Water Furnace IntelliZone2 BACnet User manual

Installation Information

Damper Installation

Thermostat Installation

Electrical

Startup Procedures

Wiring Schematic

IM1588EW 11/20

IntelliZone2 BACnet Installation Manual

Six Zone Capability

Comfort Zoning System

a

ti

on

n

a

ti

o

n

s

Int

e

lliZ

o

n

e

2

B

Comfort Zoning Syste

m

INTELLIZONE2 BACNET INSTALLATION MANUAL

Table of Contents

IntelliZone2 BACnet Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

General Installation Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Damper Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Electrical Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Zone Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

IntelliZone2 BACnet Configuration/Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

IntelliZone2 BACnet Configuration/Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Description of Operation - Package Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Blower Data - Package Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

IntelliZone2 BACnet CFM Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

System Startup and Checkout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Wiring Schematic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

IntelliZone2 BACnet Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Revision Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4

INTELLIZONE2 BACNET INSTALLATION MANUAL

IntelliZone2 BACnet Components

IntelliZone2 BACnet Zoning Board

The IntelliZone2 BACnet zoning board is the master control for the system,

has much of the programming for operation, provides basic relay logic for

the damper operation and serves as a common connection point for the

IntelliZone2 XPC Control and the heat pump.

IntelliZone2 BACnet XPC Control

The IntelliZone2 BACnet XPC Control provides the BACnet interface for the

system to the BAS. It is a communicating device that connects to all zone

sensors.

IntelliZone2 BACnet Zone Sensors

The IntelliZone2 BACnet Zone Sensors are used for all zones. Sensors are

available with humidity, CO2 and VOC options as well as with and without

temperature display and setpoint adjustment controls.

Note: Only one zone sensor with a CO2 or VOC option may be used per system.

IntelliZone2 Damper System

The IntelliZone2 BACnet Damper Systems come in round or rectangular

construction with 2 or 3-wire accuators.

5

INTELLIZONE2 BACNET INSTALLATION MANUAL

Safety Considerations

Installing and servicing heating and air conditioning

equipment can be hazardous due to system electrical

components. Only trained and qualified service personnel

should install, repair or service heating and air conditioning

equipment. When working on equipment, observe

precautions in the literature, tags and labels attached to the

unit, and other safety precautions that may apply. Follow all

safety codes. Wear safety glasses and work gloves.

WARNING: Before performing service or

maintenance operations on the system, turn

off main power switches to the indoor unit.

Turn off accessory heater power switch if

applicable. Electrical shock could cause

serious personal injury.

Delivery Information

When the equipment is received, all items should be

carefully checked against the bill of lading to be sure

all crates and cartons have been received. Examine the

contents for shipping damage, removing them from the

cartons if necessary. If any damage is noted, the carrier

should make the proper notation on the delivery receipt,

acknowledging the damage.

General rules to follow when installing a zone

system:

CAUTION: When installing the IntelliZone2

BACnet in a structure with fossil fuel (oil, gas,

propane) appliances, it is important that both

supply and return dampers are used in each zone

to avoid potential back-drafting of fossil-fueled

appliances.

• Up to six zones on variable speed, up to 4 zones with

dual capacity units (two with single speed units).

• All dampers should be located as close to the main

trunk as possible to limit the amount of pressurized

trunk line and thus limit air leakage.

• No less than three branch runs in a zone to prevent

a single branch obstruction (curtains or clothes etc.)

from affecting unit airflow.

• Insulate and seal around rectangular dampers to

prevent leakage.

• All dampers must be wired with 18-gauge wire.

NOTE: Crimp connections should never be used on

solid conductor wire.

• Ensure that the transformer can handle the power

requirements of the system.

• No more than three dampers per zone.

General Installation Information

Installation and Design Steps

1. Decide which areas of a building or office will comprise

each of the individual zones. A maximum of six

individual zones (four with dual capacity and two with

single speed equipment) can be chosen.

2. Calculate loads using software or other

recognized methodology.

3. Use software to determine the equipment size and

performance based on the total heating and cooling

demands of the building, not the sum of the individual

zone demands.

4. Find the peak heating and cooling demands and the

peak cfm required for each of the zones.

5. Determine zone design air flow and zone size settings

using IntelliZone2 BACnet Design software.

6. Lay out and size the supply air ductwork and dampers.

Care should be taken to avoid under sizing either the

supply air systems, return air systems, or diffusers.

7. Decide where to locate the zone sensors.

8. Install the unit and the IntelliZone2 BACnet Comfort

Zoning system.

