Water Furnace SPECTRA SX Series User manual

SX Series

3/4 through 6 ton Commercial

and Residential Geothermal

System Installation Instructions

Installation and servicing of air conditioning equipment can be hazardous due to system

pressure and electrical components. Only trained and qualified service personnel should install,

repair or service air conditioning equipment.

Untrained personnel can perform basic maintenance functions of cleaning coils and cleaning

and replacing filters. All other operations should be performed by trained service personnel. When

working on air conditioning equipment, observe precautions in the literature, tags and labels

attached to the unit and other safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work gloves. Use quenching cloth for brazing

operations. Have fire extinguisher available for all brazing operations.

WARNING: Before performing service or maintenance operations on system, turn off

main power switches to indoor unit. Turn off accessory heater power switch if applicable.

Electrical shock could cause personal injury.

Move units in the normal “up” orientation as indicated by the arrows on each carton. Horizontal

units may be moved and stored per the information on the carton, “Do not stack more than 3 units

in total height.” Vertical units are not to be moved, but may be stored one upon another at a

maximum height of 2 units. When the equipment is received, all items should be carefully checked

against the bill of lading to be sure all crates and cartons have been received. Examine units for

shipping damage, removing the units from the cartons if necessary. Units in question should also

be internally inspected. If any damage is noted, the carrier should make the proper notation on the

delivery receipt, acknowledging the damage.

P/N 96P537A01 rev. 4/99

Installation

Guide

Safety

Considerations

Moving and

Storage

Model

Nomenclature

Table of

Contents Initial Desuperheater Start Up 11

Electrical Connections 11-12

Unit Electrical Data 13

Unit Operating Pressures 13

Wiring Schematic 14-15

Thermostat 16

Blower Performance Data 16

Unit Start Up 17-18

Preventive Maintenance 18-19

Troubleshooting 19

Replacement Procedures 19

Model Nomenclature 1

Safety Considerations 1

Moving and Storage 1

Physical Data 2

General Installation Information 2-5

Boiler/Cooling Tower Closed Loop Systems 5

General Piping 6

System Cleaning and Flushing 6-7

Ground Source Closed Loop Systems 7-8

Open Loop Ground Water Systems 8-9

Desuperheater Connection 9-11

0X0TSXV

Unit Size

036 = 36,000 BTUH Nominal cooling

at 85°F entering water

Electrical Characteristics

0 = 208-230/60/1 Commercial

1 = 208-230/60/1 Residential

2 = 265-277/60/1 Commercial

3 = 208-230/60/3 Commercial

4 = 460-480/60/3 Commercial

5 = 575-600/60/3 Commercial

Design Vintage

Model Type

SXV = Vertical Unit

SXH = Horizontal Unit

036 C C1

Coax Options

C = Copper

N = Cupronickel

Non-Standard Options

Discharge Air Options

T = Top (Vertical)

E = End (Horizontal)

S = Side (Horizontal)

L

Return Air Options

L = Left return

R = Right return

B = Commercial Microprocessor Unit Controls

C = ElectroMechanical Unit Controls

Hot Water Options

0 = None

1 = Hot Water Generation W/Pump (Residential)

2 = Hot Water Generation Without/Pump (Commercial)

Cabinet

0 = Painted Steel Cabinet

1 =Galvanized Steel Cabinet

2

SPECTRA COMMERCIAL AND RESIDENTIAL INSTALLATION GUIDE

Unit Location

Locate the unit in an indoor area that allows easy removal of the filter and access

panels, and has enough space for service personnel to perform maintenance or repair.

Provide sufficient room to make water, electrical and duct connection(s). If the unit is

located in a confined space, such as a closet, provisions must be made for return air to

freely enter the space by means of a louvered door, etc. Any access panel screws that

would be difficult to remove after the unit is installed should be removed prior to setting the

unit. On horizontal units, allow adequate room below the unit for a condensate drain trap

and do not locate the unit above supply piping. These units are not approved for outdoor

installation and must be installed inside the structure being conditioned.

CAUTION:

Do not locate in areas where ambient conditions are not maintained

within 45

°

-95

°

F and up to 75% relative humidity.

Setting the Vertical Units

Vertical units are available in left or right air return configurations. Top flow vertical units

should be mounted level on a vibration absorbing pad slightly larger than the base to

provide isolation between the unit and the floor. It is not necessary to anchor the unit to the

floor (see figure 1). Bottom flow units

should be mounted level and sealed

well to floor to prevent air leakage.

If left side unit access will be

limited after installation, remove the

two left side control box mounting

screws before setting the unit (leave

the two front mounting screws intact).

This will allow the control box to be

removed with only the two front

mounting screws for future service.

Setting the Horizontal Units

Horizontal units are available with side or end discharge and may be field converted

from one to the other by replacing the discharge panel. The new panel must be ordered.

Horizontal units are normally suspended from a ceiling by four 3/8” diameter threaded rods

(6 on SXH042-068). The rods are usually attached to the unit corners by hanger bracket

kits furnished with each unit.

Figure 1– Vertical Unit Mounting

General

Installation

Information

Physical

Data

MODEL SX010 SX013 SX016 SX019 SX024 SX030 SX036 SX042 SX048 SX058 SX068

Fan Wheel 6 X 8 6 X 8 9 X 7 9 X 7 9 X 7 9 X 7 9 X 7 10 X 10 10 X 10 11 X 10 11 X 10

PSC Fan Motor HP - # of Speeds 1/10 - 4 1/10 - 4 1/6 - 3 1/6 - 3 1/5 - 3 1/3 - 3 1/2 - 3 1/2 - 3 1/2 - 3 3/4 - 3 1.0 - 3

Compressor Rotary Rotary Rotary Rotary Recip Recip Recip Recip Recip Scroll Scroll

R22 (oz.) 28.0 36.0 38.0 43.0 63.0 66.0 65.0 95.0 86.0 98.0 98.0

Vertical

Air Coil Dimensions (in.) 12 x 16 16 x 16 19 x 20 19 x 20 24 x 20 24 x 20 27 x 20 28 x 25 28 x 25 32 x 25 36 x 25

Air Coil Face Area (sq ft.) 1.3 1.8 2.6 2.6 3.3 3.3 3.8 4.9 4.9 5.6 6.3

Air Coil # of Rows 3 3 3 3 3 3 3333 3

Filter - 1" Throwaway (Std.) 16 X 20 16 X 20 18 X 24 18 X 24 24 X 24 24 X 24 2-14 X 24 2 -14 X 30 2 - 14 X 3

0

2 - 10 X 30 3 - 12 X 30

1 - 12 X 30

Filter - 1" Electrostatic (opt.) EAF1620 EAF1620 EAF1824 EAF1824 EAF2424 EAF2424 EAF2428 EAF2830 EAF2830 EAF3032 EAF3036

Weight 150 163 180 183 265 270 290 326 344 401 428

Horizontal

Air Coil Dimensions (in.) 12 x 16 16 x 16 18 x 21 18 x 21 18 x 27 18 x 27 18 x 30 20 x 35 20 x 35 20 x 40 20 x 45

Air Coil Face Area (sq in.) 1.3 1.8 2.6 2.6 3.4 3.4 3.8 4.9 4.9 5.6 6.3

Air Coil # of Rows 3 3 3 3 3 3 3333 3

Filter - 1" Throwaway (Std.) 16 x 20 16 x 20 18 x 24 18 x 24 2-18 x 18 2-18 x 18 2-18 x 18 1 - 20 x 12 1 - 20 x 12 1 - 18 x 20 2 - 24 x 20

1 - 20 x 25 1 - 20 x 25 1 - 24 x 20

Filter - 1" Electrostatic (opt.) EAF1620 EAF1620 EAF1824 EAF1824 EAF1836 EAF1836 EAF1836 EAF2037 EAF2037 EAF2042 EAF2048

Weight 155 164 194 204 270 272 286 343 347 431 458

Vibration

Absorbing

Mesh

Air

Pad

3

SPECTRA COMMERCIAL AND RESIDENTIAL INSTALLATION GUIDE

CAUTION: Do not use rods smaller than 3/8” diameter since they may not be

strong enough to support the unit. The rods must be securely anchored to the ceiling.

Lay out the threaded rods per the dimensions in Figure 2A, and assemble the hangers to

the unit as shown. Securely tighten the brackets to the unit using the weldnuts located on the

underside of the bottom panel. When attaching the hanger rods to the bracket, a double nut

is required since vibration could loosen a single nut. The unit should be pitched approxi-

mately 1/4” towards the drain in both directions, to facilitate condensate removal (see Figure

3B, on page 4). Use only the bolts provided in the kit. The use of longer bolts could damage

internal parts.

