iii

TABLE OF CONTENTS

GUIDES

Symbols............................................................................................................................................ 1

Abbreviations & Acronyms ............................................................................................................... 1

SPECIFICATIONS

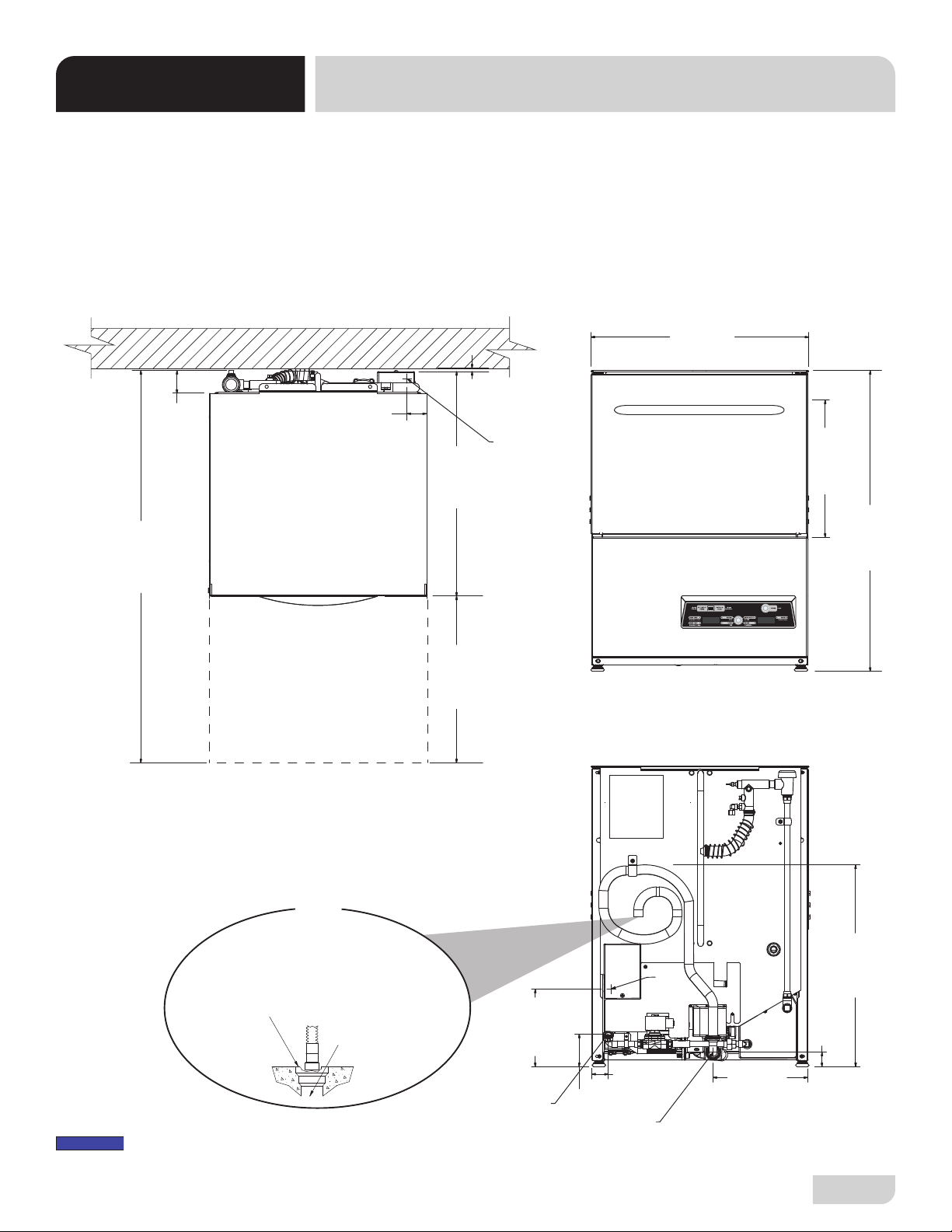

Machine Dimensions ........................................................................................................................ 2

Operating Parameters ...................................................................................................................... 3

Electrical Requirements ................................................................................................................... 4

INSTALLATION

Installation Instructions..................................................................................................................... 5

Inspection......................................................................................................................... 5

Unpacking........................................................................................................................ 5

Plumbing.......................................................................................................................... 5

Water Supply Connections .............................................................................................. 5

Pressure Regulator.......................................................................................................... 6

Shock Absorber ............................................................................................................... 6

Connecting the Drain Line ............................................................................................... 6

Plumbing Check............................................................................................................... 6

Electrical Power Connections .......................................................................................... 7

Voltage Check.................................................................................................................. 7

Surrounding Area............................................................................................................. 7

Thermostats..................................................................................................................... 7

Chemical Feeder Equipment ........................................................................................... 8

Preparing Chemical Feeder Pumps................................................................................. 8

Priming Chemical Feeder Pumps .................................................................................... 8

Programming Chemical Feeder Pumps (UL30)............................................................... 9

Leveling.......................................................................................................................... 12

Initial Fill (UH30-FND Only) ........................................................................................... 12

OPERATION

Operating Instructions .................................................................................................................... 13

Preparation .................................................................................................................... 13

Filling the Wash Tub ...................................................................................................... 13

Ware Preparation........................................................................................................... 14

Washing a Rack of Ware ............................................................................................... 14

Operational Inspection................................................................................................... 14

Shutdown & Cleaning .................................................................................................... 15

Deliming UH30-FND ...................................................................................................... 17

Deliming UL30 ............................................................................................................... 18

Detergent Control........................................................................................................... 19