S8VK-X

6

Standards

• EMI (radiated emissions) conform to Class B when this Power Supply is installed in a control panel.

• EN/IEC 61558-2-16

The S8VK-X was designed based on EN/IEC 61558-2-16.

Currently, IEC 61558-2-17 has been replaced by IEC 61558-2-16.

When certification was received for EN/IEC 60204-1 (Machinery Safety), it was necessary to go through a control transformer to the control

circuits. However, a control transformer is not always necessary for product that have been certified for the safety standard for OVCIII or for

product that use a transformer that conforms to EN/IEC 61558-2-16.

• Safety Standards for a DC Input

When DC is used, UL 60950-1, UL 62368-1, cUR (CSA 22.2 No. 60950-1), cUR (CSA C22.2 No. 62368-1), EN/IEC 60950-1, EN/IEC 62368-

1, EN 50178 and EN/IEC 61558-2-16 are applicable to safety standards.

Safety standard compliance is achievable by connecting a UL-certified fuse as specified below.

Select an external fuse that satisfies the following conditions:

S8VK-X03005-EIP, S8VK-X06012-EIP, S8VK-X06024-EIP (350 VDC or more, 6 A)

S8VK-X09024@-EIP, S8VK-X12024@-EIP, S8VK-X24024@-EIP (350 VDC or more, 8 A)

S8VK-X48024@-EIP (350 VDC or more, 12 A)

• To comply with PELV output requirements for EN/IEC 60204-1, ground the negative side of the output (-V) to a protective earth (PE).

Definitions of the Terms Under Ratings, Characteristics, and Functions

Standards

Harmonic current

emissions Conforms to EN 61000-3-2

EMI

Conducted

emissions Conforms to EN 61204-3 Class B, EN 55011 Class B

Radiated

emissions Conforms to EN 61204-3 Class B, EN 55011 Class B

EMS Conforms to EN 61204-3 high severity levels

Safety standards

UL 508, ANSI/ISA 12.12.01 (Listing) (For 30 W, 60 W, and 90 W only Class 2 Output: Per UL 1310)

CSA C22.2 No. 107.1, CSA C22.2 No. 213 (cUL) (For 30 W, 60 W, and 90 W only Class 2 Output: Per CSA C22.2 No. 223)

UL 60950-1, UL 62368-1 (Recognition) OVC II (≤3000 m) Pol2 (For 30 W, 60 W, and 90 W only LPS)

CSA C22.2 No. 60950-1, No. 62368-1 (cUR) OVC II (≤3000 m) Pol2 (For 30 W, 60 W, and 90 W only LPS)

EN 50178 OVC III (≤2000 m) OVC II (2000 m < and ≤3000 m) Pol2

EN 60950-1, EN 62368-1 OVC II (≤3000 m) Pol2 (For 30 W, 60 W, and 90 W only LPS)

EAC (TR CU 004 / 2011, TR CU 020 / 2011)

RCM (EN61000-6-4)

Korea Radio Waves Act (Law No. 10564)

Conforms to PELV (EN/IEC 60204-1)

Conforms to EN/IEC 61558-2-16

SEMI Conforms to F47-0706 (200 to 240 VAC input)

Input

conditions

Efficiency The value is when both rated output voltage and rated output current are satisfied.

Voltage range Do not use an inverter output for the product. Inverters with an output frequency of 50/60 Hz are available, but the

rise in the internal temperature of the product may result in smoking or burning. If the input is connected to a UPS,

do not connect a UPS with a square-wave output. Doing so will cause the internal temperature of the product to

increase, possibly causing smoking or burning.

Frequency

Input current The value is when both rated output voltage and rated output current are satisfied.

Leakage current The value is determined according to the Electrical Appliances and Material Safety Act.

Inrush current Values for a cold start at 25°C.

Refer to Inrush Current, Startup Time, and Output Hold Time on page 7 for details.

Output

characteristics

Voltage adjustment range

If the output voltage adjuster (V. ADJ) is turned, the voltage will increase by more than of the voltage adjustment

range.

When adjusting the output voltage, confirm the actual output voltage from the product and be sure that the load is

not damaged.

Ripple noise voltage The value is when both rated output voltage and rated output current are satisfied.

A characteristic when the ambient operating temperature is 25°C.

Static input variation

influence

This is the maximum variation in the output voltage when the input voltage is gradually changed within the allowable

input voltage range at the rated output voltage and rated output current.

Load variation influence 100 to 240 VAC input, in the range of 0 A to the rated output current.

