Water Right Sanitizer Plus Series Service manual

Sanitizer Plus Series®

Water Conditioners

TABLE OF CONTENTS

Preinstallation Instructions for Dealers . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Bypass Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Programming Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-8

Operating Displays and Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-10

Start-up Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-13

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-22

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Quick Reference Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Your Sanitizer Series water conditioners are precision built, high quality products. These units will deliver

conditioned water for many years to come, when installed and operated properly. Please study this manual carefully

and understand the cautions and notes before installing. This manual should be kept for future reference. If you have

any questions regarding your water conditioner, contact your local dealer or Water-Right at the following:

Water-Right, Inc.

1900 Prospect Court • Appleton, WI 54914

Phone: 920-739-9401 • Fax: 920-739-9406

YOUR WATER TEST

Hardness gpg

Iron ppm

pH number

*Nitrates ppm

Manganese ppm

Sulphur yes/no

Total Dissolved Solids

*Over 10 ppm may be harmful for human consumption. Water

conditioners do not remove nitrates or coliform bacteria, this

requires specialized equipment.

PREINSTALLATION INSTRUCTIONS FOR DEALERS:

BYPASS VALVE:

3

The manufacturer has preset the water treatment unit’s sequence of cycles, cycle times, salt dose,

exchange capacity and salt dose refill time.

The dealer should read this page and guide the installer regarding hardness, day override, and time of

regeneration, before installation:

For the installer, the following must be used:

• Program Installer Settings ... Hardness, Day Override (preset to 6 days), and Time of

Regeneration (preset to 2 a.m., with brine tank refill to occur four hours prior; see Operating

Displays and Instructions for more details)

• Read Normal Operating Displays

• Set Time of Day

• Read Power Loss & Error Display

For the homeowner, please read operating displays and instructions.

WATER SOFTENERS:

During operation, the normal user display is time of day and gallons per minute.

Flow Rate, Capacity Remaining and Days to a Regeneration are optional displays but are not normally

used. Each of these can be viewed by pressing NEXT to scroll through them. When stepping through any

programming, if no buttons are pressed within 5 minutes, the display returns to a normal user display.

Any changes made prior to the 5 minute time out are incorporated.

To quickly exit any Programming, Installer Settings, etc., press SET CLOCK. Any changes made prior to

the exit are incorporated. If desired, two regenerations within 24 hours are possible with a return to

the preset program. To do a double regeneration:

1. Press the REGEN button once. “REGEN TODAY” will flash on the display.

2. Press and hold the REGEN button for three seconds until a regeneration begins.

Once the valve has completed the immediate regeneration, the valve will regenerate one more time

at the preset.

The bypass valve is typically used to isolate the control valve from the plumbing system’s water pressure

in order to perform control valve repairs or maintenance. The 1" full flow bypass valve incorporates four

positions, including a diagnostic position that allows a service technician to have pressure to test a system

while providing untreated bypass water to the building. Be sure to install bypass valve onto main control

valve, before beginning plumbing. Or, make provisions in the plumbing system for a bypass. The bypass

body and rotors are glass-filled Noryl®and the nuts and caps are glass-filled polypropylene. All seals are

self-lubricating EPDM to help prevent valve seizing after long periods of non-use. Internal “O” Rings can

easily be replaced if service is required.

The bypass consists of two interchangeable plug valves that are operated independently by red arrow

shaped handles. The handles identify the direction of flow. The plug valves enable the bypass valve to

operate in four positions.

4

1. NORMAL OPERATION POSITION: The inlet and outlet handles point in the direction of flow

indicated by the engraved arrows on the control valve. Water flows through the control valve for normal

operation of a water softener. During the regeneration cycle this position provides regeneration water to

the unit, while also providing untreated water to the distribution system (Fig. 1).

2. BYPASS POSITION: The inlet and outlet handles point to the center of the bypass. The system is

isolated from the water pressure in the plumbing system. Untreated water is supplied to the building

(Fig. 2).

3. DIAGNOSTIC POSITION: The inlet handle points toward the control valve and the outlet handle

points to the center of bypass valve. Untreated supply water is allowed to flow to the system and to the

building, while not allowing water to exit from the system to the building (Fig. 3). This allows the service

technician to draw brine and perform other tests without the test water going to the building.

NOTE: The system must be rinsed before returning the bypass valve to the normal position.

4. SHUT OFF POSITION: The inlet handle points to the center of the bypass valve and the outlet handle

points away from the control valve. The water is shut off to the building. The water treatment system will

depressurize upon opening a tap in the building. A negative pressure in the building combined with the

softener being in regeneration could cause a siphoning of brine into the building. If water is available

on the outlet side of the softener, it is an indication of water bypassing the system (Fig. 4)

(i.e. a plumbing cross-connection somewhere in the building).

NORMAL OPERATION POSITION

Figure 1

DIAGNOSTIC POSITION

Figure 3

BYPASS POSITION

Figure 2

SHUT OFF POSITION

Figure 4

5

GENERAL INSTALLATION & SERVICE WARNINGS

The control valve, fittings and/or bypass are designed to accommodate minor plumbing misalignments.

There is a small amount of “give” to properly connect the piping, but the water softener is not designed to

support the weight of the plumbing.

Do not use Vaseline, oils, other hydrocarbon lubricants or spray silicone anywhere. A silicone lubricant may

be used on black “O” Rings, but is not necessary. Avoid any type of lubricants, including silicone, on red

or clear lip seals.

