Water Analytics AquaMetrix AM-ODO-TX User manual

1

ODO-TX Operating Manual N116-155 rev 1.0

AquaMetrix AM-ODO-TX

Optical Dissolved Oxygen Probe

Installation and Operation Manual

2

ODO-TX Operating Manual N116-155 rev 1.0

Contents

1. Introduction ..........................................................................................................................................3

2. Safety ....................................................................................................................................................3

3. Getting Started......................................................................................................................................4

4. ODO-TX Sensor and Specifications........................................................................................................4

4.1. System Description .......................................................................................................................4

4.2. Specifications ................................................................................................................................5

4.3. Dimensions....................................................................................................................................6

4.4. Connections to power supply and controller ...............................................................................6

5. Installation ............................................................................................................................................7

6. Communication.....................................................................................................................................8

6.1. Analog ...........................................................................................................................................8

6.2. Modbus.........................................................................................................................................9

6.2.1. Common Registers................................................................................................................9

6.2.2. Sensor Status Registers.........................................................................................................9

6.2.3. Device Specific Register 0042 Data Quality ID......................................................................9

6.2.4. Device Specific Registers.....................................................................................................10

6.2.5. Calibration Registers ...........................................................................................................13

6.2.6. Sensor Health Table ............................................................................................................15

7. Calibration...........................................................................................................................................17

7.1. One Point Calibration: Water-Saturated-Air 100% Saturation...................................................17

7.2. Second Point (0%) of Two Point Calibration...............................................................................17

7.3. Temperature and Concentration (ppm or mg/l) calibration ......................................................17

8. Maintenance.......................................................................................................................................18

8.1. Cleaning.......................................................................................................................................18

8.2. Replacing the Sensor Cap............................................................................................................18

9. Spare Parts..........................................................................................................................................19

10. Accessories..........................................................................................................................................19

10.1. Calibration Cap........................................................................................................................19

10.2. Mounting.................................................................................................................................20

10.2.1. General Installation Requirements.....................................................................................20

10.2.2. Submersion Mounting with the AM-ARM-5.......................................................................20

10.2.3. Inline Mounting with the AM-TEE-5 ...................................................................................21

3

ODO-TX Operating Manual N116-155 rev 1.0

11. Troubleshooting..................................................................................................................................23

12. Disposal...............................................................................................................................................23

13. Contact................................................................................................................................................23

Appendix A: Dissolved Oxygen Equations...................................................................................................25

Appendix B: Commkit .................................................................................................................................27

Appendix C: Definitions...............................................................................................................................32

1. Introduction

The AM-ODO is one of the most compact, durable, and easiest to use dissolved oxygen sensors on the

market. It is an optical sensor that utilizes fluorescence quenching technology. With this technology, the

quenching of fluorophores by dissolved oxygen molecules decreases the fluorescence intensity and

lifetime, the latter of which is detected by a photodetector and allows the dissolved oxygen (DO)

concentration to be quantified accurately and consistently. Unlike polarographic and galvanic

electrochemical technologies used for the measurement of dissolved oxygen, optical technology does

not consume oxygen during measurement. Also, optical technology does not require electrolyte, a

“warm-up” period, nor sample flow. The measured dissolved oxygen concentration is automatically

compensated for by integrated data from the temperature and pressure sensors and sophisticated

algorithms in the firmware.

The AM-ODO-TX is part of the AquaMetrix smart sensor series. Probes in this series are Direct Output

Digital Sensors with the precision of a controller and the accuracy of our core probes. The AM-ODO-TX

also can communicate via RS485 or Modbus protocol.

The AM-ODO-TX has two (2) analog outputs that can be mapped to Percent Saturation (%),

concentration (mg/l) or Temperature. The %-saturation measurement is a function of atmospheric

pressure while the concentration value is also a function of temperature and salinity. The ODO-TX

comes fully calibrated and can maintain this calibration for 1-2 years, depending on the environment it is

installed in.

2. Safety

Electrical hazard

Do not install the probe unless you have electrical training and you have read

the instruction manual. The probes uses 8-36V power supply and improper installation

and handling can result in injury or damage to surrounding equipment including this

probe.

4

ODO-TX Operating Manual N116-155 rev 1.0

The probe should only be installed, stored and serviced in the manner

described in this manual. Improper handling may result in damage to the unit and

surrounding equipment and may void the warranty.

