Water Powered Technologies Papa Pump User manual

a great UK

design

patented design

Owner’s Manual

Installation, Operation and Maintenance Guide

patented desig

n

Index

3

4

5

6

7

11

14

15

17

18

19

21

24

25

29

33

page no. description

Kit contents

About the Papa pump

Papa technology

How the Papa pump works

Installation principles

Catchment tank details & installations

Supply tank details and installation

Pump chamber details and installation

Multiple installations

Reference charts

Seradisc filter

Installation & commissioning

Pump parts list

Pump maintenance

Troubleshooting

Specifications

2

Kit Contents

exhaust adaptor

pump

hose assembly

c spanner

Seradisc filters

x 2

spare set valves

2” ball valve

3

pressure vessel

exhaust adaptor

pum

p

c spanner

About the Papa pump

Water Source

a typical schematic layout for a Papa Pump system

B

A

C

A: Catchment Tank

B: Supply Tank

C: Pump Chamber

D: Water Storage

D

Flow

Water powered pumping traditionally goes back 1000’s of years where it was

used primarily for low head irrigation. More recently, from the late 1700’s

hydraulic ram pumps were developed as an efficient and effective means of

transporting water over long distances and great heights where they have been

utilised to provide water in most parts of the world prior to the advent of

‘previously inexpensive’ mains water and electricity supplies.

Developed within the UK in the mid-90s, the Papa Pump represents a modern,

smaller, lighter and more effective alternative and is used in many countries to

provide water for a wide variety of uses. With the addition of the revolutionary

composite version, Papa continues to ensure that your water transport

requirements are cost-effective and delivered in a reliable and sustainable

system.

Simple water power

By utilising a naturally flowing water source, the Papa pump is able to transport

up to 30% of that water to the desired location, allowing the residual water to be

returned to the natural source. With minimal maintenance and zero fuel costs

and emissions, the Papa Pump will provide you with a clean and efficient system

for your water transportation requirements including agriculture, horticulture,

irrigation, domestic and industrial use.

4

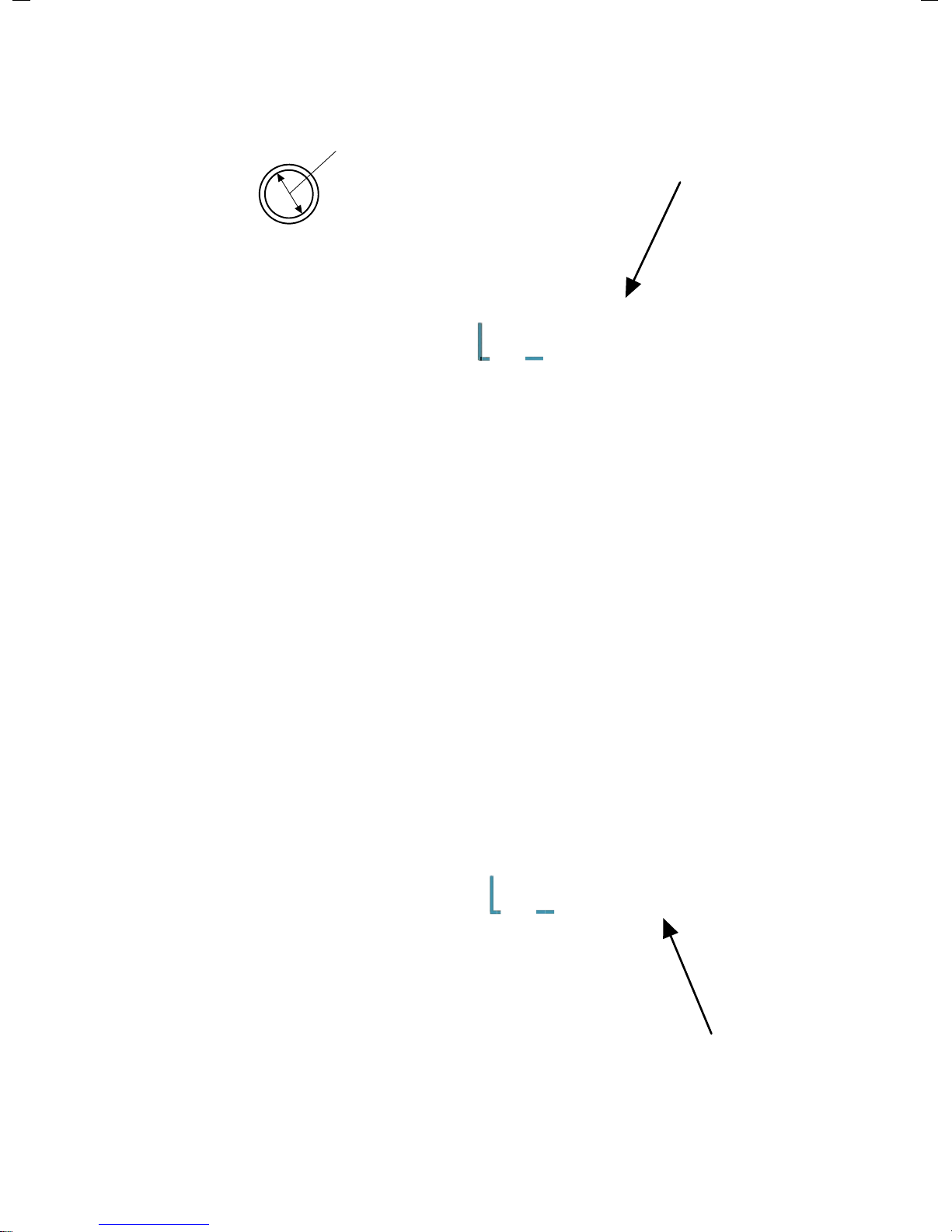

Papa technology

exhaust

port

delivery

port supply

port

main valve

non-return

valve

5

adjuster

How the Papa pump works

Water enters pump via supply port and flows around main valve to exhaust port.

