Warmington SG-EG 600 User manual

16 March 2023

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior notification.

1

Gas Type Conversion NG/LPG

NG to LPG

1. Jets needs to be replaced.

2. Jumper needs to be removed from the control box.

3. Pressures needs to be adjusted.

4. Pilot needs to replaced, make sure air-intake is opened.

LPG to NG

1. Jets needs to be drilled out

2. Jumper needs to be added to the control box.

3. Pressures needs to be adjusted.

4. Pilot needs to replaced, make sure air-intake is closed.

NG to LPG

1. Jets needs to be replaced.

2. Remove NG regulator

3. Pressures needs to be adjusted.

4. Pilot needs to be adjusted and air-intake on it opened.

LPG to NG

1. Jets needs to be drilled out

2. NG regulator to be added

3. Pressures needs to be adjusted.

4. Pilot needs to be adjusted and air-intake closed

1.1 TYPES OF CONVERSIONS

1.1.1 EG SERIES ELECTRONIC

1.1.2 SG SERIES MANUAL

16 March 2023

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior notification.

2

* Inlet Pressure not to exceed 4.0KPa

1.2 GAS SPECIFICATIONS FOR REFERENCE

MODLE SG-EG 700 SG-EG 780 SG-EG 900 SG-EG 1100SG-EG 600

LPG

Nominal Pressure kPa 2.75 kPa 2.75 kPa 2.75 kPa 2.75 kPa2.75 kPa

Nominal Injector Size mm 2 X 1.1mm 2 X 1.2mm 2 X 1.3mm 2 X 1.4mm2x 1.0 mm

Burner Pressure High kPa 2.5 2.5 2.5 2.52.50

Burner Pressure Low kPa 0.75 0.75 0.75 0.750.75

MJ/h 29 38 42 5026

Flame Effect Output Only Effect Effect Effect EffectEffect

Supply Pipe Size dia—min 3/8” 3/8” 1/2” 1/2”3/8”

Natural Gas

Nominal Pressure kPa 1.5 kPa 1.5 kPa 1.5 kPa 1.5 kPa1.5kPa

Nominal Injector Size mm 2 X 1.8mm 2 X 2mm 2 X 2.2mm 2 X 2.4mm2x1.6 mm

Burner Pressure High kPa 1111.01

Burner Pressure Low kPa 0.3 0.3 0.3 0.30.3

MJ/h 35 45 41 5827

Flame Effect Output Only Effect Effect Effect EffectEffect

Supply Pipe Size dia—min 3/8” 1/2” 1/2” 1/2”3/8”

Lab. Test No GL 923 GL 900 GL 834 GL 876CUB 008

Lab. Test Dates 20/04/2010 26/02/10 26/06/09 24/12/0913/08/2015

ESS Declaration No: 1149420106 1149520106 1149720106 1149820106n/a

2. STEPS

2.1 JET ADJUSTMENT

To access the jets the burner tray needs to be taken off. To do this undo the 2x bolts on top of the burner legs on

each side, and 1x bolt for the pilot assembly.

16 March 2023

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior notification.

3

You can then lift the burner tray up to access the jets, see below.

Jet head

For NG to LPG the jet head has to be changed over. Use a spanner to unscrew the NG jet head only

and replace the jet head with the supplied new LPG jet heads. Refer to the table in section 1.2. for the

number of jets to be replaced.

2.1.1 JET ADJUSTMENT NG TO LPG

For LPG to NG the jet head can be drilled out. To get the appropriate jet size please refer to the table

in section 1.2. The drill bit has to be accurate to the correct decimal, and can be supplied by

Warmington.

2.1.2 JET ADJUSTMENT LPG TO NG

Burner

Side-legs

16 March 2023

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior notification.

4

2.1 PRESSURE ADJUSTMENT

How to adjust the pressures depends on the type of ignition system you have. The options are

manual ignition (SG) and electronic ignition (EG) 840 (on/off), 843 (high/low) & 845 (remote).

Please refer to the table in section 1.2 for the correct pressure for the burner model.

2.1.1 PRESSURE ADJUSTMENT FOR SG MANUAL IGNITION

Turn appliance off & remove front plastic cover on igniter, pull cover to slide off.

Unscrew test nipple on the burner manifold & fit the manometer to the nipple, see diagram below.

To set high pressure: Light the burner & turn to high - Then adjust the high screw to the desired

pressure.

To set low pressure: Light the burner & turn to low - Then adjust the low screw to the desired

pressure.

Extinguish Appliance, remove test equipment and secure test nipple screw.

Check valve & burner for correct operation & check for gas leaks.

Adjustment of High & Low Settings Must be Carried out by a Certified Gas Fitter Only .

Gas test nipple

2.1.2 PRESSURE ADJUSTMENT FOR ELECTRONIC 840 IGNITION WALL SWITCH ON/OFF

Light Appliance and attached manometer to test nipple shown in section 2.1.1.

