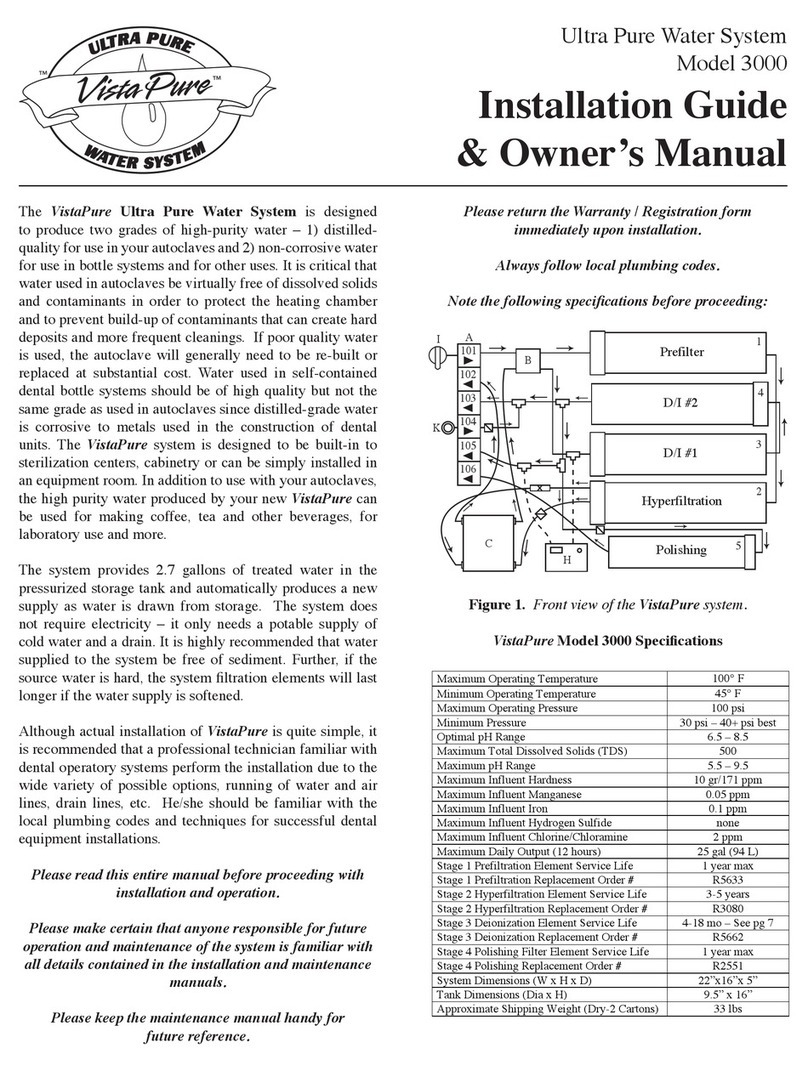

2

Button appearance and position may be different than actual valve

Cycle times, sequences, and settings in this guide are only examples of how your system may be programmed.

Actual settings are determined by the manufacturer. Please contact them if more information is needed.

Important button sequences to note:

1. UNLOCK VALVE SETTINGS: Press buttons in the following order: –, NEXT, +, CLOCK. This will allow a user to change

manufacturer’s settings. When nished, lock settings by inputting the same sequence.

2. CLEAR ERROR ON SCREEN: Press and hold NEXT and REGEN for three seconds.

3. CLEAR SERVICE ALARM: If service alarm is triggered, press and hold +and –buttons simultaneously for three

seconds to reset to original set points. This will reset both gallon and year alarms.

4. REGEN BUTTON: From a general operation screen, pressing the REGEN button schedules a regeneration for that

night. Pressing it again will cancel the regeneration for that night. On most screens besides the general operation

screens, the REGEN button works as a “back” button. Pressing it will return to the previous setting screen.