As the flow increases around the main valve a differential pressure occurs

causing the valve to suddenly close. The flow and mass of water is then directed

through the non-return valve and into the delivery port at a higher pulsed

pressure. This pressure suddenly reduces causing the main valve to reopen and

the cycle repeats.

Turning the adjuster to open the valve allows flow through the pump to be

regulated so that a greater flow generates a greater pressure and water delivery.

6

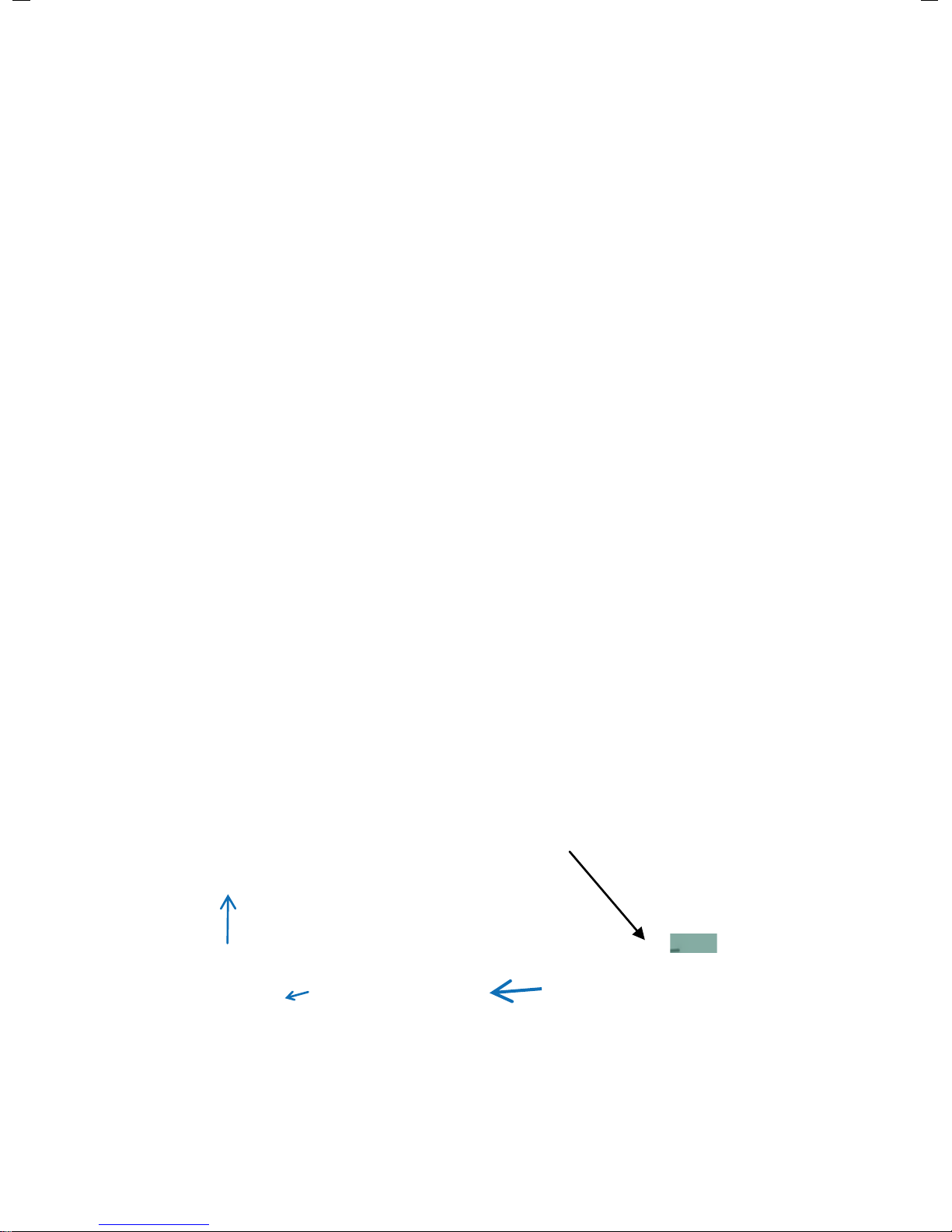

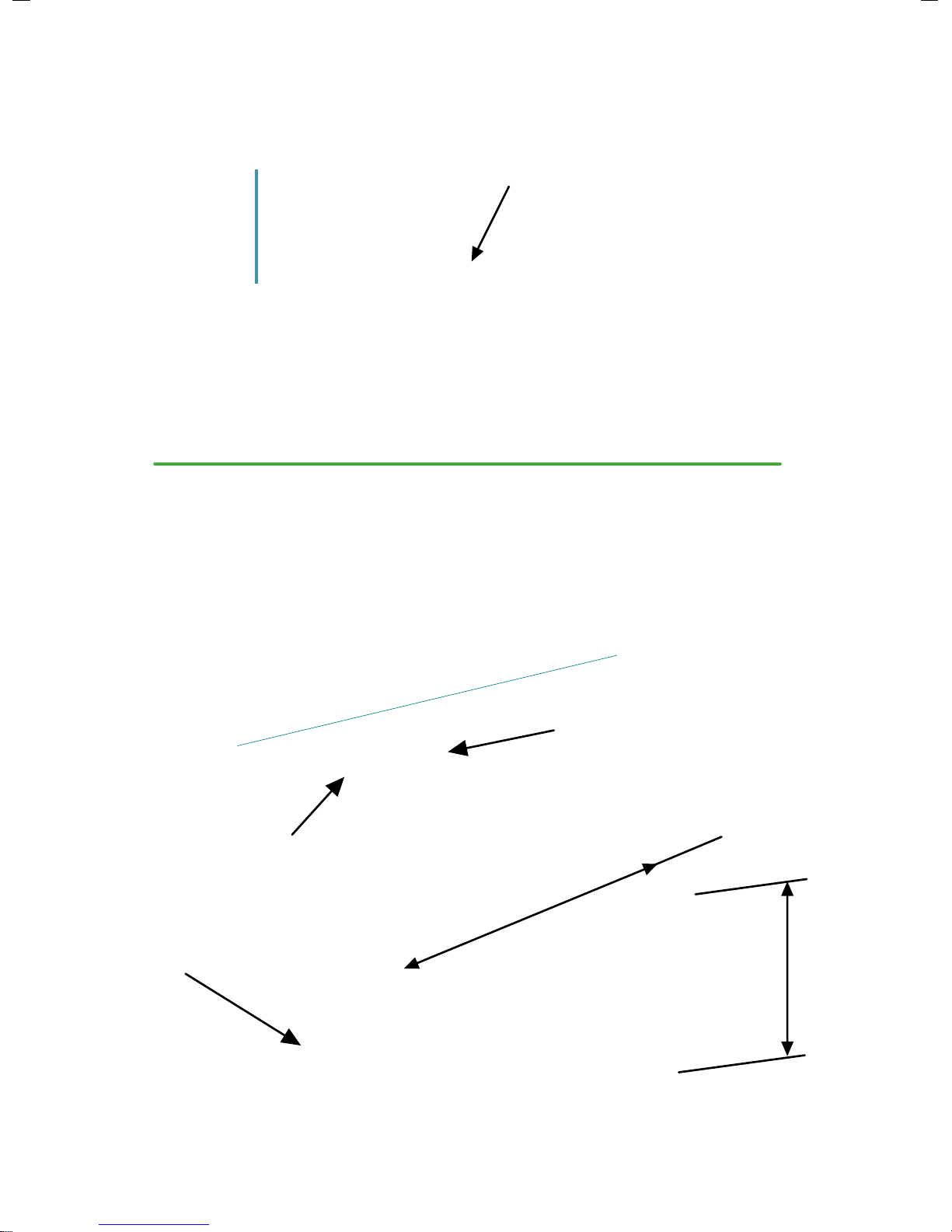

Installation principles

A natural water source is required

river

stream

spring

pond/lake

7

catchment

tank

supply

tank

pump

chamber

water source flow

Plan Elevation

Side Elevation

MORE SUPPLY HEAD = MORE WATER!

Supply

Head

Delivery

Head

catchment

tank

pump

chamber

supply

tank

storage tank

SH

DH

The greater the supply head, the more efficient

the pump is!

8

Supply Head greater

than 2 metres

SH

Site Layout Overview

MORE SUPPLY HEAD = MORE WATER!

A minimum Supply Head of 2 metres is required, but please

ensure that the maximum head is achieved for best results

9

delivery pipe

storage tank

catchment

tank

pump

chamber

supply

tank

feed pipe feed pipe

overflow

pipe

supply

pipe

NOTE! Check that the Delivery Head (DH) does not exceed the pressure rating of

pipes!

The maximum Delivery Head (DH) is 30 x the Supply Head (SH)

