3

Process Description

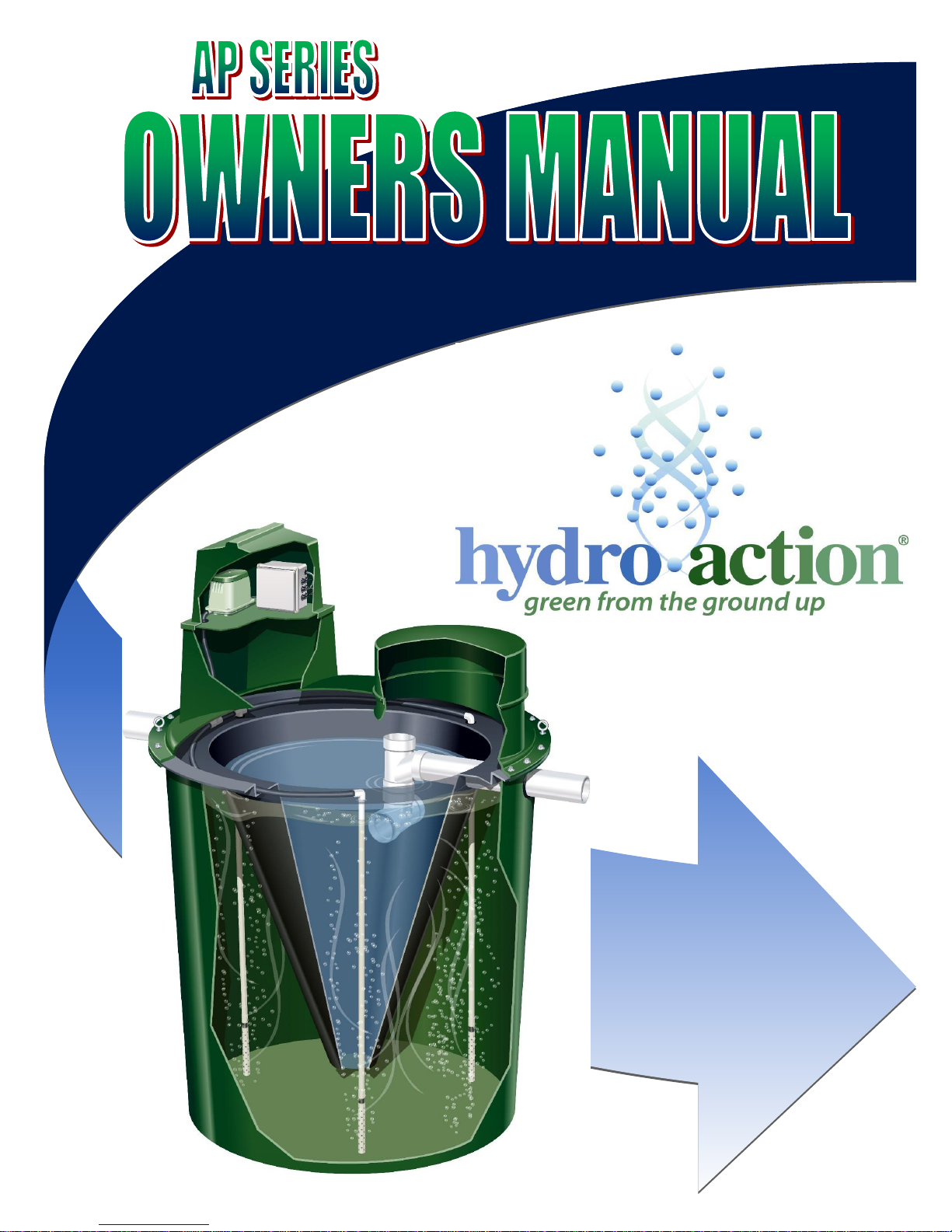

The Hydro-Action®AP Series individual

wastewater treatment plant is a self-

contained, extended aeration, aerobic

treatment facility utilizing the activated sludge

process. The plant consists of a cylindrically

shaped aeration tank with an offset service

access, a unique cone shaped clarification

compartment, and an outlet tee-assembly.

Two fine-bubble air diffuser assemblies with

ceramic stone diffusers and Hydro-Action® s’

efficient air pump are combined to provide

effective, efficient, and economical aeration.

Domestic wastewater enters the aeration

compartment and is mixed thoroughly with the

already present mixed liquor suspended

solids (MLSS) activated sludge. The injection

of air through the porous teflon air diffusers

placed near the bottom of the aeration

chamber is responsible for this complete

mixing. The fine bubble air diffusers and the

vortex area between diffuser assemblies

produce a generous quantity of dissolved

oxygen and ample mixing that maintain a

desirable aerobic environment even under

extreme conditions.

Hydraulic displacement causes the mixed

liquor to enter the clarification compartment

and move upward toward the outlet tee-

assembly. Due to the calm conditions in the

clarifier, suspended solids settle to the bottom

where they are remixed with the MLSS for

additional biological treatment. The remaining

clarified effluent leaves the plant via the outlet

tee-assembly and discharge line.

The AP Series ATUs are operated by the

OPS®. The OPS®integrates the electrical

controls, visible and audible alarms and air

pump in a protective polyethylene enclosure.

The OPS®can be either platform mounted on

the plant or remotely located. These features

plus; the offset access, air hose, and teflon

diffuser assemblies make the plant extremely

reliable and easy to service. An optional

visible and audible alarm may be added to

remotely locate to an area of your choice.

The technology used in the Hydro-Action®

plant allows it to produce excellent effluent

quality, which thereby meets all ANSI\NSF

International Standard 40 class I and the

Environmental Protection Agency’s

requirements of a secondary treatment

process. NSF requires that a Class I plant

shall be shown to meet EPA secondary

treatment guidelines for CBOD5, TSS, and

pH. The Hydro-Action®AP Series ATUs

satisfy all these requirements.

Operating Instructions

Your Hydro-Action®ATU has been designed

and built to provide efficient, dependable and

reliable service. However, as with any

individual wastewater treatment plant, routine

periodic service is required. When proper

preventive maintenance is performed, the

ATU will operate at designed performance

levels giving years of satisfactory treatment of

domestic wastewater.

The local dealer from whom you purchased

your Hydro-Action®plant will perform all

routine inspections for the first two (2) years

from the original date of installation. At the

time of inspection the plant will be checked for

proper operation. If a problem exists, service

will be performed at no charge to the owner if

the required maintenance is warranty related.

At the end of the two (2) year initial service

period, your local dealer will make available a

continuing service policy. This extended

service is available for a nominal fee.

The Hydro-Action®ATU’s electrical controls

are located within the OPS®of the plant. The

OPS®may be either remotely located or

platform mounted. The OPS®enclosure is

equipped with an alarm beacon and an

audible alarm. Also on the enclosure will be

the name, address and telephone number of

your local servicing dealer. It is this local

service provider you should contact regarding

any problems with your Hydro-Action®ATU.

An optional remote alarm with audible and

visible alarms may also be present. If the

alarm beacon or audible alarm sounds simply

switch the OPS®switch to silent and call the

service provider mentioned above. After a

power failure, if an alarm remains on for more

than 30 minutes you should call the local

dealer immediately.