Some residential applications require an attic floor installation of horizontal units. In this

case, the unit is set in a full size secondary drain pan on top of vibration absorbing mesh.

The secondary drain pan prevents possible condensate overflow or water leakage damage to

the ceiling. The secondary drain pan is usually placed on a plywood base isolated from the

ceiling joists by additional layers of vibration absorbing mesh.

Duct System

An air outlet collar is provided on vertical top flow units and all horizontal units to facilitate

a duct connection (vertical bottom flow units have no collar). A flexible connector is recom-

mended for discharge and return air duct connections on metal duct systems. Uninsulated

duct should be insulated with a minimum of one-inch duct insulation. Application of the unit to

uninsulated ductwork in an unconditioned space is not recommended as the unit’s perfor-

mance will be adversely affected.

Air Handler

Section

Compressor

Section

Figure 2A– Hanger Location and Assembly

Bolt and

Lockwasher

Vibrator

Isolator

Washer

Hex Nuts

(by others)

3/8" Threaded Rod

(by others)

MODEL

MODEL A B C D E

SXH010-013 24.75 42.5 22.5 44 -

SXH016-019 24.75 51.5 22.5 53 -

SXH022-034 24.75 61.5 22.5 63 -

SXH042-048 27.75 70.5 25.5 72 29.87

SXH058 27.75 75.5 25.5 77 29.87

SXH068 27.75 80.5 25.5 82 29.87

Figure 2B– Optional Filter Rack

1" duct connection provided

Air tight construction

MODEL A B C D E MODEL NO.

SX010-013 20.2 16.2 1.8 0.5 5.5 DCH1620

SX016-019 24.2 18.2 1.2 0.5 5.5 DCH1824

SX024-030 36.2 18.2 1.2 0.5 5.5 DCH1836

SX042-048 37.2 20.2 1.8 0.5 5.5 DCH2037

SX058 42.2 20.2 1.8 0.5 5.5 DCH2042

SX068 48.2 20.2 1.3 0.5 5.5 DCH2048

4

SPECTRA COMMERCIAL AND RESIDENTIAL INSTALLATION GUIDE

For vertical bottom flow units, cut the air discharge floor opening at least 1/2" larger than

unit air outlet.

Protect opening edges in combustible flooring with sheet metal overwrap.

Discharge air only into a suitable supply duct system and do not locate registers or open-

ings directly under unit air outlet.

If the unit is connected to existing ductwork, a previous check should have been made

to assure that the duct has the capacity to handle the air required for the unit application. If

ducting is too small, as in the replacement of heating only systems, larger ductwork should

be installed. All existing ductwork should be checked for leaks and repairs.

The duct system should be sized to handle the design airflow quietly.

To maximize

sound attenuation of the unit blower, the supply and return plenums should include internal

duct liner of glass fiber or be of ductboard construction for the first few feet.

If air noise or

excessive air flow is a problem, the blower speed can be changed. See the Blower Perfor-

mance and Fan Speed sections for further instructions.

CAUTION:

Be sure to remove the foam shipping material from the blower throat

before connecting ductwork.

Water Piping

All Residential Spectra source

water connections are swivel piping

fittings that accept a 1" Male Pipe

Thread (MPT) (see Figure 4A). The

swivel connector has a rubber gasket

seal similar to a garden hose gasket,

which when mated to the flush end of

any 1" threaded pipe provides a leak-

free seal without the need for thread

sealing tape or compound. Check to

insure that the rubber seal is in the

swivel connector prior to attempting

any connection. The rubber seals are

shipped attached to one of the swivel

connections on the unit. DO NOT

OVERTIGHTEN or leaks may occur.

To make the connection to a

ground loop system, mate the brass

connector (supplied in CK4L & CK4S

connector kits) against the rubber

gasket in the swivel connector, and

thread the female locking ring onto

the pipe threads, while maintaining

the brass connector in the desired

direction (see Figure 4B). Tighten the

connectors by hand to provide a leak

proof joint. When connecting to an

open loop (ground water) system,

thread any 1" MPT fitting (PVC or

copper) into the swivel connector and

tighten in the same manner as noted

above. The open and closed loop

piping system should include pressure/temperature taps for serviceability.

Figure 3A - Horizontal Drain Connection

1/4” Pitch

Drain

Figure 3B - Uni Pitch for Drain

Figure 4B - The

Female Locking Ring is

threaded onto the pipe

threads which holds the

male pipe end against

the gasket, and seals

the joint. HAND

TIGHTEN ONLY! DO

NOT OVERTIGHTEN!

Figure 4A

This side is soldered

to the unit tubing

Brass Body

Threaded Female

Locking Ring Retaining Ring

Gasket Seal

Brass Stop Ring

1.5" 1.5"

Vent (if needed)

3/4" PVC

3/4" barb to

glue adapter *

1/8" per foot

Clear PVC hose *

Plastic Hose Clamp *

Copper tube stub

*Included with unit

5

SPECTRA COMMERCIAL AND RESIDENTIAL INSTALLATION GUIDE

Never use flexible hoses smaller than 1" inside diameter on the unit and limit hose

length to 10 ft. per connection. Check carefully for water leaks.

Water Quality

The unit may be ordered with either a copper or a cupronickel coaxial heat exchanger.

Copper is adequate for closed loop and open loop ground water systems which are not high

in mineral content. In conditions anticipating moderate scale formation or in brackish water,

a cupronickel heat exchanger is recommended. In ground water situations where scaling

could be heavy or where biological growth such as iron bacteria will be present, a closed

loop system is recommended. Ground water unit heat exchanger coils may over a period of

time lose heat exchange capabilities due to a buildup of mineral deposits inside. These can

be cleaned, but only by a qualified service mechanic as special solutions and pumping

equipment are required. Desuperheater coils can likewise become scaled and possibly

plugged. In areas with extremely hard water, the homeowner should be informed that the

heat exchanger may require occasional acid flushing.

Freeze Protection (Commercial Microprocessor Only)

Set the freeze protection switch SW1 #2 on the microprocessor board for applications

using a closed loop antifreeze solution to" LOOP". On applications using an open loop/

ground water system or non freeze protected loop, set to "WELL" (the factory setting).

Condensate Drain

On vertical units, the internal condensate drain assembly consists of a drain tube which

is connected to the drain pan, a 3/4" PVC female adapter and a flexible connecting hose.

The female adapter may exit either the front or the side of the cabinet. The adapter should

be glued to the field-installed PVC condensate piping. On vertical units, a condensate hose

is inside all cabinets as a trapping loop; therefore, an external trap is not necessary. On

horizontal units, a copper stub is provided for condensate drain piping connection. An

external trap is required (see Figure 3A page 4). If a vent is necessary, an open stand pipe

may be applied to a tee in the field-installed condensate piping.

Air Coil

To obtain maximum performance the air coil should be cleaned before start up. A 10%

solution of dishwasher detergent and 90% water is recommended for both sides of coil. A

thorough water rinse should follow.

Boiler/Cooling Tower

The water loop is usually maintained between 60°F and 90°F (Spectra units allow 25°F -

110°F EWT) for proper heating and cooling operation. see Figure 5 page 6 for a typical

installation.

To reject excess heat from the water loop, the use of a closed circuit evaporative cooler

or an open type cooling tower with a secondary heat exchanger between the tower and the

water loop is recommended. If an open type cooling tower is used without a secondary heat

exchanger, continuous chemical treatment and filtering of the water must be performed to

ensure the water is free from damaging materials.

CAUTION: Water piping exposed to outside temperatures may be subject to freezing.

NOTE:

For Boiler/Cooling Tower Systems with no antifreeze solution, set SW1-Switch

#4 to the "WELL" position.

Boiler/Cooling

Tower Closed

Loop Systems

6

SPECTRA COMMERCIAL AND RESIDENTIAL INSTALLATION GUIDE

Figure 5- Closed Loop Cooler/Boiler System

Disconnects

Boiler/Cooling

Tower Loop

Flexible Duct

Collar

3/8”

Threaded rods

(6) on AT040-046

Hanging

Brackets

(included)

P/T Plugs

Line Voltage

To Thermostat

Insulate supply

plenum and use at

least a 90°elbow

to reduce noise Hose Kits

To Line

Power

Electric heat

assembly

(optional)

Drain per

Figure 2 On air

coil, side or end Drain per

Figure 2

Water Piping Connections

Units should not be connected to the supply and return piping until the water system

has been cleaned and flushed completely. Supply and return water connections are

standard female pipe thread. Never use flexible hoses with an inside pipe diameter that is

smaller than the water connections on the unit and limit the hose length to 10 feet or less

per connection. High-pressure flexible hoses provide sound attenuation for both normal unit

operating noise and hydraulic pumping noise. Hard piping can also be brought directly

to the unit although it is not recommended since no vibration or noise attenuation can

be accomplished.