Pressure Setting: Turn the Burner on with the switch and wait for full ignition. Screw the adjusting screw clock-

wise to Increase the Outlet Pressure or screw counter clockwise to Decrease the Pressure to the desired set-

tings. Use a standard screw driver.

Test Point Inlet

Gas Outlet

SIT 840 Control Valve

Wall Switch

Gas Inlet

Adjustment Screw

• After checking the pressure, turn the unit off, remove Manometer from the Test Point and Tighten the Test

Point Screw. Ensure to check for gas leaks.

• Turn the Appliance On and Off a few times to check ignition.

• When you are satisfied that the Appliance is working correctly , fit the Front Panel Assembly back to the Gas

Burner.

• All Burner Aerations are Factory Preset and cannot be adjusted.

16 March 2023

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior notification.

5

2.1.3 PRESSURE ADJUSTMENT FOR ELECTRONIC 843 IGNITION DOUBLE WALL SWITCH HIGH/LOW

High Pressure Setting: Set the Burner to High with the switch. Screw in Nut A to Increase the Outlet Pressure

then screw Nut A out to Decrease the Pressure to the desired settings . Use 10mm spanner.

Low Pressure Setting: Set the Burner to Low with the switch - See Wiring Diagram) and, keep Nut A stationary .

Use a screwdriver to screw in Screw B to Increase the Pressure and Screw it Out to Decrease the Pressure .

Carefully replace the Modulator Plastic Cap.

Test Point Inlet Test Point Outlet

1/2” BSPT Gas Outlet

SIT 843 Control Valve

Double wall switch

Nut A

High setting adjustment

screw

Screw B

Low setting adjustment screw

• After checking the pressure, turn the unit off, remove Manometer from the Test Point and Tighten the Test

Point Screw. Ensure to check for gas leaks.

• Turn the Appliance on and off a few times to check ignition.

• When you are satisfied that the Appliance is working correctly, fit the Front Panel Assembly back to the Gas

Burner.

• All Burner Aerations are Factory Preset and cannot be adjusted.

2.1.4 PRESSURE ADJUSTMENT FOR ELECTRONIC 845 (HIGH/LOW) IGNITION REMOTE CONTROLLED

High Pressure Setting: Set the modulator to Maximum Condition. Screw in Nut A to Increase the Outlet Pres-

sure then screw Nut A out to Decrease the Pressure to the desired settings . Use 10mm spanner.

Low Pressure Setting: Turn Off the Power to the Modulator (by disconnecting the Modulator Harness Connec-

tion at the Valve - See Wiring Diagram in Page 17 .) and, keep Nut A stationary . Use a screwdriver to screw in

Screw B to Increase the Pressure and Screw it Out to Decrease the Pressure . Carefully replace the Modulator

Plastic Cap.

Modulator Harness

Nut

Screw

• After checking the pressure, turn the unit off, remove Manometer from the Test Point and Tighten the Test

Point Screw. Ensure to check for gas leaks.

• Turn the Appliance on and off a few times to check ignition.

• When you are satisfied that the Appliance is working correctly, fit the Front Panel Assembly back to the Gas

Burner.

• All Burner Aerations are Factory Preset and cannot be adjusted.

16 March 2023

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior notification.

6

Note: When the Base screw is removed, gas will leak from the out let, ensure that the pilot is not adjusted or

the screw is removed when the fire is burning.

• Adjustment of Pilot - 3 Flame: Unscrew base screw as shown in diagram below step 2.

• Insert a screwdriver as shown in step 3 and adjust the screw inside the pilot to adjust the flame height.

• The flame must always engulf over the Electrodes on both sides.

• Replace the Base screw and check for leaks.

Pilot in

Assembled

State Correct Operation of Pilot

3

2

1

3.1 PILOT ADJUSTMENTS

3.1.2 PILOT FLAME ADJUSTMENT

3.1.3 PILOT AIR ADJUSTMENT

The air-intake ion the pilot is supposed to be fully open on a LPG burner and approx. half-way closed on

NG, please match this as shown below.

Fully open air-

intake, hence this

is a LPG unit

Half open air-

intake, hence this

is a NG unit

3.1.1 PILOT FLAME REPLACEMENT

First unscrew the two front bolts (1) to remove the spark and rectifying

probes. Then remove the single bolt on burner bracket (2) to take the

pilot assembly off. Then replace the pilot with the new assembly with

the correct gas type, install the probes and screw in place. (1)

(2)

16 March 2023

Due to continued product improvement, Warmington Ind LTD reserves the right to change product specifications without prior notification.