3. Getting Started

1. A temperature sensor is built into the probe body, close to the sensor cap. It should be completely

immersed in the sample when taking measurements.

2. Avoid sensor cap touching organic solvent, scratching, and abusive collisions to strengthen and

lengthen the working life of the sensor cap. Special care should be taken to clean the coating of cap,

to dip probe and cap in fresh water, and then to tap dry the surface with a tissue. Do not wipe the

coating surface.

3. Replace the sensor cap if the cap coating is faded or stripped away. DO NOT touch the clear window

on the probe tip after unscrewing the old cap. If any contaminants or residue are present on the

window or inside the cap, carefully remove them with a powder free wipe. Then re-screw the new

sensor cap onto the probe.

4. ODO-TX Sensor and Specifications

4.1. System Description

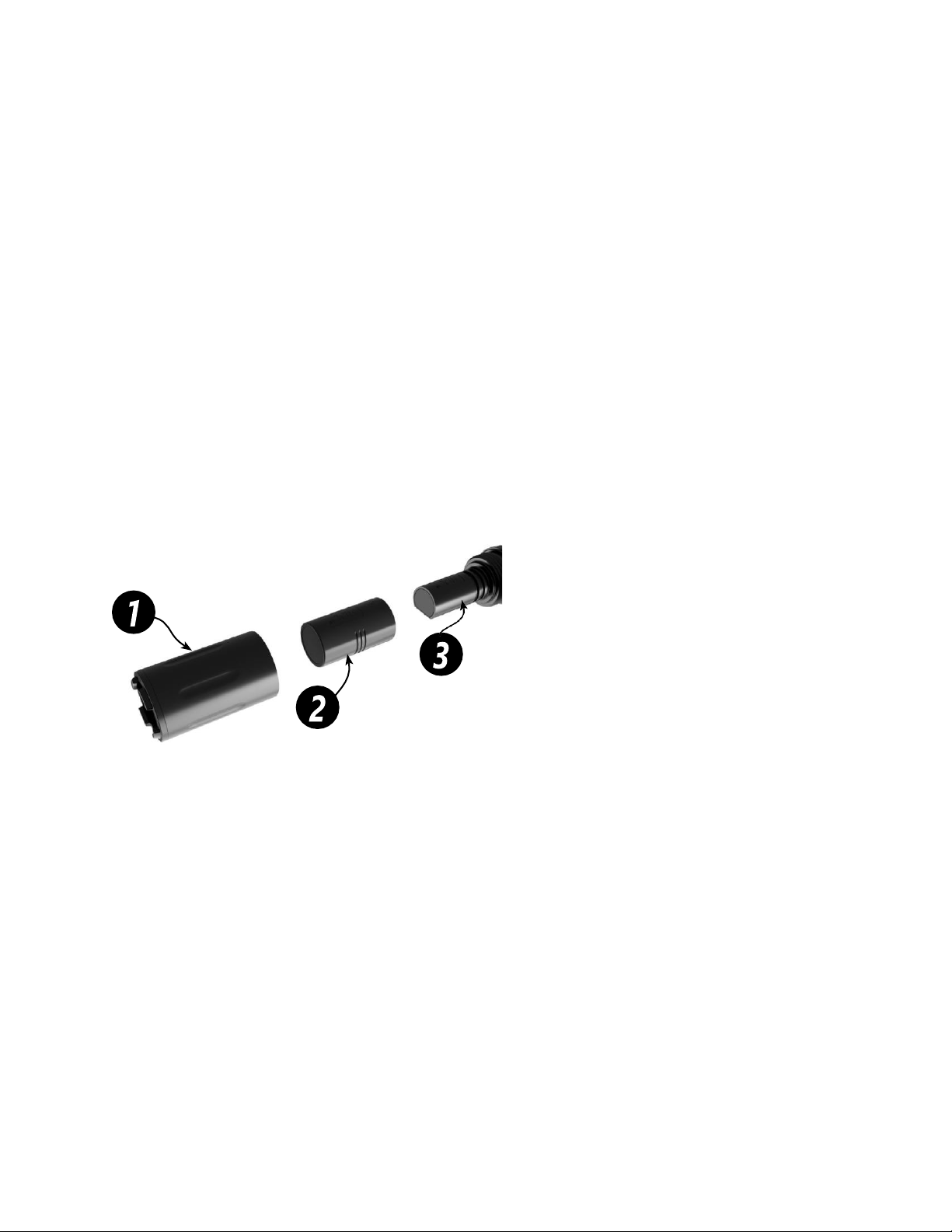

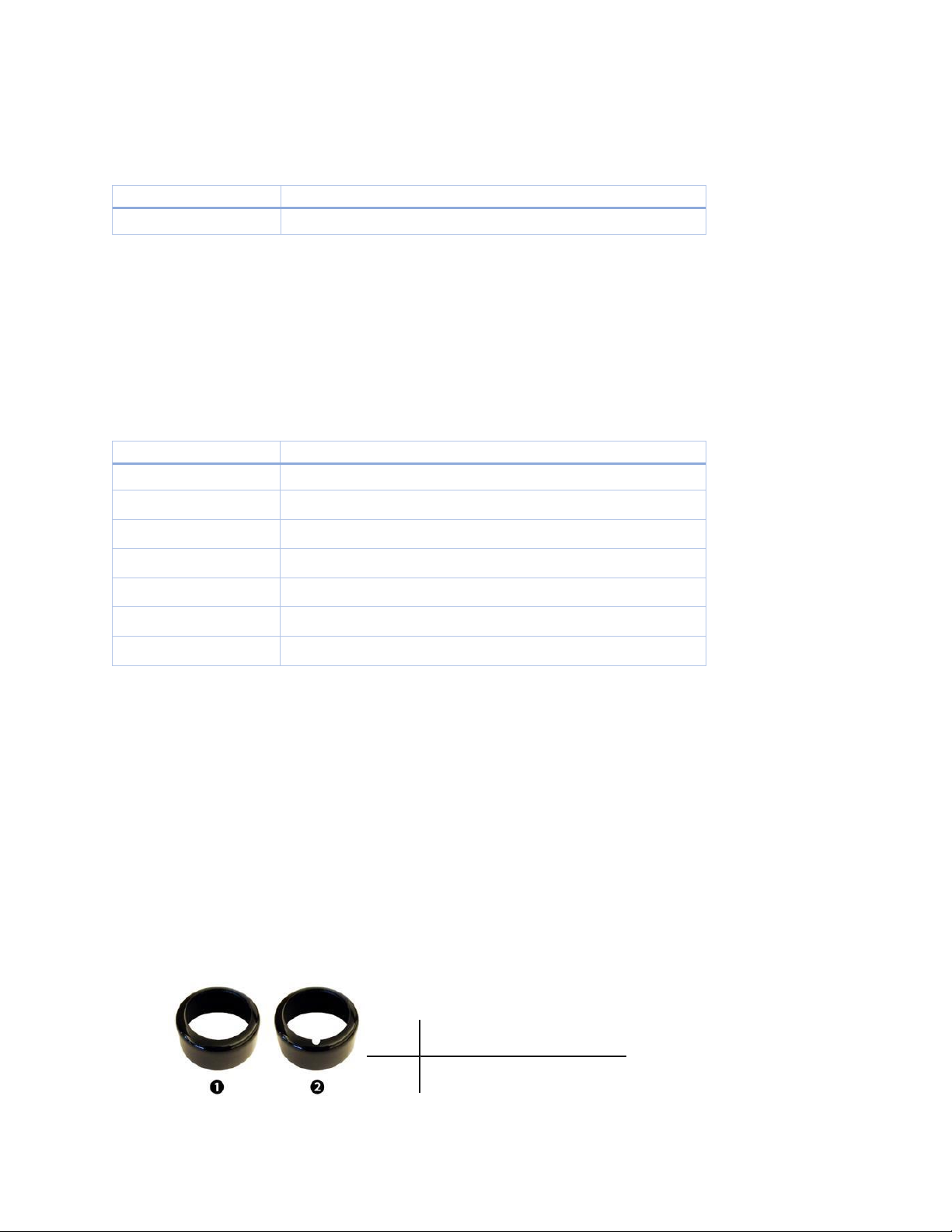

Your ODO-TX probeincludesthefollowingitems:

1

The sensor guard cap protects and seals the sensor cap in place.