Do not use pipe dope or other sealants on threads. Teflon®tape must be used on the threads of the 1" NPT

inlet and and outlet, the brine line connection at the control valve, and on the threads for the drain line

connection. Teflon®tape is not used on the nut connections or caps because “O” Ring seals are used.

The nuts and caps are designed to be unscrewed or tightened by hand or with the special plastic Service

Wrench, #CV3193-01. If necessary pliers can be used to unscrew the nut or cap. Do not use a pipe wrench

to tighten nuts or caps. Do not place screwdriver in slots on caps and/or tap with a hammer.

SITE REQUIREMENTS

• water pressure – 25-100 psi • current draw is 0.5 amperes

• water temperature – 33-100°F (0.5-37.7°C) • the plug-in transformer is for dry locations only

• electrical – 115/120V, 60Hz uninterrupted outlet

• the tank should be on a firm level surface

1. The distance between the drain and the water conditioner should be as short as possible.

2. Since salt must be periodically added to the brine tank, it should be located where it is

easily accessible.

3. Do not install any water conditioner with less than 10 feet of piping between its outlet and

the inlet of a water heater.

4. Do not locate unit where it or its connections (including the drain and overflow lines) will

ever be subjected to room temperatures under 33°F.

WELL WATER INSTALLATION MUNICIPAL INSTALLATION

INSTALLATION:

6

6. INLET/OUTLET PLUMBING: Be sure to install Bypass Valve onto main control valve before

beginning plumbing. Make provisions to bypass outside hydrant and cold hard water lines at this

time. Install an inlet shutoff valve and plumb to the unit’s bypass valve inlet located at the right rear

as you face the unit. There are a variety of installation fittings available. They are listed under

Installation Fitting Assemblies, page 21-22. When assembling the installation fitting package (inlet

and outlet), connect the fitting to the plumbing system first and then attach the nut, split ring and “O”

Ring. Heat from soldering or solvent cements may damage the nut, split ring or “O” Ring. Solder

joints should be cool and solvent cements should be set before installing the nut, split ring and “O”

Ring. Avoid getting solder flux, primer, and solvent cement on any part of the “O” Rings, split rings,

bypass valve or control valve. If the building’s electrical system is grounded to the plumbing, install a

copper grounding strap from the inlet to the outlet pipe. Plumbing must be done in accordance with

all applicable local codes.

7. DRAIN LINE: First, be sure that the drain can handle the backwash rate of the system. Solder joints

near the drain must be done prior to connecting the drain line flow control fitting. Leave at least 6"

between the drain line flow control fitting and solder joints. Failure to do this could cause interior

damage to the flow control. Install a 1/2" I.D. flexible plastic tube to the Drain Line Assembly or discard

the tubing nut and use the 3/4" NPT fitting for rigid pipe (recommended). If the backwash rate is

greater than 7 gpm, use a 3/4" rigid drain line. Where the drain line is elevated but empties

into a drain below the level of the control valve, form a 7" loop at the discharge end of the line so that

the bottom of the loop is level with the drain connection on the control valve. This will provide an

adequate anti-siphon trap. Piping the drain line overhead <10 ft is normally not a problem. Be sure

adequate pressure is available (40-60 psi is recommended). Where the drain empties into an overhead

sewer line, a sink-type trap must be used. Run drain tube to its discharge point in accordance with

plumbing codes. Pay special attention to codes for air gaps and anti-siphon devices.

NOTE: Drain line nut will not be supplied for units having a backwash rate greater than 7 gpm.

8. BRINE TANK CONNECTION: Install the 3/8" O.D. polyethylene tube from the Refill Elbow to the

Brine Valve in the brine tank.

9. OVERFLOW LINE CONNECTION: An overflow drain line is recommended where a brine

overflow could damage furnishings or the building structure. Your softener is equipped with a brine

tank safety float which greatly reduces the chance of an accidental brine overflow. In the event of a

malfunction, however, an overflow line connection will direct the “overflow” to the drain instead of

spilling on the floor where it could cause considerable damage. This fitting is an elbow on the side of

the brine tank. Attach a length of 1/2" I.D. tubing to fitting and run to drain. Do not elevate overflow

line higher than 3" below bottom of overflow fitting. Do not “tie” this tube into the drain line of the

control valve. Overflow line must be a direct, separate line from overflow fitting to drain, sewer, or

tub. Allow an air gap as per the drain line instructions.

CAUTION: Never insert a drain line into a drain, sewer

line, or trap. Always allow an air gap

between the drain line and the wastewater

to prevent the possibility of sewage being

back-siphoned into the conditioner.

7

TIME HOUR

SET

2:00

AM

1. Set time of day:

1 2

TIME MINUTES

SET

3

CURRENT DAY

SET

MON

4

PROGRAMMING PROCEDURES:

NOTE: The manufacturer has preset the unit so that the gallons between regenerations will be

automatically calculated after the hardness is entered.

STEP 1 – Press NEXT and +simultaneously for 3 seconds.

STEP 2 – HARDNESS: Set the amount of hardness in grains per gallon (default 20) using

the +or —buttons. The allowable range is from 1 to 150 in 1 grain increments.

Note: If a resin media is used in the softener, increase the grains per gallon if soluble

iron is present (1ppm = 4 gpg). This display will show “–nA– (not available)”

if “FILTER” is selected or if “AUTO” is not factory set.

Press NEXT to go to step 3. Press REGEN if you want to exit.

STEP 3 – DAYS BETWEEN REGENERATION (DAY OVERRIDE): The manufacturer has factory

set 6 DAYS as the default. This is the maximum number of days between regenerations. If

this is set to “OFF”, regeneration initiation is based solely on gallons used. If any number

is set (allowable range from 1 to 28), a regeneration initiation will be called for on that

day even if a sufficient number of gallons were not used to call for a regeneration.

