HO Structure Kit

BLAST FURNACE

933-4600

© 2020 Wm. K. Walthers, Inc., Milwaukee, WI 53218 waltherscornerstone.com I-933-4602 Printed In China

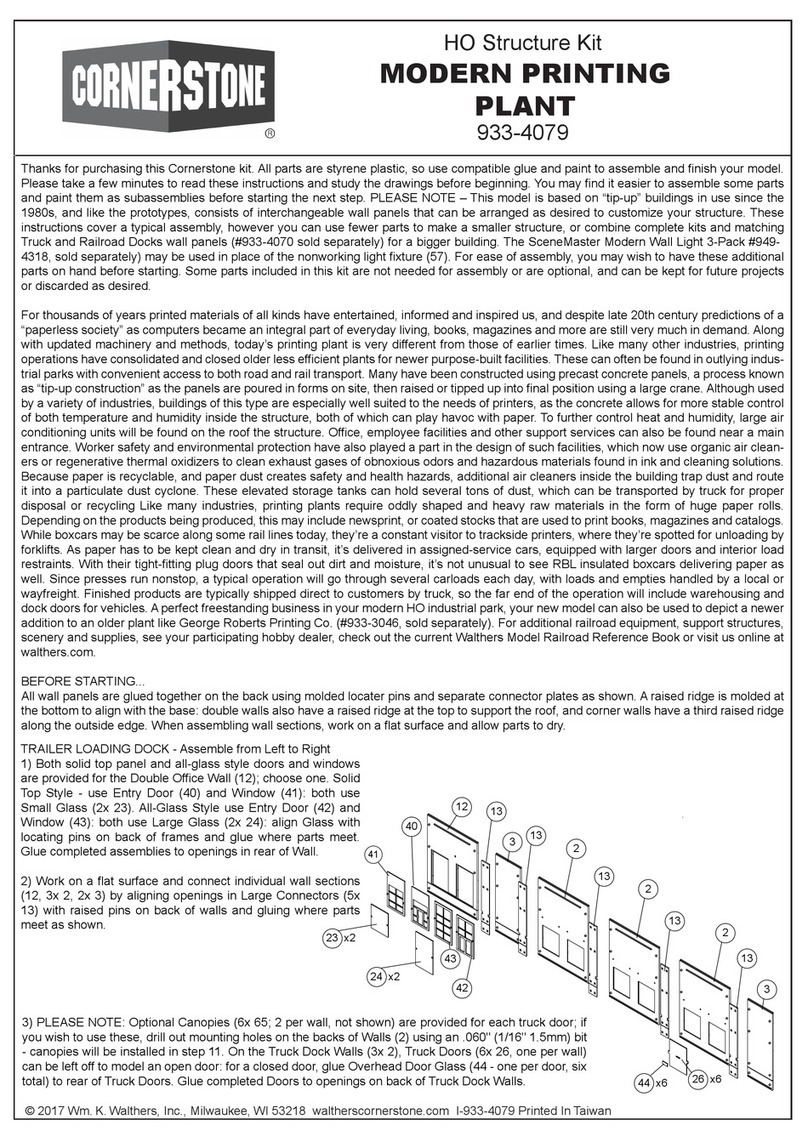

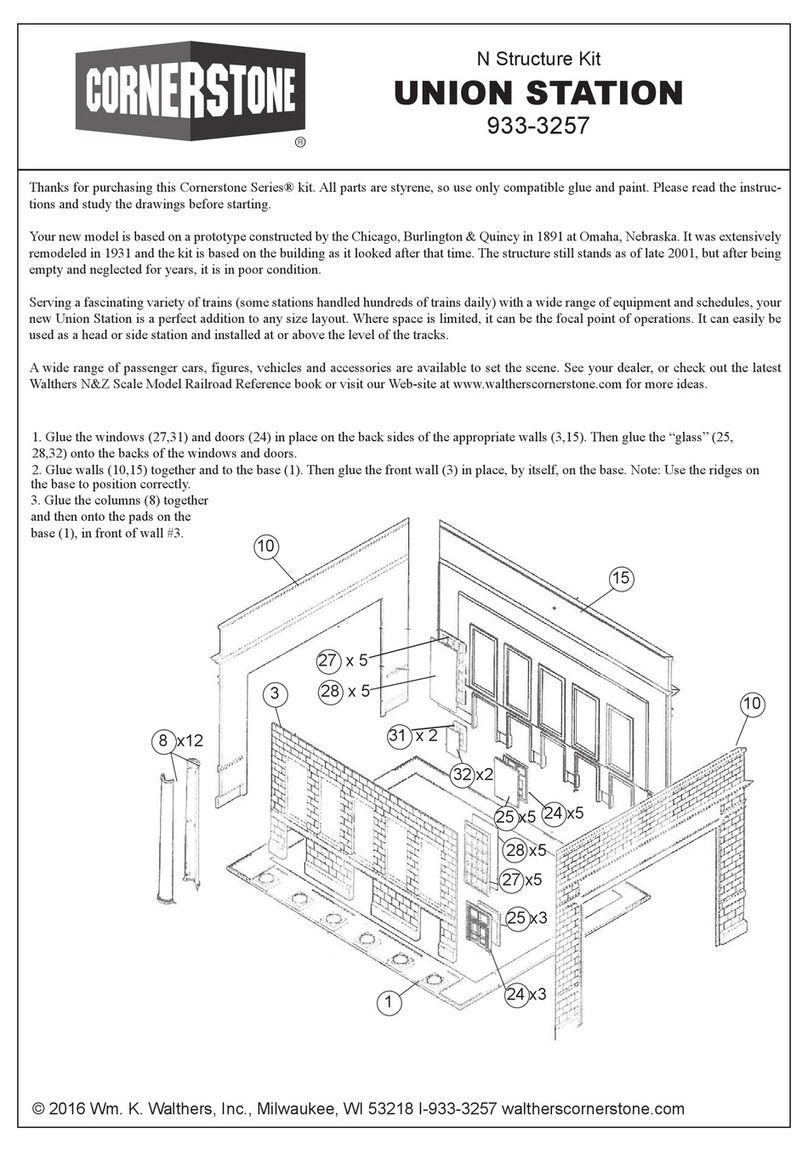

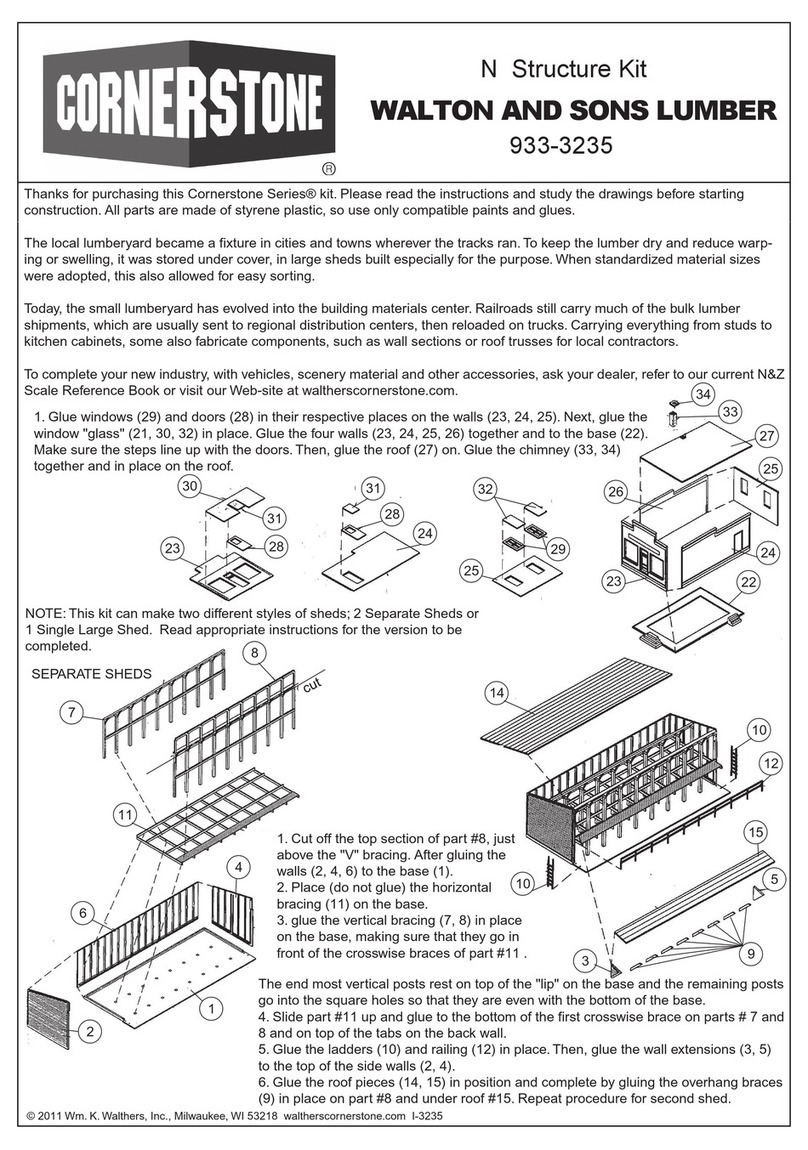

