=11>?@34@=AB& & CD&@,E"%&+FG+"HE.,#

=11>?@34@=AB& & 6D&I%F"#&J.++,+&/$+G"HF&$#KF+&

/.KF&%.*LE.#*&

=11>?@34@=AB& & MD&I%F"#&J.++,+&/$+G"HF&$#KF+&

J.H+,/H,NF&O-F+E.H"%P&%.*LE.#*&

=11>?@34@=AB& & 9D&?H"EEF+.#*&,G&%.*LE&+")/&K$F&

E,&Q"EF+&H,#KF#/"E.,#&

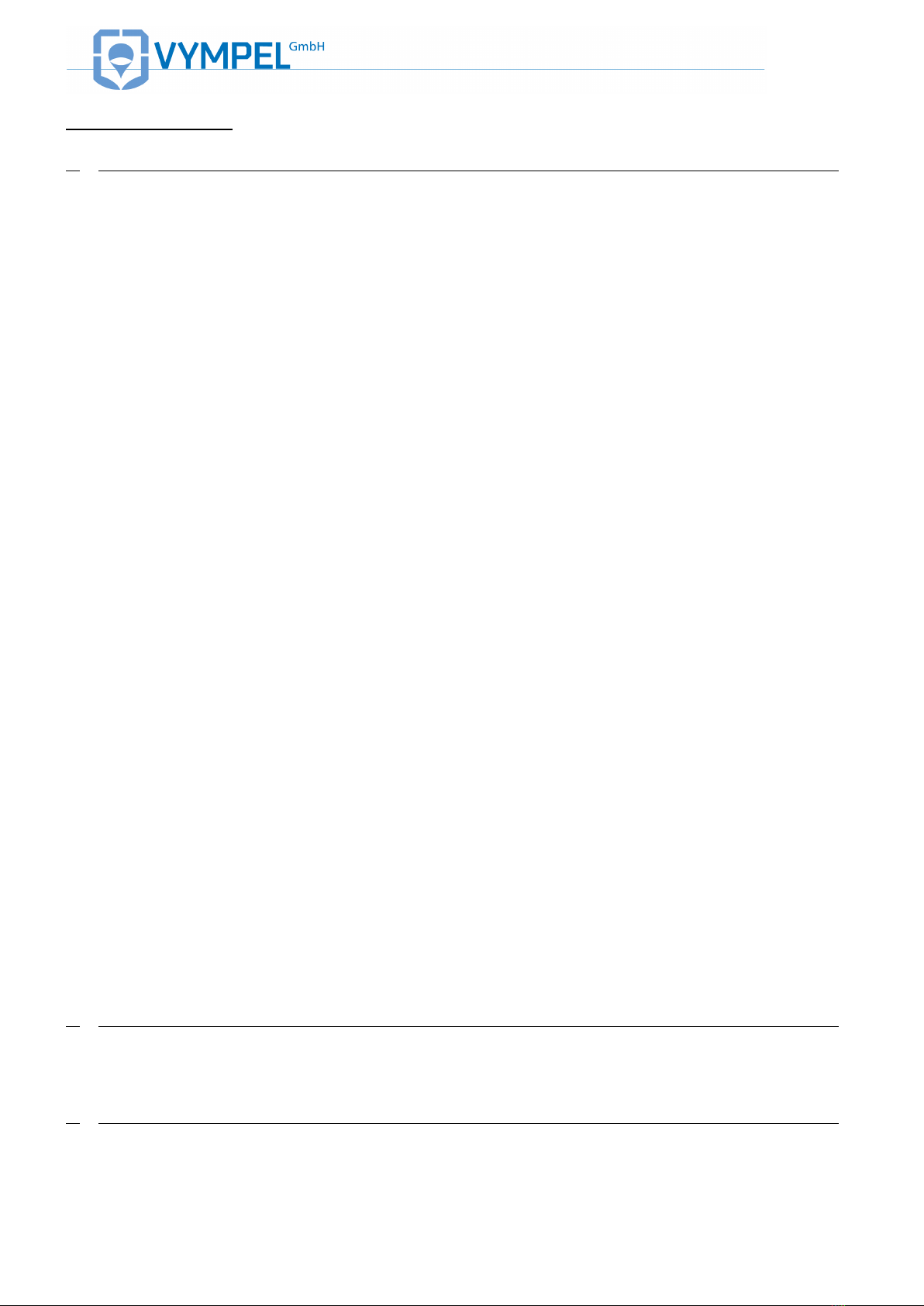

1.3. MEASUREMENT PRINCIPLE

The Hygrovision BL is a compact, portable analyzer used for tak-

ing automatic and manual measurements of the dew point tem-

perature of water and/or hydrocarbons.