Set Day Override using +or —buttons (6 is recommended):

• set number of days between regeneration (1 to 28); or

• set to “OFF”

NOTE: This valve has the capability of regenerating up to six times in

one day. This can be observed by using the —button to toggle below

once a day regeneration (see example to right). These settings are

typically used in twin system configurations or in commercial settings.

Press NEXT to go to step 4. Press REGEN if you need to return to the

previous step.

2. Programming:

Time of day should only need to be set after extended power outages or when daylight saving time begins

or ends. If an extended power outage occurs, the time of day will flash on and off indicating that the time

should be reset.

STEP 1 – Press SET CLOCK.

STEP 2 – CURRENT TIME (HOUR): Set the hour of the day using +or —buttons.

AM/PM toggles after 12. Press NEXT to go to step 3.

STEP 3 – CURRENT TIME (MINUTES): Set the minutes using +or —buttons. If it is desired to

back up to the previous step press REGEN button once. Press NEXT to go to step 4.

STEP 4 – CURRENT DAY: Set the day of the week using +or —buttons. Pressing NEXT will exit

SET CLOCK and return to the general operating display (page 10).

REGENS/DAY REGEN

SET

4 / DAY

Example: Indicates unit set

to regen 4 times in one day.

STEP 4 – REGENERATION HOUR: The manufacturer has factory set 2:00 A.M. as the default. This

is the hour of day for regeneration and can be reset by using +or —buttons. “AM/PM”

toggles after 12. The default time is 2:00 a.m. (recommended for a normal household).

Press NEXT to go to step 5. Press REGEN if you need to return to the previous step.

STEP 5 – REGENERATION MINUTES: Set the minutes using +or —buttons. Press NEXT to

go to step 6. Press REGEN to return to previous step. To initiate an immediate manual

regeneration, press and hold the REGEN button for three seconds. The system will begin

to regenerate immediately. The control may be manually stepped through the regeneration

cycles by pressing REGEN.

STEP 6 – ALARM BUZZER:The manufacturer has factory set ON as the default. Alarm will sound

immediately after regeneration if there is no salt or if another error has occurred. Turn the

alarm OFF or ON using +or —buttons. Press NEXT to exit installer programming.

REGEN TIME HOUR

SET

2:00

AM

REGEN TIME MINUTES

SET

2:00

AM

4

12

5

ALARM BUZZER

SET

ON

6

DAYS BETWEEN REGEN

SET

6

WATER HARDNESS

SET

20

GR

1 2 3

OPERATING DISPLAYS AND INSTRUCTIONS:

TIME OF DAY MON

GPM

2:408

PM

CAPACITY REMAINING

GPM GAL

1600

8

The user can scroll

between the displays

as desired.

8

1. GENERAL OPERATION: When the system is operating, one of four displays may be shown.

Pressing NEXT will alternate between the displays.

1. CURRENT TIME OF DAY and GPM

2. FLOW RATE which is the current treated water flow rate through the system in Gallons Per Minute

3. CAPACITY REMAINING which is the gallons that will be treated before the system signals a

regeneration cycle

4. DAYS TO A REGEN is the number of days left before the system goes through a regeneration

cycle, based on the days override value

34

9

If the system has called for a regeneration that will occur at the preset time of regeneration,

the words “REGEN TODAY” will appear on the display.

If a water meter is installed, “GPM” flashes on the display when water is being treated,

indicating gallons per minute going through the system.

2. REGENERATION MODE: Typically a system is set to regenerate

at a time of no water usage. If there is a demand for water when

the system is regenerating, untreated water will be delivered.

When the system begins to regenerate, the display will change to

include information about the step of the regeneration process and

the time remaining for that step to be completed. The system runs

through the steps automatically and will reset itself to provide

treated water when the regeneration has been completed.

3. MANUAL REGENERATION: Sometimes there is a need to

regenerate before the control valve calls for it. This may be

needed if a period of heavy water use is anticipated or when

the system has been operated without salt.

• To initiate a manual regeneration at the next preset

regeneration time, press and release REGEN. The words

“REGEN TODAY” will flash on the display to indicate

that the system will regenerate at the next regeneration

time (set in Programming, steps 4 and 5). If you pressed

the REGEN button in error, pressing the button again will

cancel the command.

• To initiate a manual regeneration immediately, press and

hold the REGEN button for three seconds. The system will

begin to regenerate immediately. This command

cannot be cancelled.

Once a manual regeneration is initiated, the unit will go into the FILL position. This position allows water

to enter the brine tank until it reaches the proper level. Once this position is complete, you will notice a

240 Minute (4 hours) SOFTENING position. This 4-hour window allows the salt to dissolve and achieve

proper brine strength. During these FILL and SOFTENING positions, you will have softened water

available for use. Once the unit advances to the BACKWASH position and subsequent positions

thereafter (see Start Up Instructions for regeneration sequence), the water softener will deliver water,

but it will be untreated.

IMPORTANT: With the Dry Salt Storage Feature, the brine tank will refill 4 hours before the actual

regeneration occurs. You may experience a small amount of noise for a short period of time at 10:00

p.m. (with typical setting) on the night that regeneration is to occur. This noise is only the brine tank

filling and at no time during this process will you be without treated water.

BACKWASH

8:22

REGENERATION MODE

MANUAL REGENERATION

REGEN TODAY MON

GPM

2:408

PM

REGEN TODAY and TIME OF DAY

will flash alternately if a regeneration

is expected tonight.