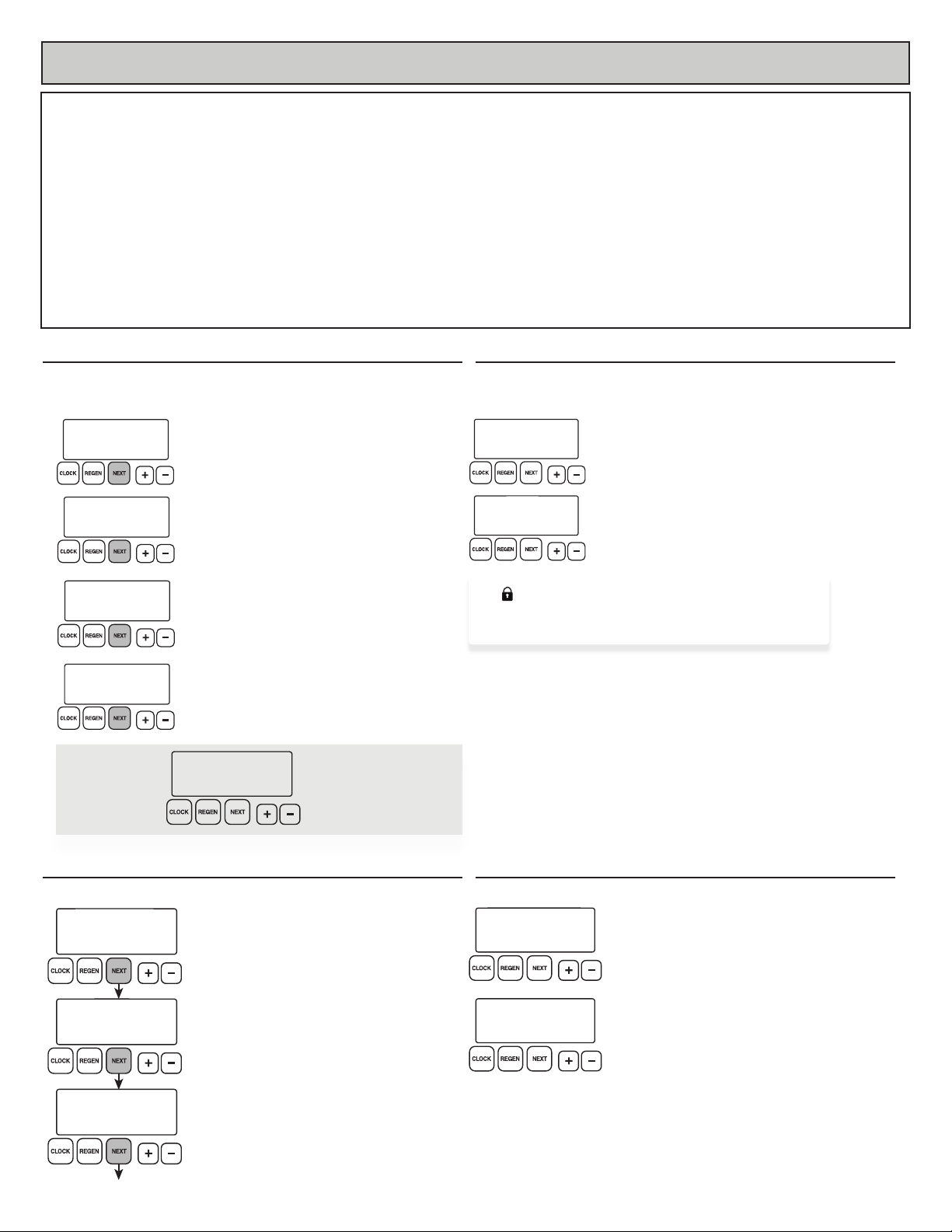

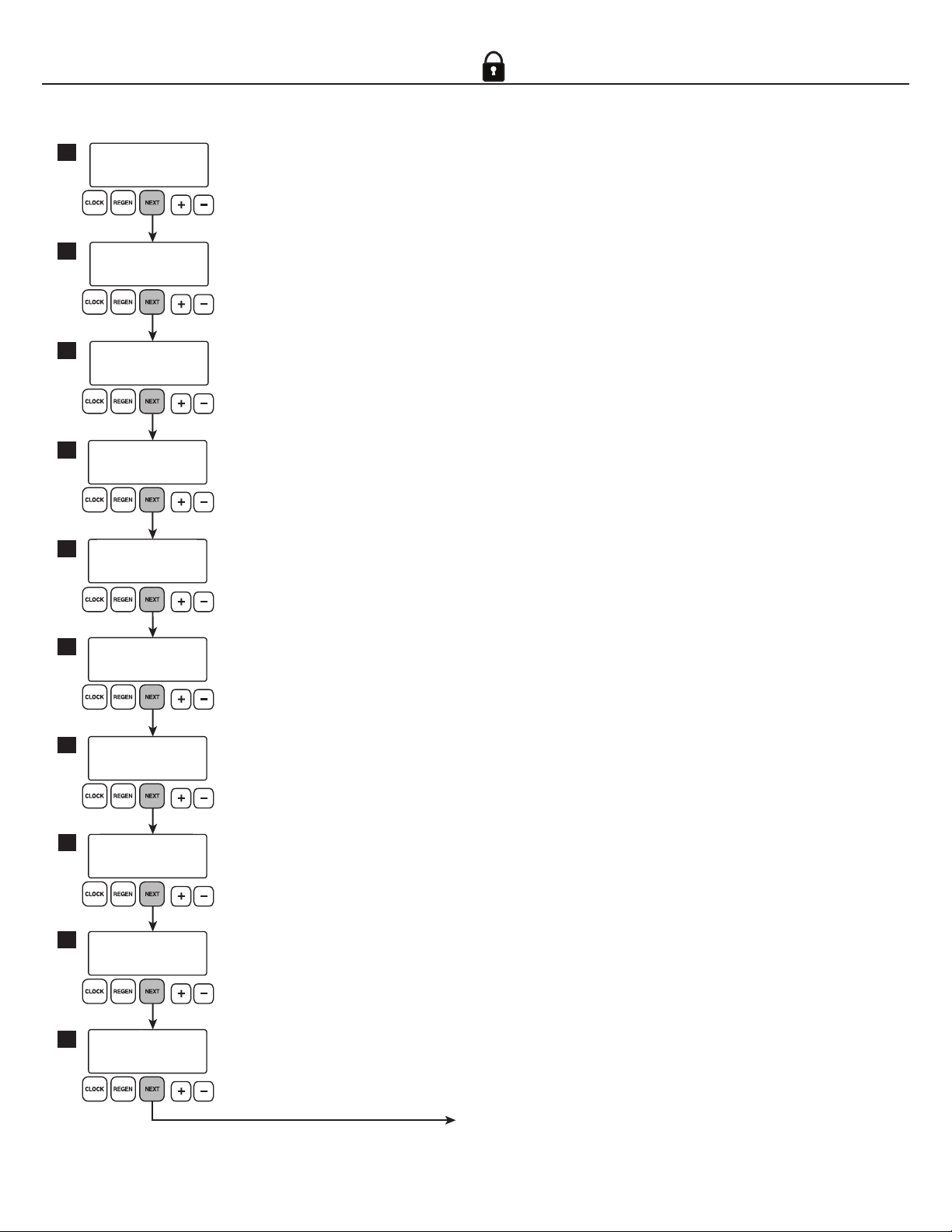

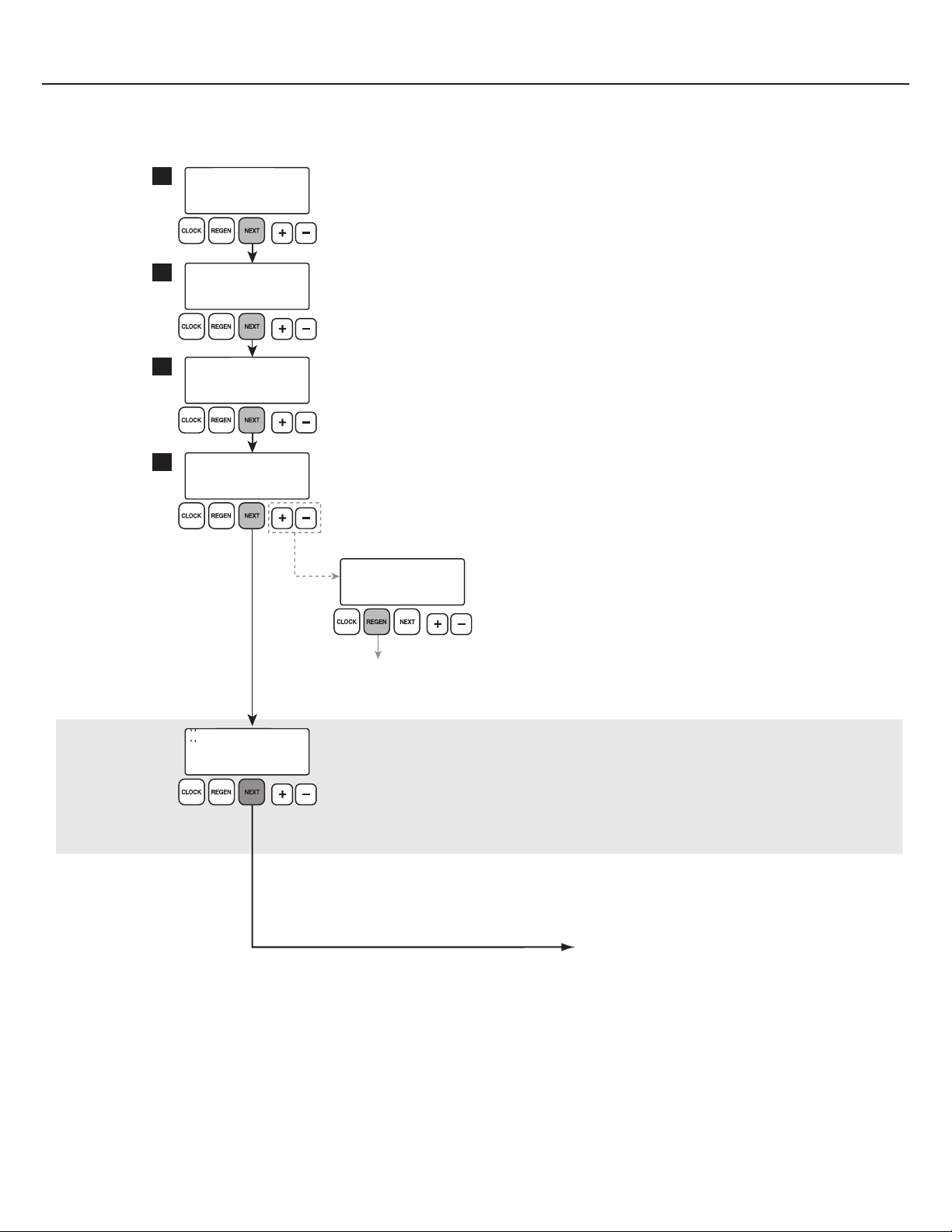

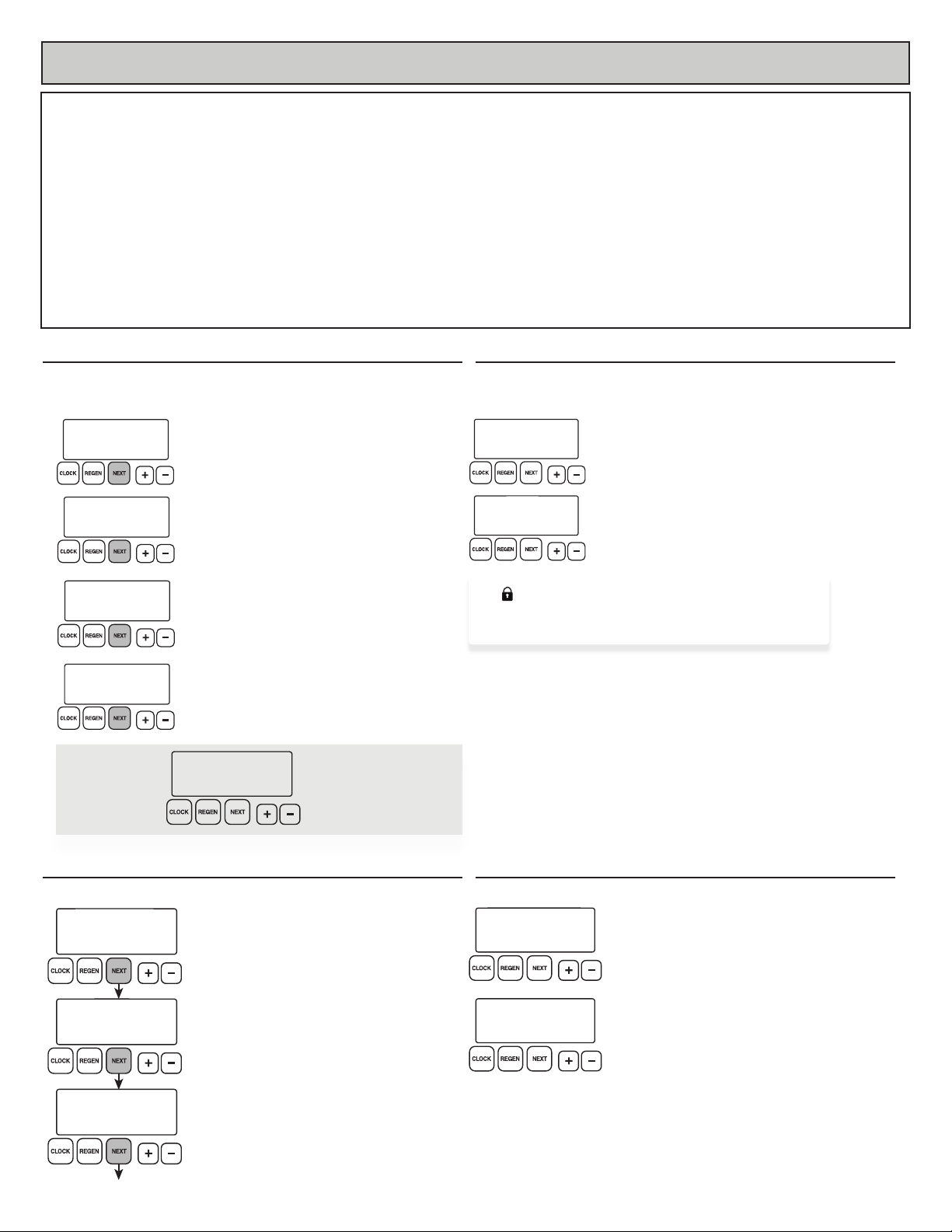

General Operation Screens

Press NEXT button to toggle between one of four displays.

Press REGEN button to schedule a regeneration for that night.

Return to general display

Displays current time

Unit defaults to this screen after a reset.

Displays a unit’s remaining capacity

This screen will not display if the unit’s gallons of

capacity is set to OFF. “REGEN TODAY” will alternate

with the current screen header if a regen is expected

that night.

Displays days remaining until a regen

This screen will not display if the unit’s day override

is set to o.