Delivery Head DH

= max 30 x SH

Supply Head

SH

10

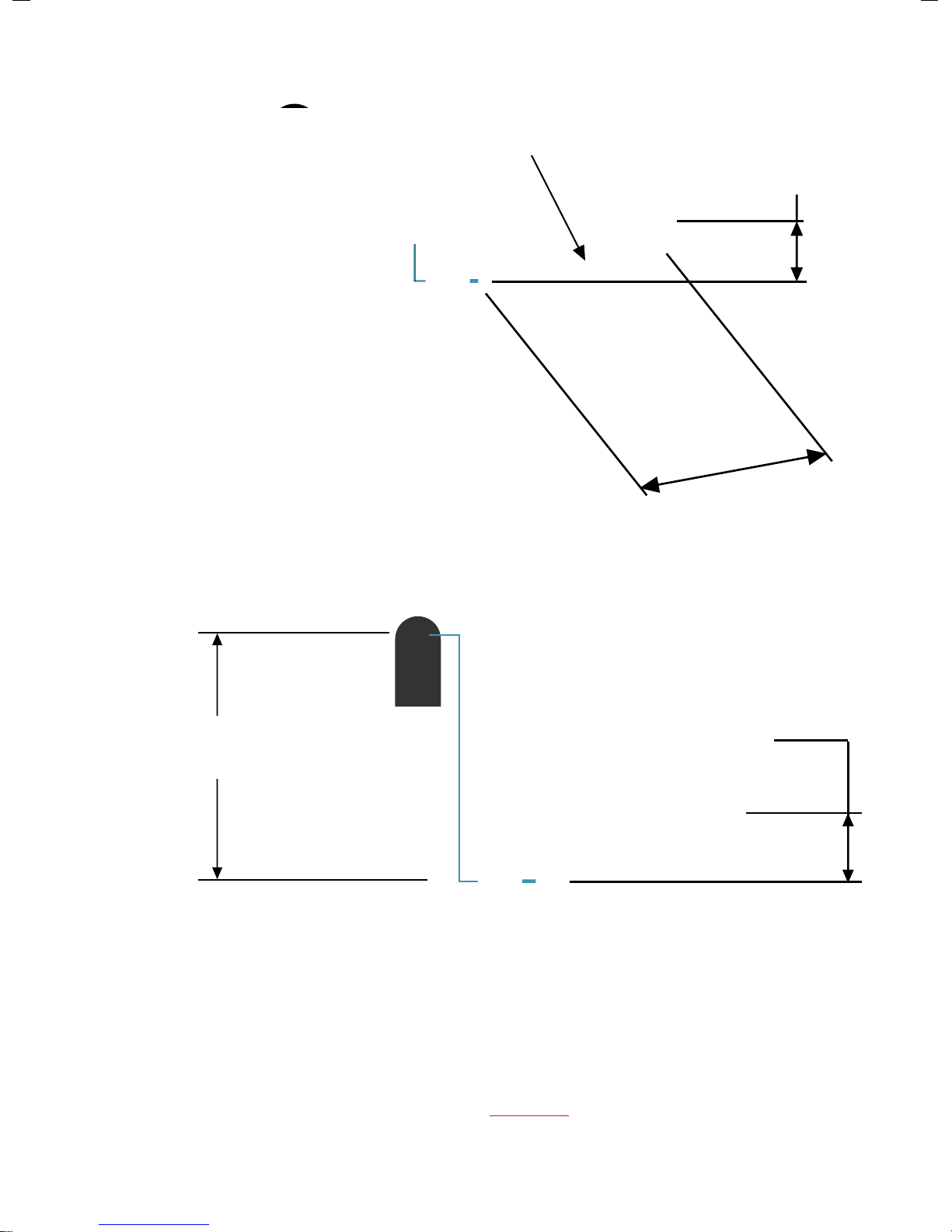

Supply Head

SH

L

Supply Pipe length

NOTE! The PAPApump can operate outside of these

parameters but the performance will be affected

Supply Pipe

length

L = 4-7 x SH

Supply Pipe

The Supply Pipe length (L) should be between 4-7 x the Supply Head (SH) for

optimum efficiency and pressure

catchment

tank

feed pipe

supply

tank

Feed Pipe should be straight with a low gradient (1:500) into the Supply Tank, but

check pipe friction chart to establish the most suitable size and gradient.

Catchment Tank details & installations

Catchment method 1

feed pipe

water flow

90 deg bend facing

downstream

1 metre

min

1 metre

min

11

Catchment method 2

feed

pipe

water ingress through

holes drilled in tank stones used as

coarse filter

feed pipe

inlet from

water source

Seradisc filters

Catchment tank

NOTE! The more Seradisc filters fitted, the better the reliability of the system

12

Feed Pipe

Overflow Pipe

NOTE! Larger diameter pipe may be required for multiple pump installations with

more than 2 pumps.

Overflow Pipe

13

4”