Cleaning and Flushing

Prior to start up of any heat pump, the water circulating system must be cleaned and

flushed of all dirt and debris.

If the system is equipped with water shutoff valves, the supply and return runouts must

be connected together at each unit location (This will prevent the introduction of dirt into the

unit, see Figure 6). The system should be filled at the water make-up connection with all

air vents open. After filling, vents should be

closed.

The contractor should start the main

circulator with the pressure reducing valve

makeup open. Vents should be checked in

sequence to bleed off any trapped air and to

verify circulation through all components of the

system.

As water circulates through the system,

the contractor should check and repair any

leaks found in the piping system. Drain(s) at

the lowest point(s) in the system should be

opened for initial flush and blowdown, making

sure water fill valves are set at the same rate.

General

Piping

System

Cleaning

and Flushing

Figure 6 - Flushing with Water Shutoff

Valve Equipped Systems

7

SPECTRA COMMERCIAL AND RESIDENTIAL INSTALLATION GUIDE

Ground

Source Closed

Loop Systems

Check the pressure gauge at the pump suction and manually adjust the make-up water

valve to hold the same positive pressure both before and after opening the drain valves.

Flushing should continue for at least two hours, or longer if required, until drain water is

clean and clear.

The supplemental heater and/or circulator pump, if used, should be shut off. All drains

and vents should be opened to completely drain the system. Short-circuited supply and

return runouts should now be connected to the unit supply and return connections.

Refill the system with clean water. Test the system water for acidity and treat as

required to leave the water slightly alkaline (pH 7.5 to 8.5). The specified percentage of

antifreeze may also be added at this time. Use commercial grade antifreeze designed for

HVAC systems only. WaterFurnace recommends the Environol™ brand antifreeze.

Once the system has been filled with clean water and antifreeze (if used), precautions

should be taken to protect the system from dirty water conditions. Dirty water will result in

system-wide degradation of performance, and solids may clog valves, strainers, flow

regulators, etc. Additionally, the heat exchanger may become clogged which reduces

compressor service life and can cause premature unit failure.

In boiler/tower applications, set the loop control panel set points to desired tempera-

tures. Supply power to all motors and start the circulating pumps. After full flow has been

established through all components including the heat rejector (regardless of season), air

vented and loop temperatures stabilized, each of the units will be ready for check, test

and start up and for air and water balancing. Use form WFS159 and when performing

commercial check, test and start up. Obtain these forms from your commercial

representative or contact WaterFurnace.

Ground Source Systems

Once piping is completed between the unit, flow center and the ground loop (Figure 7

on page 8), final purging and charging of the loop is needed. A WaterFurnace flush cart (at

least a 1.5 hp pump) is needed to achieve adequate flow velocity in the loop to purge air

and dirt particles from the loop itself. Antifreeze solution is used in most areas to prevent

freezing. Flush the system adequately to remove as much air as possible, then pressurize

the loop to a static pressure of 40-60 psi. This is normally adequate for good system

operation. Loop static pressure may decrease soon after initial installation due to pipe

expansion and loop temperature change. Running the unit for at least 30 minutes after the

system has been completely purged of air will allow for this “break-in” period. It may be

necessary to adjust static pressure (by adding water) after the unit has run for the first time.

Loop static pressure will also fluctuate with the seasons. Pressures will be higher in the

winter months than during the cooling season. This fluctuation is normal and should be

considered when charging the system initially. Pressurizing the system to 40-60 psi in the

winter may result in a 15-20 psi static pressure in the summer.

After pressurization, be sure to remove the plug in the end of the loop pump motor(s) to

allow trapped air to be discharged and to insure the motor housing has been flooded.

Insure the loop flow center provides adequate flow through the unit by checking pressure

drop across the heat exchanger and comparing it to the figures shown in Table 3 on page

17. Usually 2.5-3 gpm of flow per ton of cooling capacity is recommended in earth loop

applications. See Wiring Schematic on page 14 for loop pump power wiring details.

Note: Some systems may require adding pressure after the first heating/cooling season.

NOTE:

For closed loop systems with antifreeze protection, set SW1 Switch #4

to the "LOOP" position.

8

SPECTRA COMMERCIAL AND RESIDENTIAL INSTALLATION GUIDE

Ground Water Systems

Typical open loop piping is shown in Figure 8 on page 9. Always maintain water

pressure in the heat exchanger by placing water control valves at the outlet of the unit to

prevent mineral precipitation. Use a closed, bladder-type expansion tank to minimize

mineral formation due to air exposure. Insure proper water flow through the unit by check-

ing pressure drop across the heat exchanger and comparing it to the figures in Table 3 on

page 17. Normally, about 1.5 gpm flow rate per ton of cooling capacity (2 gpm per ton with

water temperature below 50°F) is needed in open loop systems.

Discharge water from the unit is not contaminated in any manner and can be disposed

of in various ways, depending on local building codes, i.e. recharge well, storm sewer, drain

field, adjacent stream or pond, etc. Most local codes forbid the use of sanitary sewer for

disposal. Consult your local building and zoning department to assure compliance in your

area.

NOTE:

For Open Loop/Ground Water Systems or systems that do not contain an

antifreeze solution, set SW1-DIP Switch #4 to the "WELL" position.

Open Loop

Ground Water

Systems

Figure 7- Closed Loop: Ground Source Application

Flexible Duct Collar

Vibration Absorbin

g

Pad

P/T Plugs

Drain

Disconnects

(If Applicable)

TO

LOOP

Desuperheater

Connections

Auxiliary

Heater

Knockout

External

Pump Power

Unit

Power

Unit Supply Auxiliary Heat

Supply

* For complete

Geolink Flow

Center installation

information refer

to WF P/N

96P090A01

Low

Voltage to

Thermostat

WF Ground Loop Connector

Kits with Armaflex

(CK4S or CK4L)

®

GEOLINK

Flow

Centre*

®

GEOLINK

Polyethylene with

Armaflex

®

®

9

SPECTRA COMMERCIAL AND RESIDENTIAL INSTALLATION GUIDE

Figure 8 - Open System: Ground Water Application

Water Tank Preparation

Water heater should be a family-sized model, approximately a 50-gallon capacity for

up to a family of four. For families of more than four, an 80-gallon water heater is recom-

mended, or use two 50-gallon water heaters connected in series as shown in Figure 10 and

11 page 10. Electric water heaters are recommended.

Steps:

1) Turn off power supply to the water heater. Elements will burn out if energized dry.

2) Attach water hose to water tank drain connection and run other end of hose to an open

drain or outdoors.

3) Close cold water inlet valve to water heater tank.

4) Drain tank by opening valve on bottom of tank, then open pressure relief valve or hot

water faucet.

5) Flush the tank by opening the cold water inlet valve to water heater to free the tank of

sediments. Close when draining water is clear.

6) Disconnect the garden hose and remove the drain valve from the water heater.

Plumbing Installation

Steps:

1) Thread the male end of the coaxial drain tee into the water heater drain port (see

Figures 10 and 11).

2) Solder the 1/2" long elbow into the coaxial drain tee with the 90°bend pointing in the

correct direction (see figure 9 page 10).

3) Install drain valve on drain tee assembly.

Desuperheater

Connection

Flexible Duct Collar

Vibration

Absorbing Pad

P/T Plugs

Drain

Shut-Off Valve

(to isolate solenoid valve

while acid flushing)

Disconnects

(If Applicable)

Desuperheater

Connections

Auxiliary

Heater

Knockout

Low Voltage

to Thermostat

and Valve

Unit

Power

Unit Supply

Aux. Heat Supply

Water Out

Water In

Shut Off

Valves

Boiler Drains

For HX Flushing

Strainer

Rubber Bladder

Expansion Tank

Flow Control Valve

(on oulet of solenoid valve

10

SPECTRA COMMERCIAL AND RESIDENTIAL INSTALLATION GUIDE

4) Run interconnection copper tubing (1/2”

nominal). The recommended maximum

distance is 50 ft. between the unit and water

heater (see Figures 10 and 11).

5) To prevent air entrapment in the system, install

a vent coupling at the highest point of the

interconnecting line.

6) Insulate all exposed surfaces of both

connecting water lines with 3/8" wall

closed cell insulation.

Figure 9 - Water Heater Connection Kit

Cold

Drain Valve

Coaxial

Drain Tee

In

Out

P/T Relief

Valve

Long

Elbow

Venting

Waste Valve

or Vent

Coupling

Drain Valve

P/T Relief

Valve

Hot

Do not connect electrical to pre-heat tank.