2

The membrane sensor cap (AM-ODO-TX-CAP) has a luminescent foil that responds to oxygen

molecules. This cap needs to be replaced periodically; the typical life is two years.

3

The optical system contains the optics and circuitry that enable the sensor to calculate the

concentration of dissolved oxygen.

5

ODO-TX Operating Manual N116-155 rev 1.0

4.2. Specifications

Probe Parameters

Parameters

Optical Dissolved Oxygen Sensor

Data Transmission

Analog (4-20mA), RS485, Modbus

Range, DO

0-60 mg/L; 0-600% Saturation

Accuracy, DO

+/- 0.1 mg/L (0-20 mg/L)

+/-2% (20-60 mg/L)

Resolution, DO

0.01 mg/L

Response Time, Cap

T63<5s, T90<45s, T95<60s

Units, DO

mg/L, ppm, % saturation

Range, Temp.

-5°C to 50°C (23°F to 122°F)

Accuracy, Temp

+/- 0.1°C

Resolution, Temp

0.01°C

Units, Temp

Celsius, Fahrenheit

Salinity Compensation

Fixed or real-time capable

Barometric Compensation

Fixed or real-time capable

Methods

EPA-approved methods 1002-8-2009,

1003-8-2009, 1004-8-2009 Standard

Methods 4500-O

Calibration

1-2 points via RS485 Connection OR at

local controller

Calibration Time

~1 min (for each point)

Calibration Freq

1-2 years

Physical

Wetted Material

PVC Body, Cycoloy® (PC/ABS)1

Ryton® (PPS), PC/PMMA2

Reading Rate

1 second

Power Requirements

8 to 36 VDC

Power Consumption

Maximum (measurement): 50 mA at

12 VDC

Idle (communication only): 2 mA at 12

VDC

IP Rating

IP-67 with sensor cap off; IP-68 with

sensor cap installed

Compliance

EMC 2014/30/EU

IEC 61000-6-2:2005

EN 55011:2009

1

Cycoloy is a registered trademark of SABIC GLOBAL Technologies B.V.;

2

Ryton is a registered trademark of Solvay SA.

6

ODO-TX Operating Manual N116-155 rev 1.0

Environmental

Pressure

150 psi from 0° to 50°C

Depth

100 m (328 ft) @ 25°C

Operating Temperature (non-freezing)

-5°C to 50°C (23°F to 122°F)

Storage Temperature

-40°C to 65°C (-40°F to 149°F)

Interferences

Alcohols >5%; hydrogen peroxide > 3%;

sodium hypochlorite (commercial bleach)

> 3%; gaseous sulfur dioxide; gaseous

chlorine. Do not use in organic solvents

(e.g., acetone, chloroform, methylene

chloride, etc.), which may swell the

sensing element (foil matrix) and destroy

it.

4.3. Dimensions

4.4. Connections to power supply and controller

1) The two RS485 wires can be cut if the user does not need PC monitoring or firmware updates.

2) Power supply: 5-36VDC. Make sure to follow the wiring instructions above and provide the

proper power. Connecting the probe to any power outside the normal range may result in

damage and may void the warranty.

Wire color

Description

Red

Power (8~ 36 VDC)

Black

GND (ground is shared between the power input and signal output, please

make sure grounds are connected if external power supply is used)

Green

RS 485 B (+)

White

RS 485 A (-)

Blue

Analog Output 1 (configured using CommKit)

Yellow

Analog Output 2 (configured using CommKit)

7

ODO-TX Operating Manual N116-155 rev 1.0

5. Installation

The AM-ODO-TX can be connected to an AquaMetrix AM-2300 controller or any PLC. The probe can

output either a single output or dual outputs. As factory default, the ODO-TX comes wired as such:

Using the RS485 connection the user can change the default analog outputs from the following

selections: An optional configuration outputs the temperature or pressure as a second parameter. The

AM-2300 can connect up to 4 AM-ODOTX sensors without use of an external power supply.

An external power supply may be required if the PLC doesn’t have a 5-36VDC voltage source. The power

ground and signal grounds must be connected.

Refer to the instructions below, as well as the controller/analyzer manual for proper installation and

operation instructions.

Figure 1- Wiring AM-ODO-TX to an AM-2300 controller.