IntelliZone2 BACnet Control Panel

Locate the IntelliZone2 BACnet panel in an indoor area

that has enough space for service personnel to perform

maintenance or repair. Provide sufficient room to make

electrical connection(s). The IntelliZone2 BACnet is not

approved for outdoor installation and, therefore, must be

installed inside the structure being conditioned. Do not

locate the control panel in areas where ambient conditions

are not maintained within 45°F to 95°F and are greater

than 75% relative humidity. The IntelliZone2 BACnet control

panel should be mounted on or as close to the unit as

possible by using the sheet metal screws provided. See

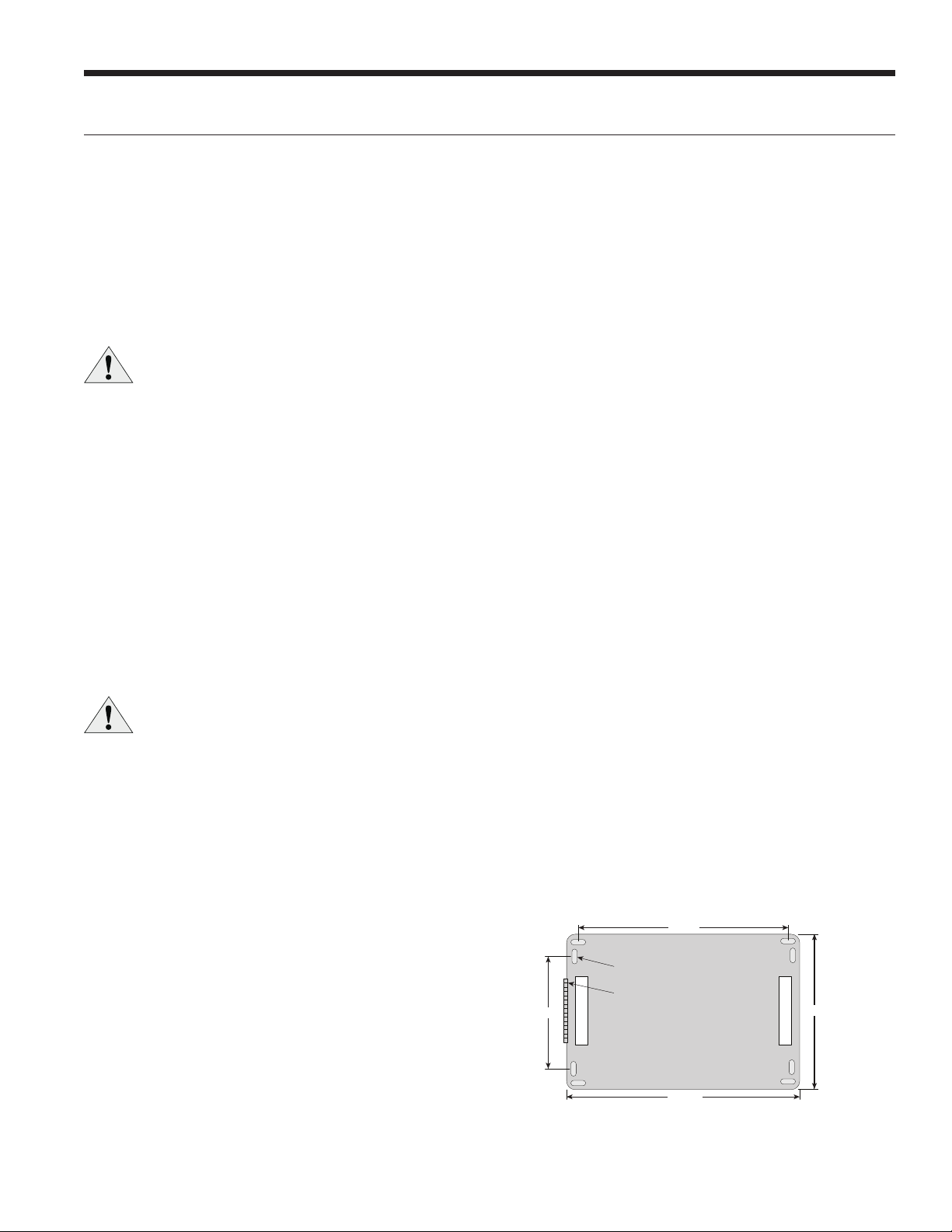

Figure 1 for mounting hole locations.

NOTE: IntelliZone2 BACnet Relay Panel to be mounted

indoors.

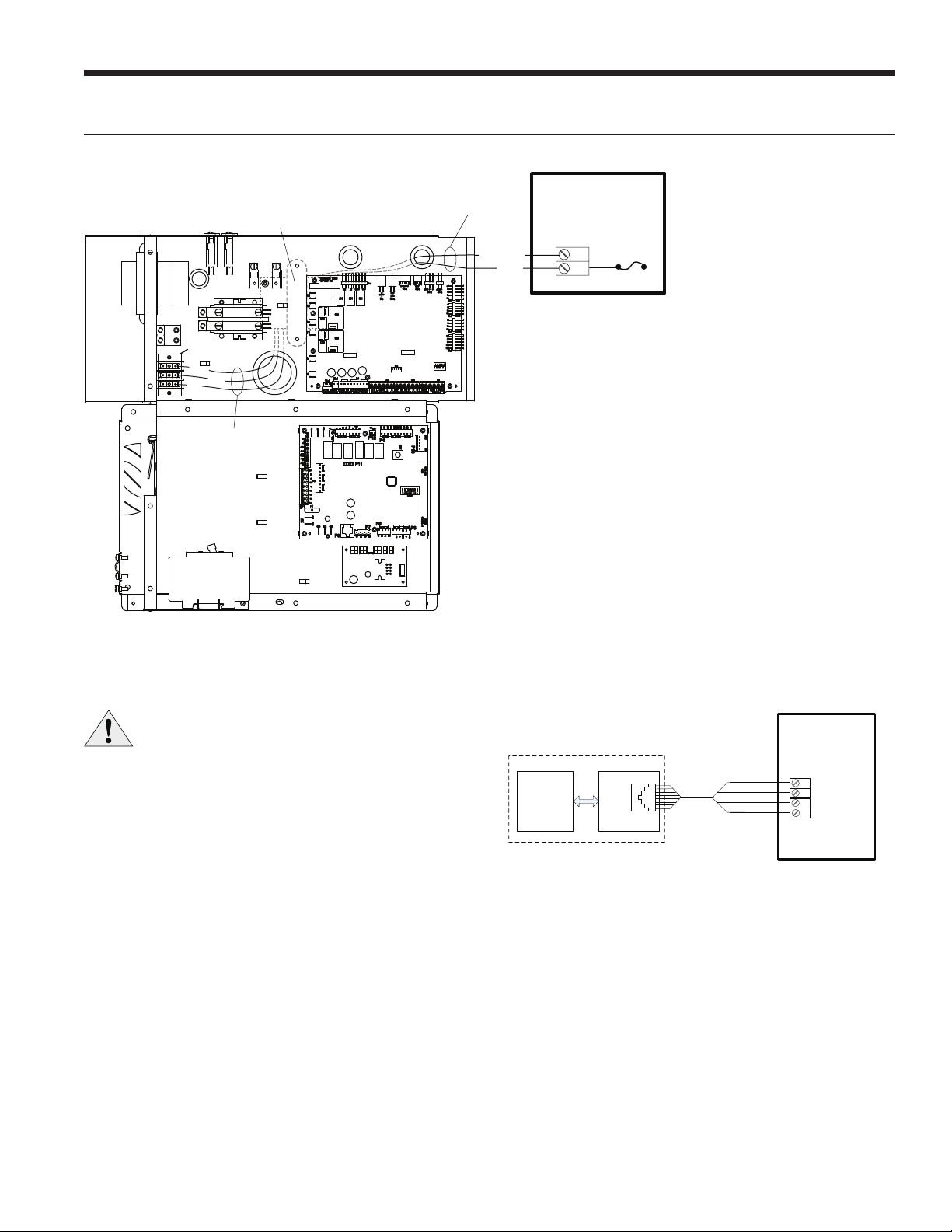

Figure 1: IntelliZone2 BACnet Relay Panel Mounting

NOTE: Use longer screws (not provided) to penetrate

through drywall into stud.

9.25 in.

6.00 in. 7.75 in.

10.35 in.

