• Flip the direction switch after

you

hear the Short Air Let-off

but

before

you

hear the

Long

Air Let-off followed

by

Air Pump sounds turning

on.

During this short t

ime

(3

seconds) the

Horn

will not blow when

you

flip the direction switch.

• Turn

up

the throttle anytime thereafter

to

operate the locomotive

in

the opposite

direction.

If you have waited until the Air Pumps start

in

Neutral and now wish to change direction,

you can either:

1.

Reduce

th

ethrottle

to

off,

change the direction switch

and

turn

the

throttle back

up

to

repower the locomotive

or,

2.

Leave the locomotive

in

Neutral, flip

the

direction switch (the

Horn

will

come

on)

and

then turn

up

the throttle.

Note: When the

locomotive

starts to

move

in the opposite direction, the Horn will

stop

automatically

and

then hoot one more time

if

the direction is Forward for a total

of

two

hoots.

Or

if

the direction is Reverse, the Horn will hoot two more times for a total

of

three

hoots7•

To

prevent the first Horn hoot from being too long, do not delay

in

turning up the

throttle afteryou have flipped the direction switch.

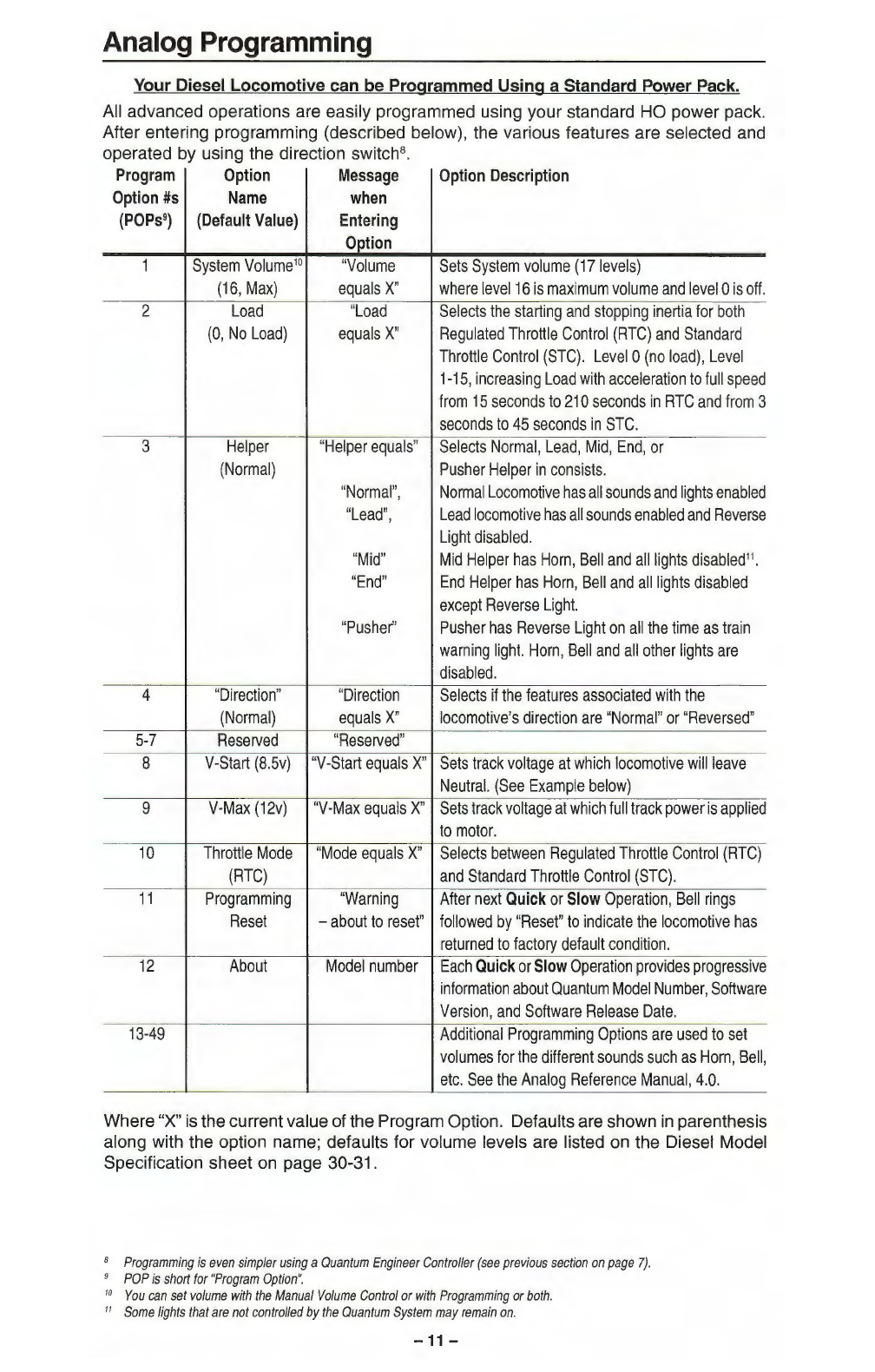

Train Load

You can set your diesel locomotive to have any of

16

different Load levels, which

represent added inertia from rolling stock (see Analog Programming, Option 2

on

page

11

).

The higher the Load setting, the greater the inertia effect during acceleration and

deceleration. Level O

is

the default, which

is

no

Load.

Sound-of-Power™

During acceleration, Diesel Motor sounds will produce heavy labored sounds (based

on

Load setting) until the locomotive has achieved its final speed where it will then

produce standard sounds appropriate to its throttle setting. Under deceleration, the

Diesel Motor sounds are less labored until

it

achieves its final speed where it will again

produce standard Diesel Motor sounds appropriate to its throttle setting.

Helpers

Prototype Helpers are locomotives that are used to provide extra power and/or braking

for a heavily loaded train. The Quantum System allows you

to

easily program how

