2 Troubleshooting

4WABCO Maintenance Manual 31 (Revised 08-18)

2 Troubleshooting

Hazard Alert Messages

Read and observe all Warning and Caution hazard alert messages in this publication. They provide information that can help prevent serious

personal injury, damage to components, or both.

To prevent serious eye injury, always wear safe eye protection when you perform vehicle maintenance or service.

Use Table A to troubleshoot the WABCO System Saver 318 air compressor.

NOTE: If you have any questions or need additional information, please contact WABCO North America Customer Care at 855-228-3203.

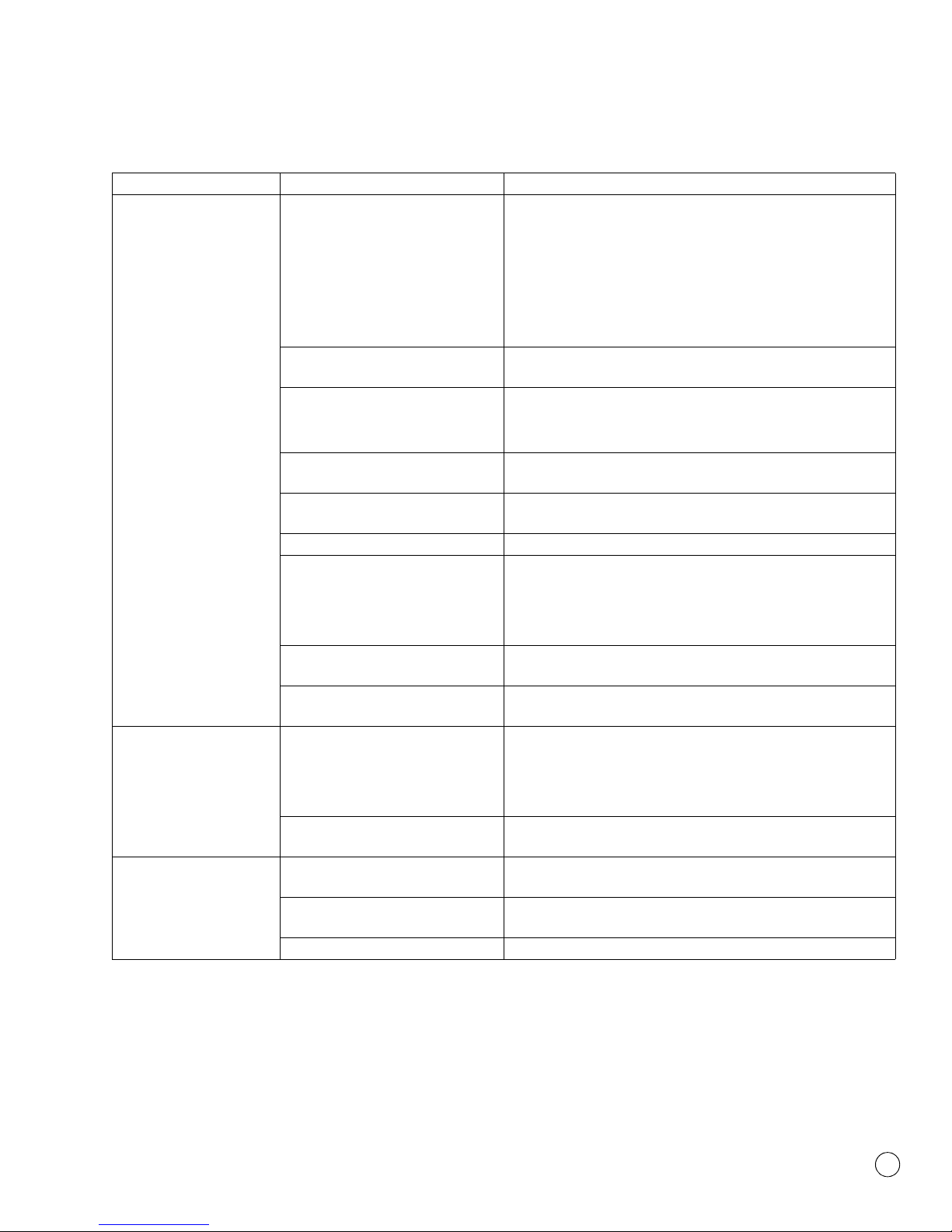

Table A: Compressor Troubleshooting Guide

Condition Possible Cause Solution

Compressor passes

excessive oil (for example,

the presence of oil at

exhaust air brake system

valves, oil in air dryer

desiccant, etc.)

Blocked or restricted oil return Clean oil drain passages in the compressor and on the engine

surface. Verify correct passage alignment.

Contaminated inlet air or oil Replace damaged, defective or dirty engine air filter.

Repair any leaking, damaged or defective compressor air intake

components.

Change engine lubricating oil.

NOTE: To avoid this condition, make sure vehicle manufacturer’s oil

and filter maintenance schedules are followed.

Restricted air inlet or excessive

vacuum present at compressor inlet

Verify engine or compressor air cleaner is functioning correctly.

Replace if necessary.

Repair compressor air inlet kinks or excessive bends.

Check vehicle specifications to ensure air and coolant lines meet all

requirements.

Excessive engine crankcase pressure Verify engine crankcase venting is to manufacturer’s specification.

Compressor duty cycle too high Check system for leaks. Make necessary repairs.

None of the above, but condition

persists

Replace the compressor.

Compressor leaks oil Physical damage or internal problems

with compressor

Replace the compressor.

Compressor continuously

cycles

Compressor unloader piston leaking With compressor unloaded, check for air leakage. If leaking, replace

the cylinder head.

Governor air leak Refer to the manufacturer’s manual for governor maintenance and

troubleshooting procedures.

Dryer purge valve air leakage Check for air dryer malfunction. Refer to air dryer manufacturer’s

service instructions.

Air leak at governor-compressor

attachment

Inspect connection for physical damage. Inspect and repair

connection.

Air leak at alcohol injector Clear line of any obstructions.

Inspect and repair connection.

Excessive reservoir contamination Drain reservoirs.

None of the above, but condition

persists

Replace the compressor.