8

7 SERIES 700A11 INSTALLATION MANUAL

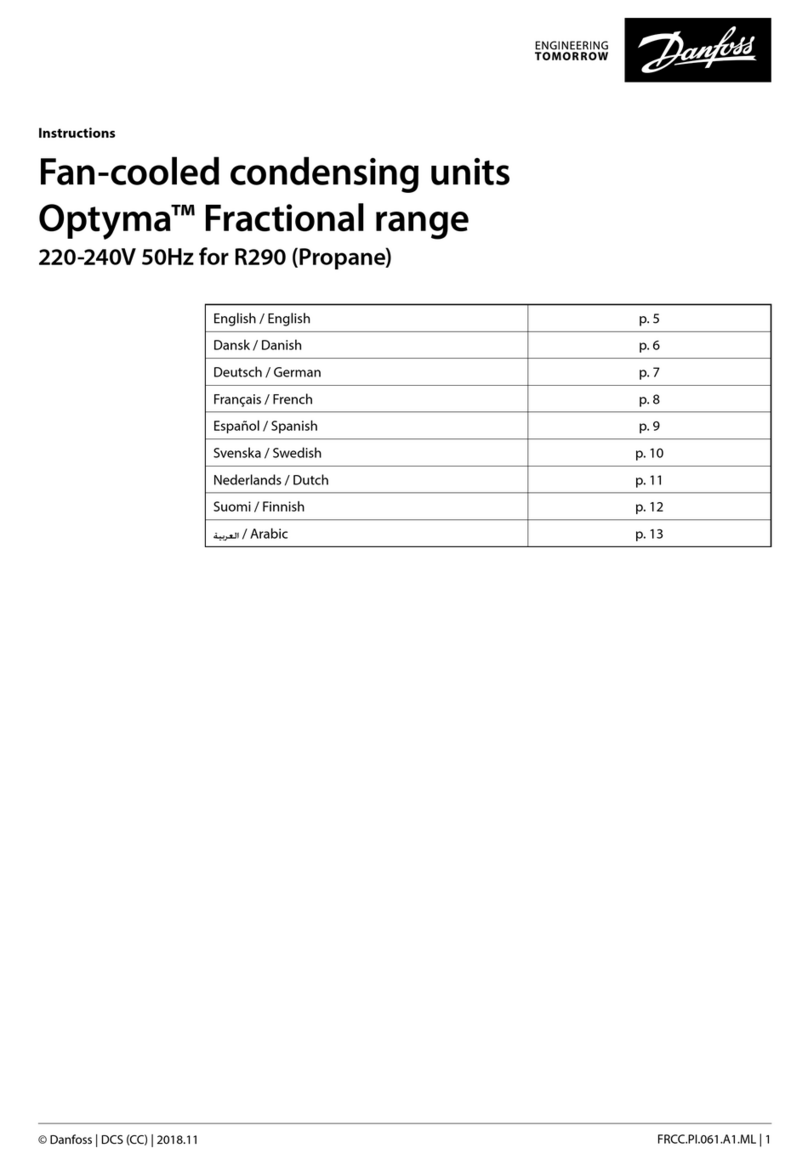

Water Quality

It is the responsibility of the system designer and installing

contractor to ensure that acceptable water quality is

present and that all applicable codes have been met in

these installations. Failure to adhere to the guidelines in

the water quality table could result in loss of warranty.

In ground water situations where scaling could be heavy

or where biological growth such as iron bacteria will be

present, a closed loop system is recommended. The heat

exchanger coils in ground water systems may, over a period

of time, lose heat exchange capabilities due to a buildup

of mineral deposits inside. These can be cleaned, but only

by a qualified service mechanic, as special solutions and

pumping equipment are required. Hot water generator coils

can likewise become scaled and possibly plugged. In areas

with extremely hard water, the owner should be informed

that the heat exchanger may require occasional flushing.

Heat pumps with cupronickel heat exchangers are

recommended for open loop applications due to the

increased resistance to build-up and corrosion, along with

reduced wear caused by acid cleaning.

Water Treatment

Do not use untreated or improperly treated water.