Feed Pipe

or

100mm

NOTE! Larger diameter pipe may be required for multiple pump installations with

more than 2 pumps. Please refer to friction chart. Add more Seradisc filters

accordingly

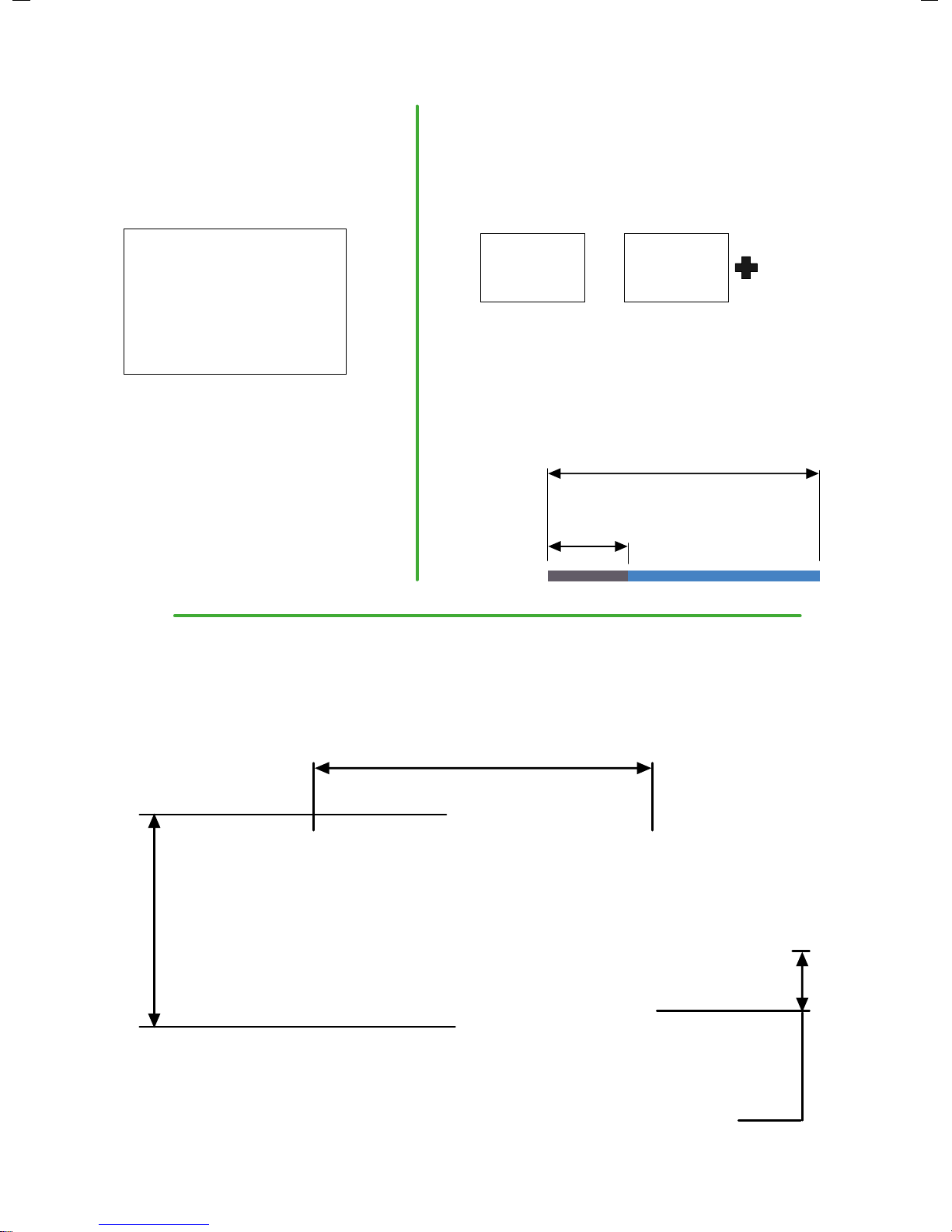

Supply Tank details & installations

feed pipe

supply pipe

overflow pipe

socket

Seradisc filter

Supply Tank

1 metre

min

1 metre

min

removable stand

pipe (used for draining

down)

Supply Pipe -1

supply pipe

2” (50mm)

Galvanised steel

or MDPE

(see next page)

14

Supply Pipe - 2

min 1/3 supply pipe length

galvanised into pump

supply pipe length

or

MDPE

either use

do not use

100% MDPE

use 100% Galvanised steel

IF DELIVERY HEAD (DH)

IS LESS THAN 15m IF DELIVERY HEAD (DH)

IS MORE THAN 15m

or

Pump Chamber details & installations

Pump Chamber

supply pipe

overflow

pipe

delivery

pipe

150mm min( allows pump to be rotated inside chamber)

1m

1m

15

Pump Chamber

Note: Chamber requires a cover if a Sureflow flow valve is fitted

supply pipe

overflow

pipe

tank drain

delivery

pipe

ball valve

pump support

nr valve

NOTE! 2 pumps can be installed in a 1m diameter ring.

Larger rings will be required for additional pumps

Delivery Pipe

NOTE! The diameter of the delivery pipe may vary depending on the number of

pumps and distance. Please refer to the pipe friction chart for the appropriate size

