Page 1

CONTENTS

Contents ...................................................................................................................................................................... 1

1 USER INSTRUCTIONS ........................................................................................................................................ 3

1.1 Intended Use ................................................................................................................................................................. 3

1.2 Compliances ................................................................................................................................................................. 3

1.3 Basic Operation ............................................................................................................................................................. 3

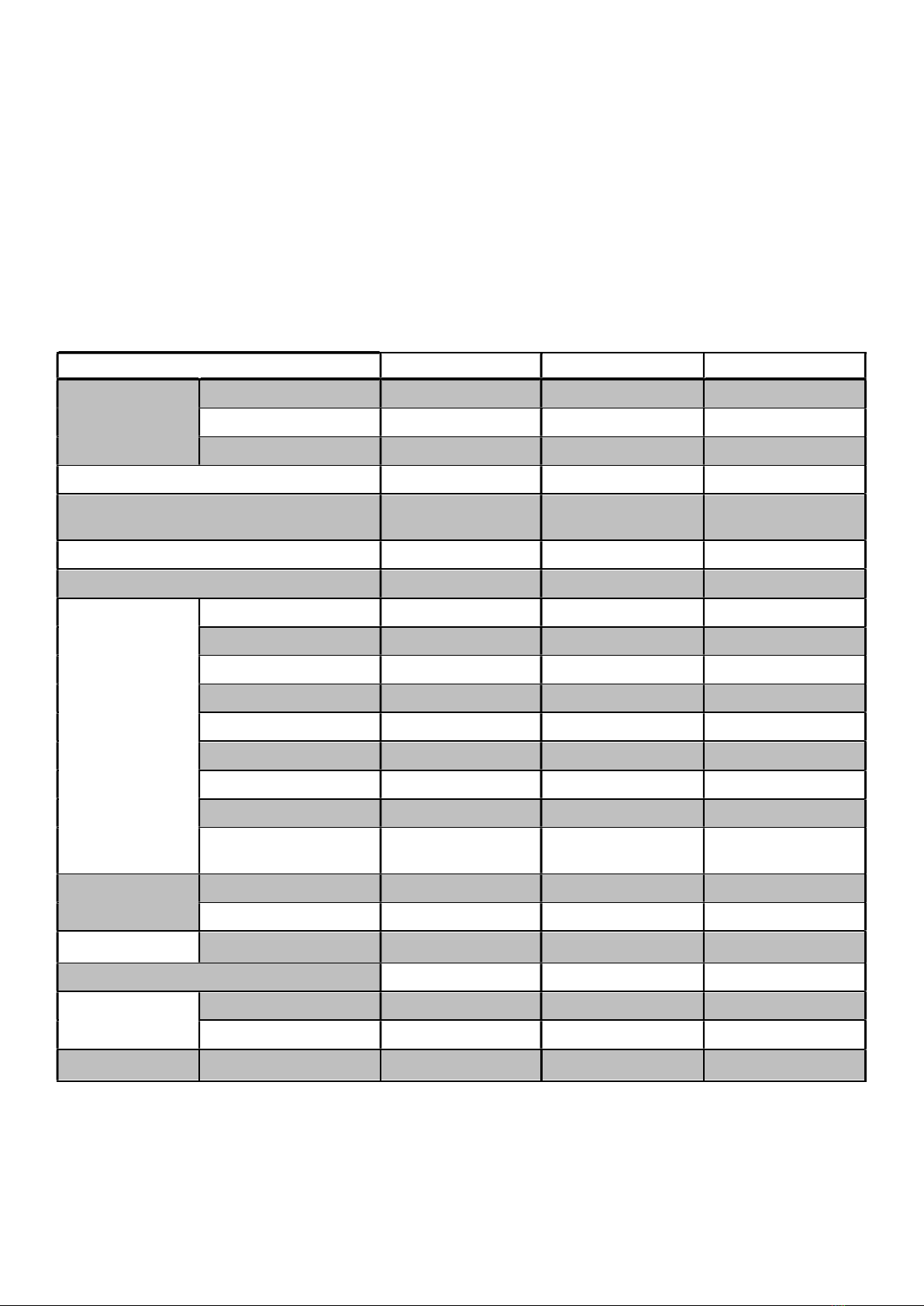

1.4 Product Data ................................................................................................................................................................. 4

