WACO Classic Aircraft Corporation

YMF WACO F5 SERIES MAINTENANCE MANUAL

REVISION: H Page

2

of

33

RELEASED: 07/21/2017 PART NO. YMFAMM-1

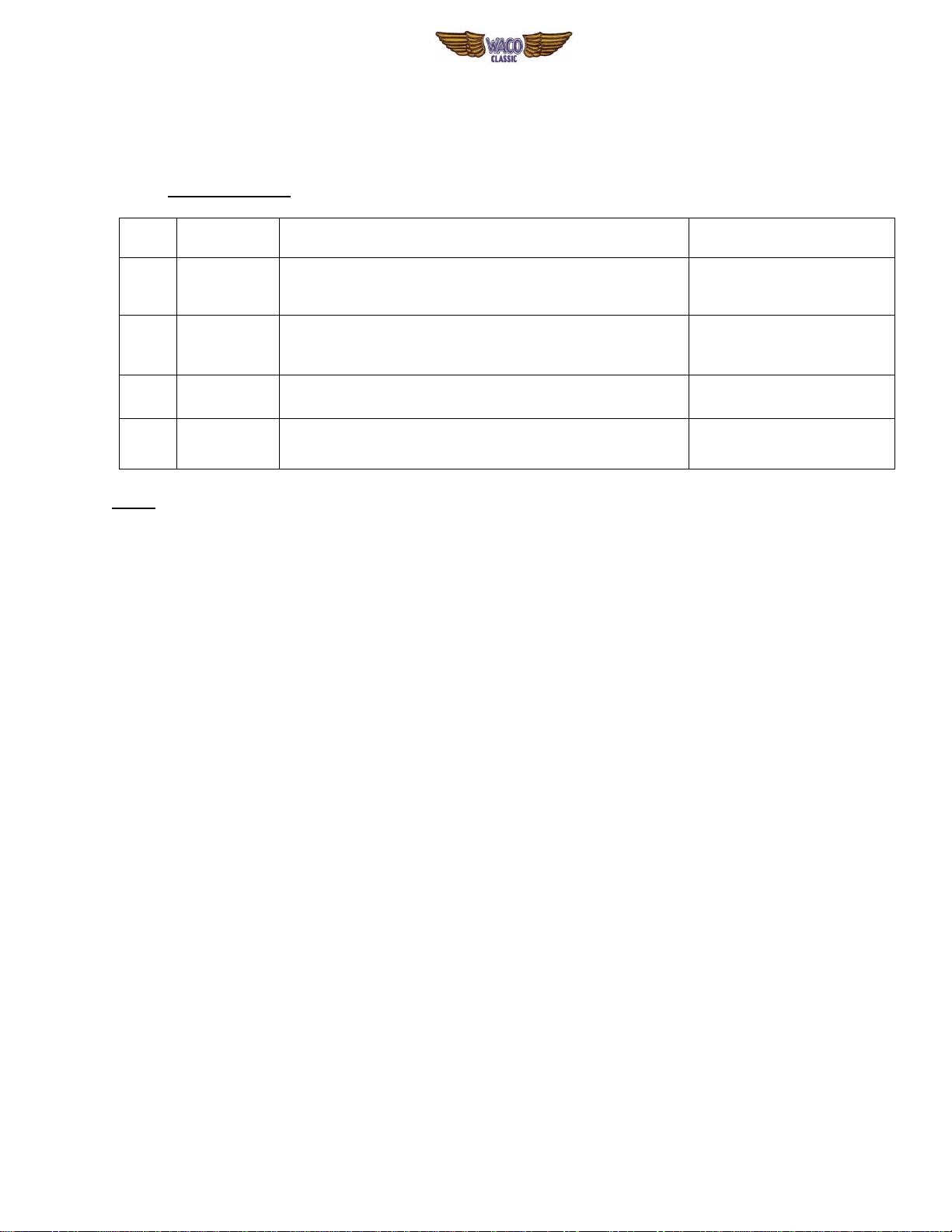

SECTION 2 CONTENTS

2.1 TABLE of CONTENTS

SECTION 1 RECORD of REVISIONS.................................................................................... 1

1.1 REVISION LOG.......................................................................................................... 1

SECTION 2 CONTENTS........................................................................................................ 2