Figure 11 - Desuperheater Installation

Preheat Tank

Drain Valve

Coaxial

Drain Tee

In

Out

P/T Relief

Valve

Long

Elbow

Venting

Waste Valve

or Vent

Coupling

Hot

Cold

Water In

Cold

Figure 10 - Typical Desuperheater Installation

for Units with Internal Pumps

11

SPECTRA COMMERCIAL AND RESIDENTIAL INSTALLATION GUIDE

Water Tank Refill

Steps:

1) Close water heater drain valve.

2) Open cold water supply to tank.

3) Open hot water faucet in house to bleed air from system then close when full.

4) Depress handle on pressure relief valve to bleed any remaining air from tank, then

close.

5) If so equipped, unscrew indicator plug on motor end of pump (note commercial units

pump exterior) until all air is purged from pump. Tighten plug. Use vent couplings to

bleed air from lines.

6) Carefully inspect all plumbing for water leaks. Correct as required.

7) Before restoring electrical or fuel supply at water heater, adjust temperature setting

on tank.

• On tanks with both upper and lower elements, the lower element should be turned

down to the lowest setting, approximately 100°F. The upper element should be

adjusted to 130°F. Depending upon the specific needs of the customer, you may

want to adjust the upper element differently.

• On tanks with a single element, lower the thermostat setting to 120°F.

8) After thermostat adjustments are completed, replace access cover and restore

electrical or fuel supply to water heater.

Steps:

1) Make sure any valves in desuperheater water circulating circuit are open. Never

operate the DHW circulating pump dry.

2) Turn on Spectra unit to first stage heat.

3) DHW pump should be running. Be sure DHW pump disable switch (SW1 #2) is ON

(refers to commercial microprocessor only).

4) The temperature difference between water entering and leaving the desuperheater

should be 5°to 15°F. The water flow should be approximately 0.4 gpm per ton of

nominal cooling.

5) Allow unit to heat water 15 to 20 minutes to be sure operation is normal.

6) When the pump is first started, allow the pump to run for at least 5 minutes to insure

water has filled the circulator properly.

Desuperheater Note:

When servicing a unit’s refrigeration circuit, it is always good practice to disable the

desuperheater pump. This can be accomplished by using the DHW pump disable switch

(SW1 #2), on the commercial microprocessor with an electronic unit, remove the orange

wire lead from the "A" terminal on the power strip. Do not run DHW pump dry. If the unit is

placed in operation before the desuperheater piping is connected, be sure the pump switch

is set to the "OFF" position.

General

Be sure the available power is the same voltage and phase as that shown on the unit

serial plate. Line and low voltage wiring must be done in accordance with local codes or the

National Electric Code, whichever is applicable.

Unit Power Connection

Line voltage connection is made by connecting the incoming line voltage wires to the “L”

side of the contactor as shown in Figure 12 on page 12. Consult the UNIT ELECTRICAL

DATA on page 13 for correct fuse size.

Initial

Desuperheater

Start Up

Electrical

Connections

12

SPECTRA COMMERCIAL AND RESIDENTIAL INSTALLATION GUIDE

208 Volt Operation

All 208-230 volt units are factory wired for 230 volt operation. For 208 volt operation, the

red and the blue transformer wires must be switched between terminal strip PS and

contactor CC.