Hinge Side

D

epth = 2.00 in. Deep with cover

Wire Access

Wire Access

Mounting Slots

6

INTELLIZONE2 BACNET INSTALLATION MANUAL

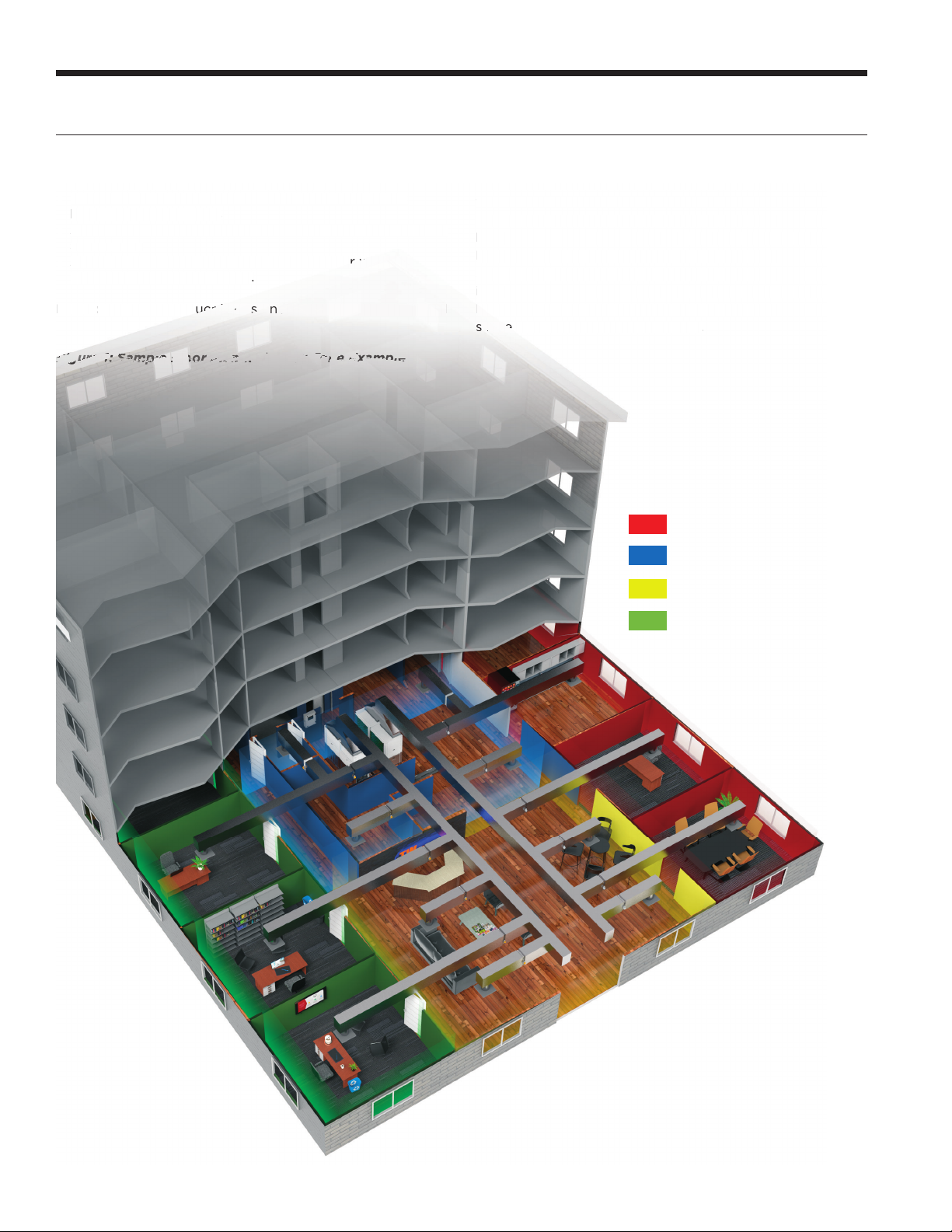

Six Zone System Representational Layout

Installing Rectangular Dampers in

Metal Ductwork

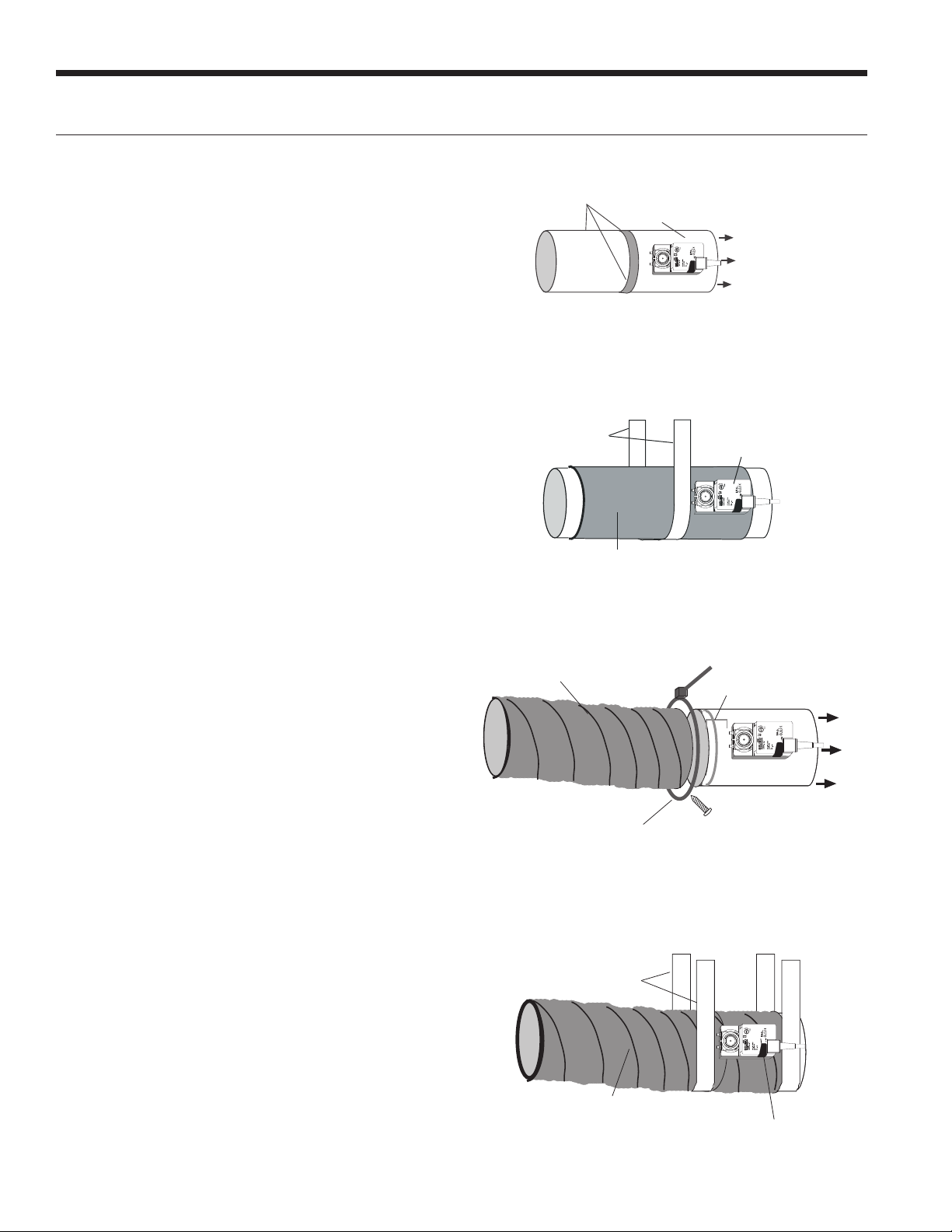

1. Cut out dimensions A and B as shown in Figure 2 by

using sheet metal snips. NOTE: Dimensions A and B are

listed in the Dimensional Examples table.

2. Use foam insulation tape on the top and bottom of

the zone damper to prevent excessive air bypass. Also

check the cross emboss for excessive air bypass (see

Figure 2).

3. Slide the zone damper into the ductwork making

sure no obstructions will interfere with damper blade

operation.

4. Use the screws provided to mount the damper flange

to the ductwork. Four to six mounting holes are

provided as shown in Figure 3.

5. Use drive cleats or regular duct mounting brackets to

attach ductwork to joist within six inches on both sides

of the damper (see Figure 3).

6. Check damper blade operation for obstructions by

holding the manual release button and rotating the

damper shaft CCW (Open) and CW (Closed) 3 Wire

only as shown in Figure 4.