delivery

pipe

25mm

16

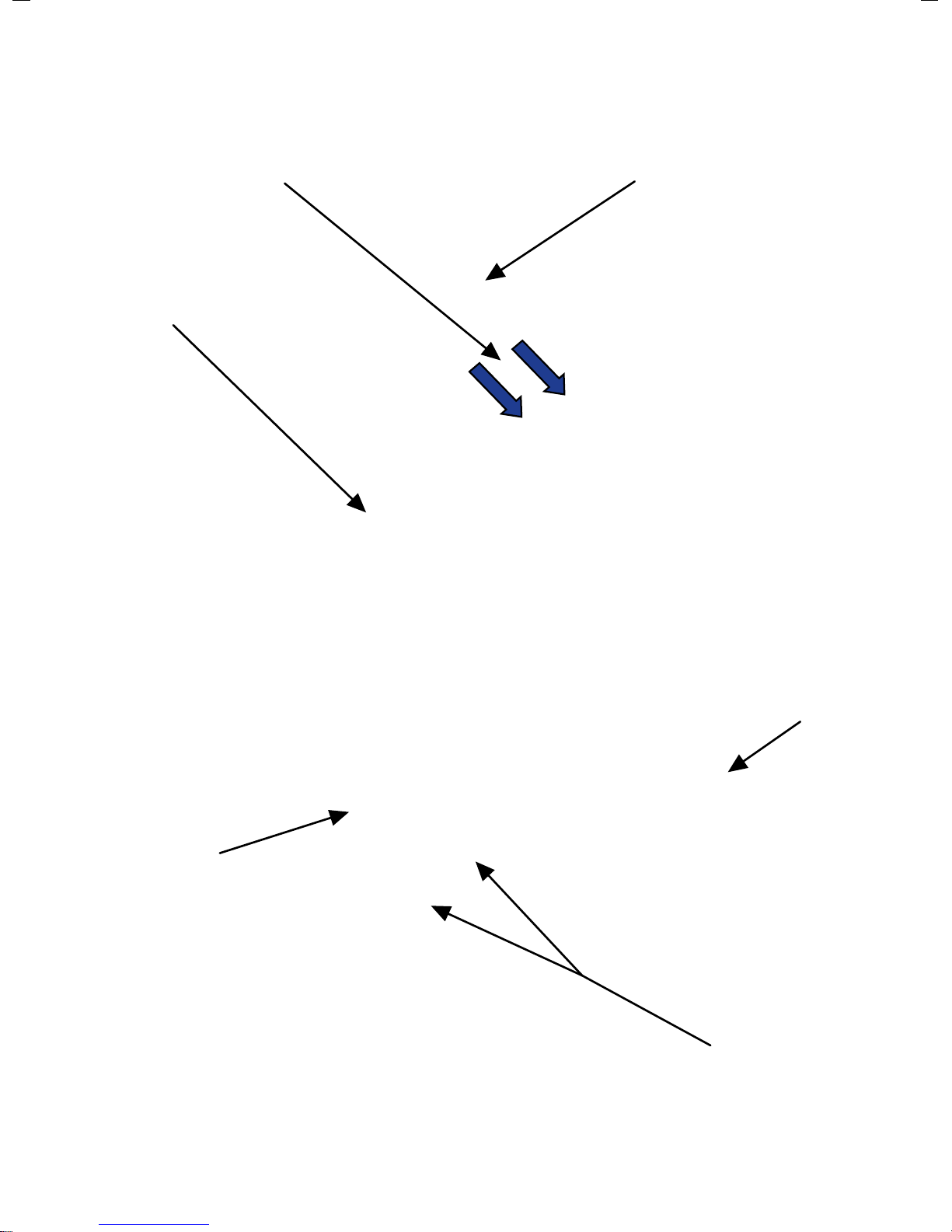

Multiple pump installations

Typical dual pump installation

delivery

pipe

feed

pipes

support

pumps

NOTE! Please check delivery pipe size by referring to the pipe friction chart

when using multiple pumps or pumping over long distances.