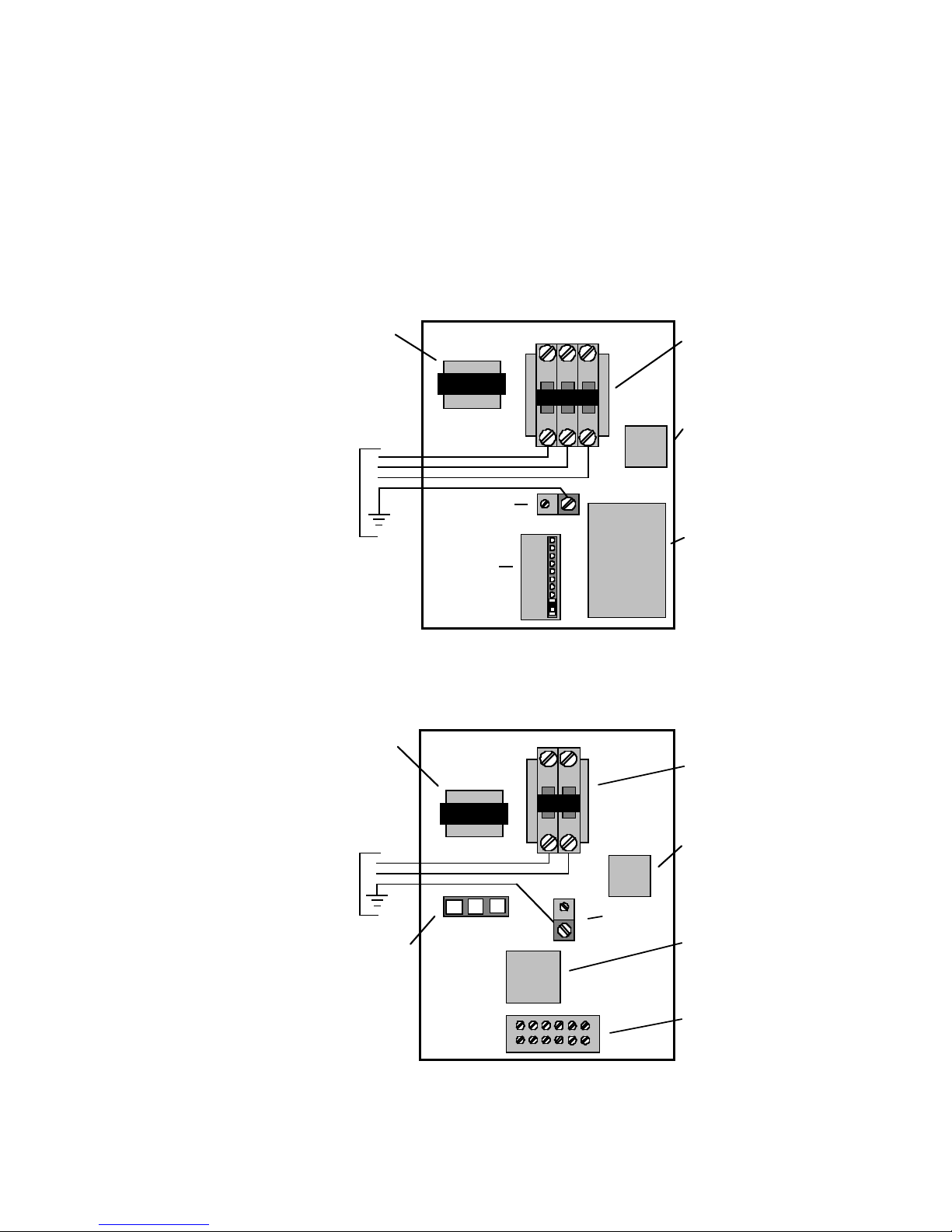

Figure 12– Spectra SX Line Voltage

Blower

Relay

Compressor

Control

Module

Transformer Compressor

Contactor

Ground

Lug

Typical Electromechanical Control Box

Configuration

Terminal

Board

Power

Strip

Electrical

Supply

with

Ground A C D

Microprocessor

Transformer Compressor

Contactor

Ground Lug

LED Board

Typical Commercial Microprocessor

Control Box Configuration

Electrical

Supply

with

Ground

Blower

Relay

13

SPECTRA COMMERCIAL AND RESIDENTIAL INSTALLATION GUIDE

Compressor Fan

Model Rated Voltage Motor

Total Unit Min. Circuit Max. Max. HACR Total Unit Min. Circuit Max. Max. HACR

Voltage Min./Max. MCC RLA LRA FLA

FLA Ampacity Fuse* Breaker* FLA Ampacity Fuse Breaker

SX010 208-230/60/1 197/254 6.9 4.4 23.0 0.6 10.8 11.9 15 15 5.0 6.1 10 10

265/60/1 239/292 4.6 2.9 16.0 0.6 - - - - 3.5 4.3 6 6

SX013 208-230/60/1 197/254 7.4 4.7 27.0 0.6 11.1 12.3 15 15 5.3 6.5 10 10

265/60/1 239/292 5.4 3.5 22.0 0.6 - - - - 4.1 4.9 6 6

SX016 208-230/60/1 197/254 9.2 5.9 29.0 1.1 12.8 14.3 20 20 7.0 8.5 10 10

265/60/1 239/292 8.5 5.4 27.0 1.0 - - - - 6.4 7.8 10 10

SX019 208-230/60/1 197/254 11.0 7.1 38.0 1.1 14.0 15.7 20 20 8.2 9.9 15 15

265/60/1 239/292 8.6 5.5 32.0 1.0 - - - - 6.5 7.9 10 10

SX024 208-230/60/1 197/254 14.6 9.4 49.0 1.2 16.4 18.7 25 25 10.6 12.9 20 20

265/60/1 239/292 12.8 8.2 44.0 1.1 - - - - 9.3 11.4 15 15

SX030 208-230/60/1 197/254 15.3 9.8 56.0 1.5 17.1 19.6 25 25 11.3 13.8 20 20

265/60/1 239/292 13.8 8.8 55.0 2.0 - - - - 10.8 13.1 20 20

208-230/60/3 197/254 10.5 6.7 51.0 1.5 - - - - 8.2 9.9 15 15

460/60/3 414/506 5.4 3.5 25.0 1.1 - - - - 4.6 5.4 6 6

SX036 208-230/60/1 197/254 21.4 13.7 75.0 2.2 21.7 25.1 35 35 15.9 19.3 30 30

265/60/1 239/292 19.4 12.4 73.0 2.0 - - - - 14.4 17.5 25 25

208-230/60/3 197/254 14.0 9.0 68.0 2.2 - - - - 11.2 13.4 20 20

460/60/3 414/506 6.7 4.3 34.0 1.1 - - - - 5.4 6.5 10 10

SX042 208-230/60/1 197/254 22.5 14.4 82.0 2.8 23.0 26.6 40 40 17.2 20.8 35 35

208-230/60/3 197/254 14.0 9.0 70.0 2.8 - - - - 11.8 14.0 20 20

460/60/3 414/506 7.1 4.6 33.0 1.4 - - - - 6.0 7.1 10 10

575/60/3 518/633 5.3 3.4 27.0 1.4 - - - - 4.8 5.6 6 6

SX048 208-230/60/1 197/254 26.6 17.1 105.0 3.5 26.4 30.6 45 45 20.6 24.8 40 40

208-230/60/3 197/254 16.7 10.7 85.0 3.5 - - - - 14.2 16.9 30 30

460/60/3 414/506 8.2 5.3 42.0 1.8 - - - - 7.1 8.4 10 10

575/60/3 518/633 6.7 4.3 34.0 1.8 - - - - 6.1 7.2 10 10

SX058 208-230/60/1 197/254 37.0 23.7 129.0 4.6 34.1 40.0 60 60 28.3 34.2 50 50

208-230/60/3 197/254 21.0 13.5 99.0 4.6 - - - - 18.1 21.4 30 30

460/60/3 414/506 11.5 7.4 49.0 2.3 - - - - 9.7 11.5 15 15

575/60/3 518/633 9.0 5.8 40.0 2.3 - - - - 8.1 9.5 15 15

SX068 208-230/60/1 197/254 45.0 28.8 169.0 5.9 40.5 47.8 70 70 34.7 42.0 70 70

208-230/60/3 197/254 27.0 17.3 123.0 5.9 - - - - 23.2 27.5 40 40

460/60/3 414/506 14.0 9.0 62.0 3.0 - - - - 12.0 14.2 20 20

575/60/3 518/633 11.0 7.1 50.0 3.0 - - - - 10.1 11.8 15 15

*Includes 5.4 amperage allowance for source side loop pump (up to 1/2 H.P.)

and 0.4 amperage allowance for desuperheater circulating pump operation.

Always refer to unit nameplate data prior to installation.

HACR circuit breaker in United States only. All fuses are class RK-5.

CommercialResidential

Unit Electrical

Data

Unit Operating Pressures*

Cooling** Heating - No Desuperheater

Entering Water Suction Discharge Water Air Suction Discharge Water Air

Water Flow Pressure Pressure Super- Sub- Temp Temp Pressure Pressure Super- Sub- Temp Temp

Temp °F GPM PSIG PSIG heat cooling Rise °F Drop °F DB PSIG PSIG heat cooling Drop °F DB Rise °F

1.5 61-70 100-117 25-35 15-25 21-24 21-26 34-39 163-183 8-12 5-9 7.6-8.4 14-20

30 2.3 62-71 92-109 25-35 15-25 13-16 21-26 37-42 165-185 8-12 5-9 4.8-5.6 16-22

3.0 62-71 88-104 25-35 15-25 6-11 21-26 38-44 167-186 8-12 5-9 3.4-4.2 16-22

1.5 79-85 145-170 15-21 12-25 20-23 20-25 51-58 175-202 10-15 5-9 10.8-11.9 23-29

50 2.3 75-83 130-155 15-21 12-25 12-15 20-25 53-62 178-206 10-15 5-9 6.7-8.1 24-30

3.0 72-82 125-150 15-21 12-25 8-12 20-25 55-65 180-208 10-15 5-9 5.1-5.9 25-31

1.5 78-88 180-200 12-18 13-18 19-22 19-24 71-82 215-250 15-24 3-7 14.0-15.2 28-34

70 2.3 78-90 169-187 12-18 13-18 11-14 19-24 77-89 203-235 15-24 3-7 9.0-10.2 30-37

3.0 78-91 160-180 12-18 13-18 7-12 19-24 81-92 200-235 15-24 3-7 6.7-7.9 31-38

1.5 79-92 230-272 12-18 13-18 18-21 17-23 - - - - - -

90 2.3 80-93 215-248 12-18 13-18 10-14 17-23 - - - - - -

3.0 80-93 208-240 12-18 13-18 6-11 17-23 - - - - - -

*Based on Nominal 400 cfm per ton airflow and 70°F EAT htg. and 80/67°F EAT cooling.

**Cooling air and water numbers can vary greatly with changes in humidity.

14

SPECTRA COMMERCIAL AND RESIDENTIAL INSTALLATION GUIDE

C ommon

E Heat

A uxiliary Heat

F an

2 4VA C

R eversingVa lve

R unSignal

C ompressor

F aultSignal

C C

B lue

2 30V

T ransformer

2 4V

O

L

Y 1

B rown

R V

G

T B

N OTE1

R ed

2 08V

R

P S

Y 2

W 2

W 1

R B

Yellow

B lack

C om

G rey/White

R ed

R BI

5

3

1

2

4

C

B lack

B lack/White

Ta n

R ed

W hite

W hite

O PTIONAL

E MSERIES

A UXILIARY HEAT

X 2

X 1

Ta n

1

3

2

1

3

2

S

L P

H P

B lack

B lack

B lue

L P

H P

C CG

C C

L O

Y

R

C

G reen

11

44

2

2

5

5

3

3

6

6

B lue

Yellow

O range

O range

V iolet

B lue/

W hite

P ink

B lack

O range

B lk/Wht

O range

C CM

B lack/

W hite

B lack

B lack

B lue

B lue

CD

A

C ompressor

U nit

P owerSupply

2 08-230/60/1

C ap

C C

T 1

L 1

T 2

Ta n

R B

B lack

W hite

B rown

C ap

B rown

W hite

P SC

F anMotor

G reen

MHL

L oop

P ump

W hite

B lack

O rangeOrange

G

C

R

S

B lackRed

B lue

F 1 F 1

3

1

C ap

B rn

W h

W hBlk

R ed

G rn

321 C

Yel 4 AirFlow

S ettings

B lu

P SC

F anMotor

N OTE4

N OTE3

D HW

P ump

P inkBlue

O rangeOrange

O range

N OTE2

F 1 F 1

O rangeOrange

H WL

B lack Black

O range

D esuperHeaterOption

3 Airflow

S ettings

4

L 2

O range

F actory lowvoltagewiring

L egend

S witch-Highpressure

S witch-Lowpressure

R elaycoil

Te mperatureLimitSwitch

F ieldwirelug

G round

R elayContacts-

N .O.,N.C.

P olarizedconnector

N otes:

1 -Switchblueandredwiresfor208Voperation.Factory linevoltagewiring

F ieldlowvoltagewiring

F ieldlinevoltagewiring

O ptionalblock

Q uickconnectterminal

W irenut

S crewterminal-

f ieldconnection

2 -BlackandOrangeDSHpumpwireissuppliedwith

d esuperheateroptionbutnotconnectedatfactory.

To enableDSHpumpforoperation,Blackand

C C-

H P-

L P-

R B-

R V-

T B-

R BI-

H WL-

C ompressorcontactor

H ighpressureswitch

L owpressureswitch

B lowerrelay

R eversingvalvecoil

Te rminalboard

B lowerinterlockrelay

H otwatertemperaturelimit

C CM-CompressorControlModule

F 1-Fuse

3 -Orangelooppumpwiresaresuppliedwith

residentialapplicationsbutarenotconnected

O rangewiresmustbeconnectedasshown.

4 -FourspeedblowermotorisusedonSpectra

SX010throughSX012units.Refertoinstructions

C apacitor onblowermotorforchangingspeedsofoperation.

atfactory.