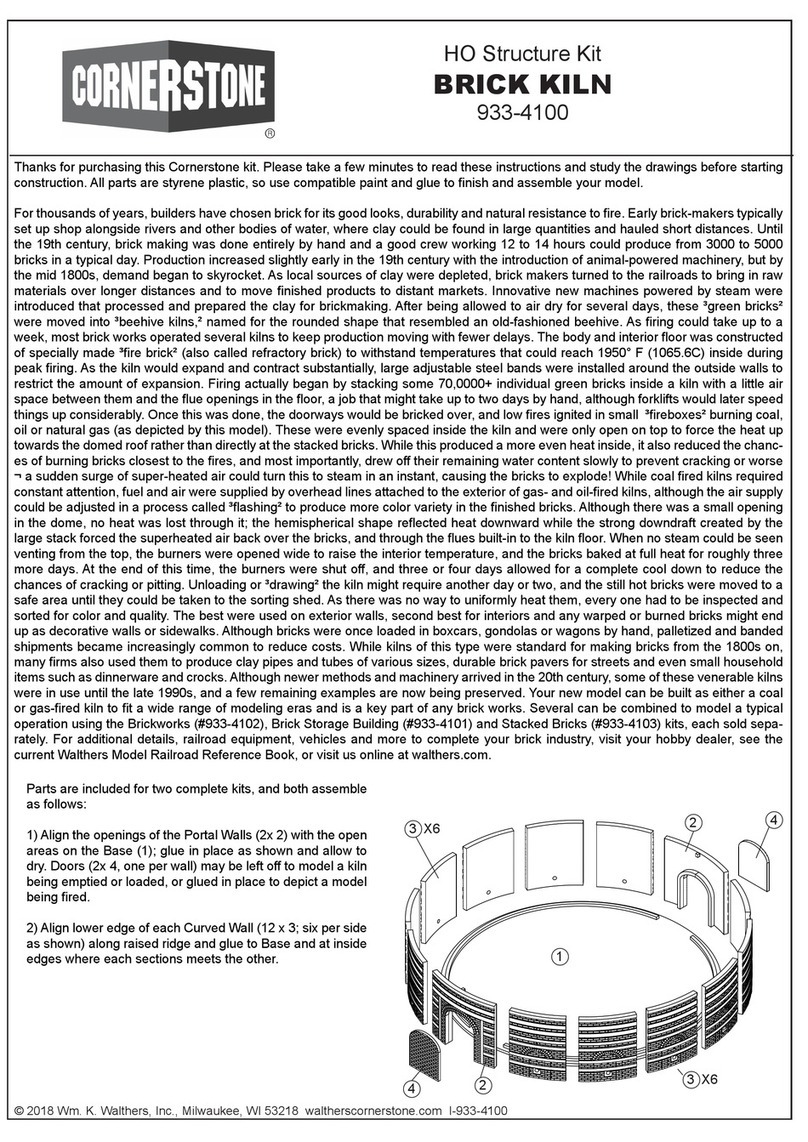

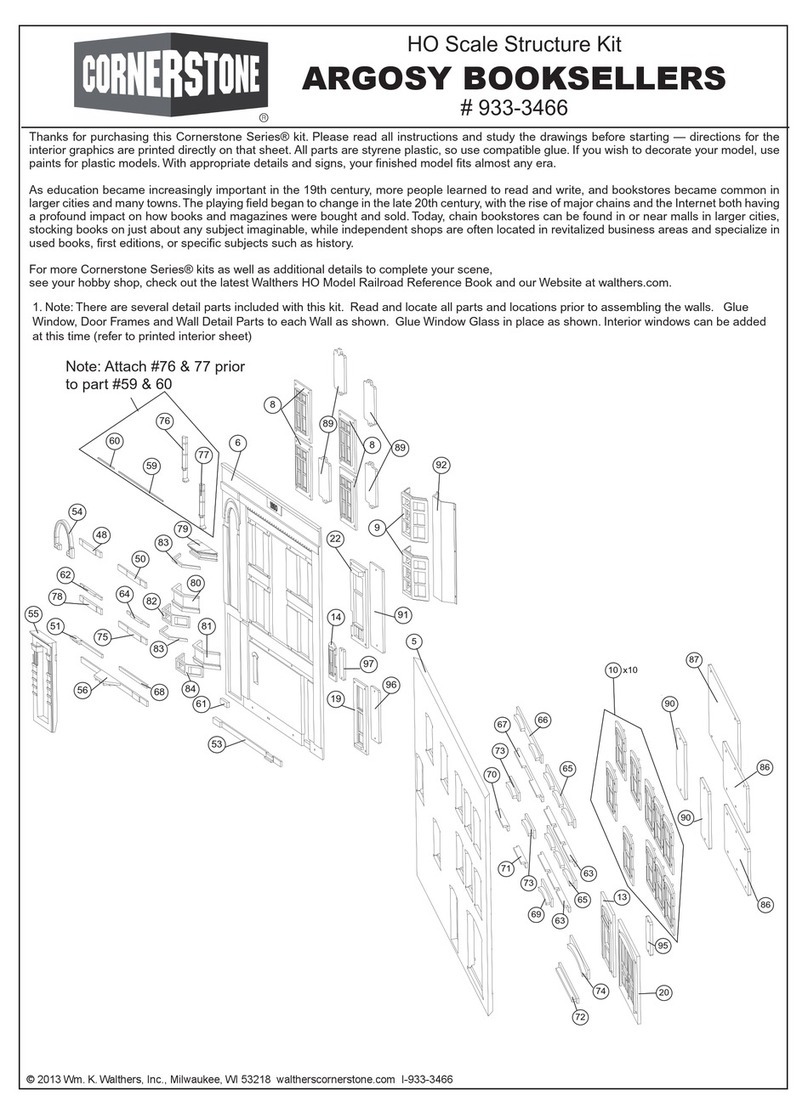

Thanks for purchasing this Cornerstone® kit! Please take a few minutes to read the instructions and study the drawings before

starting each step. While this is a large kit, each step can be completed in stages: work slowly and highlight or check off each

completed assembly sequence. All parts are made of styrene, so use only compatible glue and paint to assemble and finish your

model. You may find it easier to build and paint some parts as subassemblies before moving on to the next step. PLEASE

NOTE: Most individual part numbers are molded on sprues, however some sprues have been trimmed; please refer to illustra-

tions to properly identify parts.