Manifolded multiple pump installation

17

delivery

pipe manifold

delivery

pipe

feed

pipes

NR valve

18

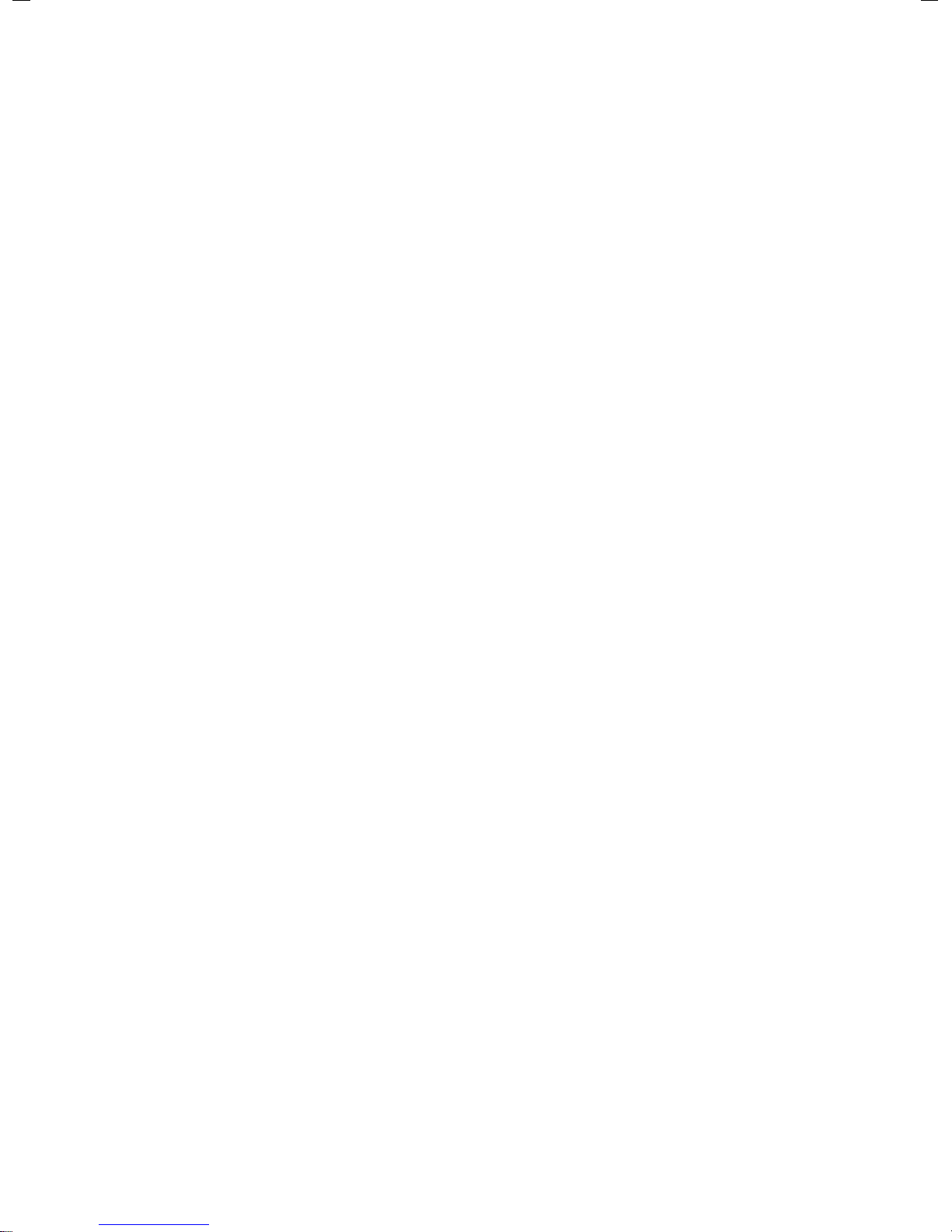

Pump performance chart

19

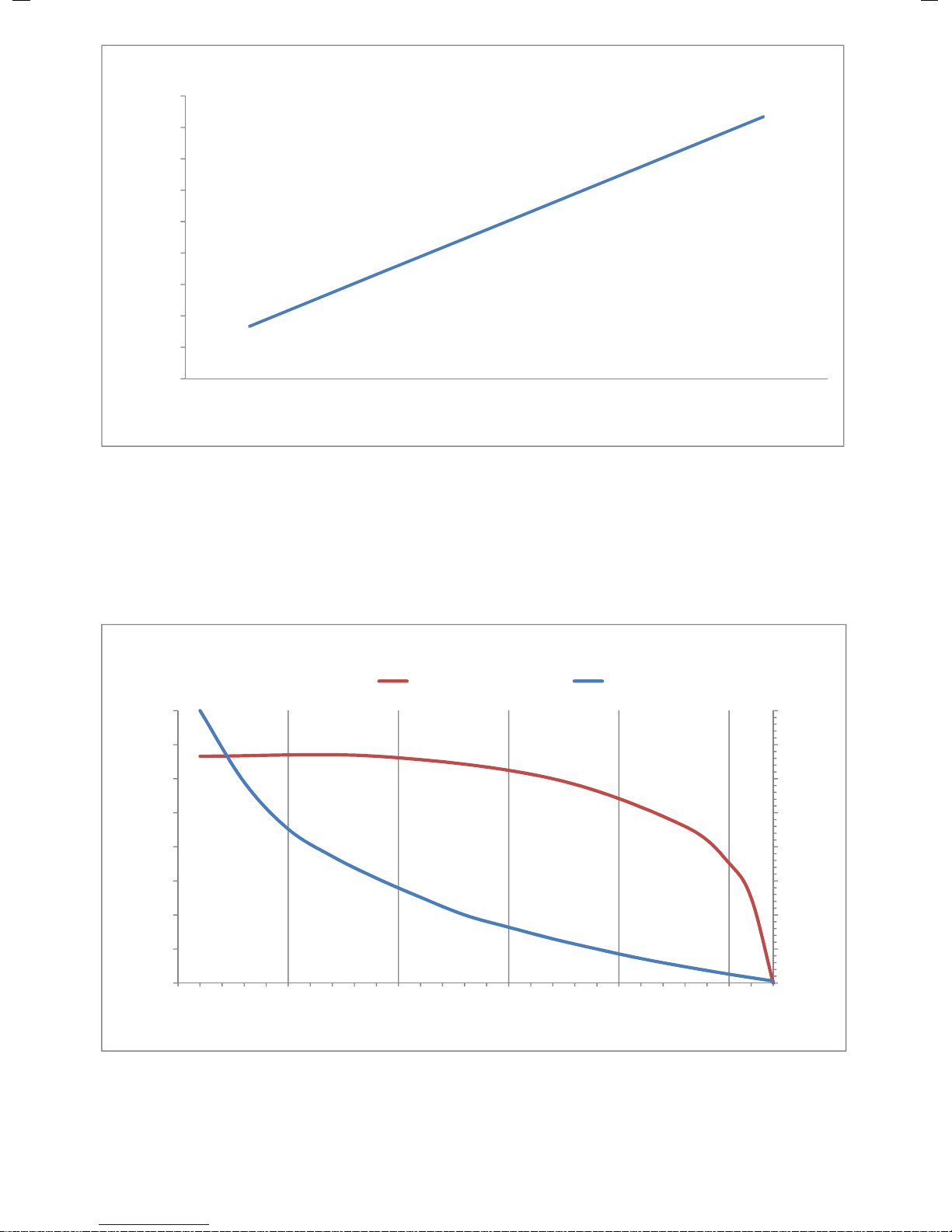

seradis TM

Installation methods and performance details

NOTE! The more Seradisc filters fitted, the better the reliability of the system

cut 2 ¼” dia. holes in pipe

and screw in filters

use flexible coupling

supplied with filter

Note: Particulate sizes are calculated. Due to the flexible nature of the discs,

Seradisc filters fitted with lower numbers of discs may allow ingress of

particulates slightly larger than as indicated on the graph.

