

• after unpacking, each panel's quality should be checked (for scratches, pattern print errors, discolorations)

• prior to the installation, the panels should be stored in the room where they are to be installed – to adjust to

the ambient temperature

• the panels should be assembled in the sequence specified by the numbers on their backsides

• the panels may be finished with trim or without trim

• the product can be installed in damp areas (kitchen, bathroom), providing it has been sealed with silicon

• it must not be installed in areas of increased temperatures (above 60° C), like a sauna, on a chimney, next to

a cooker

• the product is only suitable for indoor applications

• 100% recyclable

• any non-compliance with the instructions will void the product's warranty

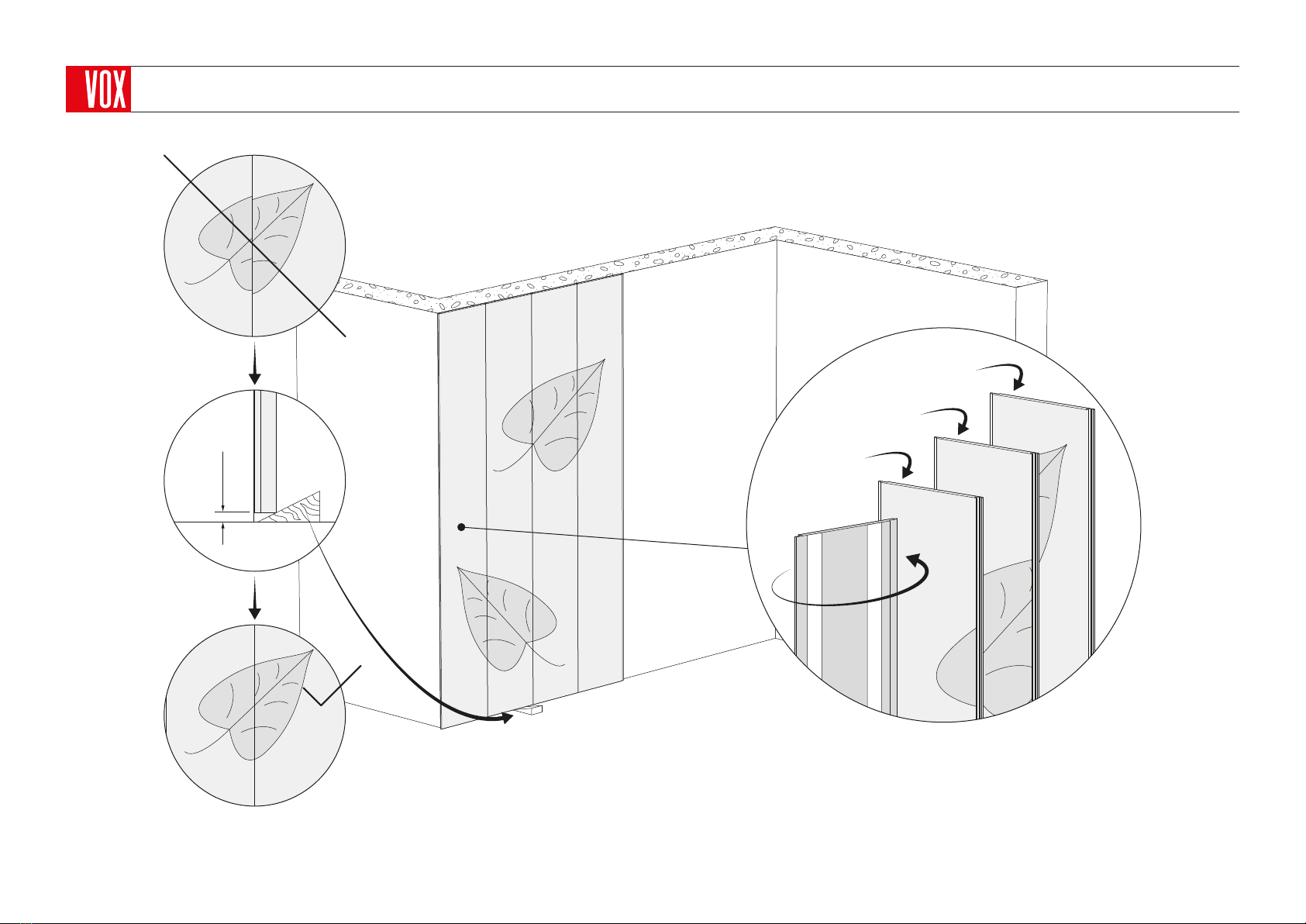

2. Installation of the panels

• the installation should always be done from the left to the right and from the bottom to the top

• after placement of the first panel, you need to verify its vertical / horizontal alignment and fasten it, then

you slide on the next panel and fasten it with a hammer and a tapping block

• before fastening the panel permanently, you need to make sure that there is no gap between the panels

and verify again its vertical / horizontal alignment

3. Wooden frame construction

• the frame should be made of wooden battens fastened directly to the wall

• using a level, you must level the battens so they are flush with each other; if necessary, you can use

shims or wedges to keep the panels level

• the battens should run perpendicular to the direction of the panels – if the panels are being assembled

vertically, the battens should be placed horizontally, and the other way around

• distance between the battens – 40 cm

• the battens should be:

- made of good quality wood, without any knots

- attached to the wall in a secure and strong manner, with screws or other mounting devices that are

appropriate for the given surface

- the battens should be stored in the room in which they will be mounted for at least 24 hours (to adjust

to the ambient temperature and humidity)

4. Installation on wooden frame

• screw down the panels to the battens through the panel's tongue, along the long edge and within the

area marked by a groove

• the screw should go in deep enough so that it does not snag when you slide on the next panel

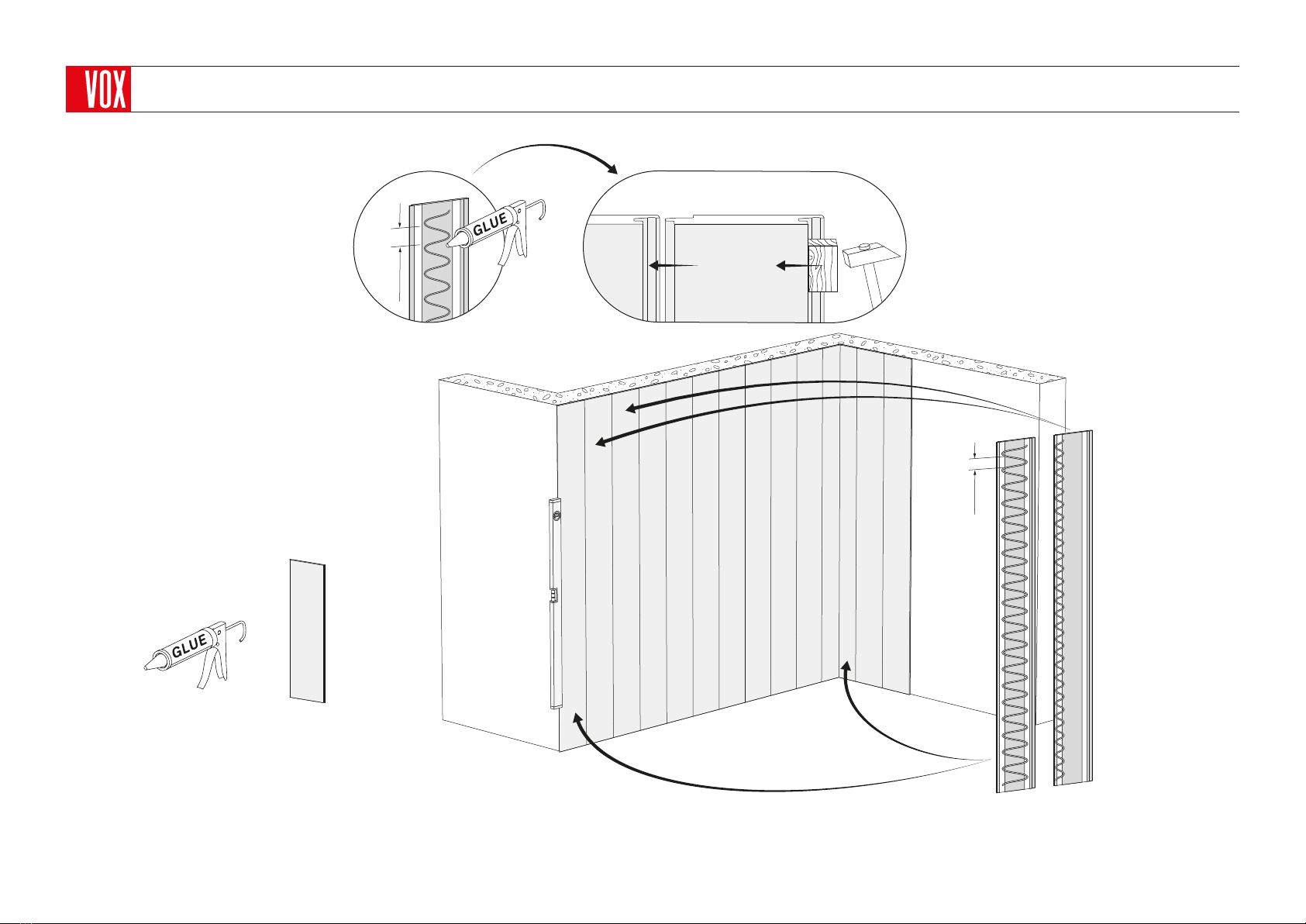

5. Installation with glue

• the surface should be smooth, not crumbling, ensuring good adhesion

• we recommend to use a highly flexible glue, based on a hybrid polymer formulation, intended for indoor

applications and for various building and construction materials – including damp materials: concrete, brick,

drywall, natural stone, wood and wood-based products, metals, glass and ceramics, the majority of plastics,

for example PVC, styrofoam, polyacrylates and polycarbonates

• the glue should be applied according to its instructions, in a well ventilated area