L 1

1

3

2

P

Typical Electromechanical Wiring Schematic

208-230/60/1

97P585A01 1/25/99

15

SPECTRA COMMERCIAL AND RESIDENTIAL INSTALLATION GUIDE

T r ansformer

2 4V

N OTE3

R ed208V

B lue230V

B lackCom

R

C

C

R

C C

C CG

O nO ff

Te st/Normal

L oop/Well

P 2

P 1

S W1

C ommercial/Normal

I O Display/Normal

1

2

3

4

5

P 3

M otorizedVa lve/Normal

F

A

N

F

A

N

C

O

M

C Pu

F P

L P

H P

R V

C O

R B

C C

L SN SE SL OGOYCR

T hermostat

2

4

V

A

C

C

o

m

m

o

n

C

o

m

p

r

e

s

s

o

r

R

V

F

a

n

L

o

c

k

o

u

t

E mergencyShutdown

N ightSetback

L oadshed

N OTE1

N OTE2

R

R

R

R

R

G

Y

R

S W2

S

t

a

t

u

s

L

E

D

P

C

B

1

7

P

5

0

3

A

0

1

R

e

v

A

N OTE4

M V

G rey/White

V iolet

V iolet

Yellow

B lack/White

T

B lack

B lack

B lue

B lue

B rown

O range

O range

Ye llow

Ye llow

3 -Switchblueandredwiresfor208Voperation.

4 -Whenfieldinstalled24VACmotorized

valve(MV)isused,connecttoCandYof

P1,andsetSW1-5totheoffposition.

R elayContacts-

N .O.,N.C.

T hermistor

R elaycoil

S witch-Highpressure

S witch-Lowpressure

P olarizedconnector

C ondensateOverflow

F actory lowvoltagewiring

F actory linevoltagewiring

F ieldlowvoltagewiring

F ieldlinevoltagewiring

O ptionalblock

I nternaljunction

Q uickconnectterminal

W irenut

F ieldwirelug

G round

L 1

L egend

P

N otes:

1 -Requirescommonconnectionor24VACfor

activation.

2 -NightsetbackusedonlywithWaterFurnace

thermostatTA32U02.

O range

D CvoltagePCBtraces

B lue460V

G reen

1

6

2

7

3

8

4

9

5

1 0

C ompressor

C C

T 1

L 1

T 2T 3

C

R

S

R edB lue B lack

L 3 L 2

C ap

B rn

W h

G rn

R B

B rown

B lack

W hite

G

U nit

P owerSupply

2 08-230/60/3

4 60/60/3

5 -Consultinstallationmanualforblowerspeed

wiringinstructions.

N OTE5

C ap

W h

B rn

P SC

F an

M otor

G rn

P 3 OraYe l

M ILI

MHLLIMIH M L

P SC

F an

M otor

B lack W hite

T

1

3

2

C ompressorcontactor

C ondensateoverflow

F reezeprotectionsensor

C C-

C O-

F P-

H P-

L P-

R B-

R V-

S W1-

H ighpressureswitch

L owpressureswitch

B lowerpowerrelay

R eversingVa lvecoil

D IPswitch#1

S W2-Switch#2usedforinput-

o utputdisplay

Typical Commercial Wiring Schematic

208-230/60/3 and 460/60/3

97P577A03 12/1/98

16

SPECTRA COMMERCIAL AND RESIDENTIAL INSTALLATION GUIDE

Installation

Position the thermostat backplate against the wall so that it is level and the thermostat

wires protrude through the middle of the backplate. Mark the position of the backplate

mounting holes and drill holes with a 3/16" bit. Install supplied anchors and

secure plate to the wall. Thermostat wire must be 18 AWG wire. Shielded wire is recom-

mended when running parallel to line voltage wires or conduit for more than 1 foot. Strip the

wires back 1/4" (longer strip lengths may cause shorts) and insert the thermostat wires into

the connectors as shown in Figure 13. Tighten the screws to insure tight connections. The

thermostat has the same type connectors, requiring the same wiring. See instructions

enclosed in the thermostat for detailed installation and operation information.

Thermostat

Figure 13 - Thermostat Wiring

SX Series Fan Blower Motor Airflow (cfm) at External Static Pressure (in. wg)

Model Spd Size HP 0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45 0.50 0.60 0.70 0.80 0.90 1.00

H 450 440 420 410 380 360 340 330 310 300 - - - - -

SX010* MH 6 x 8 1/10 410 400 380 370 350 330 310 300 280 270 - - - - -

ML 370 360 340 330 310 290 280 270 250 240 - - - - -

L 310 300 280 270 250 240 230 220 210 200 - - - - -

H450 440 420 410 390 370 350 340 320 310 - - - - -

SX013* MH 6 x 8 1/10 400 390 380 370 350 340 320 310 290 280 - - - - -

ML 370 360 340 330 310 300 290 280 260 250 - - - - -

L 330 320 310 300 290 280 260 250 230 220 - - - - -

H 790 780 775 770 765 760 740 720 690 670 610 - - - -

SX016 M 9 x 7 1/6 720 690 685 680 670 660 650 640 620 600 - - - - -

L 590 570 560 550 545 540 530 520 510 500 - - - - -

H790 780 775 770 765 760 740 720 690 670 610 - - - -

SX019 M 9 x 7 1/6 720 690 685 680 670 660 650 640 620 600 - - - - -

L 590 570 560 550 545 540 530 520 510 500 - - - - -

H1020 990 960 930 900 870 850 830 800 770 690 - - - -

SX024 M 9 x 7 1/5 860 840 820 800 780 760 740 720 690 670 - - - - -

L 720 700 680 650 640 620 600 580 570 550 - - - - -

H1120 1100 1070 1050 1040 1030 1020 1010 1000 980 830 - - - -

SX030 M 9 x 7 1/3 1020 1000 980 960 920 880 860 840 820 790 - - - - -

L 860 850 840 830 810 800 780 760 740 710 - - - - -

H1360 1340 1300 1270 1230 1200 1170 1150 1120 1090 990 870 - - -

SX036 M 9 x 7 1/2 1190 1170 1140 1120 1090 1060 1030 1010 970 930 - - - - -

L 1010 990 970 950 940 920 900 880 860 840 - - - - -

H- - 1730 1700 1670 1650 1620 1580 1540 1490 1400 1290 - - -

SX042 M 10 x 10 1/2 1510 1500 1490 1480 1450 1430 1400 1380 1350 1320 - - - - -

L 1170 1160 1150 1140 1130 1120 1100 1080 1050 1030 - - - - -

H- - 1870 1820 1780 1750 1720 1680 1630 1580 1450 1330 1190 - -

SX048 M 10 x 10 1/2 1710 1660 1630 1590 1560 1530 1490 1460 1410 1370 - - - - -

L 1280 1250 1230 1220 1200 1180 1150 1120 1090 1050 - - - - -

H----2180 2160 2130 2100 2070 2040 1990 1910 1810 1690 -

SX058 M 11 x 10 3/4 2030 2010 1990 1970 1950 1930 1910 1880 1850 1830 1780 - - - -

L 1790 1770 1760 1750 1730 1720 1700 1690 1670 1640 - - - - -

H----2540 2520 2490 2460 2430 2410 2320 2230 2130 1980 1820

SX068 M 11 x 10 1 2430 2390 2360 2340 2310 2290 2270 2250 2220 2190 2120 2050 - - -

L 2000 1980 1970 1950 1930 1920 1900 1860 1830 1780 - - - - -

Factory settings are all high speed except (SX016- M & SX010 MH).

Includes allowance for wet coil and standard filter.

Blower

Performance

Data

R

Y1

C

W

O

G

L1

24VAC

(Hot)

24VAC

(Common)

Compressor

Aux. Heat

Reversing

Valve

Blower

Relay

System

Monitor

17

SPECTRA COMMERCIAL AND RESIDENTIAL INSTALLATION GUIDE

Before Starting Unit, Check The Following:

❏High voltage is correct and matches nameplate

❏Fuses, breakers and wire size correct

❏Low voltage wiring complete

❏Piping completed and water system cleaned and flushed

❏Air is purged from closed loop system

❏Isolation valves are open, water control valves or loop pumps wired

❏Condensate line open and correctly pitched

❏Transformer switched to lower voltage tap if needed

❏Dip switches set correctly (commercial microprocessor only)

❏DHW pump switch off unless piping is completed and air has been purged

❏Blower rotates freely - foam shipping support has been removed

❏Blower speed correct (taps on correct pins)

❏Air filter is clean and in position

❏Service/access panels are in place

❏Return air temperature is between 60-80°F in heating and 70-95°F in cooling

❏Air coil cleaned

Start Up Steps:

1) Initiate a control signal to energize

the blower motor. Check blower

operation.

2) Initiate a control signal to place the

unit in the cooling mode. Cooling

set point must be set below room

temperature.

3) First stage cooling will energize

after a time delay.