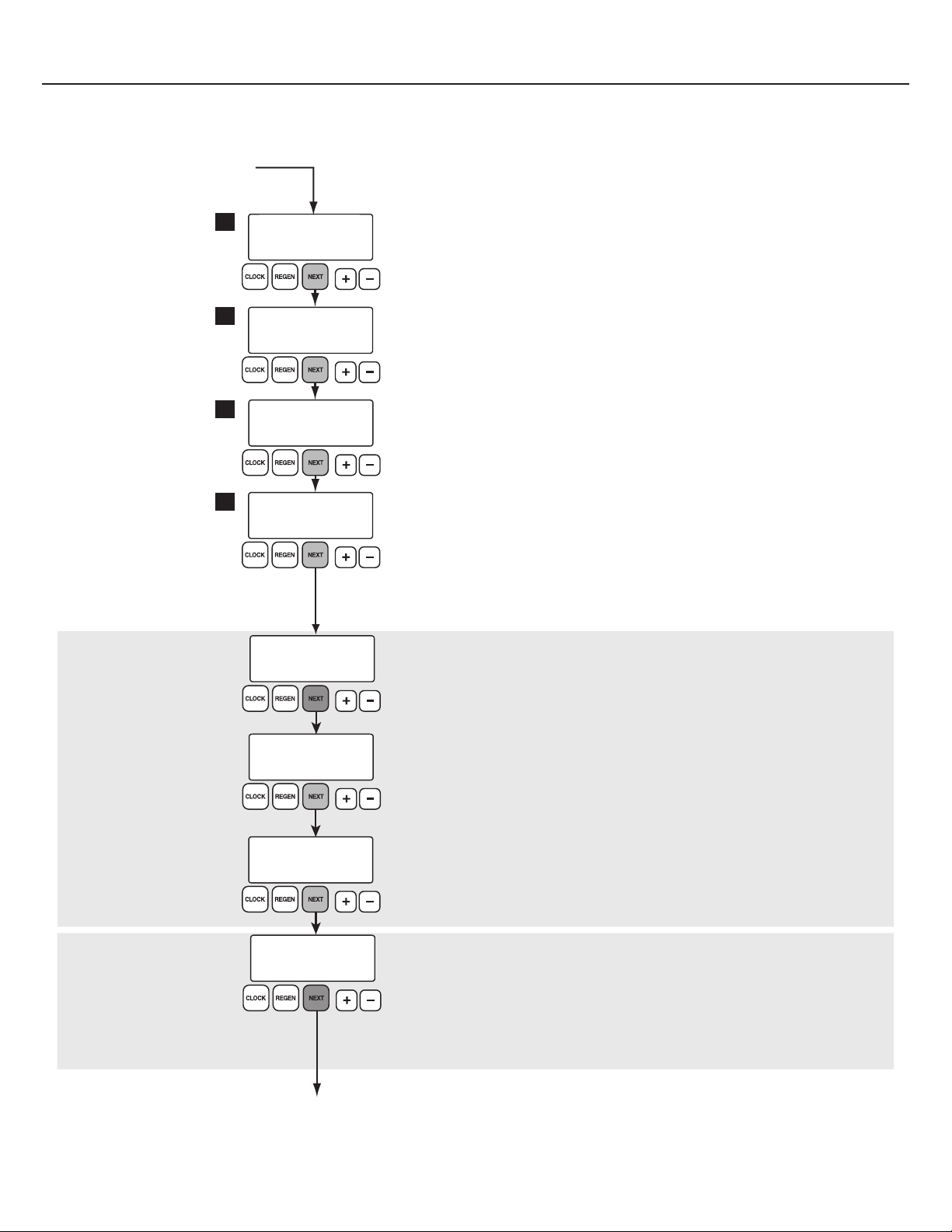

Set hours with + or — buttons

AM/PM toggles after 12 AM.

Displays time remaining in current regeneration cycle

“2” ashes for a second backwash if two backwashes are

programmed.

Displays time remaining incurrent cycle

If a chlorine generator is connected and set to ON, the

brine concentration will be checked during draw. Text will

alternate between DRAW TIME & GENERATOR ON.

Set minutes with + or — buttons

AM/PM toggles after 12 AM.

Set current day with + or — buttons

The default setting is WED.

Displays scrolling dealer

name and phone number

To change dealer name and

phone number, see page 3.

Displays current flow rate

“Current Flow Rate” is the amount of water currently

owing through, and being treated by, the unit. “GPM”

and the ow rate ash while the turbine is rotating.

555 5555555

DEALER NA

If set, a scrolling

dealer name and

phone number

screen will

alternate with the

selected general

operation screen.

