iii

GUIDES

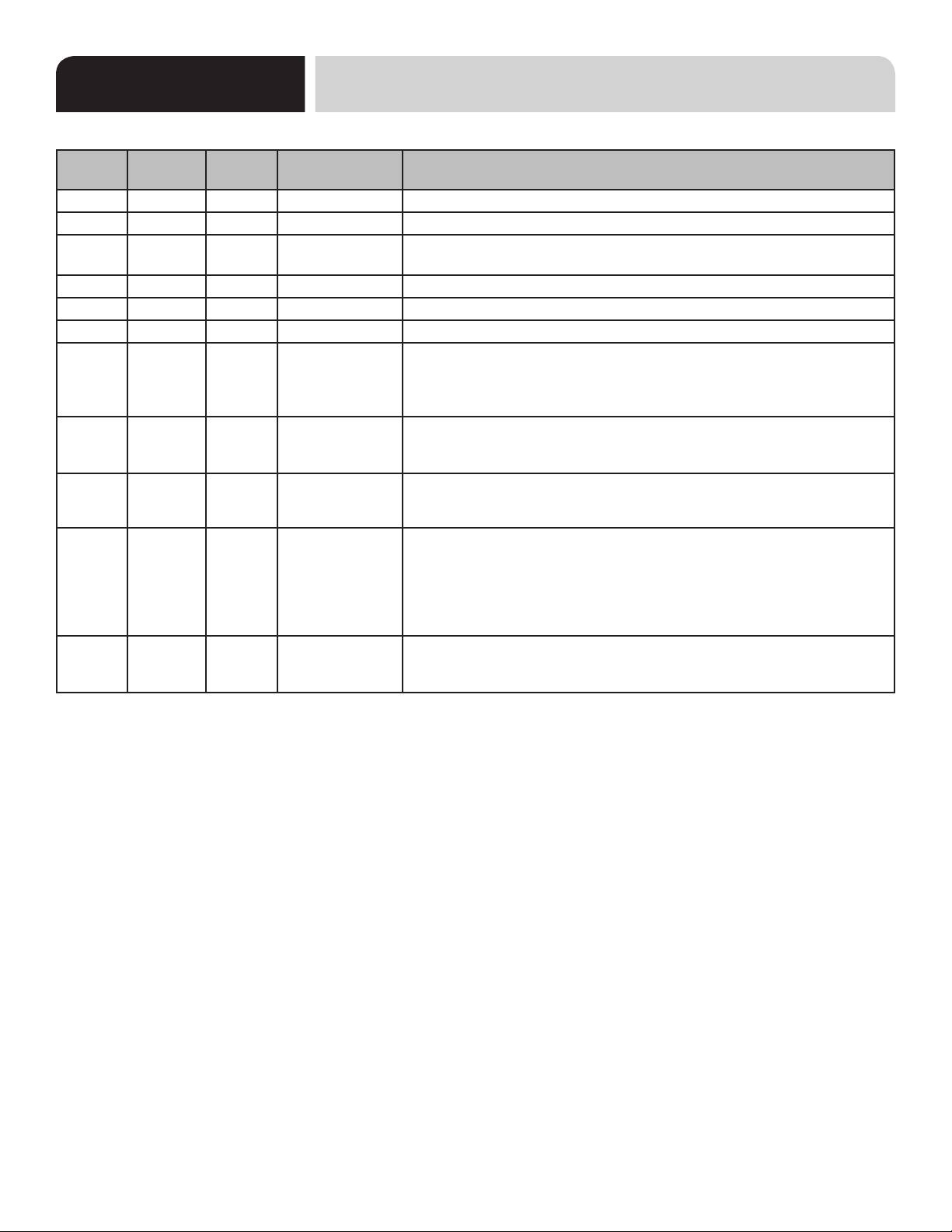

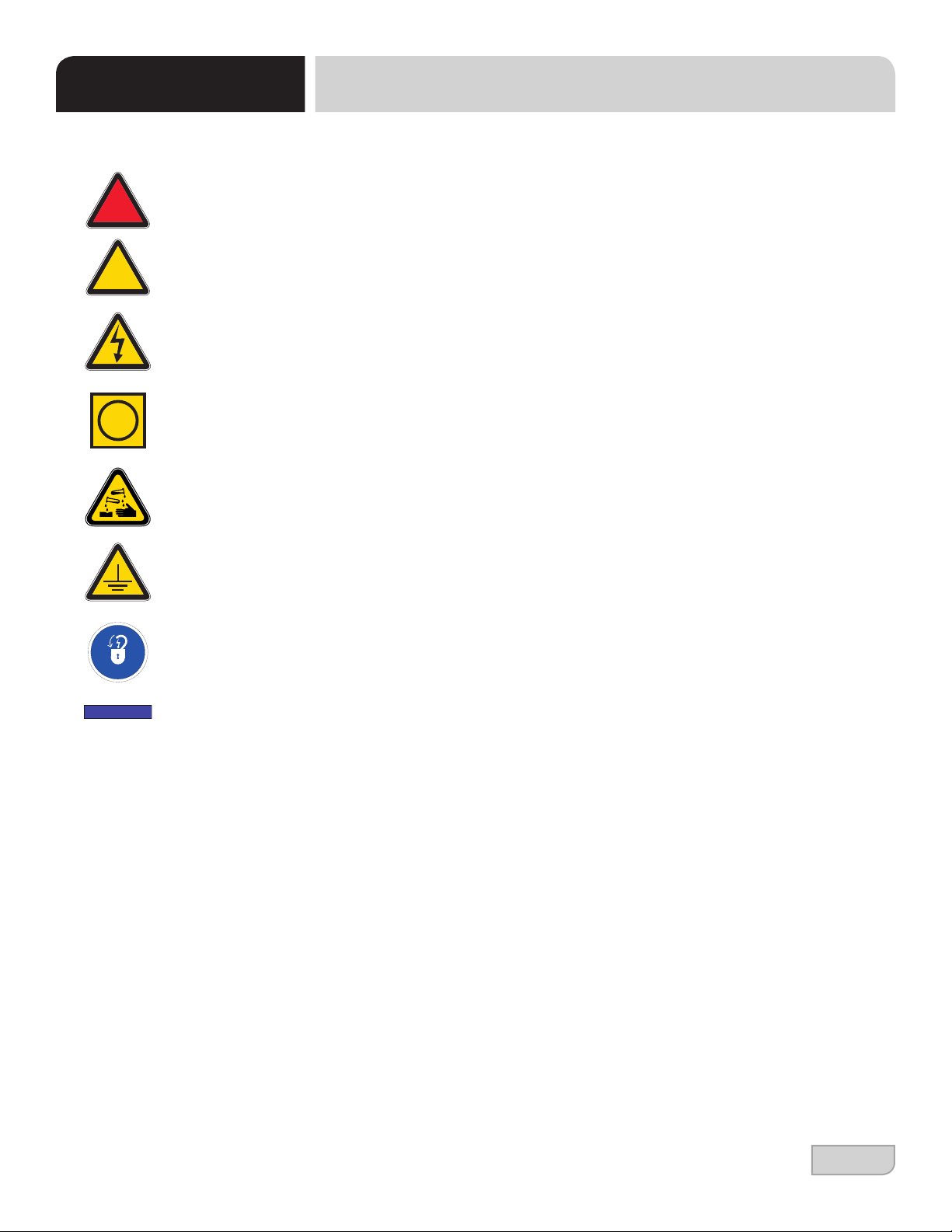

Symbols .......................................................................................................................1

Abbreviations & Acronyms ..........................................................................................1