FLOW RATE

GPM

8.0

DAYS TO A REGEN

GPM

3

8

10

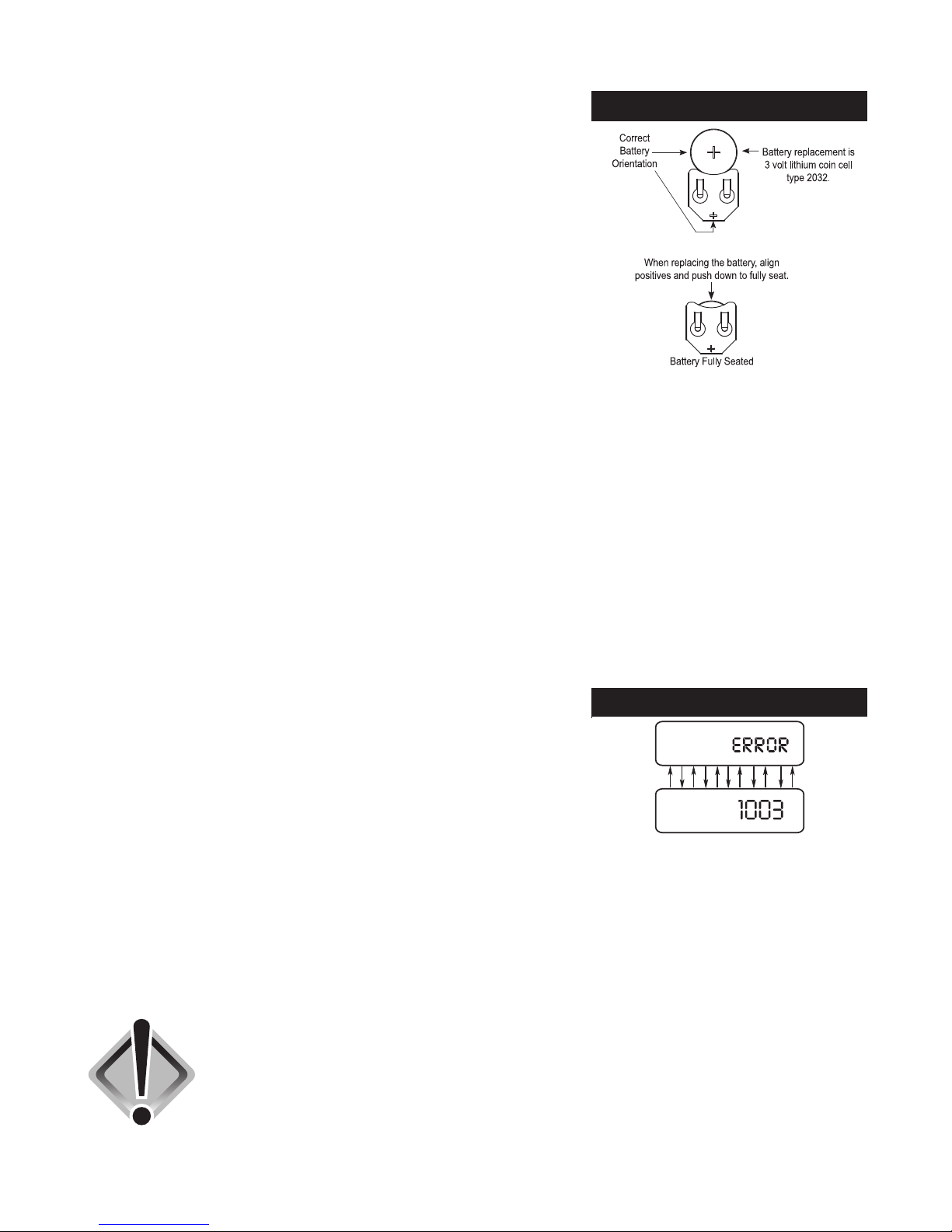

4. POWER LOSS AND BATTERY REPLACEMENT:

The AC transformer comes with a 15 foot power cord and is

designed for use with the control valve; the transformer should

only be used in a dry location.

In the event of a power outage, the control valve will remember

all settings and time of day. If an extended power outage occurs,

the control valve will keep time of day until the battery is depleted.

When the battery becomes depleted, the only item that needs to

be reset is the time of day and will be indicated by the time of

day flashing. All other settings are permanently stored in the

nonvolatile memory.

If a power loss occurs and the time of day flashes, this indicates that

the battery is depleted. The time of day should be reset and the non-

rechargeable battery should be replaced. The battery is a 3 Volt

Lithium Coin Cell type 2032 and is readily available at most stores.

To access battery location, remove front cover (see diagram on

page 14 for battery location).

5. CHECK SALT INDICATOR AND AUDIBLE ALARM: This control valve is equipped with a Low Salt

Warning to alert homeowners that the system is operating in a low salt condition. This usually indicates

that the salt level in the brine tank is too low to operate properly. If “CHECK SALT” appears on the screen,

there will usually be an audible alarm that sounds also (if turned on), alerting you to these conditions.

To turn off alarm: If the audible alarm sounds due to a low salt condition, press any button on the

face of the control valve to turn off. If salt is not added to the brine tank before the next regeneration, the

CHECK SALT indicator will alarm again.

IMPORTANT: If you feel that the salt level is adequate (at least 1/3 full) in the brine tank, please contact

the dealer that installed your system for service.

6. ERROR MESSAGE: If the word “ERROR” and a number are

alternately flashing on the display record the number and contact

your dealer for help. This indicates that the control valve was not

able to function properly.