2.1 TABLE of CONTENTS................................................................................................ 2

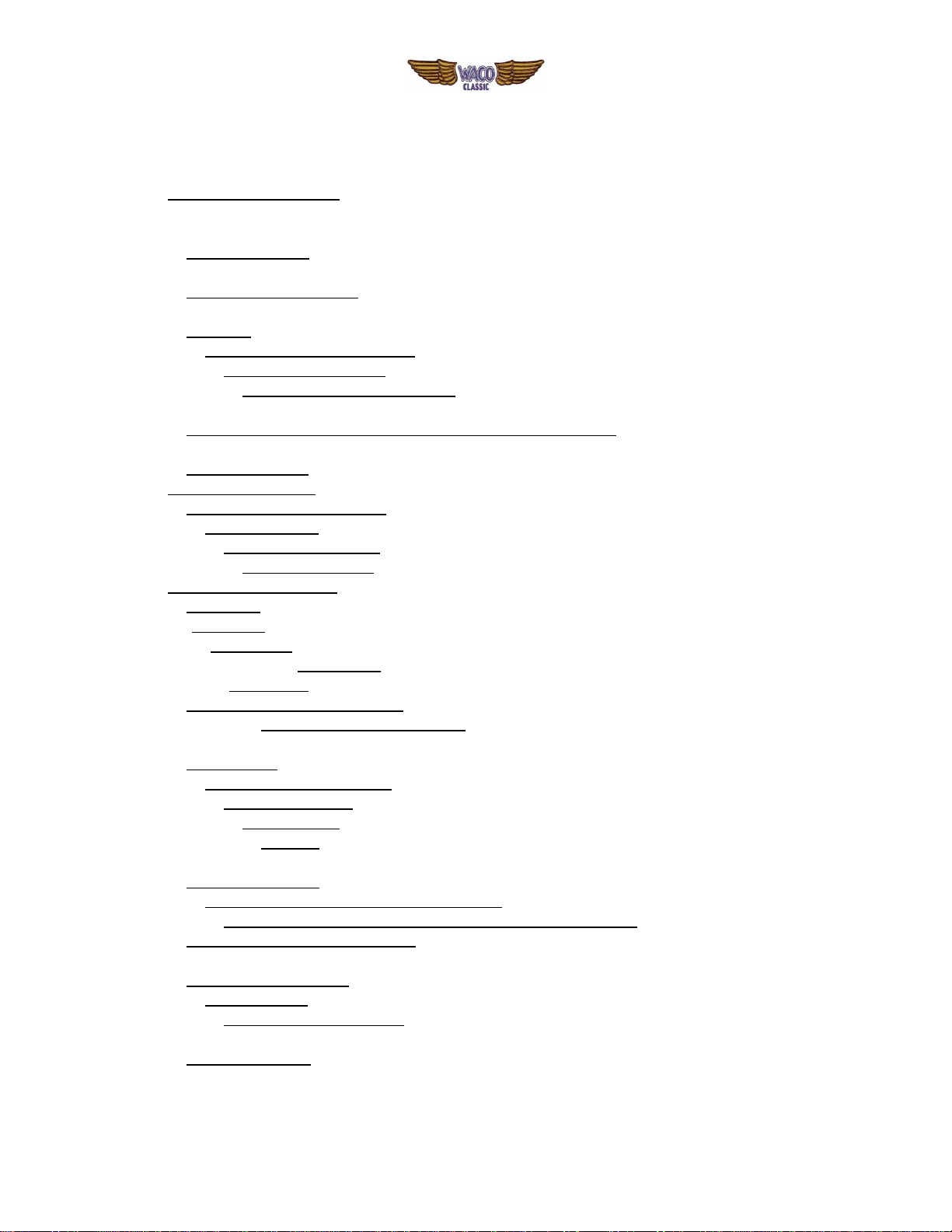

SECTION 3 DEFINITIONS..................................................................................................... 4

3.1 TERMS:...................................................................................................................... 4

3.2 SPECIAL INSTRUCTIONS:.................................................................................... 4

3.3 SERVICE LETTERS:.......................................................................................... 4

3.4 SERVICE INSTRUCTIONS:............................................................................ 4

SECTION 4 INTRODUCTION ................................................................................................ 5

