Thanks for purchasing this

Cornerstone Series®Kit. Please

take a few minutes to read these

instructions and study the draw-

ings before starting construction.

All parts are made of styrene, so

use compatible paint and glue to

finish your model.

For thousands of years, natural

obstacles such as rivers and val-

leys prevented humans from trav-

eling easily. In ancient times, we

used natural bridges or created our

own from fallen logs, piles of

stones, or by twisting natural

materials together. These three

starting points were the founda-

tion for the beam, arch and sus-

pension bridges of today.

Over time, the art and science of

bridge building continued to

evolve. With the rise of the

Roman Empire and its extensive

road system, bridge building took

on a new importance across

Europe. During this time, engi-

neers made significant advances

including the development of the

masonry arch and the use of natu-

ral cement. During medieval

times, bridges were often con-

structed by religious orders, often

incorporating shops and fortifica-

tions in their designs. By the

Renaissance, advances in mathe-

matics led to improved truss and

arch designs, and a better under-

standing of the workings of pil-

ings and supports. In this period,

bridges were designed with more

attention to how they fit the ideal

of a city scene, with more atten-

tion to visual and artistic details.

While iron had been used in a

very limited way since ancient

times, it became available in large

quantities for the first during the

late 18th century. Engineers had a

new and durable material with

which to work, and iron bridges

began to appear. With its

increased load-bearing ability, iron

was also adapted to the heavier

bridges required by the new rail-

roads.

But iron had its limita-

tions and by the late 19th century,

steel was taking over as the

material of choice, especially for

railroad bridges that had to sup-

port heavier trains.

At the same time, advances in

concrete and cement technology

made it increasingly popular as a

building material for both founda-

tions and bridges. Engineers soon

found that pouring concrete over a

skeleton of iron screen, rods or

bars increased the strength of the

finished design and allowed for a

variety of shapes and forms. On a

larger scale, this “reinforced con-

crete” became increasingly com-

mon as a material for new bridges.

As America began shifting from

horses to horsepower, a new gen-

eration of highway bridges

appeared. Increasing volumes of

trucks and automobiles presented

problems for bridges built to carry

horses and carriages in cities, as

major routes became increasingly

congested. And as the highway

system expanded into rural areas,

older wooden bridges had to be

replaced. During the 1920s and

30s, many of these older bridges

were replaced as state and federal

projects. These combined ancient

ideas such as the arch with mod-

ern technology to produce

durable, attractive structures.

Many of these bridges remained

in use for decades, until outdated

by newer safety standards,

increasing volumes of traffic and

old age. On less traveled routes,

some survive today.