6. BRINE TANK MAINTENANCE AND SALT: Refill the brine tank

as necessary, making sure at least 1/3 of the brine tank is full at all

times. Without proper salt levels, the water softener may not

operate properly.

Because “typical” settings of this water softener include a dry salt storage feature (no water in brine tank

between regeneration), the manufacturer recommends the use of solar salt for best results. The brine tank

is manufactured for the use of solar, pellets or rock salt. Do not use block salt. If pellet or rock salt is

used, a cleaning of the brine tank every six months is recommended. If the dry salt storage feature is not

being utilized, block salt may be used.

CAUTION: Do not use any resin cleaners, nor place any resin cleaners

into the brine tank. Furthermore, do not use any salt that

indicates it is an iron cleaning salt or that contains any

cleaning additives. This may be harmful to the water softener

and for human consumption. Consult dealer for proper

cleaning instructions.

ERROR

BATTERY REPLACEMENT

11

• After installation is complete, rotate bypass handles to bypass mode (see Fig.2 on page 4).

• Turn on water and check for leaks.

• Fully open a cold water faucet — preferably a laundry sink or bathtub without an aerator.

• Allow water to run until clear to rid pipes of debris which may have occurred during installation.

System regeneration sequence is in the following order. (If it is desired to change this sequence, please

refer to the Dealer Manual or contact the manufacturer.)

1) BRINE TANK REFILL

2) 4 HOURS (240 minutes) OF SOFTENING MODE WHILE SALT IS DISSOLVING

3) BACKWASH

4) BRINE DRAW AND SLOW RINSE

5) FAST RINSE

6) END (return to service)

The system is now ready for filling with water and for testing.

1. With the softener in the bypass mode (Fig. 2 on page 4) and the control valve in normal operation

where the display shows either the time of day or the gallons remaining, manually add 3" of water to

the regenerant tank.

NOTE: If too much water is put into the brine tank during softener start up, it could result in a

“salty water” complaint after the first regeneration.

During the first regeneration the unit will draw out the initial volume of brine/regenerant and refill it

with the correct preset amount.

2. Press and hold the REGEN button until the motor starts. Release button. The display reads “FILL” and the

remaining time in this step is counting down. Check to verify that the regenerant tank is filling at a rate

of 1/2 gallon per minute. Since the regenerant tank was already filled in Step 1 press REGEN again

and the display will read SOFTENING 240 (During a full regeneration this will be a 4 hour period for

salt to dissolve). Press REGEN again to put the valve into “BACKWASH.” Unplug the transformer so that

the valve will not cycle to the next position. Open the inlet handle of the bypass valve very slightly

allowing water to fill the tank slowly in order to expel air.

CAUTION: If water flows too rapidly, there will be a loss of

media to the drain.

3. When the water is flowing steadily to the drain without the presence of air, slowly open the inlet valve.

Restore power and momentarily press the REGEN button to advance the control to the “BRINE” position.

4. The bypass is now in the diagnostic mode (Fig. 3 on page 4). Check to verify that water is being

drawn from regenerant tank with no air leaks or bubbles in the brine line. There should be a slow flow

to the drain.

5. Momentarily press REGEN again until the display reads “RINSE.” There should be a rapid flow to the

drain. Unplug transformer to keep the valve in the “RINSE” position. Allow to run until steady, clear and

without air. While the unit is rinsing load the brine tank with water softener salt. Restore power.

6. Place bypass valve in the normal operating mode (Fig. 1 on page 4) by opening the outlet bypass

handle. Press REGEN and the unit will return to the service position with time of day being displayed.

START-UP INSTRUCTIONS:

12

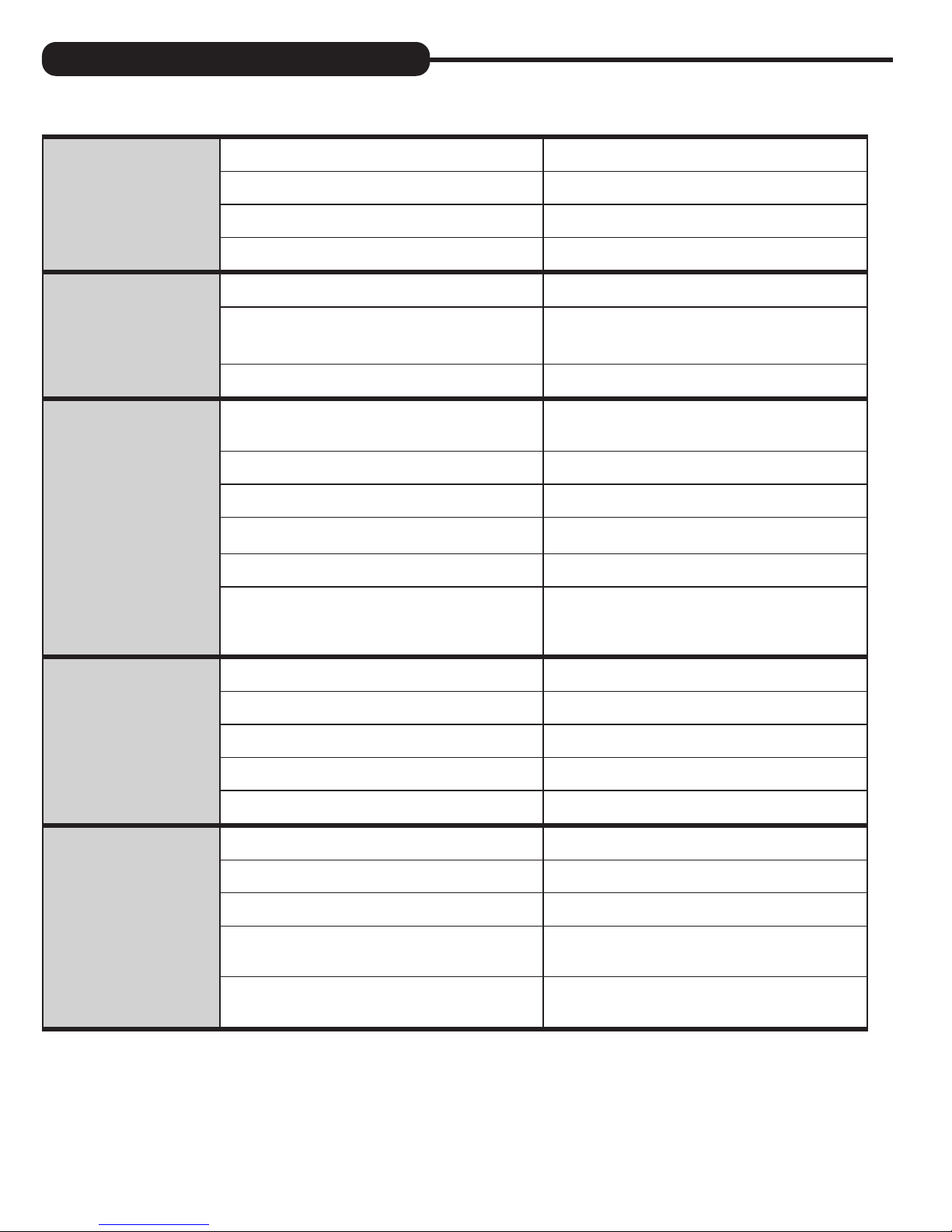

Timer does

not display

time of day

A. transformer unplugged A. reconnect transformer

B. no power at outlet B. repair or use working outlet

C. defective transformer C. replace transformer

D. defective PC board D. replace PC board

Timer does not

display correct

time of day or

time of day

flashes

A. outlet is on a switch A. use unswitched outlet

B. power outage; transformer was unplugged

from either wall outlet or from PC board

B. reset time of day and replace battery

(see instructions on page 10)

C. defective PC board C. replace PC board

“Check Salt”

appears on

screen with

audible alarm

A. low salt in brine tank A. push any button on cover to stop alarm

and add salt to brine tank

B. plugged injector and/or injector screen B. clean or replace injector and screen

C. drain line plugged or restricted C. clear drain line restriction

D. chlorine generator probes are dirty D. clean or replace chlorine generator

E. system drawing in air E. tighten fittings in brine system

F. system “short brining”

F. clean brine line flow control, check for

bridging or hardened salt around brine

well, increase brine refill time

No softening/

filtering display

when water is

flowing

A. bypass valve in bypass position A. put bypass in service position

B. meter cable disconnected B. reconnect PC board

C. restricted/stalled meter turbine C. remove meter and check for debris

D. defective meter D. replace meter

E. defective PC board E. replace PC board

Unit regenerates

at wrong time

of day

A. past power outage A. reset time of day

B. incorrect time of day displayed B. reset time of day

C. time of regenerant set incorrectly C. reset time of regeneration

D. control set at “on 0” D. check with regeneration time option in

programming

E. control set at “NORMAL + on 0” E. check with regeneration time option in

programming

TROUBLESHOOTING GUIDE:

PROBLEM CAUSE CORRECTION

Valve stalled in

regeneration

A. motor not operating A. replace motors

B. no power at outlet B. repair outlet or use working outlet

C. defective transformer C. replace transformer

D. defective PC board D. replace PC board

E. broken drive gear or drive cap assembly E. replace gear or drive cap assembly

F. broken piston retainer F. replace drive cap assembly

G. broken main or regenerant piston G. replace main or regenerant piston

Valve does

not regenerate

automatically

when REGEN

button is pressed

A. transformer unplugged A. connect transformer and PC board power

B. no power at outlet B. restore power

C. broken drive gear or drive cap assembly C. replace gear or drive cap assembly

D. defective PC board D. replace board

Valve does

not regenerate

automatically

but does when

REGEN button is

pressed

A. bypass valve not in normal operating mode A. see bypass diagrams on page 4

B. meter disconnected B. reconnect to PC board

C. obstructed meter turbine C. clear obstruction

D. defective meter D. replace meter

E. programming error E. review programming

F. defective PC board F. replace board

“Error” followed

by code #

“Error” code 1001 —

unable to recognize

start of regeneration

“Error” code 1002 —

unexpected stall

“Error” code 1003 —

motor ran too long

Timed out trying

to reach next cycle

position

If other codes

appear, contact

factory

A. valve has just been serviced

A. press NEXT and REGEN for 3 seconds or

momentarily unplug power source from

PC board

B. foreign material stuck in valve B. check piston and spacer stack for

obstruction

C. excessive piston resistance C. replace piston(s) and spacer stack assembly

D. piston not in home position D. press NEXT and REGEN or momentarily

unplug PC board power

E. motor gears not fully engaged — motor

wires broken — failed motor E. check motor wiring

F. center drive gear reflector dirty or

damaged — missing or broken gear F. replace or clean drive gear(s)

G. drive bracket incorrectly aligned on

backplate G. reset drive bracket

H. PC board is damaged or defective H. replace PC board

I. PC board incorrectly aligned on drive bracket I. reset PC board onto drive bracket

13

PROBLEM CAUSE CORRECTION

14

REPLACEMENT PARTS:

2

7

1

3

5

4

6

FRONT COVER AND DRIVE ASSEMBLY

Item No. Part No. Description Qty.

