v

Table of Contents

1. Symbols & conventions .......................................................................... 1

2. Package contents................................................................................... 2

3. Safety information .................................................................................. 3

3.1 Warning ............................................................................................................................. 4

4. Use ......................................................................................................... 5

4.1 Intended use ...................................................................................................................... 5

4.2 Unintended use.................................................................................................................. 5

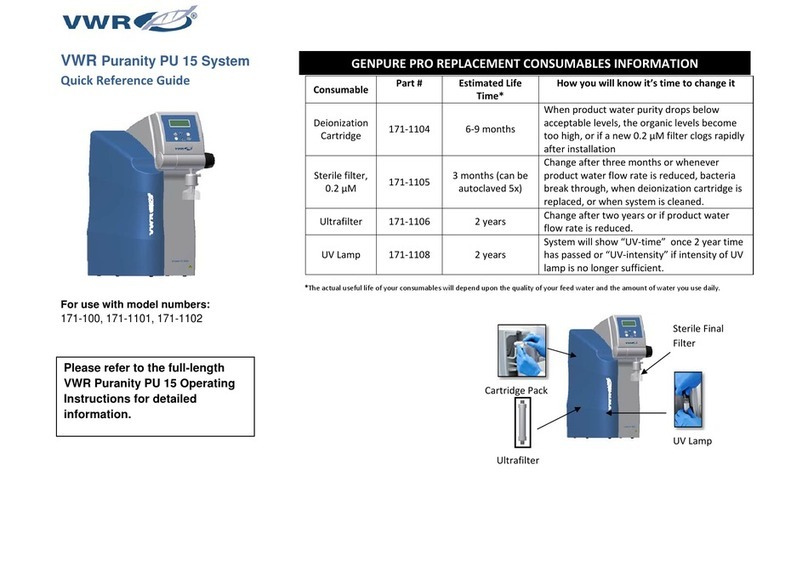

5. Accessories & spares............................................................................. 6

5.1 Spares ................................................................................................................................ 7

5.2 Accessories ....................................................................................................................... 7

6. Specifications ......................................................................................... 8

7. Describtion of how the systems functions ............................................ 10

7.1 Flow chart for Puranity PU 15.......................................................................................... 10

7.2 Flow chart for Puranity PU 15 UV/UF .............................................................................. 11

7.3 Flow chart for Puranity PU 15 UV.................................................................................... 12

8. Installation ............................................................................................ 13

8.1 Installation area ............................................................................................................... 13

8.2 Installation........................................................................................................................ 14

8.3 Mounting the power pack (voltage supply) ...................................................................... 16

8.4 Wall mounting (option)..................................................................................................... 17

9. Putting the system into operation ......................................................... 18

9.1 Venting the sterile filter .................................................................................................... 18

10. Instruction for use............................................................................... 19

11. The system control .............................................................................. 20

11.1 Menu.............................................................................................................................. 21

11.1.1 Feedwater conductivity ........................................................................................... 21

11.1.2 Ultrapure water limiting value:................................................................................. 21

11.1.3 UV-Lamp operating time and intensity: ................................................................... 22

11.1.4 Filter cartridge operating time counter: ................................................................... 22

11.1.5 Rinsing .................................................................................................................... 22

11.1.6 Disinfection.............................................................................................................. 23

11.1.7 Display of fault storage:........................................................................................... 24

11.1.8 Data print out........................................................................................................... 25

11.1.9 Unlocking the system .............................................................................................. 25