Damper Installation

Manual release

CW

Closed

CCW

Open

Rotate by hand

Figure 4: Checking Damper Blade for Obstructions

Cross emboss for

duct stiffness may

cause excessive

air bypass

Foam Seal

Foam Tape

(top and bottom)

A

B

3.75”

Figure 2: Foam Taping Zone Damper

Figure 3: Mounting Damper

Mounting Screws

(4 places)

Attach duct/damper

to joist within 6" on

both sides

Dimensional Examples

Damper

Model HWA B

ZDR1024 10 in. 24 in. 10 in. 3.75 in.

ZDR0812 8 in. 12 in. 8 in. 3.75 in.

Premier2

72

72

72

72

72

72

C

e

Cl

7

INTELLIZONE2 BACNET INSTALLATION MANUAL

Insulating Rectangular Dampers in

Metal Ductwork

Insulate ductwork as shown in Figure 5. All metal must

be covered. Care must be taken not to obstruct the shaft

from rotating when insulating. Do not insulate the zone

damper actuator.

Installing Rectangular Dampers

in Duct

1. Cut out dimensions A and B by using a duct

knife. NOTE: Dimensions A and B are listed in the

Dimensional Examples table.

2. A duct spacer should be installed on the end of

the damper frame as shown in Figure 7 to prevent

excessive air bypass. For example: A one-inch-thick,

8 in. x 20 in. duct and a 8 in. x 20 in. zone damper

would have a one-inch gap at the end of the frame

once it is installed without a duct spacer. Use the piece

cut out for installation.

3. Foam insulation tape should be used on the top and

bottom of the zone damper to prevent excessive air

bypass as shown in Figure 7.

4. Slide the zone damper into the duct making

sure no obstructions will interfere with damper

blade operation.

5. Tape the damper face flange to the duct using foil

tape making sure the damper is secure and air tight as

shown in Figure 8.

6. Support the full length of the duct underside within six

inches and on both sides of the damper as shown in

Figure 8.

7. Check the damper blade operation for obstructions

by holding the manual release button and rotating the

damper shaft CCW and CW (see Figure 4).

Damper Installation cont.

Do not insulate zone

damper actuator

Duct wrap insulation

Figure 5: Insulating Rectangular Metal Ductwork

A

B

Duct board

Keep spacer clear

of end bushing

Foam tape

(top and bottom)

Insulate between

actuator and damper

spacer

Figure 7: Taping Zone Damper with Foam Tape

Foil tape damper face

to ductboard

Support the full length of ductboard

underside within 6” of damper

Figure 8: Taping Damper Flange to Duct

8

INTELLIZONE2 BACNET INSTALLATION MANUAL

Insulating Rectangular Duct/

Metal Sleeve

Care must be taken not to obstruct the shaft from rotating

when insulating. Do not insulate the zone damper actuator.

Installing Circular Dampers in Round

Metal Duct

1. Crimp the end of the duct that is the supply air to

damper. Insert into circular damper no more than

1.5 inches.

2. Fasten the duct to the damper with three screws.

Screws installed more than one inch from either end

may obstruct damper blade rotation.

3. Seal completely around the duct with metal duct tape

or mastic to prevent air leakage as shown in Figure 10.

4. Check the damper blade operation for obstructions by

holding the manual release button and rotating damper

shaft CCW and CW (3 wire only). See Figure 4.

5. Support the duct to joist within six inches of the

damper as shown in Figure 9.

Insulating Circular Dampers in Round

Metal Duct

Insulate ductwork as shown in Figure 10. All metal must be

covered to prevent condensation. Care must be taken not

to obstruct the shaft from rotating when insulating. Do not

insulate the zone damper actuator.

Installing Circular Dampers in

Flexible Duct

1. Slide flexible duct two to three inches over the damper

pipe past the damper rib as shown in Figure 11.

2. Fasten duct to damper with a nylon duct strap,

screwing the strap to the pipe to prevent the duct from

slipping off. Screws installed more than one inch from

either end may obstruct damper rotation.

3. Seal completely around the duct with metal duct tape

or mastic to prevent any air leakage.

4. Check the damper blade operation for obstructions by

holding the manual release button and rotating damper

shaft CCW (Open) and CW (Closed) - 3 wire only. See

Figure 4.

5. Support the damper to joist within six inches on both

sides of the damper as shown in Figure 12.

Insulating Damper Actuators

Insulate the damper as shown in Figure 12. All metal must

be covered to prevent condensation. When insulating, care

must be taken not to obstruct the shaft from rotating. Do

not insulate the zone damper actuator.

Damper Installation cont.

Support with wide

steel strap

1-1/2’’or 2’’ if in unconditioned space

Do not insulate

damper actuator

Figure 12: Supporting and Insulating Circular Damper

Flexible duct

Clamp with duct strap. Install screw no farther

than 1” from either end of damper

Slide duct 2-3’’ past

damper end rib

Air Flow

Figure 11: Attaching Flexible Duct to Damper

Three screws sealed

with duct tape or mastic

Manual release button

Air Flow

Figure 9: Taping Round Duct to Circular Damper

Do not insulate

damper actuator

1-1/2" or 2" if in unconditioned space

Support with

wide steel strap

Figure 10: Supporting and Insulating Circular Damper

9

INTELLIZONE2 BACNET INSTALLATION MANUAL

Wiring Damper Actuators

All wiring must comply with local and state codes.

Disconnect the power supply before beginning to wire to

prevent electrical shock or equipment damage. All wiring

should be run back to the control panel. Keep wires a

minimum of 12 inches from any high voltage lines. Follow

the damper wiring schematic as shown in Figure 13. Verify

that damper rotation direction is correct. The 3-wire

damper rotation direction is reversible with switch on front

cover.

Figure 13: Damper Actuator Wiring

Electrical Wiring

Wire Nuts Strain Relief

Figure 14: Actuator Wiring

Damper Actuator Wiring Notes

1. Minimum of 18-gauge thermostat wire is recommended.

2. Use wire nuts to connect the thermostat wire to the

actuator wire (solid wire to stranded wire) as shown in

Figure 14.

3. The actuator wiring should be secured using a wire tie to

prevent the wires from being separated (see Figure 14).

3-Wire Damper

Zone 4

Com

Open

Close

G

Minimum

18-gauge wire

(Indicated rotation direction

is valid for switch position ‘0’ )

BlkCOM

Grn

CCW

Red

CW

IntelliZone/IntelliZone2 PCB

2-Wire Damper

Minimum

18-gauge wire

Zone 4

IntelliZone/IntelliZone2 PCB

Com

Open

Close

G

COM Gray

CCW Yellow

Damper Switch

Reverse Rotation

Note:

1. Each zone must have

dampers that match by

manufacturer and type.

2. Each IntelliZone

System must have

dampers that match,

either 2-wire or 3-wire.

IntelliZone2 BACnet

IntelliZone2 BACnet

10

INTELLIZONE2 BACNET INSTALLATION MANUAL

WARNING: All wiring must comply with local

and state codes. Disconnect the power supply

before beginning to wire to prevent electrical

shock or equipment damage.