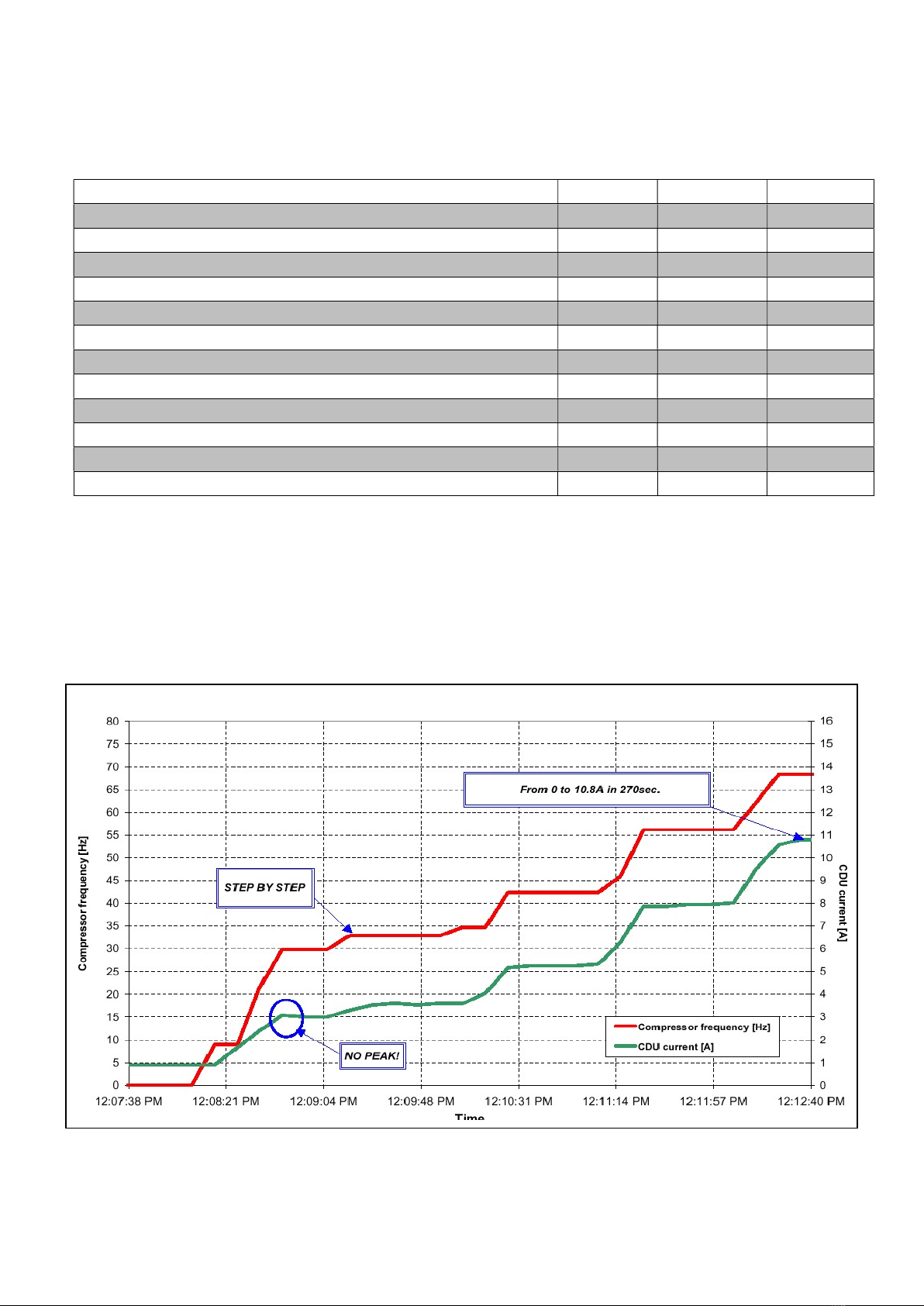

1.4.1 Starting Current ..................................................................................................................................... 6

1.5 Construction .................................................................................................................................................................. 7

1.6 Supplied Components ................................................................................................................................................... 7

1.7 Storage / Transport ....................................................................................................................................................... 8

2 USER INTERFACE .............................................................................................................................................. 9

2.1 Home Screen Icons ....................................................................................................................................................... 9

3 AIR SOURCE HEAT PUMP INSTALLATION ................................................................................................... 33

3.1 General ....................................................................................................................................................................... 33

3.2 Access ......................................................................................................................................................................... 35

3.3 Unpacking ................................................................................................................................................................... 35

3.4 Heating Circuit Connection .......................................................................................................................................... 36

3.4.1 Heating Medium .................................................................................................................................. 36

3.4.2 Heating Connections to the Heat Pump ............................................................................................. 36

3.4.3 Heating Circuit and Integrated Circulator............................................................................................ 36

3.4.4 Bypass / Open Zones ......................................................................................................................... 36

3.4.5 Freeze Protection ................................................................................................................................ 37

3.4.6 Heating Circuit Line Components ....................................................................................................... 37

3.5 Defrosting .................................................................................................................................................................... 39

3.6 Air Vent ....................................................................................................................................................................... 39

3.7 Buffer tank ................................................................................................................................................................... 39

3.8 Bypass Valve............................................................................................................................................................... 39

3.9 3-Port Motorised Valve ................................................................................................................................................ 40

3.10 Electrical Installation .................................................................................................................................................... 41

3.10.1 Incoming Supply ................................................................................................................................. 41

3.10.2 Digital Inputs ....................................................................................................................................... 41

3.10.3 Temperature Sensors ......................................................................................................................... 42

3.10.4 Digital Outputs .................................................................................................................................... 43

3.10.5 User Interface (Controller) .................................................................................................................. 44

3.10.6 DTU Module ........................................................................................................................................ 44

3.11 Parameter List ............................................................................................................................................................. 46

Commissioning ......................................................................................................................................................................... 51

3.11.1 Recorded Details ................................................................................................................................ 51

3.11.2 Testing Flow Rate ............................................................................................................................... 51

3.11.3 Weather Compensation Mode ............................................................................................................ 51

............................................................................................................................................................................ 52

3.11.4 DHW Cylinder Heat Up Test ............................................................................................................... 52

3.11.5 Sign Off ............................................................................................................................................... 53

3.12 System Hand Over ...................................................................................................................................................... 53

3.13 Servicing ..................................................................................................................................................................... 53