4) Be sure that the compressor and

water control valve or loop pumps

are activated.

5) Verify that the water flow rate is

correct by measuring the water

pressure drop through the heat

exchanger using the P/T ports and

comparing to water pressure drop

found in Table 3.

6) Check the temperature of both the

supply and discharge water. Refer

to Start Up Performance Table 2

7) Check for an air temperature drop

of 15°to 25°F across the air coil,

depending on the fan speed and

entering water temperature. Refer

to unit operating pressures on

page 13.

8) Adjust the cooling set point above

the room temperature and verify

that the compressor and water

valve or loop pumps deactivate.

Unit Start Up

Table 3 - Water Pressure Drop Table

Table 2 - Temperature Change Through Heat Exchanger

Water Flow Rate Water Temperature

(GPM) Change (Deg °F)

Rise (Clg) Drop (Htg)

For Closed Loop: Ground Source or 9 - 12 4 - 8

Cooler/Boiler systems at 3 gpm/ton

For Open Loop: Ground Water systems 20 - 26 10 - 17

at 1.5 gpm/ton

FLOW RATE PRESSURE DROP (PSI)

MODEL GPM 30°F50°F90°F

1.5 2.1 2.0 1.9

SX010 2.0 3.4 3.2 3.0

2.5 5.2 4.9 4.6

1.5 2.0 1.9 1.8

SX013 2.5 4.6 4.4 4.1

3.5 8.1 7.7 7.2

2.0 3.0 2.9 2.7

SX016 3.0 5.9 5.7 5.3

4.0 9.7 9.3 8.7

3.0 1.2 1.2 1.1

SX019 4.0 2.1 2.0 1.9

5.0 3.5 3.3 3.1

3.0 1.5 1.4 1.3

SX024 4.5 3.2 3.1 2.9

6.0 6.0 5.8 5.4

4.0 1.2 1.2 1.1

SX030 5.5 2.1 2.0 1.9

7.0 3.2 3.1 2.9

5.0 2.4 2.2 2.1

SX036 7.0 3.9 3.7 3.5

9.0 6.2 5.9 5.5

5.0 1.7 1.6 1.5

SX042 8.0 3.5 3.3 3.1

11.0 6.2 5.9 5.5

6.0 3.5 3.1 2.3

SX048 9.0 6.7 5.9 4.2

12.0 10.7 9.5 7.0

8.0 4.1 3.7 2.8

SX058 11.0 6.6 6.0 4.7

14.0 10.0 8.9 6.6

10.0 6.1 5.4 3.9

SX068 13.0 9.3 8.2 6.0

16.0 13.0 11.7 9.0

Note: To obtain maximum performance the air coil should be cleaned

before start up. A 10% percent solution of dishwasher detergent and water

is recommended for both sides of coil. A thorough water rinse should follow.

18

SPECTRA COMMERCIAL AND RESIDENTIAL INSTALLATION GUIDE

9) Initiate a control signal to place the unit in the heating mode. Heating set point must

be set above room temperature.

10) First stage heating will energize after a time delay.

11) Check the temperature of both the supply and discharge water. Refer to Table 2 on

page 17.

12) Check for an air temperature rise of 20°to 35°F across the air coil, depending on the

fan speed and entering water temperature. Refer to Unit Operating Pressure on

page 13.

13) If auxiliary electric heaters are installed, adjust the heating set point until the electric

heat banks are sequenced on. All stages of the auxiliary heater should be sequenced

on when the thermostat is in the "Emergency" Heat mode. Check amperage of

each element.

14) Adjust the heating set point below room temperature and verify that the compressor

and water valve or loop pumps deactivate.

15) During all testing, check for excessive vibration, noise or water leaks. Correct or repair

as required.

16) Set system to desired normal operating mode and set temperature to maintain desired

comfort level.

17) Instruct the owner/operator of the proper operation of the thermostat and system

maintenance.

18) During all testing, check for excessive vibration, noise or water leaks. Correct or repair

as required.

19) Set system to desired normal operating mode and set temperature to maintain desired

comfort level.

20) Instruct the owner/operator of the proper operation of the thermostat and system

maintenance.

NOTE: If performance during any mode appears abnormal, refer to the troubleshooting

section on page 19.

Water Coil Maintenance

1) Keep all air out of the water. An open loop system should be checked to insure that the

well head is not allowing air to infiltrate the water line. Lines should always be airtight.

2) Keep the system under pressure at all times. It is necessary in open loop systems that

the water control valve be placed in the discharge line to prevent loss of pressure

during off cycles. Closed loop systems must have positive static pressure or air vents

may draw air into the system.

NOTE:

If the installation is performed in an area with a known high mineral content (125

P.P.M.or greater) in the water, it is best to establish with the owner a periodic maintenance

schedule so the coil can be checked regularly. Should periodic coil cleaning be necessary,

use standard coil cleaning procedures which are compatible with either the cupronickel or

copper water lines. Generally, the more water flowing through the unit the less chance

for scaling.

Other Maintenance

Filters - Filters must be clean to obtain maximum performance. They should be in-

spected every two to three months under normal operating conditions and be replaced

when necessary. Units should never be operated without a filter.

Preventive

Maintenance

19

SPECTRA COMMERCIAL AND RESIDENTIAL INSTALLATION GUIDE

Condensate Drain - In areas where airborn bacteria produce a slime in the drain pan, it

may be necessary to treat chemically to minimize the problem. The condensate drain can

pick up lint and dirt, especially with dirty filters. Inspect twice a year to avoid the possibility of

overflow.

Air Coil - The air coil must be cleaned to obtain maximum performance. Check once a

year under normal operating conditions and, if dirty, brush or vacuum clean. Care must be

taken not to damage the aluminum fins while cleaning.

CAUTION: Fin edges are sharp.

Desuperheater Coils - See Water Coil Maintenanc, page 18.

CONTROLS

Commercial Microprocessor

To check the unit control board for proper operation:

1) Place control board into “Diagnostics-inputs” mode (see Schematic page 14 and 15).

Place Switch #1 in “Test” mode. Remember to place Switch #1 back to “Normal” mode

before leaving.

2) Adjust thermostat to “Call” for heating or cooling.

3) Check LEDs for proper operation.

4) If LEDs indicate proper operation of thermostat, check “Diagnostics-Outputs”.

5) If LEDs are not indicating proper operation, remove thermostat connections.

• Jumper desired test input (Y, O, G) to “R” to simulate a thermostat signal.

• Check operation with “Diagnostics-input” mode.

• Check thermostat and field control wiring.

• If steps above show that the unit control board is not indicating proper results

(i.e. LED indication), replace board.

• If LEDs are indicating properly, replace thermostat.

6) Do not replace unit control board or thermostat until all diagnostic checks

have been made.

Residential Electromechanical

The compressor control module has a test mode that resets all timed delays to seconds

in duration. Simply ground the 1/4" spade connector labeled "test" to initiate test mode.

REFRIGERANT SYSTEM

To maintain sealed circuit integrity do not install service gauges unless unit operation

appears abnormal. Reference the operating chart on the page 13.

Verify that air and water flow rates are at proper levels before servicing the refriger

ant circuit.

Obtaining Parts

When contacting WaterFurance International for service or replacement parts, refer to

the model number and serial number of the unit as stamped on the serial plate attached to

the unit. If replacement parts are required, mention the date of installation of the unit and the

date of failure, along with an explanation of the malfunctions and a description of the

replacement parts required.

In-Warranty Material Return

Material may not be returned except by permission of authorized WFI service personnel.

Contact your local distributor or the WFI service department for warranty return authorization

and assistance.

Troubleshooting

Replacement

Procedures

WaterFurnace has a policy of continuous product research and

development and reserves the right to change design and speci-

fications without notice. WaterFurnace is a registered trademark

and Spectra is a trademark of WaterFurnace International, Inc.

©1999 WaterFurnace International, Inc.