each locomotive will behave by selecting between a Lead locomotive, Mid Helper,

End Helper, or Pusher. Each type of Helper locomotive has different lights and sounds

enabled or disabled, as described

in

the table under Option

3,

in

Analog Programming,

page

11.

Normal and Reversed Direction

Quantum also allows you to reverse the directional sense of your locomotive. This

is

normally not

an

issue with

DC

two-rail trains since all locomotives will go

in

the same

direction whether they are facing forwards or backwards. However, certain features

like Directional Lighting or diesel Low Idle do depend

on

the directional sense. When

making

up

a train with different Helper types, it

is

recommended that you also change

the directional sense of any Helper that

is

intended to

be

operated backwards within

the consist. See "Option 4 Direction

",

Analog Programming, page

11

.

Additional Analog Operation Features Available with the Quantum Engineer™

Controller

Your Quantum diesel locomotive

is

equipped wi

th

QSl's QARC™ (Quantum Analog

Remote Control) Technology. QARC Technology uses special remote control signals

to operate various Quantum System features without the need for complicated and

expensive digital systems. With QARC technology, you can operate features that are

otherwise available only

in

Digital Command Control (DCC), plus some new features

that are not yet available

in

DCC. QARC will allow you to:

1)

turn

on

or off individual

lights, 2) shut down and start

up

locomotives,

3)

make

up

consists easily,

4)

simplify

Analog programming,

5)

set System Volume or Mute while train

is

operating,

6)

trigger

Coupler Crash sounds,

7)

operate prototype-like Air Brakes,

8)

turn

on

Dynamic Brakes,

9)

activate Status or Speed Reports and operate many other features. The QARC

System makes Analog operation more fun and more prototypical than DCC by

7

Standard

US

prototype

railroad

signaling

is

two

hoots

before

starting

in

forward

and

three

hoots

before

starting

in

reverse.

Other

countries

have

different

signaling.

Check

your

Diesel

Model

Specification

sheet

for

horn

sequences

used

on

your

model.

www.walthers.com -

8-