While no other structure is so closely associated with a steel works, blast furnaces actually produce “pig iron.” Named for an

early casting method resembling a mother pig nursing little ones molten iron flowed into a large main trench called the “sow,”

then into several smaller trenches, where it cooled to form “pigs.” Once charged and “blown in,” the furnaces run non-stop at

temperatures up to 3500°F (1926.7°C). Each ton of pig iron produced requires about three tons (2.7t) of raw materials: nearly

two tons (1.8t) of ore, about 1500 pounds (0.6804t) of coke and the rest in fluxing stone (usually limestone or dolomite), plus a

few hundred pounds of iron and steel scrap. Finally, four (3.6t) to four-and-one-half tons (4.0t) of air will be consumed. For every

ton of iron, 700 pounds (317k) of slag (a lava-like material reclaimed for sale to the construction industry) and six tons (5.4t) of

gases are produced. And since part of the charge is always melting, voids are created that have to be refilled constantly.

Meeting this voracious appetite is the job of the ore yard, where huge quantities of raw materials arrive by boat (ore carriers,

despite their size, are known as “boats” on the Great Lakes) and rail. Materials are transported from here to the furnaces in older

open hopper cars and ore jennies on an elevated stretch of two or three parallel tracks known as the “highline.” Running behind

the furnace, the tracks span storage bins where coke, scale, scrap, dolomite, ore and limestone are kept ready.

Raw materials for the charge (or burden) enter the furnace through the top via conveyors at newer facilities, or in a pair of

wheeled carts called skip cars fed by a bridge crane, that constantly ride up and down on steeply pitched rails. As one skip

loads, the other is emptied at the top.

The “blast” in a blast furnace comes from the blowing engine house; here giant air compressors pressurize the cold blast main,

a huge pipe feeding air into three or more heated and refractory-lined stoves to raise the temperature to 1800°F (982.2°C). This

superheated air is fed under pressure into the furnaces via a bigger pipe known as the hot blast main. So there’s a constant

supply of air available, the process rotates through each stove with one on blast, one heating and one on standby.

Once combustion begins, the hot air blast forces the coke in the charge to burn faster producing more heat, and large amounts

of carbon monoxide and other reducing gases that are also burned. For each ton of iron, there may be 100 to 300 pounds (100-

136k) of flue dust suspended in this gas, which is rich in iron and coke particles and reclaimed for use. This begins at the top of

the furnace, where four offtakes resembling huge upside down slingshots converge into a single downcomer. This feeds gas

into a dust catcher, capturing large dry particles like a vacuum cleaner in a holding bin. The gas then passes through sprays of

water inside a gas washer and a precipitator to capture progressively smaller particles, with the resulting slurry pumped to a

settling operation, where solids settle to the bottom. From here, the dust and slurry are sent to a sintering plant (dust in old

covered hoppers, slurry via pipelines) where it’s pressed into large pellets that are sent back to the furnaces.

The heart of the furnace is the hearth at the bottom, where molten iron and slag collect. Two or three hours before the iron is

tapped, slag is drawn off. More will be removed about an hour before the cast, and the balance is tapped with the iron. When

the iron is ready, a clay plug in the bottom of the hearth is drilled open. Molten iron then flows into a refractory-lined iron runner

on the floor of the cast house, essentially a large covered platform with open sides and ends to dissipate heat, and into smaller

runners loading hot metal cars for the trip to the converters, where the impurities will be burned out to create molten steel, or

slag cars which dump their loads in an open pit some distance away.

The centerpiece of your steel works, you can easily model a complete operation with the Blowing Engine House with Piping

Extensions (#933-4602), along with the WalthersProto® Hot Metal Bottle Car 2-Packs (#920-107900 Gray or #920-107901

Rust) and Slag Car 2-Packs (#920-1079010 Gray or #920-107911 Rust) and Bridge Crane (#933-2906). For more models,

photos and information on Walthers Steel Series, visit your participating hobby shop, see the latest Walthers Model Railroad

Reference Book or visit us online at walthers/products/steel-series.

PLEASE NOTE: As individual part numbers are molded on a sprue that has been trimmed , please

refer to the illustrations to properly identify parts.