Safety Precautions

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL,

MAINTAIN AND REPAIR ELECTRICAL REFRIGERATION EQUIPMENT, WHO SHOULD

PERFORM THE INITIAL FIELD STARTUP AND ADJUSTMENTS OF THE EQUIPMENT

COVERED BY THIS MANUAL.

READ THIS MANUAL THOROUGHLY BEFORE OPERATING, INSTALLING, PERFORMING

MAINTENANCE ON, OR REPAIRING THE EQUIPMENT.

WARNING Failure to follow all the instructions in this manual can cause property

damage, injury or death.

WARNING Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury or death.

WARNING Electrical connections should be performed only by a certified professional.

Electrical and grounding connections must comply with the applicable portions of the

National Electric Code and/or all local electric codes. Failure to comply with this

procedure can cause property damage, injury or death.

WARNING Before connecting the unit to the electrical supply, verify that the electrical

and grounding connections comply with the applicable portions of the National Electric

Code and/or other local electrical codes. Failure to comply with this procedure can

cause property damage, injury or death.

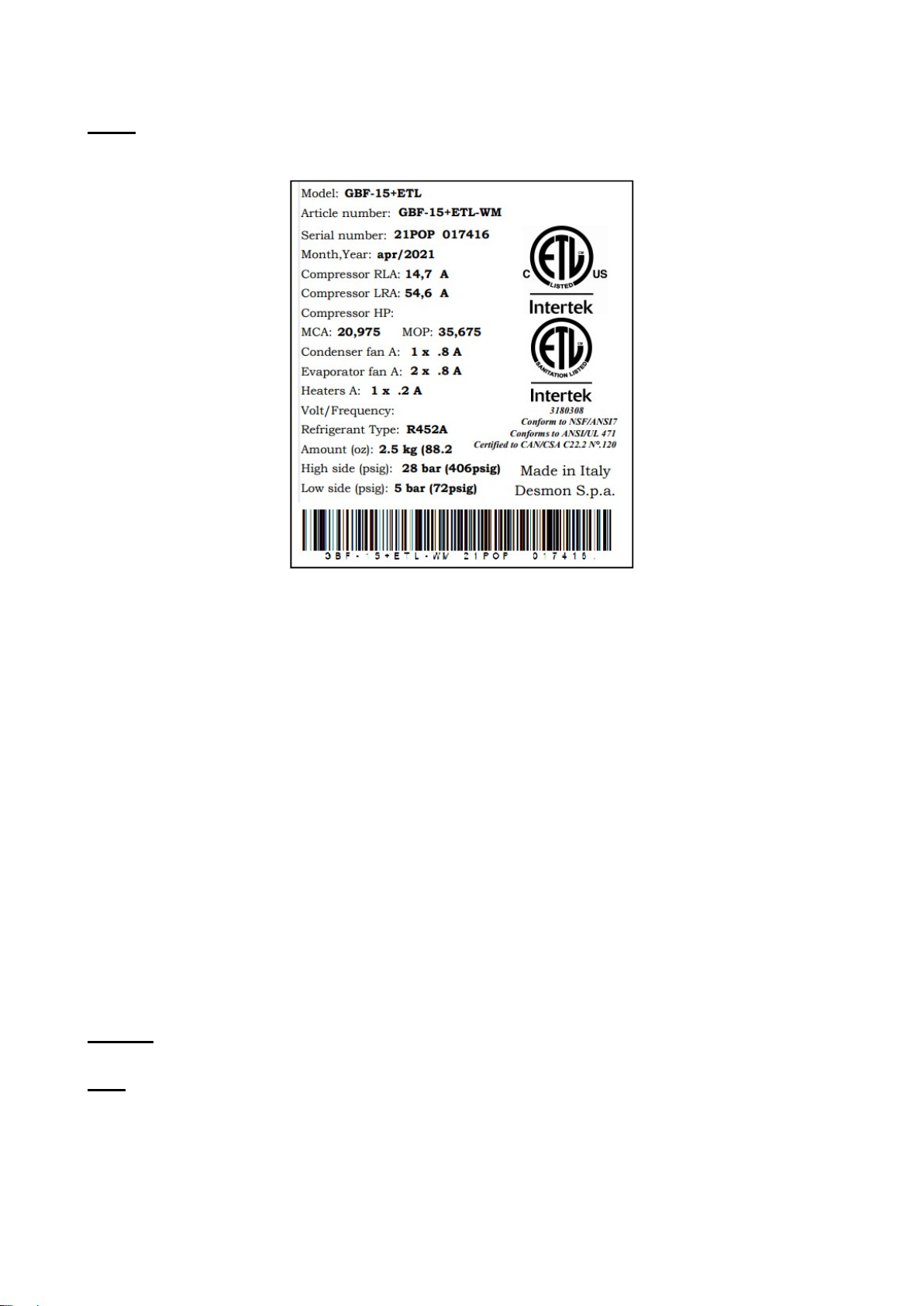

WARNING Before connecting the unit to the electrical supply, verify that the electrical

connection agrees with the specifications on the data plate. Failure to comply with this

procedure can cause property damage, injury or death.

WARNING Appliance must be connected to a grounded, metal, permanent wiring

system. Or an equipment-grounding conductor must be run with the circuit conductors

and connected to the equipment-grounding terminal or lead on the appliance. Failure to

comply with this procedure can cause property damage, injury or death.

WARNING Appliances equipped with a flexible electric supply cord, are provided with a

three-prong grounding plug. It is imperative that this plug be connected into a properly

grounded three-prong receptacle. Failure to comply with this procedure can cause

property damage, injury or death.

WARNING If the receptacle is not the proper grounding type, contact an electrician. Do

not remove the grounding prong from the plug. Failure to comply with this procedure

can cause property damage, injury or death.

WARNING Before performing any service that involves electrical connection or

disconnection and/or exposure to electrical components, always perform the Electrical

LOCKOUT/TAGOUT Procedure. Disconnect all circuits. Failure to comply with this

procedure can cause property damage, injury or death.