GUIDES

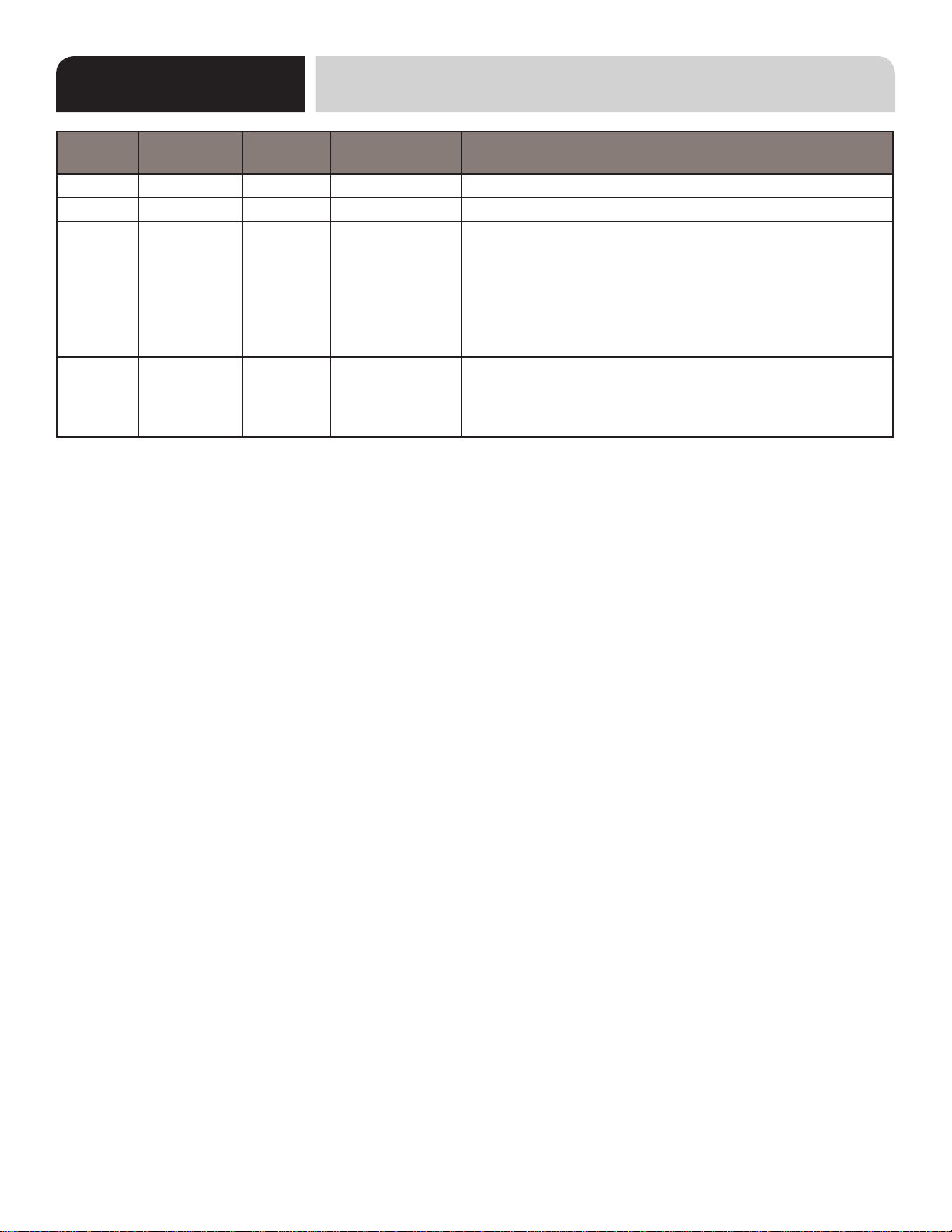

Symbols......................................................................................................................................1

Abbreviations & Acronyms..........................................................................................................1

SPECIFICATIONS

I-X Dimensions ...........................................................................................................................2

Table Dimensions .......................................................................................................................3

Operating Capacities..................................................................................................................4

Electrical Requirements..............................................................................................................5

INSTALLATION

Installation Instructions............................................................................................................... 6

Inspection......................................................................................................................... 6

Unpacking........................................................................................................................ 6

Leveling............................................................................................................................ 6

Plumbing.......................................................................................................................... 6

Water Supply Connections .............................................................................................. 6

Pressure Regulator.......................................................................................................... 7

Shock Absorber ............................................................................................................... 7

Connecting the Drain Line ............................................................................................... 7

Plumbing Check............................................................................................................... 7

Electrical Power Connections.......................................................................................... 8

Ventilation ........................................................................................................................ 8

Thermostats..................................................................................................................... 8

Voltage Check.................................................................................................................. 9

Preparing Chemical Feeder Pumps................................................................................. 9

Priming Chemical Feeder Pumps.................................................................................... 9

CAM Timer Operation.....................................................................................................11

I-X False Panel Instructions........................................................................................... 13

OPERATION

Operating Instructions............................................................................................................... 14

Preparation .................................................................................................................... 14

Power Up....................................................................................................................... 14

Filling the Wash Tub ...................................................................................................... 14

First Rack....................................................................................................................... 15

Ware Preparation........................................................................................................... 15

Washing a Rack of Ware ............................................................................................... 15

Operational Inspection................................................................................................... 15

Shutdown & Cleaning .................................................................................................... 16

Deliming Instructions ................................................................................................................ 18

TABLE OF CONTENTS

iii