8

ODO-TX Operating Manual N116-155 rev 1.0

Figure 2- Wiring AM-ODO-TX to an AM-2252 or a PLC with an external power supply

6. Communication

6.1. Analog

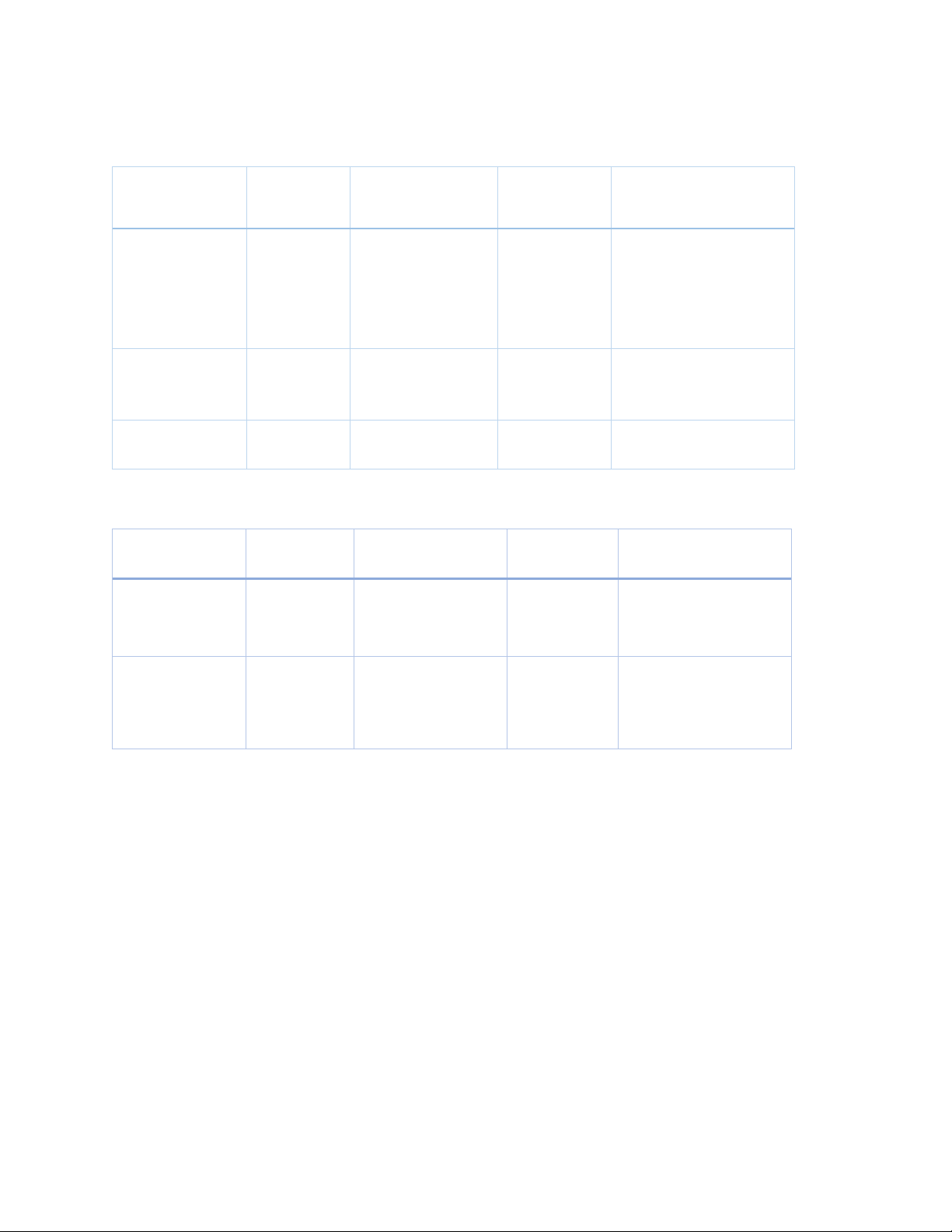

The standard mapping for the ODO-TX analog output is:

Output

Output Parameter

4mA

20mA

Analog 1

Dissolved Oxygen (Percent Saturation)

0

200

Analog 2

Dissolved Oxygen (concentration)

0

20

The Two (2) Analog outputs can be remapped at the factory and by the customer

Output Parameter

Min

Max

Temperature

-5

50

Dissolved Oxygen (concentration)

