2

Basic Principles

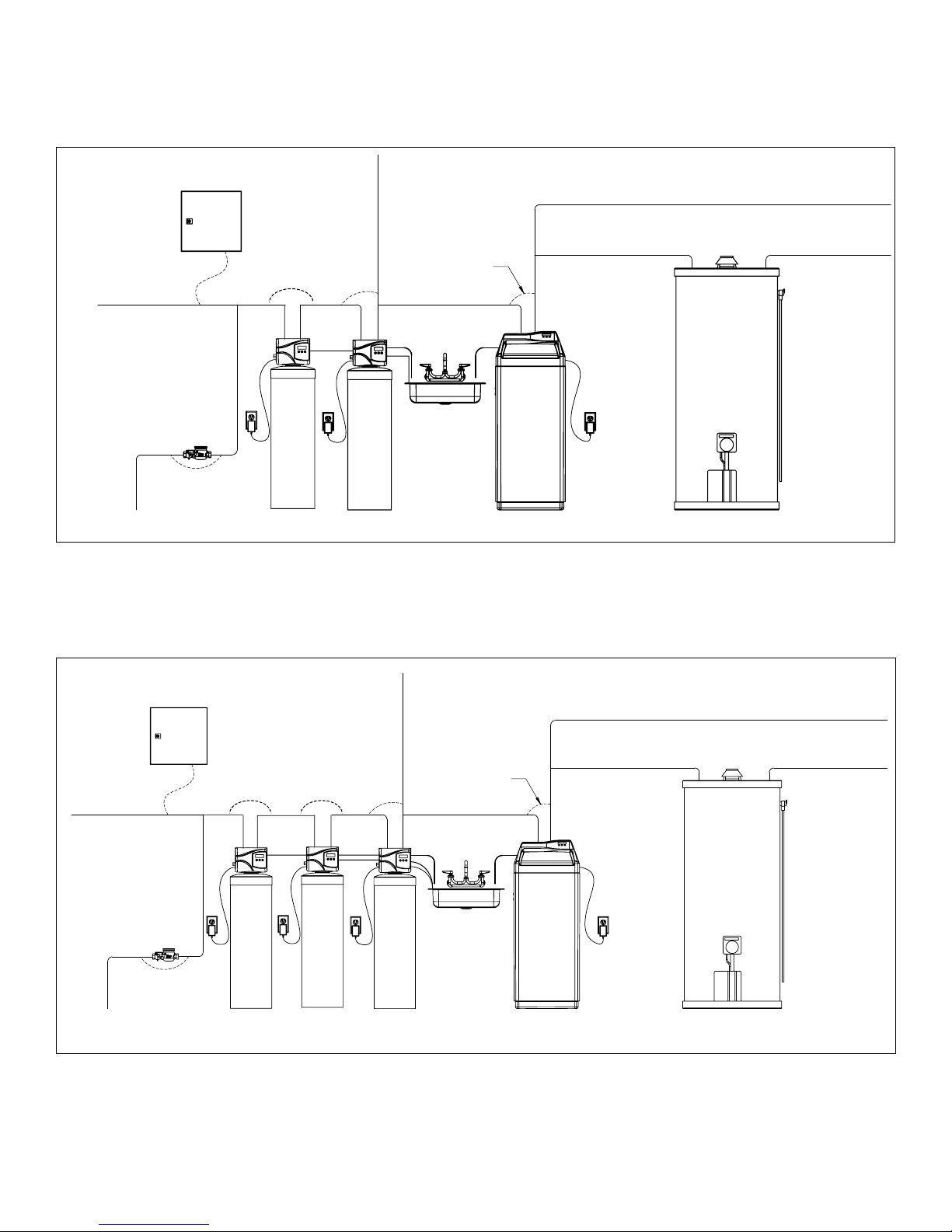

The success of the installation will depend, to a great extent, on advanced planning and preparation. Careful attention

to the location of the unit, accessibility to electrical and drain facilities, and the availability of the proper tools will ensure a

professional-looking installation. Of utmost importance is the assurance that the filter has been properly applied and meets

all specifications.

Application

Correct application is directly associated with the performance and life expectancy of any water filter. It is important, there-

fore, to understand how your WaterGroup Water Filter functions and to know its capabilities and limitations so that a correct

application can be made. By following the guidelines and recommendations set forth in this manual, you can be certain

your filter is applied correctly.