CURRENT DAY

SET

WED

TIME MINUTES

SET

TIME HOUR

SET

2:00

2:35

AM

AM

MIN

BACKWASH REMAINING

2

3:30

GENERATOR ON

53:45

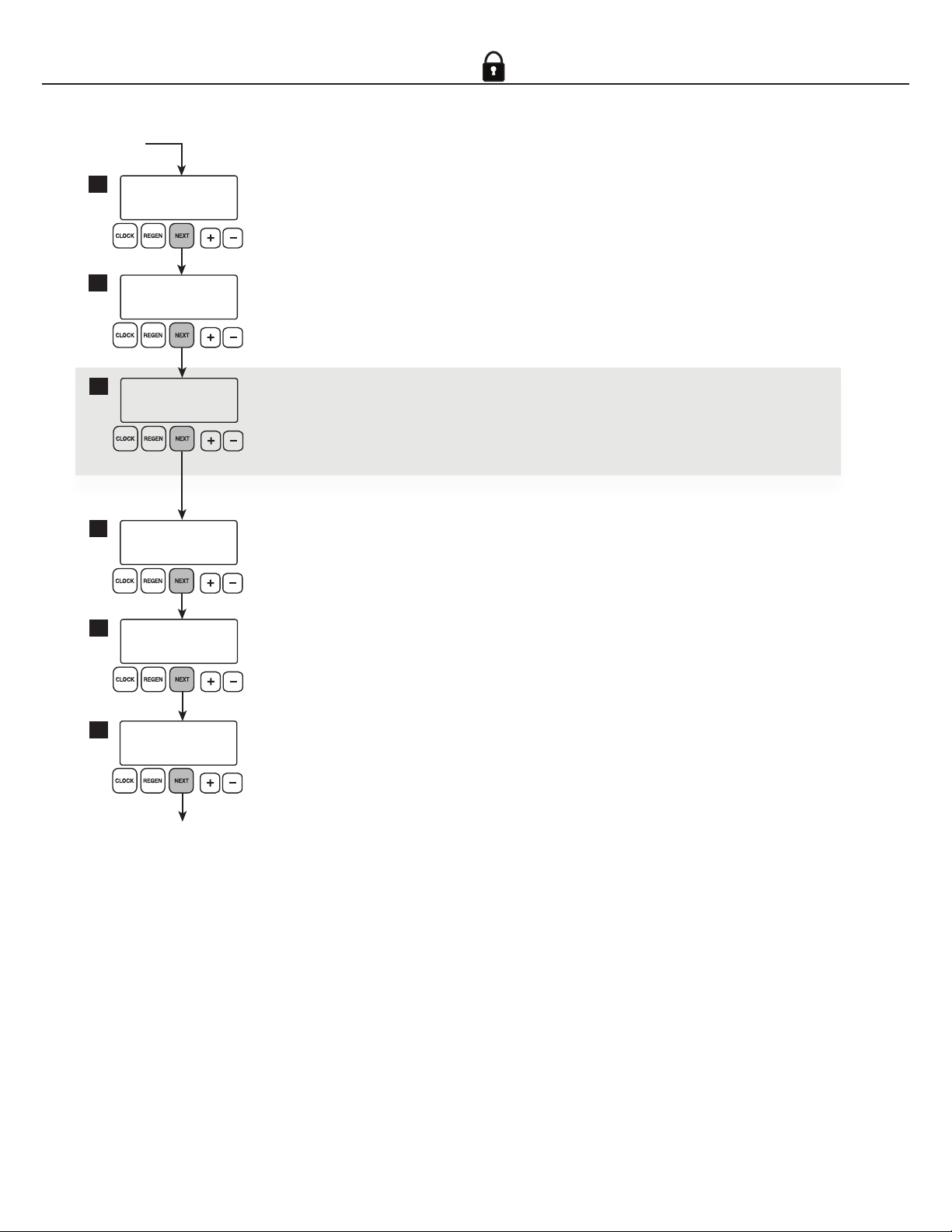

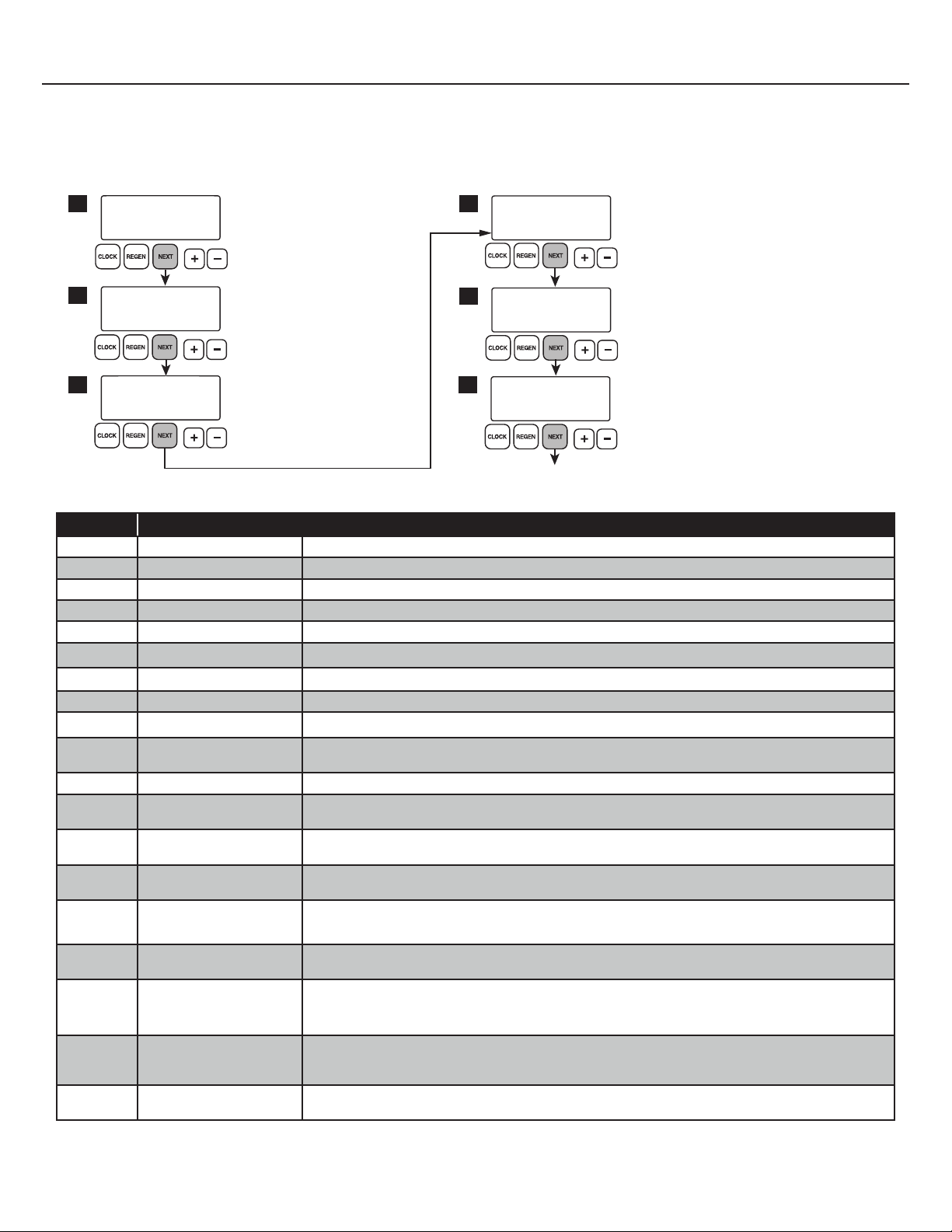

Unlock and Lock Controller

The following screens will flash when the correct button sequence is

inputted to unlock valve settings.

Indicates that the valve controller is unlocked

Unlocks access to advanced programming features

within the controller.

Indicates that the valve controller is locked

It is strongly advised to lock the controller following any

changes. This helps to prevent any accidental access to

advanced programming settings.