This portable chilled-mirror automatic hygrometer operates ac-

cording to the principle of direct measurement and employs a

temperature-controlled mirror to establish the dew point. During

the measurement process the reflectivity of the mirror is meas-

ured. As the temperature of the mirror is lowered, its reflectivity

begins to go down when the dew point is reached and condensa-

tion begins to form. In this process condensates are deposited on

the mirror (reflective surface).

A special system uses optical properties to register the formation

of this condensate film.

This system utilizes the phenomenon of total refraction to register

dew point.

A laser emitting vertically polarized light illuminates the interface

of a heterogeneous media (gas) 1 and a reflective dielectric sur-

face (temperature controlled mirror) 2 at a specific angle. This

angle is known as Brewster’s Angle.

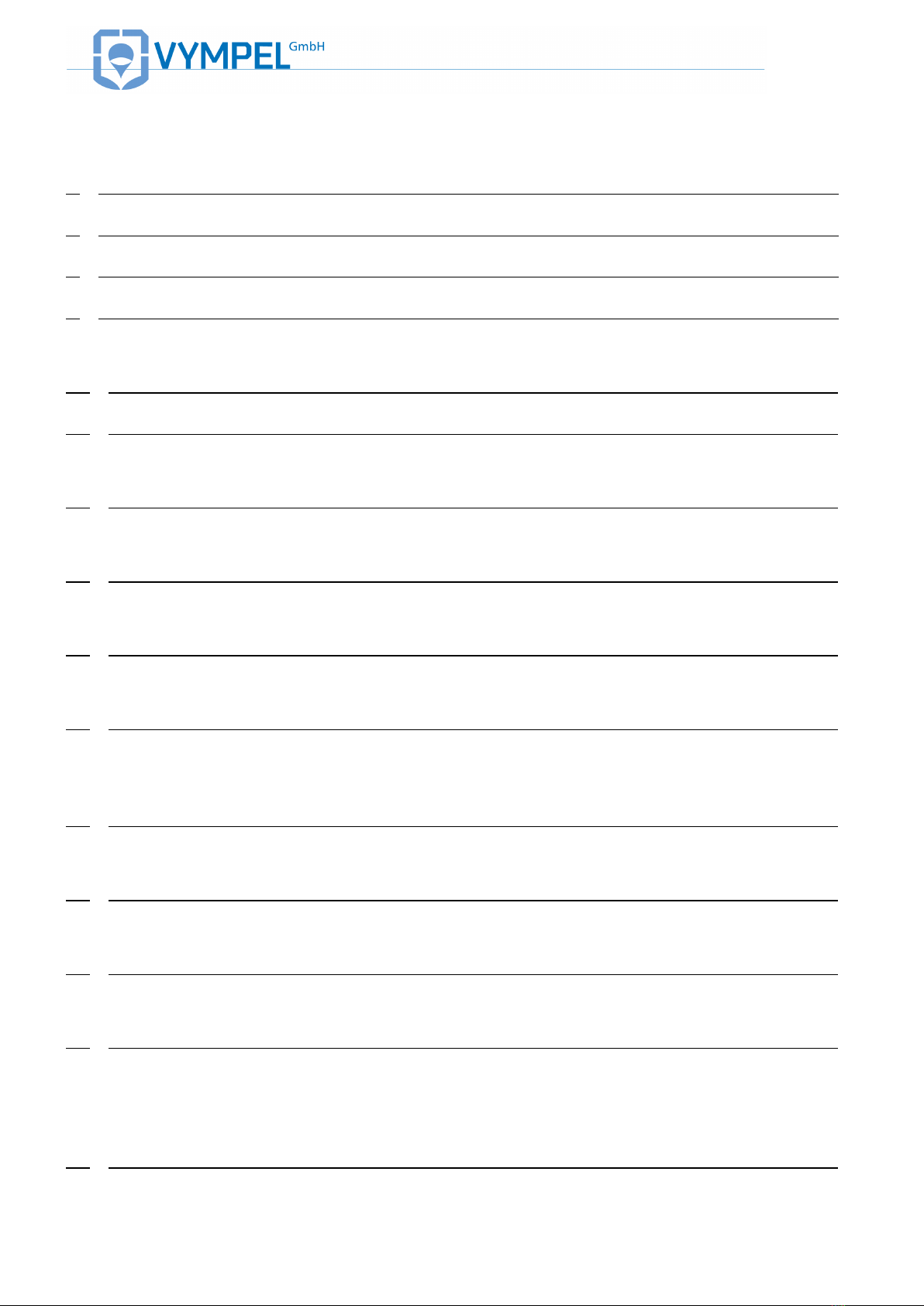

When the dew point mirror (dielectric surface) is clean, in other

words, when no condensate has formed, the polarized light rays

falling on the interface between the gas and the mirror’s surface

are completely refracted. As a result no light is reflected onto ei-

ther of the photo detectors (F1 and F2). This results in a null sig-

nal from the sensors (ILLUSTRATION 1). With the microscope

attached, total refraction can be observed visually under both side

lighting and vertical lighting. Under side lighting*, the surface of

the dielectric mirror appears black (illustration 2). Under micro-

scope (vertical) lighting the mirror’s surface appears light blue

(ILLUSTRATION 3).