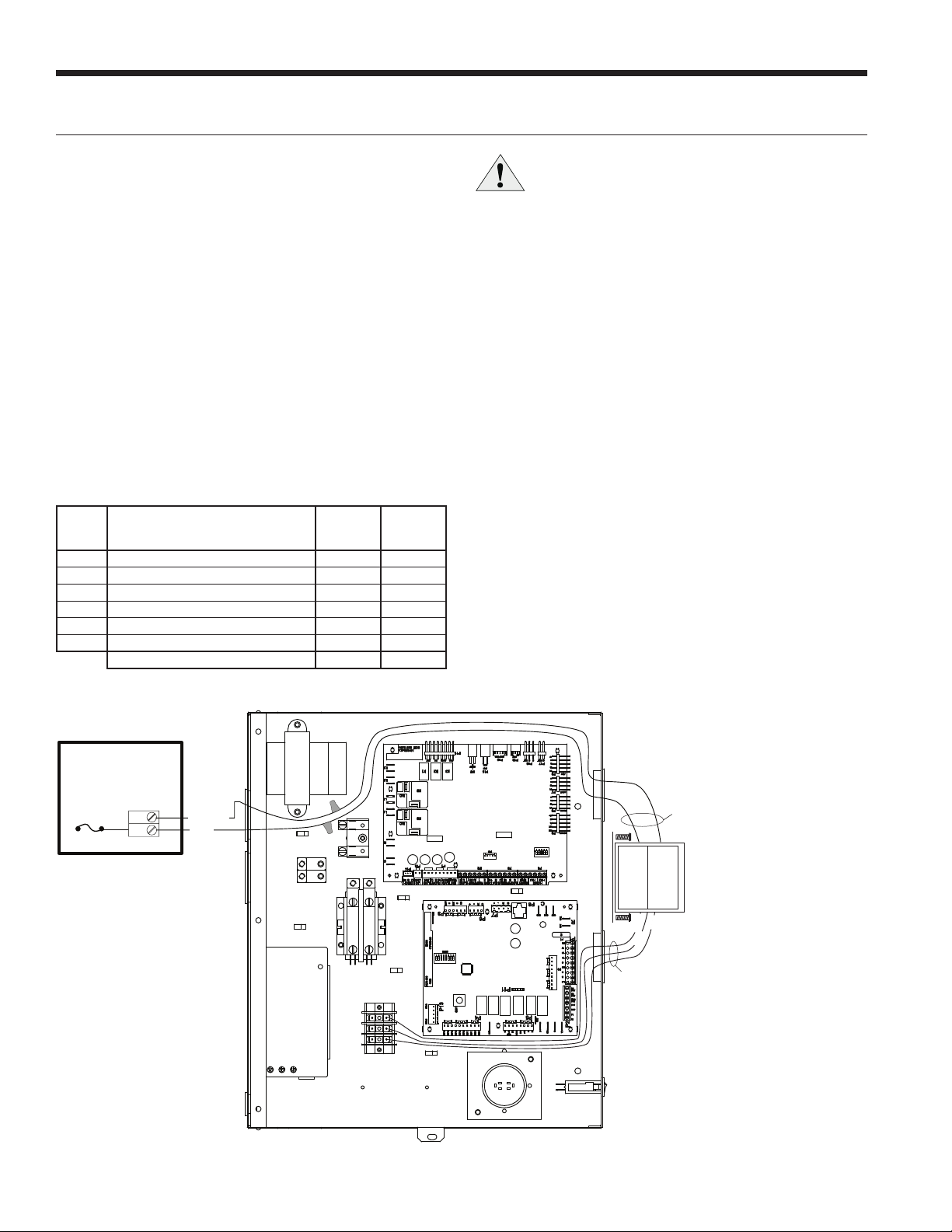

Mount the transformer onto the side of the unit’s control

box by inserting and tightening screws (provided) into the

pre-punched holes. Thread all transformer wires through

the hole with bushing and follow the wiring schematic for

connecting the transformer primary and secondary leads

as shown in Figure 15 and Figure 16 examples. NOTE: Actual

control box layout may vary depending on the product

configuration.

For 208 volt operation, the red and blue transformer wires

must be switched. Use wire nuts only for connections to

thermostat wire.

Transformer Sizing

The heat pump transformer should never be used to power

the zone dampers. Damage to the heat pump or dampers

may occur. Providing adequate transformer power (VA)

to supply the system is an important requirement. Each

IntelliZone2 BACnet 3-wire damper requires 3.0VA at

nominal voltage and each 2-wire damper requires 7.0VA

at nominal voltage. The standard available transformer is

a 75VA with an integrated circuit breaker (Part # ZTK240

or ZTK460). The Transformer ‘VA’ Calculation table shows

a sample sizing procedure for both the 3-wire and 2-wire

dampers that should be carried out for each installation.

If the total VA is greater than 70VA, then a second 75VA

transformer should be wired in parallel to provide a total

power capability of 150VA. As the ‘VA’ Calculation table

shows the 2-wire damper requires much more VA than the

3-wire damper.

Transformer ‘VA’ Calculation

Zone Number of Dampers

Powered in Zone

3-Wire

Actuator

2-Wire

Actuator

113.07.0

213.07.0

3 2 6.0 14.0

4 3 9.0 21.0

5 2 6.0 14.0

613.07.0

Total VA Draw (10 Dampers) 30.0 70.0

Electrical Wiring cont.

Figure 15: Mounting and Wiring Transformer to Control Box (Versatec VS shown)

R

C

P18

Damper Power

F1 Damper

Fuse Black/White

5A Fuse

IntelliZone2

Relay Board

Primary Leads

Secondary

Leads

Zone

Transformer

75 VA

(PN) ZTK240

Black

Blue

Red

Yellow

AXB

ABC

PB2

11

INTELLIZONE2 BACNET INSTALLATION MANUAL

Wiring IntelliZone2 BACnet to the Unit

WARNING: All wiring must comply with local

and state codes. Disconnect the power supply

before beginning to wire to prevent electrical

shock or equipment damage.

Follow the wiring schematic in Figure 17 for unit control

connections. Insert the wires from the supplied harness into

the zoning board connector as shown in Figure 17. Tighten

the screws to ensure tight connections.

Figure 16: Mounting and Wiring Transformer to Control

Box

Figure 17: IntelliZone2 BACnet to Heat Pump Control

Electrical Wiring cont.

A+

R

C

B-

P17 – Heat Pump

IZ2 BACnet

Control Board

P8

Aurora ABC

Aurora AXB

Heat Pump Controls

12345678

Red & Orange

Black & White

Blue & Green

Brown & Yellow

Zone Transformer

(mounted on backside

of control box)

R

C

P18

Damper Power

F

1 Damper

Fuse

5A Fuse

IntelliZone2

Relay Board

Black/White

Yellow

Black Blue

Red

Secondary

Leads

Primary

AXB

ABC

PS

Leads

NOTE: The harness supplied with the IntelliZone2 BACnet

is designed to plug into the Aurora ABC P8 connector

only.

12

INTELLIZONE2 BACNET INSTALLATION MANUAL

Zone Selection

General Zone Selection Rules

• Minimum of three branch runs per zone.

• Zone together areas of like uses, but separate areas

based on differing uses

• Avoid grouping rooms of different levels or floors into the

same zone.

