Changzhou Wantai Electrical Appliance Co., Ltd

Introduction:

DQ860MA is a type of two-phase hybrid stepping motor driver, The drive voltage of which is

from 24VDC to 80VDC. It is designed for use with 2-phase hybrid stepper motor of all kinds with

57mm to 110mm outside diameter and less than 7.8A phase current. This circuit that it adopts is

similar to the circuit of servo control which enables the motor running smoothly almost without

noise and vibration. Holding torque when DQ860MA runs under high speed, is also significantly

higher than the other two-phase driver, what’s more, the positioning accuracy is also higher. It is

widely used in middle and big size numerical control devices such as curving machine, CNC

machine, and computer embroider machine, packing machines and so on.

Features:

l High performance, low price

l Average current control, 2-phase sinusoidal output current drive

l Supply voltage from 24VDC to 80VDC

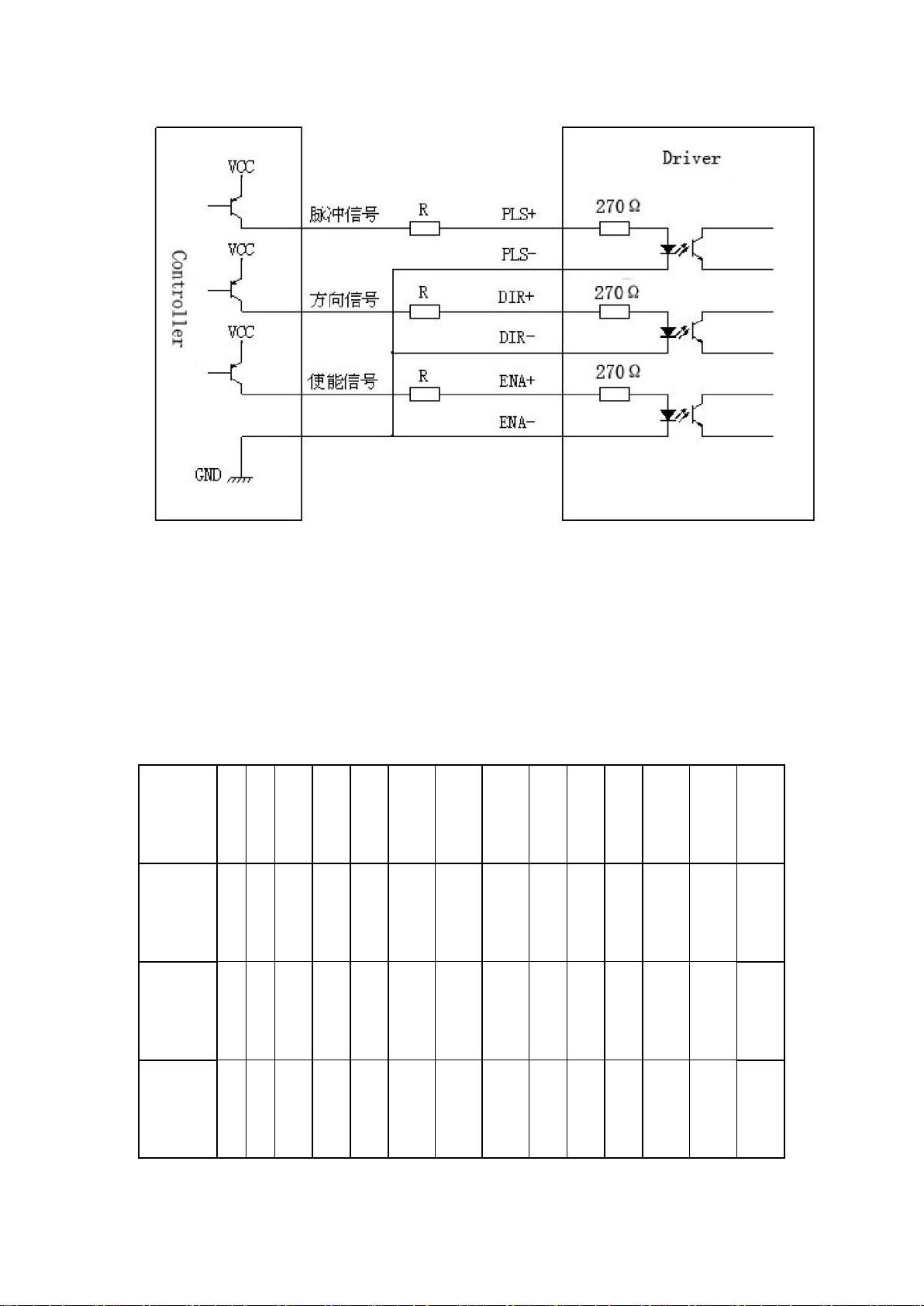

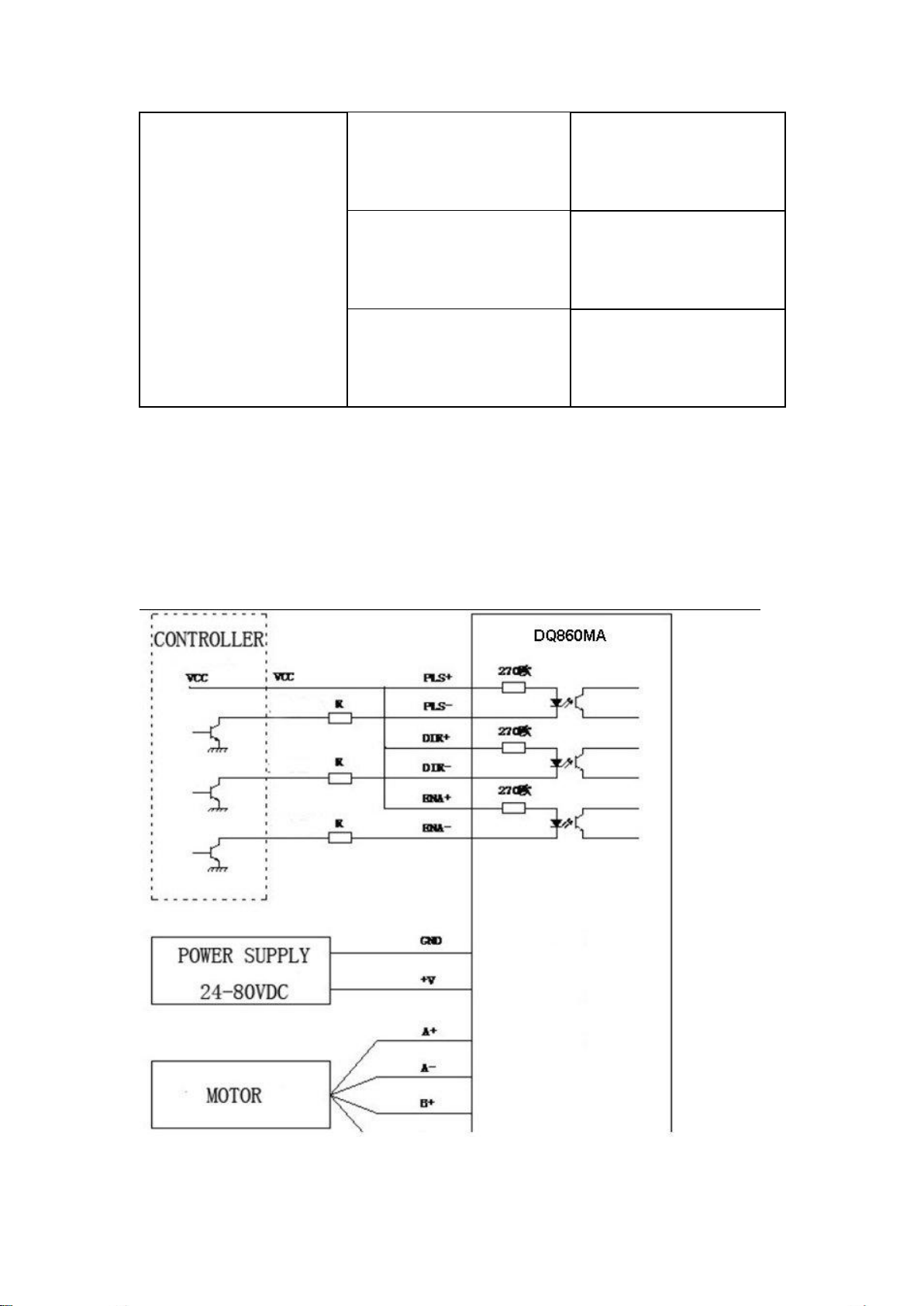

l Opto-isolated signal I/O

l Overvoltage, under voltage, over-current, phase short circuit protection

l 14 channels subdivision and automatic idle-current reduction

l 8 channels output phase current setting

l Offline command input terminal

l Motor torque is related to speed, but not related to step/revolution

l High start speed

l High holding torque under high speed

Electrical specification:

Consumption:80W;Internal

Insurance:10A