Equipment damage may occur. The use of improperly

treated or untreated water in this equipment may result in

scaling, erosion, corrosion, algae or slime. Purchase of a pre-

mix antifreeze could significantly improve system reliability

if the water quality is controlled and there are additives in

the mixture to inhibit corrosion. There are many examples

of such fluids on the market today such as Environol™ 1000

(pre-mix ethanol), and others. The services of a qualified

water treatment specialist should be engaged to determine

General Installation Information cont.

Material Copper 90/10 Cupronickel 316 Stainless Steel

pH Acidity/Alkalinity 7 - 9 7 - 9 7 - 9

Scaling Calcium and

Magnesium Carbonate

(Total Hardness)

less than 350 ppm

(Total Hardness)

less than 350 ppm

(Total Hardness)

less than 350 ppm

Corrosion

Hydrogen Sulfide Less than 0.5 ppm (rotten egg

smell appears at 0.5 ppm) 10 - 50 ppm Less than 1 ppm

Sulfates Less than 125 ppm Less than 125 ppm Less than 200 ppm

Chlorine Less than 0.5 ppm Less than 0.5 ppm Less than 0.5 ppm

Chlorides Less than 20 ppm Less than 125 ppm Less than 300 ppm

Carbon Dioxide Less than 50 ppm 10 - 50 ppm 10 - 50 ppm

Ammonia Less than 2 ppm Less than 2 ppm Less than 20 ppm

Ammonia Chloride Less than 0.5 ppm Less than 0.5 ppm Less than 0.5 ppm

Ammonia Nitrate Less than 0.5 ppm Less than 0.5 ppm Less than 0.5 ppm

Ammonia Hydroxide Less than 0.5 ppm Less than 0.5 ppm Less than 0.5 ppm

Ammonia Sulfate Less than 0.5 ppm Less than 0.5 ppm Less than 0.5 ppm

Total Dissolved Solids (TDS) Less than 1000 ppm 1000 - 1500 ppm 1000 - 1500 ppm

LSI Index +0.5 to -0.5 +0.5 to -0.5 +0.5 to -0.5

Iron Fouling

(Biological Growth)

Iron, FE2+ (Ferrous)

Bacterial Iron Potential < 0.2 ppm < 0.2 ppm < 0.2 ppm

Iron Oxide Less than 1 ppm, above this

level deposition will occur

Less than 1 ppm, above this

level deposition will occur

Less than 1 ppm, above this

level deposition will occur

Erosion

Suspended Solids Less than 10 ppm and filtered

for max. of 600 micron size

Less than 10 ppm and filtered

for max. of 600 micron size

Less than 10 ppm and filtered

for max. of 600 micron size

Threshold Velocity

(Fresh Water) < 6 ft/sec < 6 ft/sec < 6 ft/sec

NOTES: Grains = ppm divided by 17

mg/L is equivalent to ppm

2/22/12

what treatment, if any, is required. The product warranty

specifically excludes liability for corrosion, erosion or

deterioration of equipment.

The heat exchangers and water lines in the units are copper

or cupronickel tube. There may be other materials in the

buildings piping system that the designer may need to take

into consideration when deciding the parameters of the

water quality. If antifreeze or water treatment solution is

to be used, the designer should confirm it does not have a

detrimental effect on the materials in the system.

Contaminated Water

In applications where the water quality cannot be held to

prescribed limits, the use of a secondary or intermediate

heat exchanger is recommended to separate the unit fro

the contaminated water. The table above outlines the

water quality guidelines for unit heat exchangers. If these

conditions are exceeded, a secondary heat exchanger is

required. Failure to supply a secondary heat exchanger

where needed will result in a warranty exclusion for primary

heat exchanger corrosion or failure.

Low Water Coil Limit

Set the freeze sensing switch SW2-1 on the Aurora Base

Control (ABC) printed circuit board for applications using

a closed loop antifreeze solution to “LOOP” (15°F). On

applications using an open loop/ground water system (or

closed loop no antifreeze), set this dip switch to “WELL”

(30°F), the factory default setting. (Refer to the DIP Switch

Settings table in the Aurora Control section.)