0

60

Dissolved Oxygen (Percent Saturation)

0

600

9

ODO-TX Operating Manual N116-155 rev 1.0

6.2. Modbus

6.2.1. Common Registers

Register

Size

Mode & Access

Level (R/W)

Data Type

Description

9001

1

R/W

ushort

Device ID = 36 or 37

(analog model)

9002

2

R/W

ulong

Device serial number

9004

3

R/W

time

Manufacture date

6.2.2. Sensor Status Registers

Register

Size

Mode & Access

Level (R/W)

Data Type

Description

0005

3

R1

time

Cap start date/time 0

= no cap

0008

3

R1

time

Cap end of usable

life date/time 0 = no

cap

6.2.3. Device Specific Register 0042 Data Quality ID

Register 0042 is responsible for returning the various data quality IDs for the ODO-TX sensor. For a list of

the Data Quality IDs and definitions, see the Sensor Health Table in the Service and Troubleshooting

section of this manual.

10

ODO-TX Operating Manual N116-155 rev 1.0

6.2.4. Device Specific Registers

Register

Size

Mode & Access

Level (R/W)

Data Type

Description

Dissolved Oxygen Concentration

0038

2

R1

float

Measured value, Co

0040

1

R1

ushort

Parameter ID = 20

0041

1

R1/W2

ushort

Units ID

117 = mg/L (default)

118 = ug/L

0042

1

R1

ushort

Data quality ID (See

the Sensor Health

Table)

0043

2

R1/W3

float

Offline sentinel

value (default = 0.0)

0045

1

R1

16 bits

Available units =

0x0030 (48)

11

ODO-TX Operating Manual N116-155 rev 1.0

Temperature

0046

2

R1

float

Measured value

0048

1

R1

ushort

Parameter ID = 1

0049

1

R1/W2

ushort

Units ID

1= °C (default)

2= °F

0050

1

R1

ushort

Data quality ID

0051

2

R1/W3

float

Offline sentinel

value (default = 0.0)

0053

1

R1

16 bits

Available units =

0x00030 (3)

Dissolved Oxygen % Saturation

0054

2

R1

float

Measured value

0056

1

R1/W2

ushort

Parameter ID = 21

0057

1

R1/W2

ushort

Units ID

177 = percent

saturation (default)

0058

1

R1

ushort

Data quality ID

0059

2

R1/W3

float

Offline sentinel

value (default = 0.0)

0061

1

R1

16 bits

Available units =

0x0001 (1)

12

ODO-TX Operating Manual N116-155 rev 1.0

Oxygen Partial Pressure

0062

2

R1

float

Measured value

0064

1

R1

ushort

Parameter ID = 2

(pressure)

0065

1

R1/W2

ushort

Units ID

26 = torr (default)

0066

1

R1

ushort

Data quality ID

0067

2

R1/W3

float

Offline sentinel

value (default = 0.0)

0069

1

R1

16 bits

Available Units =

0x0200 (512)

13

ODO-TX Operating Manual N116-155 rev 1.0

6.2.5. Calibration Registers

Register

Size

Mode & Access

Level (R/W)

Data Type

Description

0118

2

R1/W3

float

Live salinity value

(PSU)

0120

2

R1/W3

float

Default salinity value

(PSU, default = 0.0)

0122

2

R1/W3

float

Live barometric

pressure (mbar)

0124

2

R1/W3

float

Default barometric

pressure (mbar,

default = 1013.25)

0126

2

R1/W3

float

100% saturation

calibration reading

(mg/L)

0128

2

R1/W3

float

100% saturation

temperature reading

(°C)

14

ODO-TX Operating Manual N116-155 rev 1.0

0130

2

R1/W3

float

100% saturation

salinity value (PSU)

0132

2

R1/W3

float

100% saturation

barometric pressure

(mbar)

0134

2

R1/W3

float

0% saturation

calibration reading

(mg/L)

0136

2

R1/W3

float

0% saturation

temperature reading

(°C)

0138

2

R1/W3

float

Calibration slope

(default = 1.0)

0140

2

R1/W3

float

Calibration offset

(default = 0.0)

15

ODO-TX Operating Manual N116-155 rev 1.0

6.2.6. Sensor Health Table

The instrument records a data quality ID between 0 and 7 with each reading. This ID indicates whether

errors occurred during the reading. It is stored in the instrument’s data quality register. See the table

below for details.