• apply the glue in a S-shaped motion

• the surface of the first panel on a given wall should be completely covered with glue; each successive one

only along the edge with the tongue

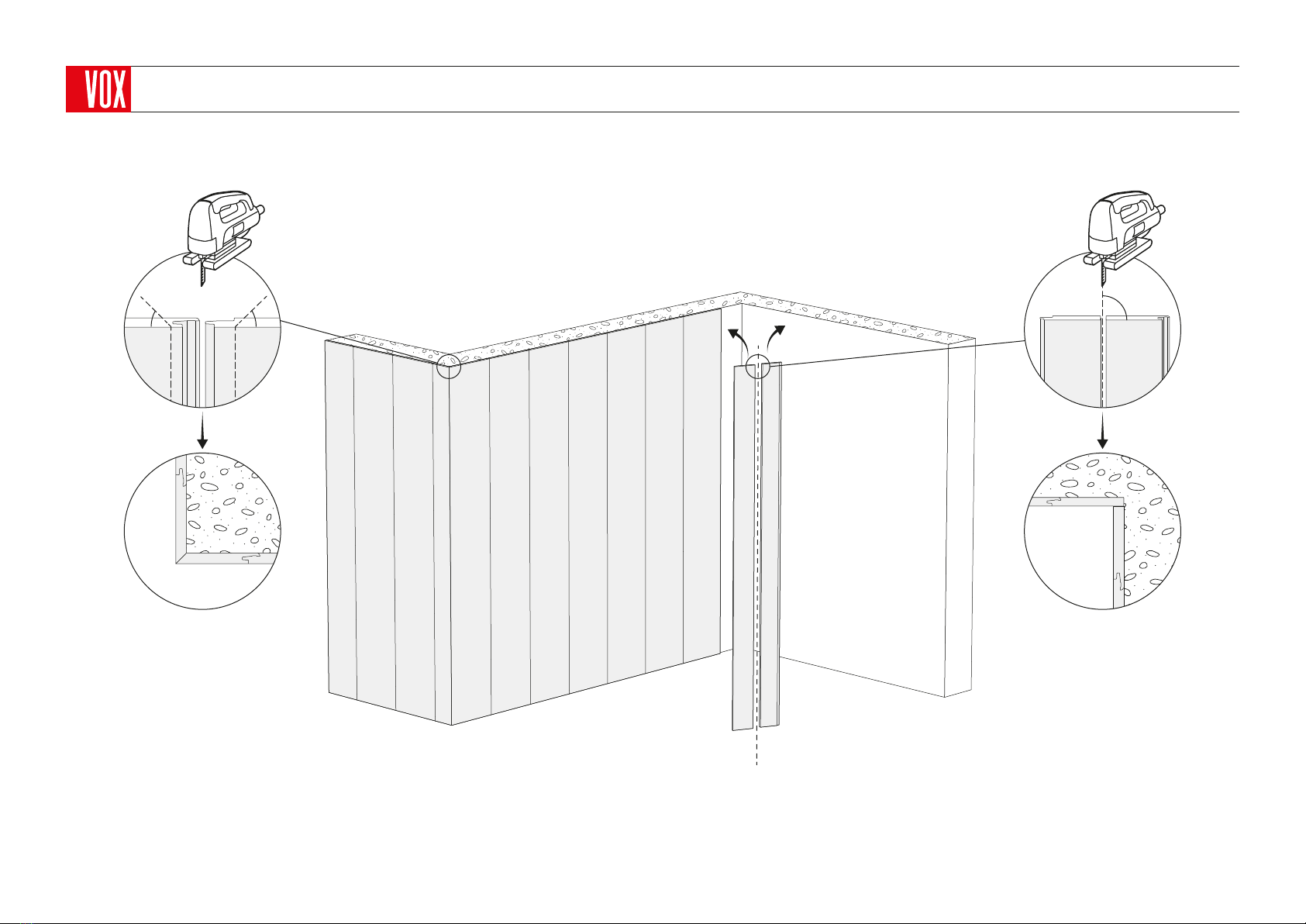

6. Cutting the panels

• to cut the panels you can use: hand saw, jigsaw, table saw

• when adjusting the panel for the trims, cut off the tongues or grooves with a sharp knife

7. Hanging shelves on the panels

• no additional weight should be applied to the panel, and neither should it be a bearing element in

construction

• no hangers, shelves or any other objects may be directly screwed to the panel

• instead, they should be mounted to the surface underneath the panel, with screws or anchors intended

for the given type of surface. To do so, drill the appropriate hole in the panel, allowing for such possibility

8. Cleaning

• do not allow liquid stains to dry

• from time to time, clean the panels with a damp cloth and a mild detergent

• intensive scrubbing and use of strong detergents may damage the panel's surface or cause its

discoloration

• do not clean with coarse and rough clothes, sponges or brushes

• never use for cleaning any solvents, acids, nor any other liquids based on these substances

• no cleaning liquids should be left on the surface, they must be rinsed off with water; cleaning substances

left out on the surface may cause its discoloration