• Avoid grouping rooms with opposite sun or weather

exposures in the same zone.

NOTE: Ensure zone duct is designed to handle cfm required

Locating the Zone Sensors

The zone sensors must be located in the room or zone

that each controls. Locate a zone sensor about five feet

above the floor. Do not locate a zone sensor where it may

be exposed to direct sunlight, drafts or direct supply air.

Do not place a zone sensor on an outside wall. Follow the

same guidelines that apply with standard zone sensor

installation. If two or more rooms are on a single zone,

locate the zone sensor in a hallway or area where it can

sense the return air from all rooms.

Figure 1: Sample Floor Plan with Four Zone Example

•

Minimum

of

three

branch

runs

per

zon

e.

•

Zone to

g

ether areas of like uses, but separate areas

based on differin

g

use

s

•

Avoid grouping rooms of different levels or floors into the

sam

e

z

o

n

e.

•Avoi

d

grouping rooms wit

h

opposite s

un

o

o

r

r

w

we

at

h

er

exposures in the same zone

.

NO

TE

:

Ensure zone

d

d

d

d

uc

uc

uc

u

t

t

t

i

is

is

d

d

es

es

ig

ig

ne

ne

d

d

to handle cfm requir

ed

The

zone

sensors

must

be

located

in

the

room

or

zo

ne

that each controls. Locate a zone sensor about five fe

a

bove the floor. Do not locate a zone sensor where it

m

be exposed to direct sunlight, dra

f

ts or direct suppl

y

a

D

o not place a zone sensor on an outside wall. Follow

same guidelines that appl

y

with standard zone sens

or

installation. I

f

two or more rooms are on a single zon

e

lo

lo

ca

c

te the zone sensor in a hallwa

y

or area where it c

a

se

se

ns

s

e

e

e

th

e

r

e

turn air fr

o

m all r

oo

ms

.

Fi

Fi

Fi

Fi

Fi

Fi

Fi

Fi

Fi

Fi

Fi

Fi

Fi

F

Fi

gu

gu

gu

gu

gu

gu

gu

gu

g

g

re

re

re

re

re

re

r

re

e

e

e

e

e

e

e

e

e

e

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

S

Sa

Sa

Sa

Sa

Sa

a

S

Sa

Sa

Sa

S

S

Sa

Sa

Sa

Sa

Sa

mp

mp

mp

mp

mp

m

mp

p

mp

p

p

p

mp

p

p

p

l

le

le

l

l

le

le

le

le

le

le

e

F

F

F

F

F

F

F

F

lo

lo

o

o

o

o

o

o

o

o

o

o

o

o

o

o

or

or

or

or

or

or

or

P

P

P

P

P

la

la

la

la

la

n

n

n

nn

wi

wi

wi

wi

wi

th

h

th

th

t

F

F

ou

ou

r

r

r

Zo

Zo

Zo

Zo

nene

e

e

ne

E

E

E

E

E

E

E

xa

xa

xa

xa

x

a

mp

mp

mp

mp

mp

m

le

le

le

le

Zone 1 Offices

Zone 2 Utility Space

Zone 3 Lobby

Zone 4 Offices

13

INTELLIZONE2 BACNET INSTALLATION MANUAL

IntelliZone2 BACnet Configuration/Diagnostics

For configuration of the IZ2 BACnet system and viewing di-

agnostic values, the Equipment Touch Application for An-

droid based tablets may be used. This software application

allows you to connect to the unit in real time to configure

and monitor the IZ2 BACnet system. The interface is very

user friendly and easy to follow. The tablet is connected

to the system via a USB-C adaptor and cable that is con-

nected to the XPC or to a Rnet zone sensor

Home Screen

The home screen shows an overview of the current operat-

ing status of the IZ2 BACnet system as well as links to the

configuration and detailed diagnostic screens.

Systems Settings

The System Settings screen is used to set most system

level IZ2 BACnet operating parameters.

Equipment Touch Software Icon

Equipment Type

Selection for the heat pump being controlled by the IZ2

BACnet system. The selection options are Variable Speed,

Dual Capacity, and Single Capacity.

Number of Zones

Selection for the number of zones controlled by the system.

The selection options are from 2 to 6, depending on the

Equipment Type.

Single Capacity – Maximum of 2 zones

Dual Capacity – Maximum of 4 zones

Variable Speed – Maximum of 6 zones

Zoning Operation

This option allows selects the mode of operation for the

Zoning system.

Normal – Normal operation uses the individual

zone conditions to operate the system dampers

and equipment.

Central Zone – In Central Zone mode all dampers

are opened, and zone condition readings are taken

ONLY from Zone 1. This will approximate operation

without a zone system and can be useful during

initial commissioning or during service etc.

Damper Type

Selection of system damper type of either Spring (2 wire

spring closed) or Power (3 wire power open/power closed).

Damper Time

Selection to set the amount of time in seconds that the sys-

tem dampers take to open or close. The damper operation

time can be set from 30 to 120 seconds.

PID Selection

Selection to determine how quickly the system heating and

cooling demands will increase and decrease. When the Ag-

gressive value is selected, all system heating and cooling

demands will ramp up and down more quickly.

Scheduling Option

Selection between using the internal program schedules

and network control where the occupied / unoccupied con-

dition is set by the BAS.

Staging

The staging options allows custom selection of staging for

heating and cooling operation. The IntelliZone2 BACnet

system allows separate staging options for heating and

cooling. There are four distinct options for heating and

cooling modes which are explained below. Once compres-

sor operation has been initiated by a zone demand, the

compressor will be upstaged using one of the four staging

options.

14

INTELLIZONE2 BACNET INSTALLATION MANUAL

IntelliZone2 BACnet Configuration/Diagnostics cont.

Heat Staging Setting

The options displayed here determine how the staging dur-

ing the heating phase is carried out in the unit. It could be

one of four options; Normal, Quicker, Faster or Faster EH.

Normal – This “as shipped” mode will upstage the

blower and compressor normally.

Quicker – This mode will upstage the blower,

compressor and auxiliary electric heat more ex-

pediently than “normal” mode for increased com-

fort. Generally, the compressor will be upstaged 1

extra speed more than normal.

Faster – When heating, this mode will upstage the

blower and auxiliary electric heat slightly faster

than “quicker” mode. Generally, the compressor

will be upstaged 2 extra speeds more than nor-

mal.

Faster EH – This mode allows for a timed element

in compressor and electric heat upstaging in larg-

er zones for situations in which ‘Faster 1’ upstag-

ing is inadequate. This staging position should be

reserved for the most demanding and aggressive

situations.

Cool Staging Setting

The options displayed here determine how the staging dur-

ing the cooling phase is carried out in the unit. It could be

one of four options; Normal, Quicker, Faster 1 or Faster 2.

Normal – This “as shipped” mode will upstage the

blower and compressor normally.

Quicker – This mode will upstage the blower

and compressor more expediently than “normal”

mode for increased comfort. Generally, the com-

pressor will be upstaged 1 extra speed more than

normal.

Faster 1 – This mode allows for a timed element

in compressor upstaging in larger zones for situ-

ations in which Quicker staging is not meeting

demand.