Abbreviation

Data Quality

ID

Text

Description

None

0

None

Normal Data Quality

Parameter measured without

errors using an expired user

calibration.

UC

1

User Cal Expired

Parameter measured without

errors using an expired

factory calibration.

FC

2

Factory Cal Expired

ERR

3

Unknown Error

Parameter measured with

error, sentinel value supplied.

16

ODO-TX Operating Manual N116-155 rev 1.0

WU

4

Sensor Warm-up

Sensor is warming up,

sentinel value supplied.

DIS

5

Sensor Warning

Parameter measured but does

not meet normal quality

criteria. The sensor has

sustained moderate damage,

or the recommended lifespan

has been reached.

CAL

6

Sensor Calibrating

Sensor is calibrating,

calibration value supplied.

OL

7

Sensor Missing

Sensor communication failed,

sentinel value supplied. Make

sure the sensor cap is

installed and properly seated.

17

ODO-TX Operating Manual N116-155 rev 1.0

7. Calibration

Connect the ODO-TX to a computer using the RS485 connection and open Commkit communication.

Alternately, connect the ODO-TX to an appropriate controller or PLC with calibration capability. If using

a PLC or controller to calibrate, refer to your controller manual. You can either perform a one-point or

two-point calibration as noted below.

7.1. One Point Calibration: Water-Saturated-Air 100% Saturation

1. Saturate a sponge with deionized water and insert it into the calibration cup.

2. Gently dry the probe and sensor cap with a paper towel. Make sure to remove all water and

debris.

3. Place the ODO-TX probe in the calibration cup so the sensor surface is about 2.5 cm (1”)

above the sponge.

4. Wait 5 to 10 minutes for temperature stabilization, but do not leave the probe in the

calibration cup for more than 30 minutes. Condensation can form on the sensor surface,

which may result in false readings after calibration. If condensation occurs, remove and

thoroughly dry the probe.

5. Once stable execute/complete single or first point calibration.

a. If using a PLC or controller to calibrate, refer to your controller manual.

7.2. Second Point (0%) of Two Point Calibration

1. Perform a one-point calibration as described above.

2. Remove the sponge from the calibration cup. Fill the cup to the fill line. This requires

approximately 10 mL of fresh sodium sulfite solution.

3. Place the instrument in the calibration cup. Leave at least 13 mm (1/2”) between the

surface of the sensing material and the bottom of the calibration cup.

4. Make sure the sensor is completely submerged in the solution.

5. Allow at least five minutes for the temperature to stabilize.

6. Once stable execute/complete second point calibration.

1. If using a PLC or controller to calibrate, refer to your controller manual.

7. After calibration, remove the probe. Detach the sensor. Thoroughly rinse the probe and

sensor to remove all sodium sulfite solution.

7.3. Temperature and Concentration (ppm or mg/l) calibration

Calibration for these parameters can be completed as a one or two-point calibration methpd on a

controller or PLC using respective reference meter.

Concentration calibration is automatically executed when calibrating the probe using Commkit

18

ODO-TX Operating Manual N116-155 rev 1.0

8. Maintenance

8.1. Cleaning

Probe maintenance includes cleaning the sensor cap, as well as the proper conditioning, preparation,

and storage of the test system. With the membrane sensor cap and guard cap installed on ODO-TX,

gently scrub the probe with a soft-bristled brush or nylon dish scrubber. Use Alconox or similar

cleaning solution to remove grease or other matter. Soak in vinegar and DI water to remove mineral

deposits or extensive fouling.

8.2. Replacing the Sensor Cap

The membrane Sensor Cap has a 2-year typical life after the sensor takes its first reading.

1. Remove the probe guard cap.

2. Use a lint-free cloth to remove any moisture from the probe.

3. Pull the used membrane sensor cap off of the sensor, without twisting.

4. Remove the existing O-rings from the sensor.

Do not touch orcleanthelens with anything other than the supplied lens wipe.

5. Use your finger to apply a very light layer of silicone-based lubricant around the O-ring

grooves.

6. Place the O-rings on the sensor. Apply another thin layer of lubricant to the O-rings and

grooves.