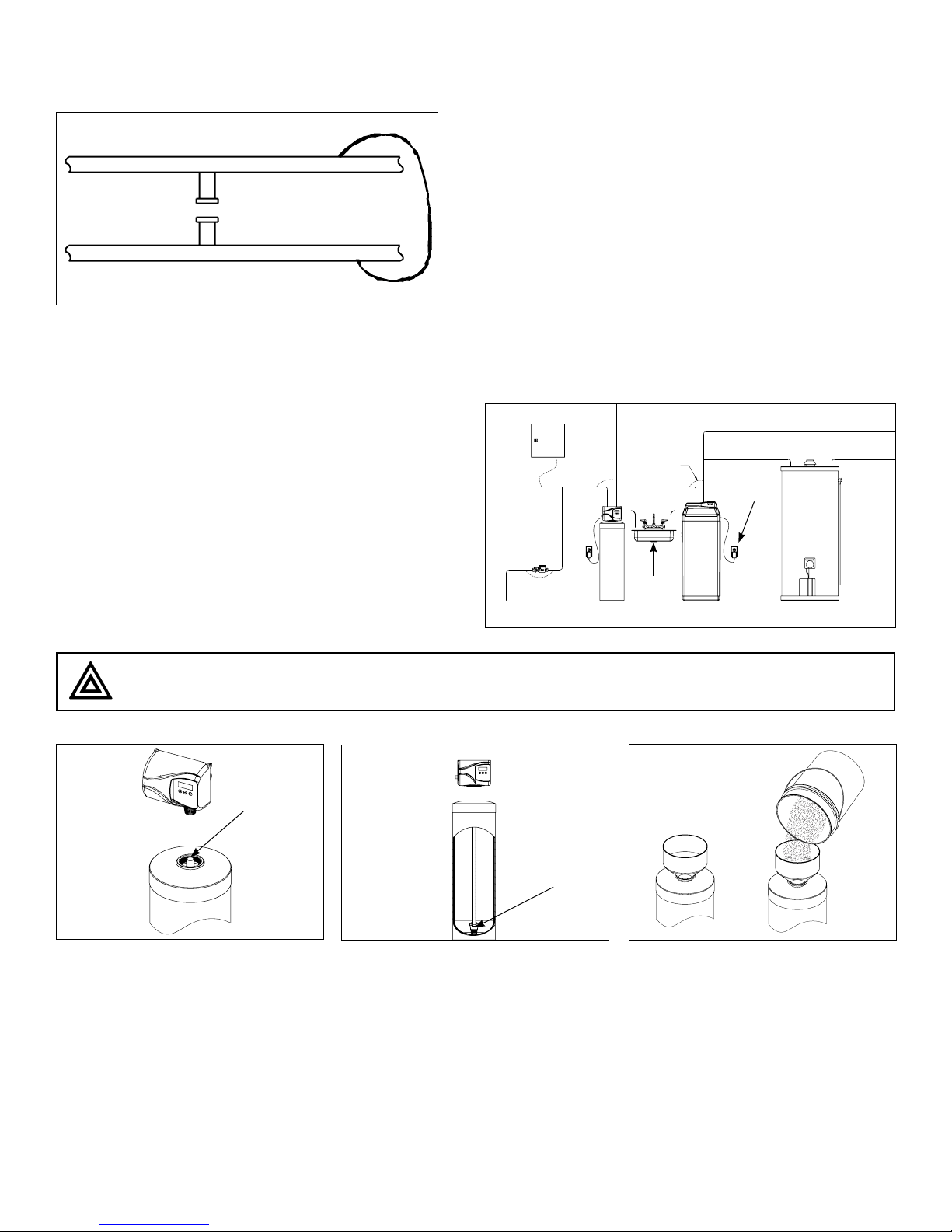

MMF Filter

The Automatic Water Filter is capable of removing particulate matter particle size as small as 30 microns. It will not remove

color, organics, colloidal turbidity or dissolved solids. Some applications include:

• Removal of suspended matter in any water system

• Removal of particulate matter, such as clay, mud, etc.

• Prefiltration of oxidized iron prior to an automatic or manual softener

• Removal of light sand

The quality and number of gallons of filtered water between backwashes will depend upon the amount, type, and size

of the particulate matter being filtered. If a water sample is sent to a laboratory, where application of a MMF Type unit is

contemplated. The laboratory will test for Nephelometric Turbidity Units (NTU) and suspended solids (mg/L). The sample will

also be filtered through 10 micron filter paper and NTU run on a filtered sample. If the NTU of the raw water exceeds 150,

suspended solids exceed 150 mg/L, or the filter water throught the 10 micron filter paper has unacceptable quality, a MMF

filter might not be applicable. As a guide, the U.S. Public Health Drinking Water standards states the turbidity should not

exceed 1 NTU. The exact number of gallons filtered between backwashes can not be given because of many variables.

ACF Filter

Automatic Water Filter with Activated Media will control chlorine taste and odor, and it will also remove most objectionable

organic colors. It will not remove hydrogen sulfide. It is important to note that whenever the cause of an objectionable taste

or odor has not been established, Health Authorities should determine if the water is safe to drink. Do not use with water that

is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system.

NF Filter

Automatic Water Filter with Neutralizing Media will neutralize slightly acid water (pH 5.2 to >6.8) and thus help to prevent

unsightly brown or green stains due to corrosion of household plumbing. If the pH is between 5 and 6, one part of Magne-

sium Oxide Media should be mixed with five parts of Calcite Media to provide additional neutralizing capability. If the water

to be treated has a pH less than 5, a high hardness, or a high carbon dioxide level, NF might not be applicable; a solution

feeder should be used. Because NF adds hardness, it should be used prior to a softener.

NOTE Under dynamic conditions it might be necessary to mix five parts Calcite with one part Magnesium

Oxide to effectively raise the pH. In order to size and apply the equipment correctly, a complete analysis of the

water supply should be obtained.

CAUTION! Do not use where the water is microbiologically unsafe or with water of unknown quality without

adequate disinfection before or after the unit.