Faster 2 – This mode also allows for a timed ele-

ment in compressor upstaging in larger zones for

situations in which Faster 1 staging is not meeting

demand. The difference between Faster 1 and

Faster 2 is how quickly the compressor upstages.

Fan Staging Setting

The Fan Staging Setting applies only to variable speed sys-

tems and may be set to either Normal or Expanded.

Normal – System operates using normal recom-

mended airflow based on compressor speed.

Expanded – System airflow may be increased or

decreased by one speed from the normal speed

corresponding to the current compressor speed,

based on the fan demand total zone percentage.

Auxiliary Heating Lockout

This allows the configuration to lockout electric heat (aux-

iliary heat) above a selected outdoor temperature. If aux-

iliary heating lockout is enabled, the outdoor temperature

may be provided by a sensor connected to the IntelliZone2

BACnet control board, or it may be supplied by the BAS.

Aux Lockout Temp

If auxiliary heating lockout is enabled, this setting deter-

mines the temperature at which the auxiliary lockout will

occur. This temperature can be set from 0°F to 50°F. This

will provide full heat pump capacity without electric heat

above the selected temperature. When the outdoor tem-

perature drops below the selected temperature, then elec-

tric heat will be energized when the demand is present.

OAT Display

This setting allows the option of either enabling or dis-

abling the display of the outdoor temperature value on the

tablet. This setting does not impact the operation of the

sensor or auxiliary heating lockout.

OAT Source

This setting allows the selection of the source for the out-

door temperature sensor. The options are either to be

supplied locally by a sensor connected to the IntelliZone2

BACnet control board, or to be a network supplied value

from the BAS.

Zone Settings

The Zone Settings screen is used to set the overall zone

system configuration values and has links for the detailed

settings for each individual zone.

Zone Size

The Zone Size selection represents an approximation of the

maximum heating or cooling load percentage of the zone

and thus to a certain extent volume of airflow. The Intelli-

Zone2 BACnet system allows zone size selection of Off

15

INTELLIZONE2 BACNET INSTALLATION MANUAL

IntelliZone2 BACnet Configuration/Diagnostics cont.

(0%), Small (25%), Medium (45%), and Large (70%). Some

general rules to follow in this selection procedure are as

follows:

• Pick the larger percentage for areas of major

activity.

• Pick the smaller percentage for areas of minor

activity.

• Pick a larger percentage if more branches are

required than the load indicates due to large

area per load.

• The IntelliZone2 BACnet determines operating

modes and capacity as a proportion of the total

demand.

All zone % calculations are “normalized” using the follow-

ing process: The effective size of each zone is determined

by dividing each individual zone setting percentage by the

total combined percentages of the active zones. A simple

example would be a three zone system with the three zone

sizes set to Large (70%), Medium (45%), and Small (25%).

The total percentage would be 70% + 45% + 25% = 140%.

The effective zone sizes would then be:

Zone 1 = 70 / 140 = 50% effective zone size

Zone 2 = 45 / 140 = 32% effective zone size

Zone 3 = 25 / 140 = 18% effective zone size

The effective system demand contributed by each zone is

then determined by multiplying the effective zone size by

the current zone demand percentage. Each zone may have

an active heating or cooling demand from 0% to 100%. An

example of the total system demand would be the previous

three zone system with a 50% cooling demand in zone 1, a

25% cooling demand in zone 2, and no demand in zone 3.

The total system cooling demand would then be:

50% (demand) * 50% (size) + 25% (demand) * 32%

(size) + 0% (demand) * 18% (size) = 33% system

cooling demand

Operating Mode

The operating mode selections allow each zone to be

individually configured to either be Off, Auto changeover,

Cooling Only, or Heating Only.

Note: Zone 1 may also be set to Emergency Heat. If Emer-

gency Heat is selected for zone 1, the entire system will

operate in emergency heat with all dampers open and the

system operating from the zone 1 sensor.

Fan Setting

The fan selections allow each zone to be configured indi-

vidually to operate the fan continuously when there is no

active system demand (On), or to only operate with an ac-

tive demand in the zone (Auto).

Zone Priority

The zone priority setting for each zone is used to deter-

mine how quickly cooling or heating may be activated to

condition the zone. If there is an active demand in a zone

set for Comfort, the compressor will be activated more

quickly than if active demands are only present in zones set

for Economy.

Detailed Zone Settings

Each zone in the system will have a Detailed Zone Settings

screen that can be accessed from the main Zone Settings

screen. Each Detailed Zone Settings screen can be used

to adjust the same settings available on the Zone Settings

screen, as well as modifying occupancy, setpoint, and tem-

perature sensor settings.

Occupancy Setting

The occupancy setting selections determines what space

conditioning setpoints will be used for the zone. Each zone

may be individually configured to either be Occupied, Un-

occupied, Temporarily Occupied, or Standby.

Occupancy Sensor

The occupancy sensor setting is used to select if the zone

has an occupancy sensor, and if so, what it’s function will

be.

No Sensor – When configured for “No Sensor”,

even if an occupancy sensor is connected it will

not be used to control the occupancy of the

zone.

Occupied Sensor – When configured for “Oc-

cupied Sensor”, an active occupancy sensor

will put the zone into the occupied mode if it

is currently unoccupied by either command or

schedule.

Temp Occupied Sensor – When configured for

“Temp Occupied Sensor”, an active occupancy

sensor will put the zone into the temporary

occupied mode if it is currently unoccupied by

either command or schedule.

16

INTELLIZONE2 BACNET INSTALLATION MANUAL

IntelliZone2 BACnet Configuration/Diagnostics cont.

Standby Sensor – When configured for “Standby

Sensor”, an active occupancy sensor will put the

zone into the occupied mode if it is currently in

standby by either command or schedule.

Occupied Setpoints

The Occupied Heating Setpoint and Occupied Cooling

Setpoint values are used when the zone is in the occupied

or temporary occupied mode either by command,

schedule, or override.

Unoccupied Setpoints

The Unoccupied Heating Setpoint and Unoccupied

Cooling Setpoint values are used when the zone is in the

unoccupied mode either by command or schedule.

Standby Setpoints

The Standby Heating Setpoint and Standby Cooling

Setpoint values are used when the zone is in the standby

mode either by command or schedule.

Zone Temperature Adjustment

The zone temperature adjustment value is used as a

calibration or offset value for the Rnet sensor for the zone.

Zone Temperature Selection

The zone temperature selection is used to choose between

using the temperature value from a connected Rnet zone

sensor, or a zone temperature supplied from the BAS

system.

BAS Temperature Override

The BAS temperature override value is the zone

temperature value to be used when the Zone Temperature

Selection is set to BAS.

Minimum Setpoint Differential

The minimum setpoint differential is the minimum allowed

value between the heating and cooling setpoints for the

zone.

Zone Sensor Setpoint Span

The zone sensor setpoint span is the amount of adjustment

allowed at the Rnet zone sensor when and appropriate

sensor is used, and the adjustment is allowed.

Humidity Control

The Humidity Control screen allows the settings for

humidity control of the system to be set. Humidity control

settings are system wide, not set individually for each zone.

Humidity Control

Humidity Control

The humidity control selection determines what type of

humidity control, if any the system will use.