0

200

400

600

800

1000

1200

1400

1600

1800

12 34 5

litres/min

no. of filters in parallel

Flow through standard 16-disc filters in parallel configuration

0

0.5

1

1.5

2

2.5

3

3.5

4

0

50

100

150

200

250

300

350

400

15 20 25 30 35 40

particulate size (mm)

litres/min

no. of discs in filter assembly

Flow through filter and particulate screening

filters in parallelf ilters in series

flow particulate size

20

Table of contents

Popular Water Pump manuals by other brands

Annovi Reverberi

Annovi Reverberi AR 713 instruction manual

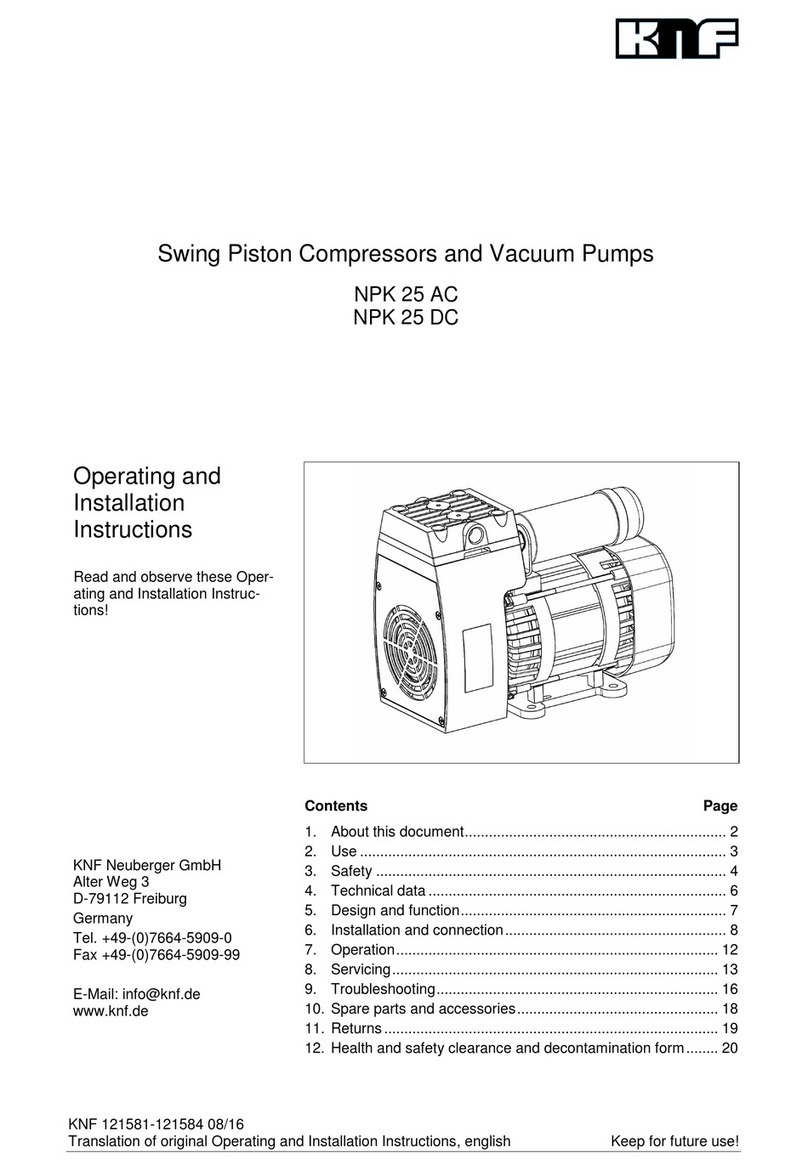

KNF

KNF NPK 25 AC Operation and installation instructions

ARKSEN

ARKSEN 002-AU-20439 owner's manual

Xylem

Xylem FloJet 3426 Series manual

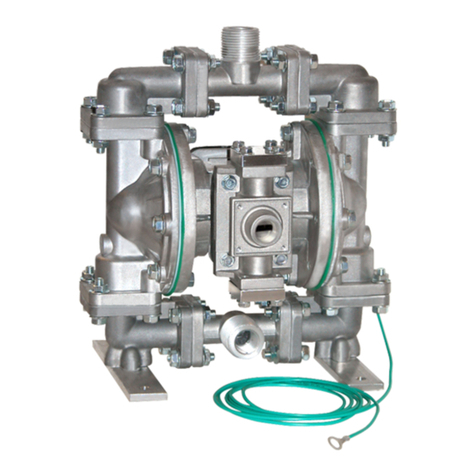

YAMADA

YAMADA 140 Series instruction manual

WITA

WITA HE OEM 2 40 Series Translation of the original operating instruction

Biral

Biral AX 12 Installation and operating instructions

Sandpiper

Sandpiper G Series Service & operating manual

3B SCIENTIFIC PHYSICS

3B SCIENTIFIC PHYSICS 1003317 instruction sheet

Trebor

Trebor Mega 120E Operation & maintenance manual

HÄNY

HÄNY 2550-BA operating instructions

JABSCO

JABSCO 18940-0010 Installation and operation