*Please note: the side-lighting unit and the laser are not the same

component.

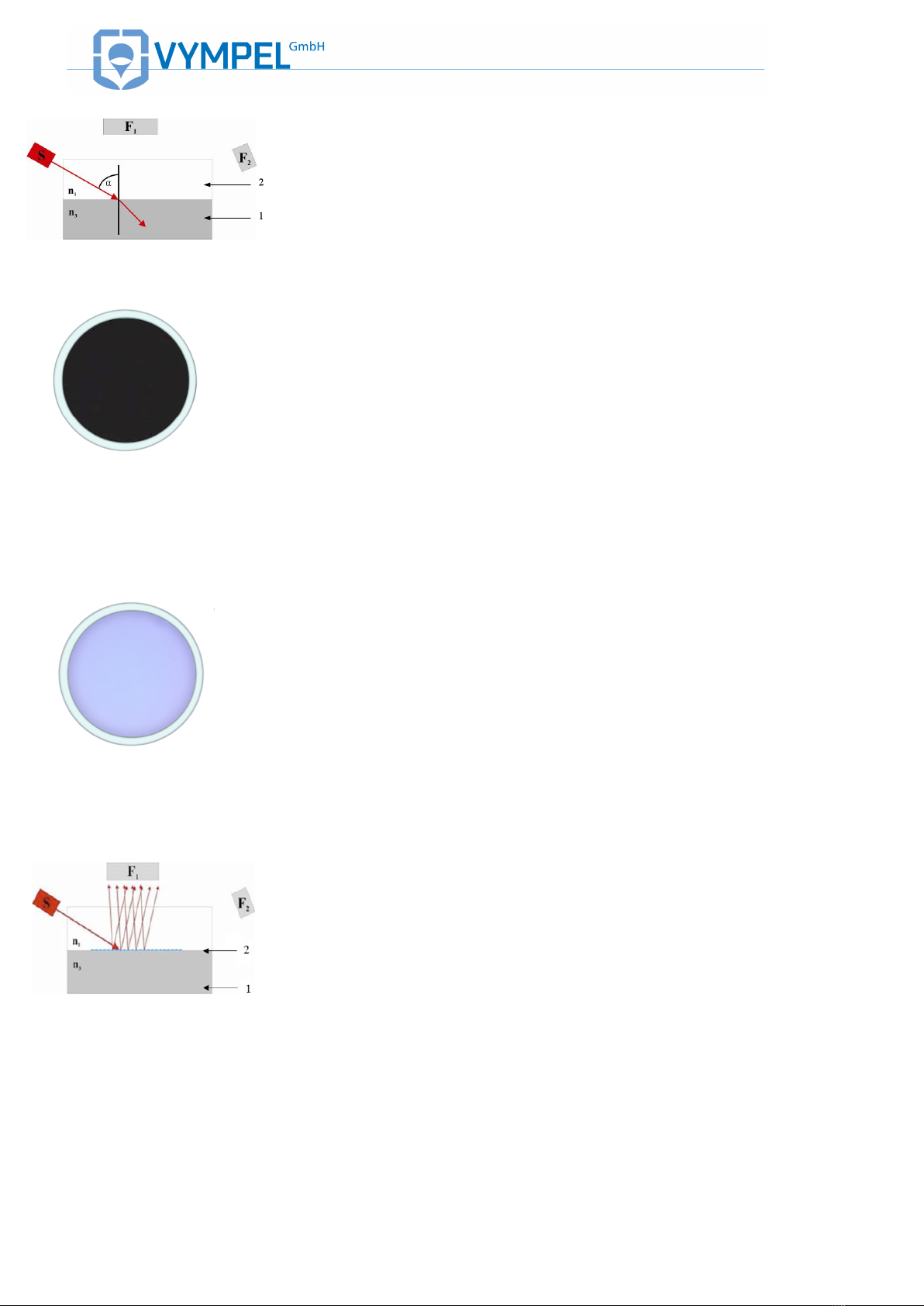

In the case of water vapor, as the temperature of the mirror is

lowered and condensation droplets begin to form, the angle at

which the polarized light strikes the surface changes with the re-

sult that refraction no longer occurs. Instead, the light rays are

reflected and scattered. The photoelectric registration system re-

cords an increase in the intensity of the light detected by the

photo detector located in position F1(ILLUSTRATION 4). The

signal intensity (aka signal level) is dependent on the amount of

water condensation.

Under side lighting, water condensation appears in the form of an

accumulation of luminous, somewhat similarly sized red droplets