9000 Conservation Way

Fort Wayne, IN 46809-9794

Phone: 1-219-478-5667 or

1-800-934-5667

FAX: 1-800-783-5667

http://www.waterfurnace.com

In Canada Call: 1-800-463-8108

P/N 96P537A01 4/99

This manual suits for next models

17

Table of contents

Other Water Furnace Temperature Controllers manuals

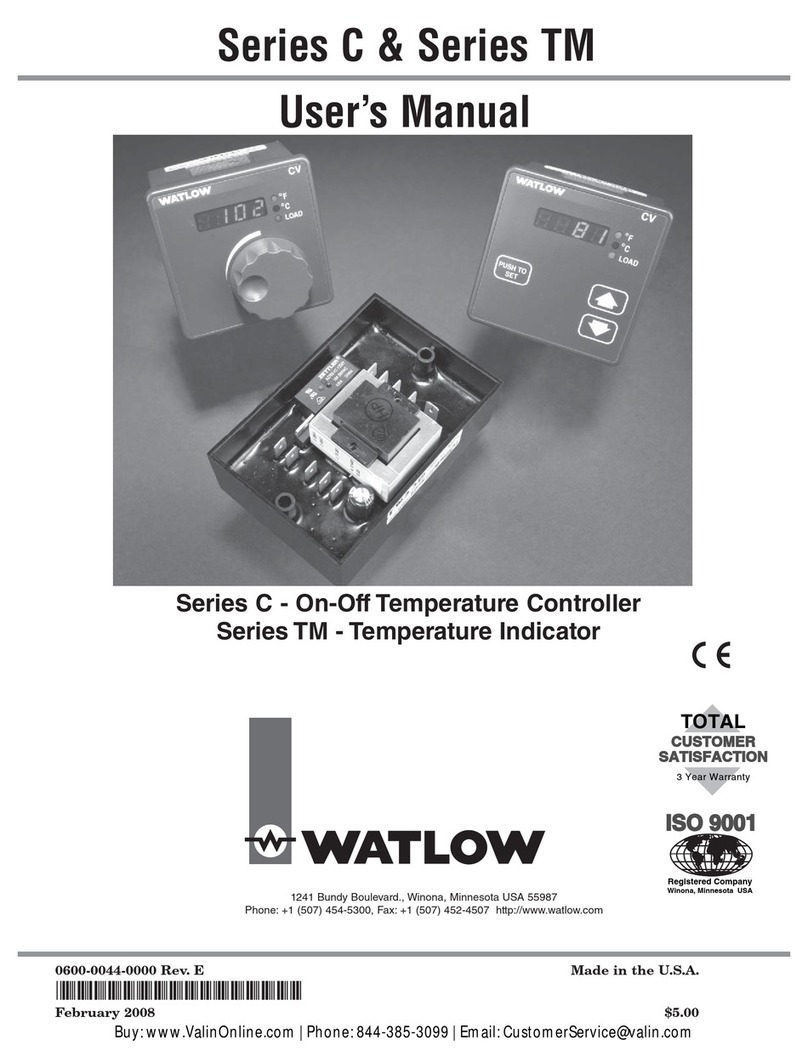

Popular Temperature Controllers manuals by other brands

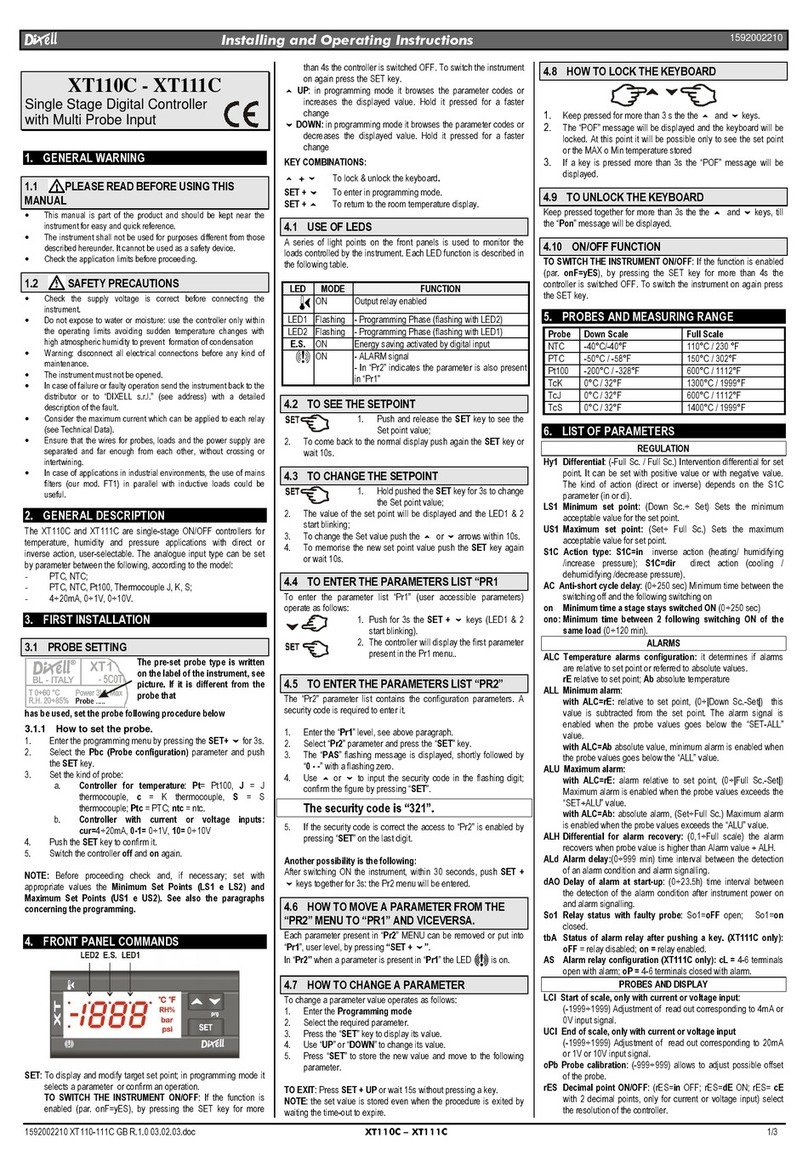

dixell

dixell XH460L operating instructions

Daikin

Daikin OM-SLM-0501 Operation manual

AMX

AMX AXC-TEMP AND RTS-1 TEMPERATURE CONTROL CARD AND ROOM TEMPERATURE... instruction manual

Liebert

Liebert Liebert iCOM user manual

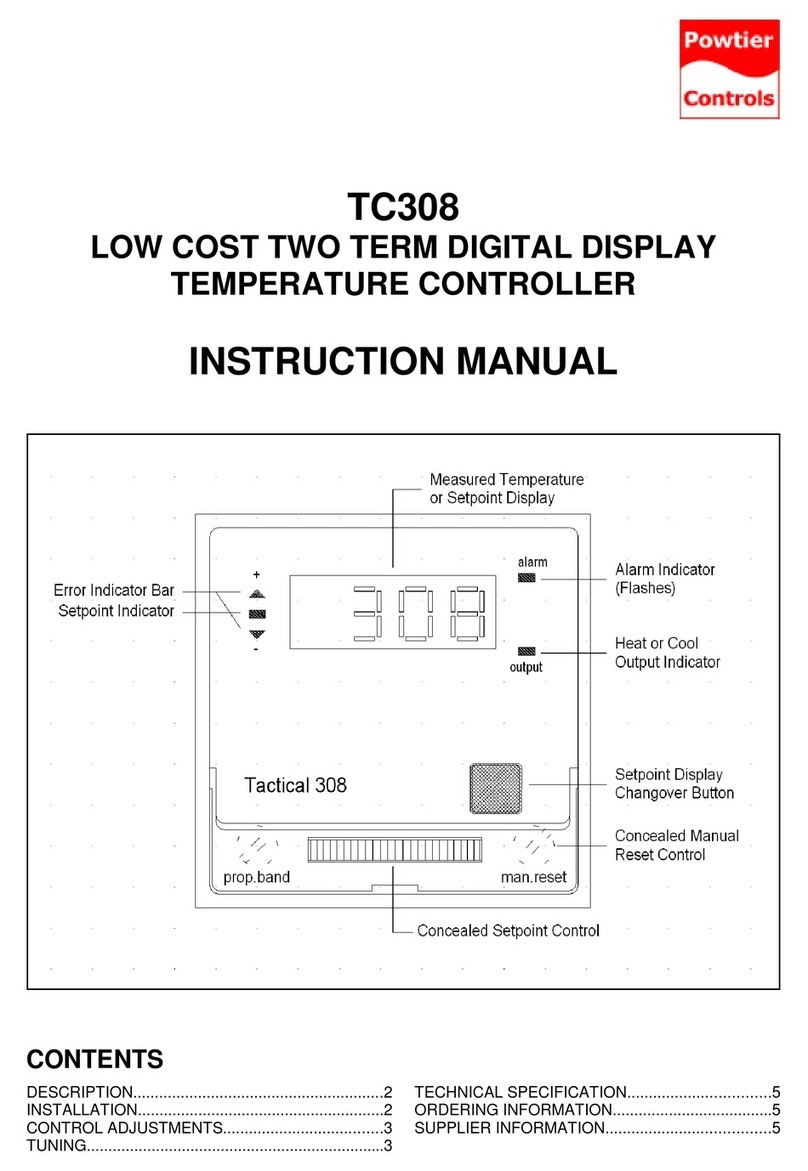

Powtier Controls

Powtier Controls TC308 instruction manual

Danfoss

Danfoss EKC 366 manual