Note: Do not transfergreaseto the lens orsensorpins.

7. Remove the new cap from its sealed packaging and attach it to the sensor, being careful to

press firmly, without twisting, until it seals over the lens. Make sure that the O-rings are not

pinched or rolled between the cap and the sensor.

8. Replace the guard cap.

9. Each membrane cap comes factory calibrated, but for enhanced performance, perform a 1- or

2-point calibration to pair the new membrane sensor cap with the probe.

The ODO-TX series does consist of any user-serviceable parts. The membrane is a consumable item

and thus should only be replaced. If the guard Cap is damaged that should also be replaced. The

optical system can not be serviced and thus users/technicians must not attempt to open the probe

beyond removing the membrane sensor came and the guard cap.

19

ODO-TX Operating Manual N116-155 rev 1.0

9. Spare Parts

Part #

Description

AM-ODO-TX-CAP

ODO-TX-Replacement Sensor Cap

Sensor Cap Storage

Prior to installation—Store in factory supplied container.

Installed—Store in the calibration chamber with the storage cap attached and a few drops of

clean water.

10.Accessories

Part #

Description

AM-ODO-TX-CAL

Calibration Cap

AM-JB2

Junction box with integrated terminal strip

AM-HTA-R5

Ball Valve assembly for Hot-Tap insertion

AM-ARM-5

Submersion mounting kit

AM-TEE-R5

1” Union Tee with 3/4” adapter

AM-CFT-R5

Compression Fitting for 1” NPT sensors

AM-CBL

Extension cable

10.1. Calibration Cap

Calibrate the sensor with the Comm Kit Software or calibrate the sensor directly with your controller or

PLC.

1-Point Calibration

The optical Rugged Dissolved Oxygen sensor is very stable. The factory calibration should produce

readings within 3% accuracy. If you require readings with greater accuracy we recommend that you

perform a 1-point, 100% water-saturated air calibration as described below.

Water-Saturated Air

1. Remove the storage cap from the top of the calibration chamber and replace it with the vented

calibration cap.

1

2

Storage cap

Vented calibration cap

20

ODO-TX Operating Manual N116-155 rev 1.0

2. Place the sponge wafer in the bottom of the calibration chamber and saturate with

approximately 10 mL water.

3. Gently dry the instrument and sensing material with a paper towel, making sure there is no

water or debris on the instrument or on the sensing surface.

4. Place the instrument into the calibration chamber about 2.5 cm (1 in.) above the water-

saturated sponge.

5. Allow 5 to 10 minutes for temperature stabilization prior to starting the calibration procedure.

Do not leave the instrument in the calibration chamber for more than 30 minutes. This can allow

condensation to form on the sensing material, which will produce false low readings after

calibration. If condensation does occur, remove the instrument, dry the sensing material, place

the instrument in the chamber, and calibrate.

10.2. Mounting

10.2.1. General Installation Requirements

Check the probe to ensure that no air bubbles have formed on the electrodes during submersion.

10.2.2. Submersion Mounting with the AM-ARM-5

The ODO-TX is a fully submersible sensor. Although not required, submersion hardware to protect the

cable from wear and tear is advisable. The AM-ARM-5 consists of a 4-foot long CPVC pipe with a 1” FNPT

fitting on the front end on which to mount the probe and a strain relief on the back end. A wire bracket,

constructed of thick aluminum wire, is used to secure the arm onto the edge of a tank or basin.

Table of contents

Other Water Analytics Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Powerfix Profi

Powerfix Profi 278296 Operation and safety notes

Test Equipment Depot

Test Equipment Depot GVT-427B user manual

Fieldpiece

Fieldpiece ACH Operator's manual

FLYSURFER

FLYSURFER VIRON3 user manual

GMW

GMW TG uni 1 operating manual

Downeaster

Downeaster Wind & Weather Medallion Series instruction manual

Hanna Instruments

Hanna Instruments HI96725C instruction manual

Nokeval

Nokeval KMR260 quick guide

HOKUYO AUTOMATIC

HOKUYO AUTOMATIC UBG-05LN instruction manual

Fluke

Fluke 96000 Series Operator's manual

Test Products International

Test Products International SP565 user manual

General Sleep

General Sleep Zmachine Insight+ DT-200 Service manual