4.1 INSTRUCTIONS FOR CONTINUED AIRWORTHINESS:........................................... 5

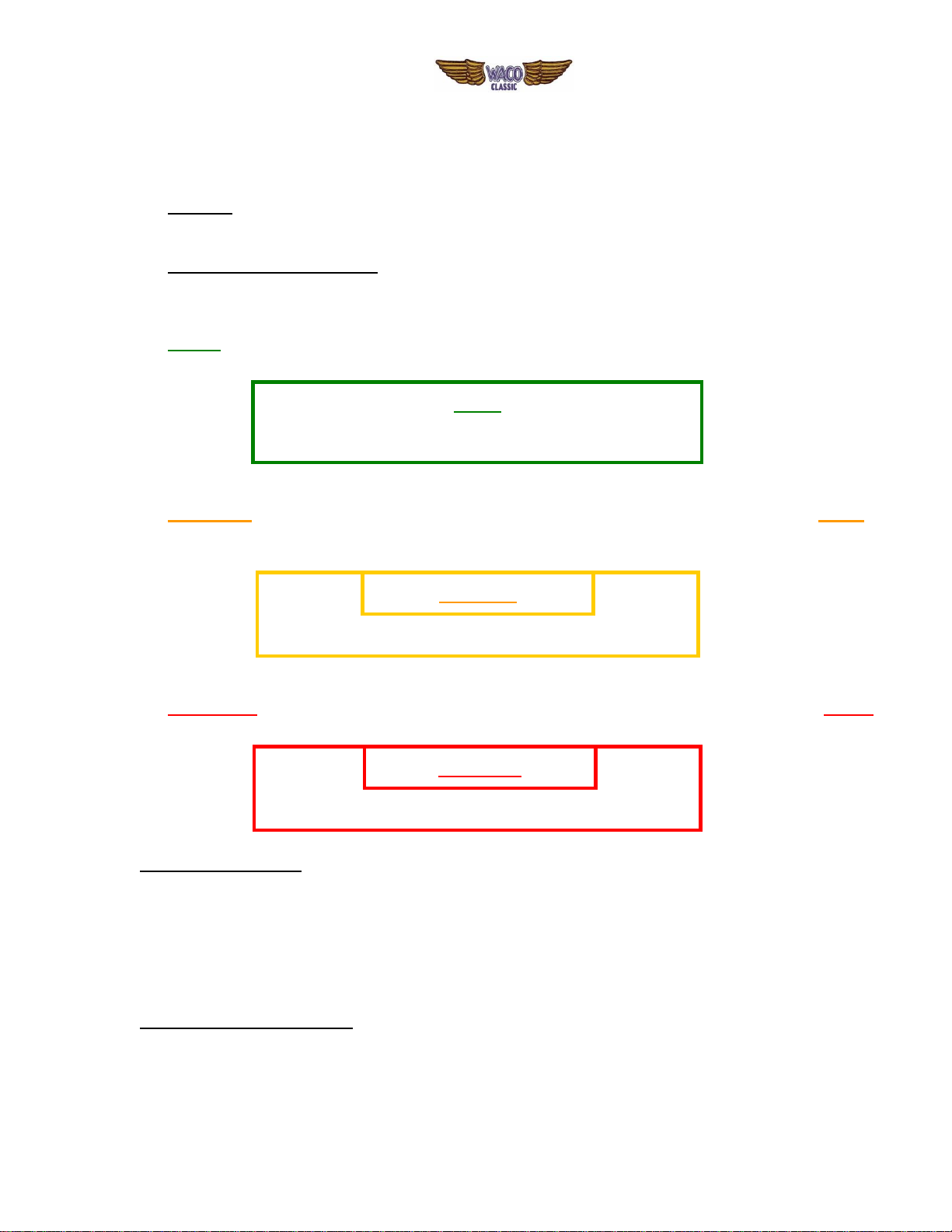

SECTION 5 GENERAL:.......................................................................................................... 6

5.1 DESCRIPTION:.......................................................................................................... 6

5.2 SPECIFICATIONS:......................................................................................................... 7

5.2.1 MODEL DESIGNATIONS:.......................................................................................... 7

5.2.2 DIMENSIONS:........................................................................................................ 7

5.2.3 FLUID CAPACITIES:.......................................................................................... 8

5.2.4 FLUID GRADES: ............................................................................................ 8

5.3 GROUND HANDLING.................................................................................................... 8

5.3.1 MOVING:.................................................................................................................... 8

5.3.2 TAXIING:................................................................................................................... 9

5.3.3 PARKING:............................................................................................................11

5.3.4 MOORING..........................................................................................12

5.3.5 JACKING:.........................................................................................................12