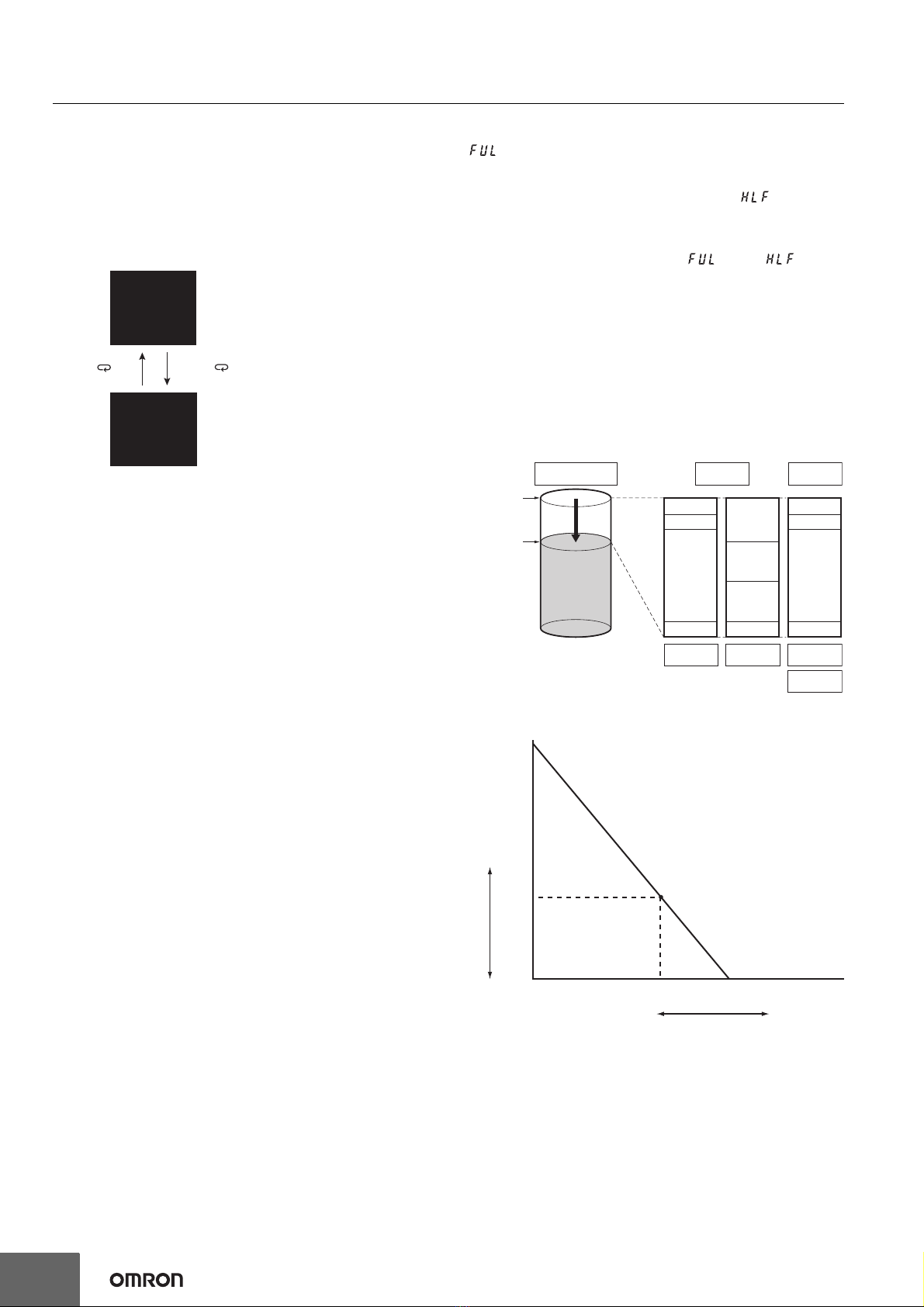

Startup time

The value is when both rated output voltage and rated output current are satisfied and at room temperature (25°C).

Refer to Inrush Current, Startup Time, and Output Hold Time on page 7 for details.

Hold time

The value is when both rated output voltage and rated output current are satisfied and at room temperature (25°C).

Refer to Inrush Current, Startup Time, and Output Hold Time on page 7 for details.

Environment Ambient operating

temperature

At -40 to -25°C, time will be required before the rated output voltage is output after the input voltage is input. Also,

the ripple noise value may exceed the value shown in the above table.

Reliability MTBF

MTBF is calculated according to JEITA RCR-9102.

MTBF stands for Mean Time Between Failures, which is calculated according to the probability of accidental device

failures, and indicates reliability of devices.

Therefore, it does not necessarily represent a life of the product.

Life expectancy

Refer to Recommended Replacement Periods and Periodic Replacement for Preventive Maintenance on page 27 for details.