None – When configured for “None” the

system will not adjust operation for either

dehumidification or humidification.

Dehumidification Only – When configured for

“Dehumidification Only” the system may adjust

operation based on the current system humidity

value and active dehumidification setpoint.

There will be no system humidifier output

generated for humidification operation.

Both – When configured for “Both” the

system may adjust operation based on the

current system humidity value and active

dehumidification setpoint for dehumidification

operation and may activate the system

humidifier output based on the current system

humidity value and active humidification

setpoint for humidification operation.

Humidification Only – When configured for

“Humidification Only” the system may activate

the system humidifier output based on the

current system humidity value and active

humidification setpoint. System operation will

not be adjusted for dehumidification.

Occupied Setpoints

The Occupied Dehumidification Setpoint and Occupied

Humidification Setpoint values are used when the zone

is in the occupied or temporary occupied mode either by

command, schedule, or override.

Unoccupied Setpoints

The Unoccupied Dehumidification Setpoint and

Unoccupied Humidification Setpoint values are used when

the zone is in the unoccupied mode either by command or

schedule.

17

INTELLIZONE2 BACNET INSTALLATION MANUAL

IntelliZone2 BACnet Configuration/Diagnostics cont.

Damper Limit Settings

The Damper Limit Settings screen allows a maximum and

minimum position setting for each zone in the system.

Minimum Position

The minimum position settings for each zone should be set

to 0% in most cases. The only exception should be to meet

absolute minimum air delivery requirements. Setting the

minimum damper position to anything other than 0% can

cause over-cooling or over-heating of the zone reducing

the overall system comfort level.

Maximum Position

The maximum position settings for each zone are typically

set to 100%. These values may be reduced to help balance

the airflow delivered to various zones if needed.

Demand Ventilation

The Demand Ventilation screen shows the current

operating status for demand–controlled ventilation, as well

as the settings to configure the operation.

Demand Controlled Ventilation

The demand–controlled ventilation setting is used to enable

or disable the DCV operation, which controls an outside air

damper based on the system air quality.

DCV Control Variable

The DCV control variable setting is used to select between

using CO2 or VOC as the air quality value to control the

DCV operation.

DCV Minimum Damper Position

The DCV minimum damper position setting is the damper

position associated with the DCV Low PPM Setting Value.

The DCV minimum damper position is normally set to

provide the minimum required outside air.

DCV Maximum Damper Position

The DCV maximum damper position setting is the damper

position associated with the DCV High PPM Setting Value.

DCV Low PPM Setting Value

The DCV low PPM setting value setting is the air quality

PPM value associated with the DCV Minimum Damper

Position.

DCV High PPM Setting Value

The DCV high PPM setting value setting is the air quality

PPM value associated with the DCV Maximum Damper

Position.

Internal Schedule

The Internal Schedule screen allows the internal XPC

occupancy schedule associated with each zone to be

selected and edited. On this screen the Schedule Object

number is the zone number the schedule is associated with.

Individual Zone. When an individual zones internal schedule

is selected, it may be viewed as a monthly or weekly

schedule. For either display type, individual days may

then be selected and the start / stop times for occupied

operation may be adjusted.

18

INTELLIZONE2 BACNET INSTALLATION MANUAL

IntelliZone2 BACnet Configuration/Diagnostics cont.

Manual Overrides

The Manual Overrides Screen allows manual operation

of the heat pump system as well as the individual zone

dampers.

NOTE: For any manual operation the System Override

Setting must be set to “Manual”. If Normal damper

operation is selected when the system is set for manual

operation, the system will open all dampers and operate in

the central zone mode.

When the manual mode is active, each component

(Compressor, Blower, VS Pump) may either be allowed

to operate automatically based on system conditions or

the operation of other outputs, or they can be manually

controlled individually. For example, if manual compressor

operation is selected, the compressor speed would be

based on the manual setting, but the blower and VS pump

could be allowed to operate automatically based on the

currently selected compressor speed.

Aurora Settings

The Aurora Settings screen allows most Aurora settings

that are typically set using an AID tool to be set using the

tablet interface.

Network Commands

The Network Commands screen displays settings that are

typically set or controlled by the BAS. The values may be

changed using this screen, but if the BAS is actively writing

to the point, the value from the BAS will override any

adjustments made on this screen.

OAT Value Source Config

The OAT value source config value selects between the

BAS and the zone panel as the source for the system

outdoor air temperature value.

BAS OAT Override Value

The BAS OAT override value is the system outdoor

temperature value used if the OAT Value Source Config

value is set to BAS.

BAS Humidity Override Value

The BAS humidity override value is the system humidity

value used if being supplied by the BAS.

BAS CO2 Override Value

The BAS CO2 override value is the system CO2 value used

if being supplied by the BAS.

BAS VOC Override Value

The BAS VOC override value is the system VOC value used

if being supplied by the BAS.

System Status

The System Status screen displays the current operating

conditions of the overall system, including zone

configurations and demands along with the current heat

pump operating status.

19

INTELLIZONE2 BACNET INSTALLATION MANUAL

IntelliZone2 BACnet Configuration/Diagnostics cont.

Aurora Conditions

The Aurora Conditions screen displays the current

operating status of the heat pump system, with many of

the main diagnostic values.

Additional Aurora Data

The Additional Aurora Data screen displays additional

diagnostic information on the heat pump and Aurora

control system.

Aurora Timers / Details

The Aurora Timers / Details screen displays the

current Aurora timer values as well as the status of the

communicating components in the system, fault codes, and

the current software revision of each control.

Aurora Control Signals

The Aurora Control Signals screen displays the current

status of the primary control inputs and main outputs of

the Aurora control system.

20

INTELLIZONE2 BACNET INSTALLATION MANUAL

IntelliZone2 BACnet Configuration and Wiring

Each zone may have either one or two Rnet sensors, or the zone temperature may be provided by the BAS. If more than

one Rnet sensor is used for a single zone, the values from the two sensors will be averaged to be used for the effective

zone temperature.

Rnet Sensor Wiring

For best results Rnet zone sensors should be wired in a daisy chain configuration using (2) 18AWG twisted pair unshielded

communication cables. One twisted pair should be used for the 12v supply and ground wire connections and the other

twisted pair should be used for the Rnet+ and Rnet- connections.

Rnet Sensors Wired in Daisy Chain Configuration

Rnet Sensor Addressing

Each Rnet zone sensor is addressed using the DIP switch on the back of the ZS sensor. Each sensor in the system must

have a different address, and unique pre–defined addresses have been assigned for each zone. If only one sensor is used

for a zone, it may use either of the two addresses defined for that zone.

Note: Only one Rnet zone sensor with a CO2 or VOC option may be used per system.

DIP Zone 1 Zone 2 Zone 3 Zone 4 Zone 5 Zone 6 DIP

DIP 1 Off Off On On Off Off On On Off Off On On DIP 1

DIP 2 Off Off Off Off On On On On Off Off Off Off DIP 2

DIP 3 Off Off Off Off Off Off Off Off On On On On DIP 3

DIP 4 Off On Off On Off On Off On Off On Off On DIP 4

1 2 3 4

Table of contents

Other Water Furnace Temperature Controllers manuals