1CV3540S-A Black cover 1

CV3540-WS-A Gray cover 1

2CV3107-1 Motor 1

3CV3106-1 Drive bracket & spring clip 1

4CV3554WS PC board, CC 1

5CV3110 Drive gear, 12 x 36 3

6CV3109 Drive gear cover 1

7CV3002CC Drive assembly, CC -

CV3526 Transformer, 110V-12V 1

CV3543 Optional weather cover 1

NOTE: Battery Location

15

6

8

10

11

7 9

7

12

4

2

3

5

1

13

14

NOTE:Not available on

1¼" valve.

REPLACEMENT PARTS:

PISTON ASSEMBLY

Item No. Part No. Description Qty.

1CV3005 1" spacer stack assembly 1

CV3430 1.25" spacer stack assembly 1

2CV3004 Drive cap assembly 1

3CV3135 O-ring 228 1

4

CV3011 1" piston assembly downflow 1

CV3011-01 1" piston assembly upflow 1

CV3407 1.25" piston assembly downflow 1

5CV3174 Regenerant piston 1

6CV3180 O-ring 337 1

7CV3105 O-ring 215 1

8CV3556 Screw, 1/4-20x1-1/2 18-8SS 1

9CCI-00318337 Nut, 1/4 -20 HEX 18-8SS 1

10 CV3016 QC2 clamp assembly (includes screw & nut) 1

11 CV3452 O-ring 230 1

12 CV3015 WS1 QC2 tank adapter assembly (includes O-rings) 1

13

CV3001 1" body assembly downflow 1

CV3001UP 1" body assembly upflow 1

CV3020 1.25" body assembly downflow 1

14 CV3541 Drive backplate 1

16

REPLACEMENT PARTS:

BYPASS VALVE

Item No. Part No. Description Qty.

1CV3151 Nut, 1" quick connect 2

2CV3150 Split ring 2

3CV3105 O-ring 215 2

4CV3145 Bypass rotor, 1" 2

5CV3146 Bypass cap 2

6CV3147 Bypass handle 2

7CV3148 Bypass rotor seal retainer 2

8CV3152 O-ring 135 2

9CV3155 O-ring 112 2

10 CV3156 O-ring 214 2

17

INJECTOR ASSEMBLIES

Item No. Part No. Description Qty.

1CV3176 Injector cap 1

2CV3152 O-ring 135 1

3CV3177 Injector screen 1

4CV3010-1Z Injector assembly plug 1

5

CV3010-1A A injector assembly, BLACK

1

CV3010-1B B injector assembly, BROWN

CV3010-1C C injector assembly, VIOLET

CV3010-1D D injector assembly, RED

CV3010-1E E injector assembly, WHITE

CV3010-1F Finjector assembly, BLUE

CV3010-1G Ginjector assembly, YELLOW

CV3010-1H H injector assembly, GREEN

CV3010-1I Iinjector assembly, ORANGE

CV3010-1J Jinjector assembly, LIGHT BLUE

CV3010-1K Kinjector assembly, LIGHT GREEN

not shown CV3170 O-ring 011, lower *

not shown CV3171 O-ring 013, lower *

* The injector plug and the injector each use one lower and one upper o-ring

REPLACEMENT PARTS:

1

2

3

6

4

5

CHLORINE GENERATOR ASSEMBLY

Item No. Part No. Description Qty.

1JCP-P-6 Polytube 3/8

" insert

1

2JCPG-6PBLK Nut compression, 3/8" black 1

3CV3395 Chlorinator, NPT WR body assembly 1

4CV3163 O-ring 019 1

5CH4615 Locking clip 1

6CV3195-01 Refill port plug assembly 1

ASSEMBLIES

CV3395-A Complete chlorinator assembly 1

DRAIN LINE ASSEMBLY 3/4"

Item No. Part No. Description Qty.

1CH4615 Elbow locking clip 1

2CPKP10TS8-BULK Optional insert, 5/8" tube 1

3CV3192 Optional nut, 3/4" drain elbow 1

4CV3158-01 Drain elbow, 3/4" NPT with O-ring 1

5CV3163 O-ring 019 1

6CV3159-01 DLFC retainer assembly 1

7

CV3162-007 0.7 DLFC for 3/4" elbow

1

CV3162-010 1.0 DLFC for 3/4" elbow

CV3162-013 1.3 DLFC for 3/4" elbow

CV3162-017 1.7 DLFC for 3/4" elbow

CV3162-022 2.2 DLFC for 3/4" elbow

CV3162-027 2.7 DLFC for 3/4" elbow

CV3162-032 3.2 DLFC for 3/4" elbow

CV3162-042 4.2 DLFC for 3/4" elbow

CV3162-053 5.3 DLFC for 3/4" elbow

8CV3331 Drain elbow and retainer assembly

Items 2 and 3, nut and insert are only used with 1/2" I.D.

by 5/8" O.D. polytubing. For other piping material, the

3/4" NPT is used.

Proper DLFC orientation

directs water flow towards

the washer face with

rounded edge and lettering.

Water

Flow

3/4" NPT

18

REPLACEMENT PARTS:

19

WATER METER & METER PLUG

Item No. Part No. Description Qty.