WEIGHING THE AIRPLANE .....................................................................................12

5.3.6 CARE OF THE AIRPLANE.........................................................................14

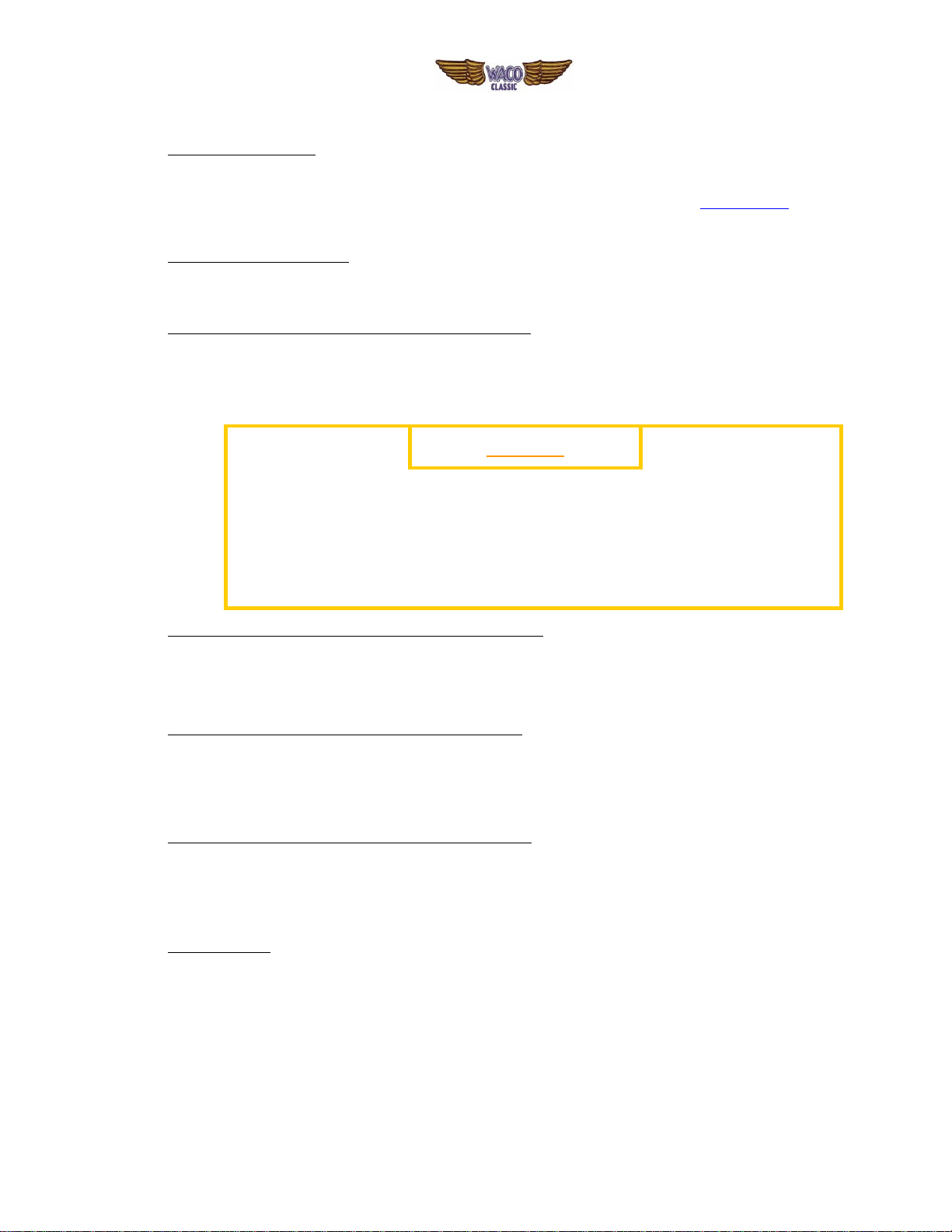

SECTION 6 AIRFRAME........................................................................................................15

6.1 FUSELAGE...............................................................................................................15

6.2.1 INSPECTION PERIODS........................................................................................15

6.2 LANDING GEAR................................................................................................19

6.3 EMPENAGE...................................................................................................20

6.4 WINGS.......................................................................................................21

SECTION 7 POWERPLANT..................................................................................................23

7.1 ENGINE COWLS.......................................................................................................23

7.2 ENGINE REMOVAL & INSTALLATION.................................................................23

7.4 COMPRESSION TESTING OF ENGINE CYLINDERS:.....................................28

PROPELLER INSTALLATION...................................................................................29

SECTION 8 SYSTEMS..........................................................................................................31

8.1 GASOLINE SYSTEM.................................................................................................31

8.2 OIL SYSTEM.........................................................................................................31

8.3 ELECTRICAL SYSTEM.....................................................................................31

SECTION 9 AIRWORTHINESS LIMITATIONS .....................................................................32

9.1 APPLICABILITY ........................................................................................................32

SECTION 10 MISCELLEOUNEOUS MAINTENANCE INFORMATION...............................33

A. WCAC FORM SMWS SCHEDULED MAINTENANCE WORKSHEET...........................33