SPECIFICATIONS

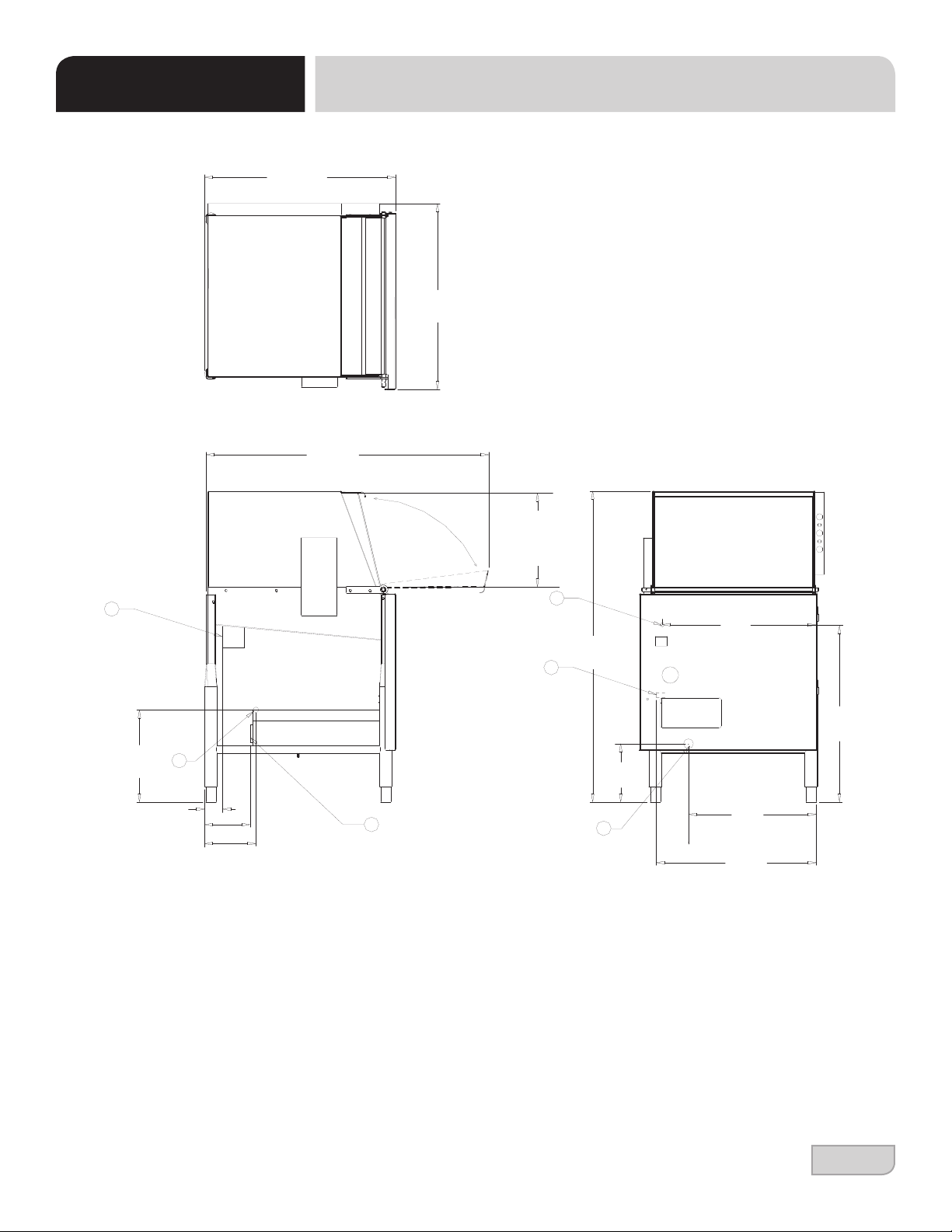

Machine Dimensions ...................................................................................................2

Operating Specs..........................................................................................................3

Electrical Requirements...............................................................................................4

INSTALLATION

Installation Instructions ................................................................................................5

Inspection..........................................................................................................5

Unpacking .........................................................................................................5

Leveling.............................................................................................................5

Plumbing ...........................................................................................................5

Pressure Regulator...........................................................................................6

Shock Absorber ................................................................................................6

Drain Line .........................................................................................................6

Plumbing Check................................................................................................6

Electrical Power Connections ...........................................................................7

Voltage Check ..................................................................................................7

Surrounding Area..............................................................................................7

Temperature Setpoints .....................................................................................7

Chemical Feeder Equipment ............................................................................8

Priming Chemical Feeder Pumps.....................................................................8

OPERATION

Operation Instructions .................................................................................................9

Preparation .......................................................................................................9

Power Up ..........................................................................................................9

Initial Start-up....................................................................................................9

Ware Preparation..............................................................................................11

Daily Start-up ....................................................................................................11

Washing a Rack of Ware..................................................................................11

Operational Inspection......................................................................................12

Shutdown & Cleaning .......................................................................................12

Detergent Control ........................................................................................................13

Deliming.......................................................................................................................14

TABLE OF CONTENTS