1CV3151 Nut, 1" QC 1

2CV3003 Meter assembly, includes items 3 & 4 1

3CV3118-01 Turbine assembly 1

4CV3105 O-ring 215 1

5CV3003-01 Meter plug assembly 1

6CV3013 Optional mixing valve 1

REPLACEMENT PARTS:

20

REPLACEMENT PARTS:

2

3

4

5

6

7

8

10

1

9

11

BRINE TANK ASSEMBLY

Item No. Part No. Description Qty.

1CG2191-49 Brine tank cover, injection molded WR 1

CG2180 Brine tank cover, standard 1

2CH1072-01 Optional 18" diameter salt grid 1

CH1080 Optional 24" diameter salt grid 1

3

CG21833CB1C00 18" x 33" brine tank, black 1

CG21840CB1C00 18"

x 40" brine tank, black

1

CG22441CB1C00 24" x 41" brine tank, black 1

4CH1030-27 4" x 27" brine well (18 x 33 BT) 1

CH1030-34.5 4" x 34.5" brine well (18 x 40, 24 x 40 BT’s) 1

5CH1018 2 piece overflow set 1

6CH4500-48 474 air check assembly, 1/2" x 48" 1

7CH4640-32 474 float assembly, 32" w/ 2 grommets 1

8CH4600-50 474 safety brine valve w/ .5 gpm flow control 1

9CH7016 Cap 4" brine well 1

10 CH4626 Nut safety brine valve stand off 1

ASSEMBLIES

11 CH4700-27WR-1 .5 gpm safety float assembly, 18" x 33"

CH4700-34.5WR-1 .5 gpm safety float assembly, 18" x 40"

SAFETY FLOAT BRINE ELBOW

Item No. Part No. Description Qty.

1CH4655 474 .5 gpm flow control 1

2CV3163 O-Ring 019 1

3CH4613 3/8" elbow cap 1

CH4612 1/2" elbow cap 1

4CH4615 Elbow locking clip 1

5CJCPG-5PBLK 3/8" compression nut 1

CJCPG-8PBLK 1/2" compression nut 1

6FP10332 Poly tube insert 1

1

2

34

5

6

Other manuals for Sanitizer Plus Series

2

Table of contents

Other Water Right Water Filtration System manuals

Popular Water Filtration System manuals by other brands

MANN+HUMMEL

MANN+HUMMEL TRIDIM Tri-Lock BG Operation & maintenance manual

truu

truu home 2 2022 Customer's operating and assembly instructions

AMI

AMI Pure Plus Mineral RO HD-22PP Instruction handbook for installation, operation and maintenance

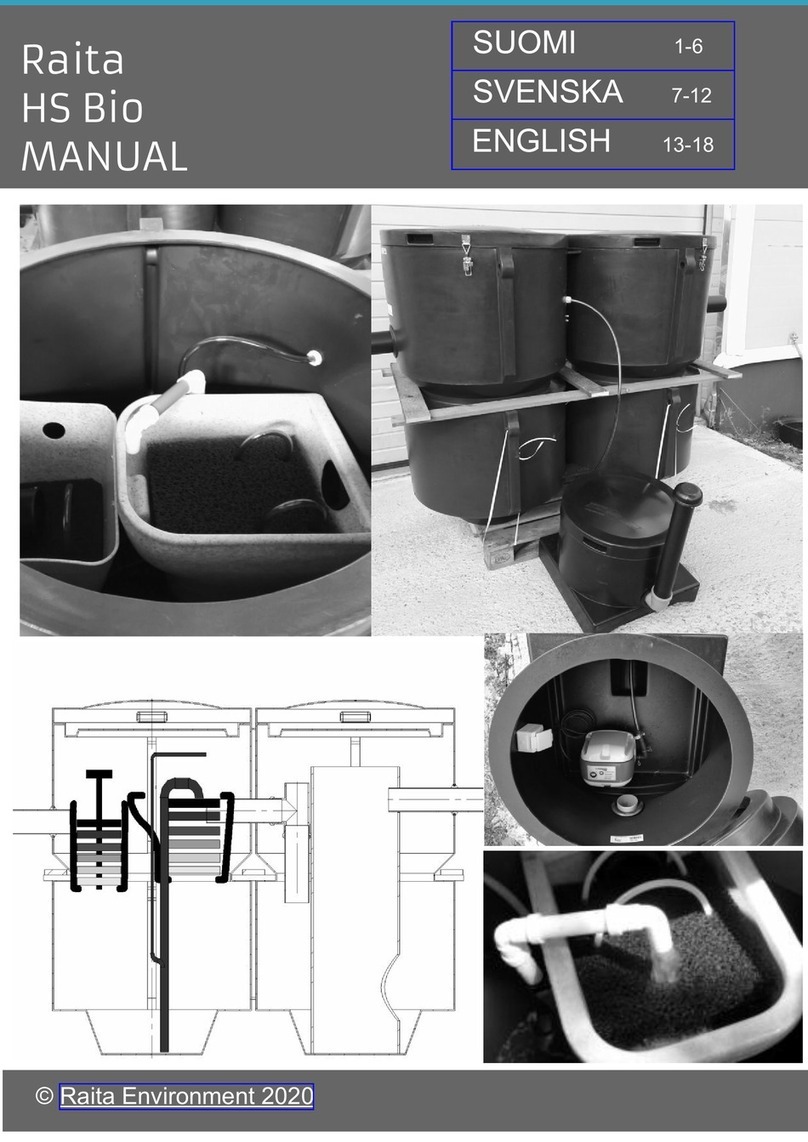

Raita

Raita HS Bio manual

purway Crystal Group

purway Crystal Group PUR QUICK 7 600 GPD user manual

Hydro Action

Hydro Action AP Series owner's manual