7

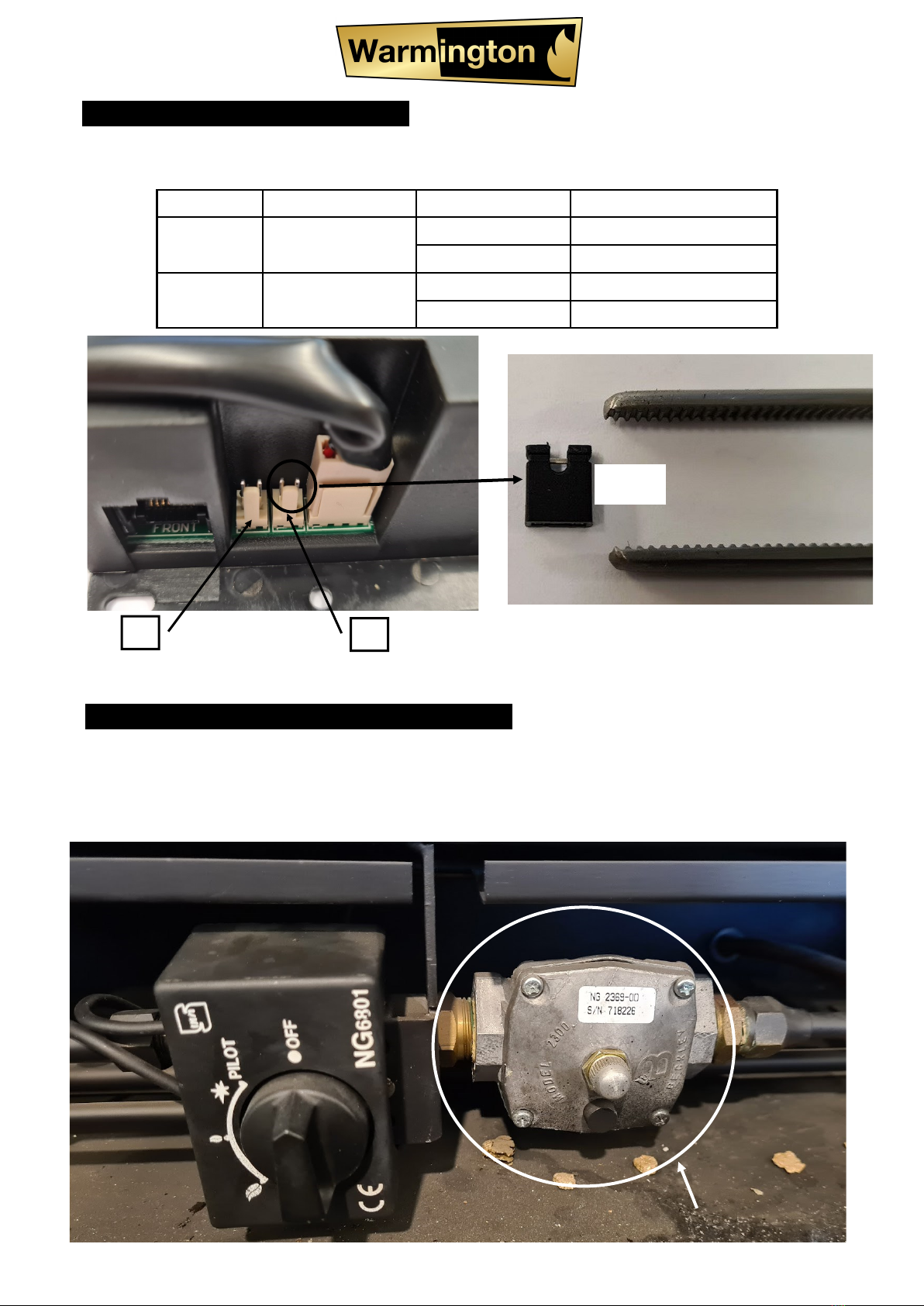

4.1 EG CONTROL BOX ADJUSTMENT

The black Millennium control box gas has a jumper to differentiate between NG and LPG, see below for

the different jumper settings:

Connector Description Jumper Selection

J6 Gas Select ON NG

OFF LPG

J8 Mode Select ON Power Flue ONLY

OFF Regular Flue System

J8 J6

NOTE: The jumper is small and can be tricky to put in or take out, best tool to use is tweezers. Take care

not to lose the jumper as it is small and can be hard to recover if lost.

Jumper

5.1 NG REGULATOR FOR SG (MANUAL) FIRES ONLY

All manual NG gas burners come installed with a regulator that sits on the inlet of the manual ignitor. If the

fire is converted from NG to LPG this needs to be removed. If the fire is converted from LPG to NG this

needs to be installed. Regulator will be supplied by Warmington and removal or installation of one has to

be done by a certified gas fitters, as the plumbing of the gas fire will have to be changed. Check for leaks

after the swap has been completed. See below for correct installation of regulator.

NG REGULATOR

Other manuals for SG-EG 600

1

This manual suits for next models

5

Table of contents

Popular Network Hardware manuals by other brands

Matrix Switch Corporation

Matrix Switch Corporation MSC-HD161DEL product manual

B&B Electronics

B&B Electronics ZXT9-IO-222R2 product manual

Yudor

Yudor YDS-16 user manual

D-Link

D-Link ShareCenter DNS-320L datasheet

Samsung

Samsung ES1642dc Hardware user manual

Honeywell Home

Honeywell Home LTEM-PV Installation and setup guide