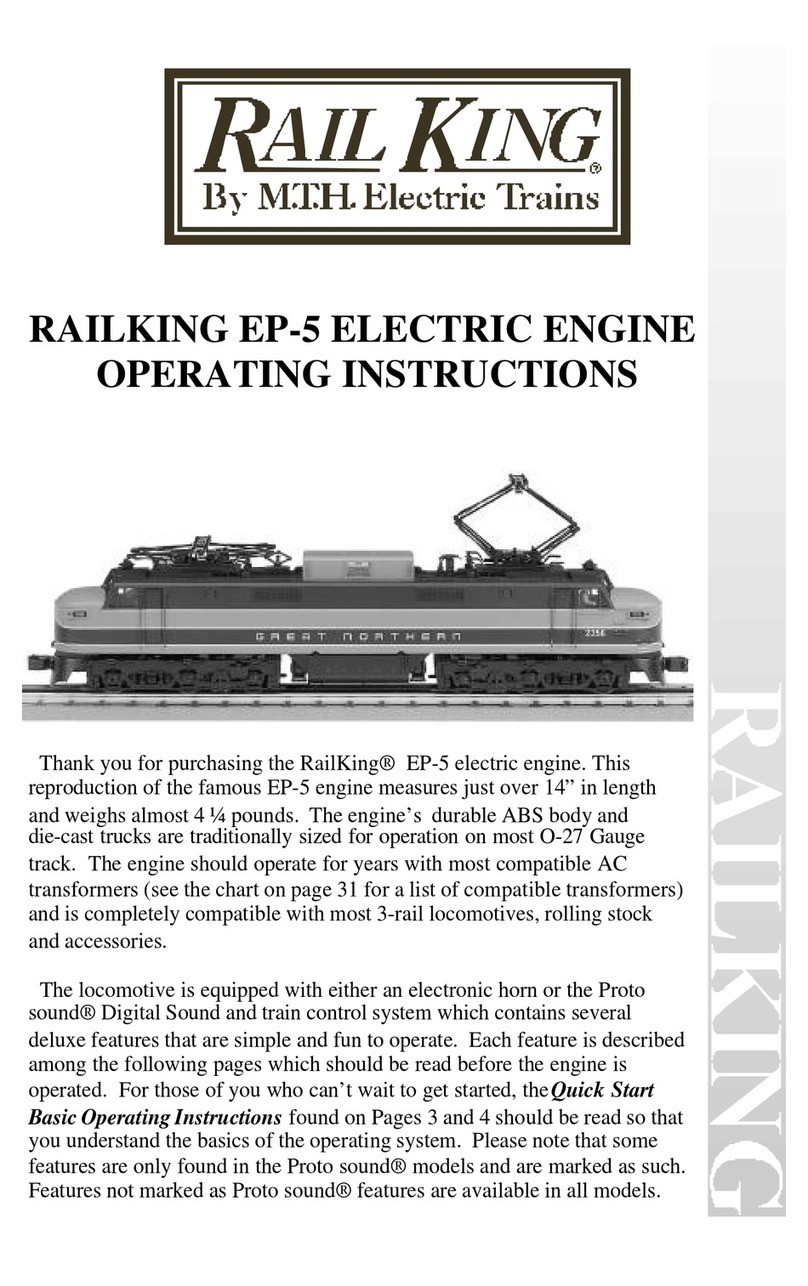

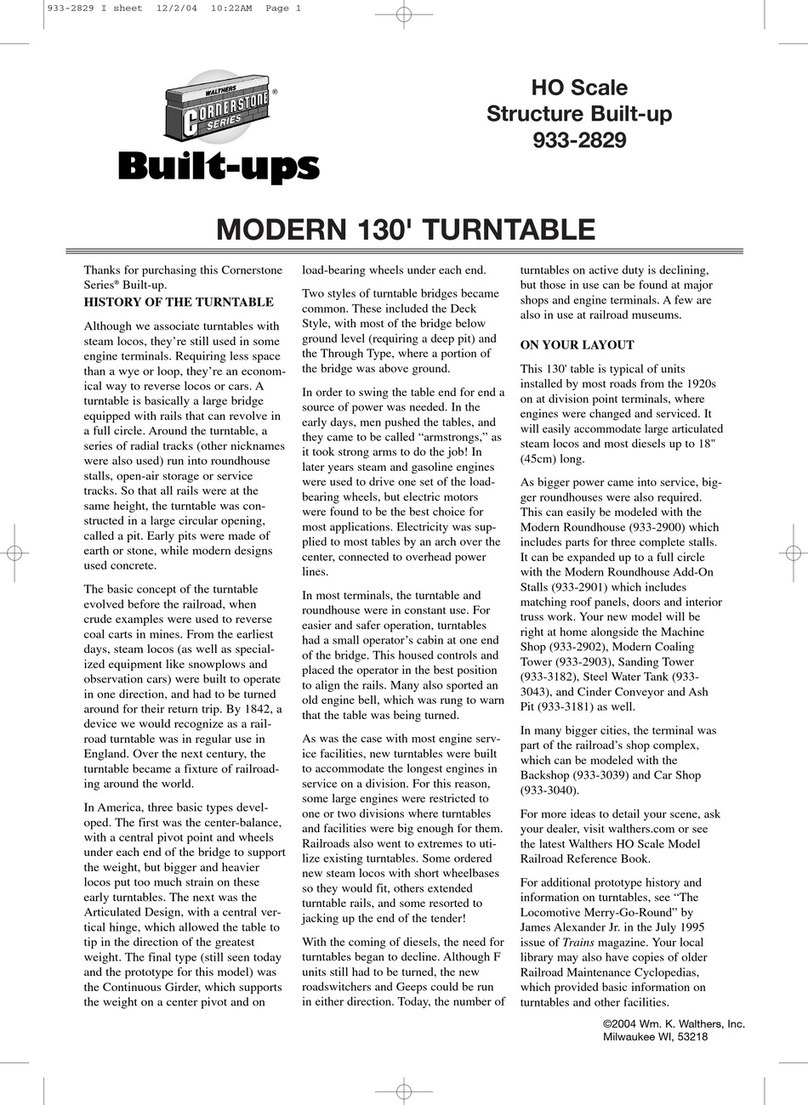

ON YOUR LAYOUT

Perfect for any highway from the

1920s to the present, this single

arched, concrete bridge is typical

of those built all over America.

Handling traffic above and below,

bridges like this were often con-

structed in areas where existing

intersections were creating bottle-

necks and safety hazards.

Both the deck and the lower level

are designed for use with any of

Walthers Cornerstone Series

Street Systems components,

which are available to model

brick, concrete or asphalt streets

to fit a wide range of modeling

eras. You can also set the time and

place of your street scene quickly

and easily with the many styles of

Cornerstone Series Built-Ups

Street Lamps (#933-1080 and

#933-1090 series).

HO Scale Kit

ARCHED ROAD BRIDGE

933-3196

For additional figures, vehicle and

accessories to set the scene, see

your dealer, check out the lastest

Walthers HO Scale Model Railroad

Reference book or visit our Web site

at waltherscornerstone.com for

more ideas.

© 2012 Wm. K. Walthers, Inc., Milwaukee, WI 53218 waltherscornerstone.com I-933-3196