DAYS TO A REGEN

GPM

3

8

CAPACITY REMAINING

GPM GAL

1600

8

FLOW RATE

GPM

8.0

TIME OF DAY MON

GPM

2:408

PM

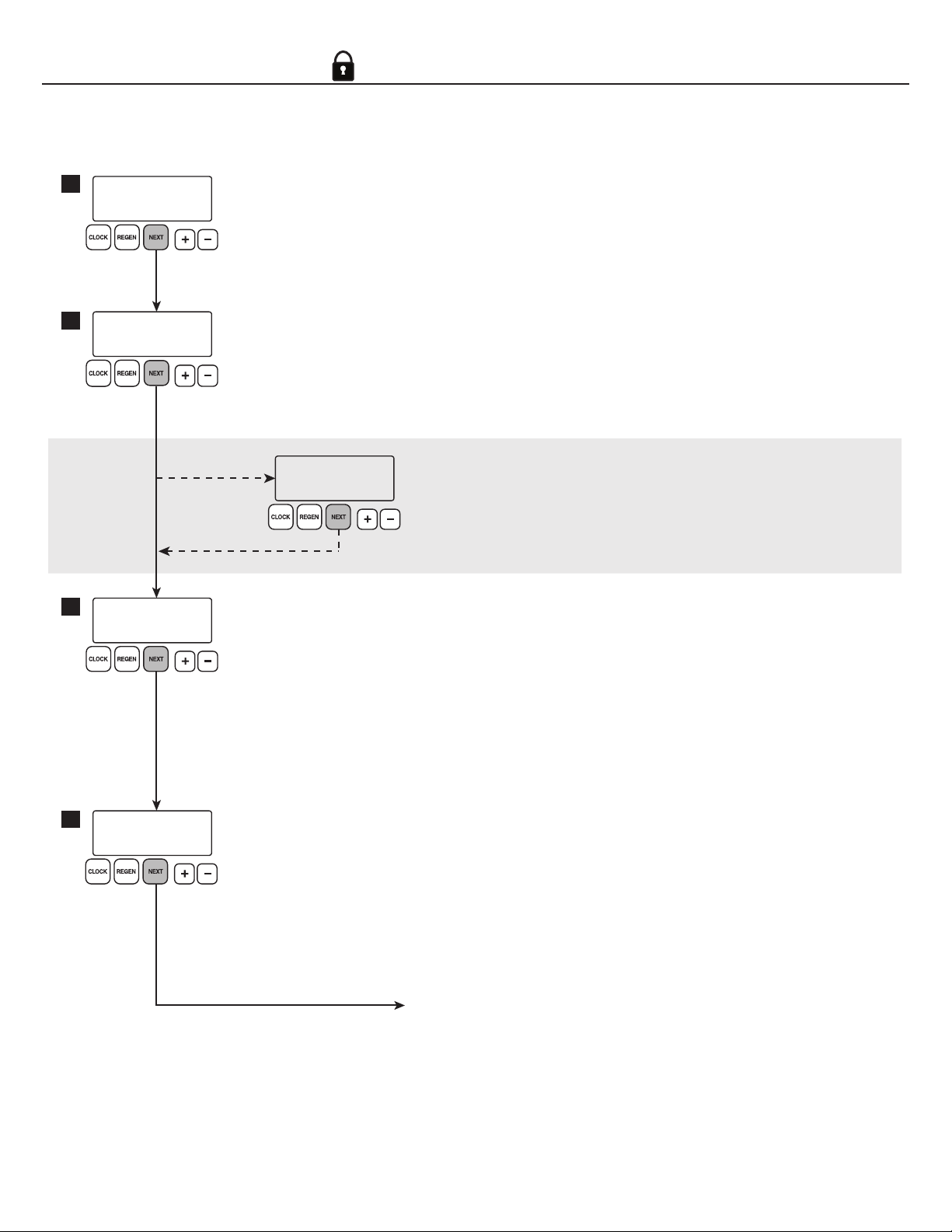

Set Time Screens Typical Regeneration Screens

Accessed by pressing the CLOCK button. Only visible when unit is in regeneration

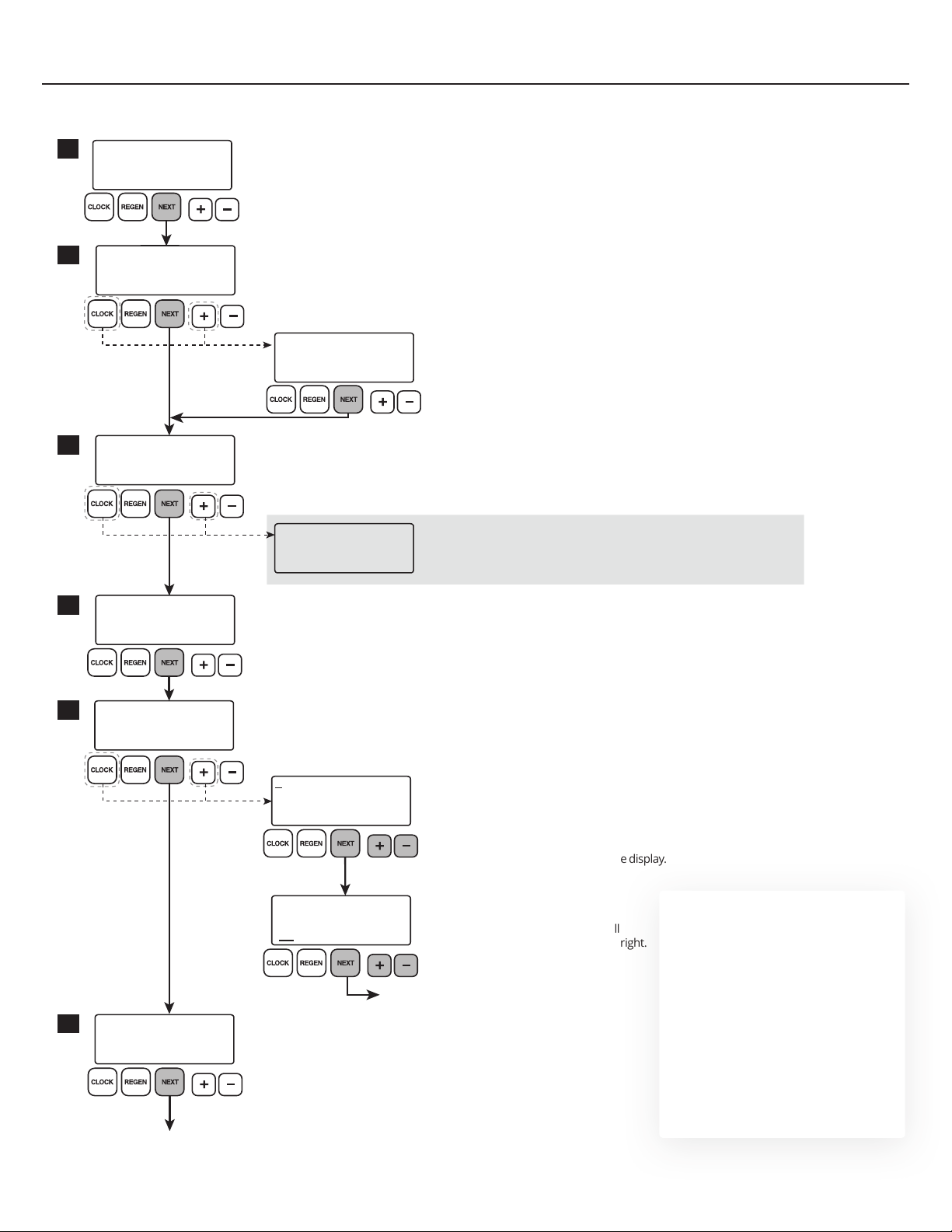

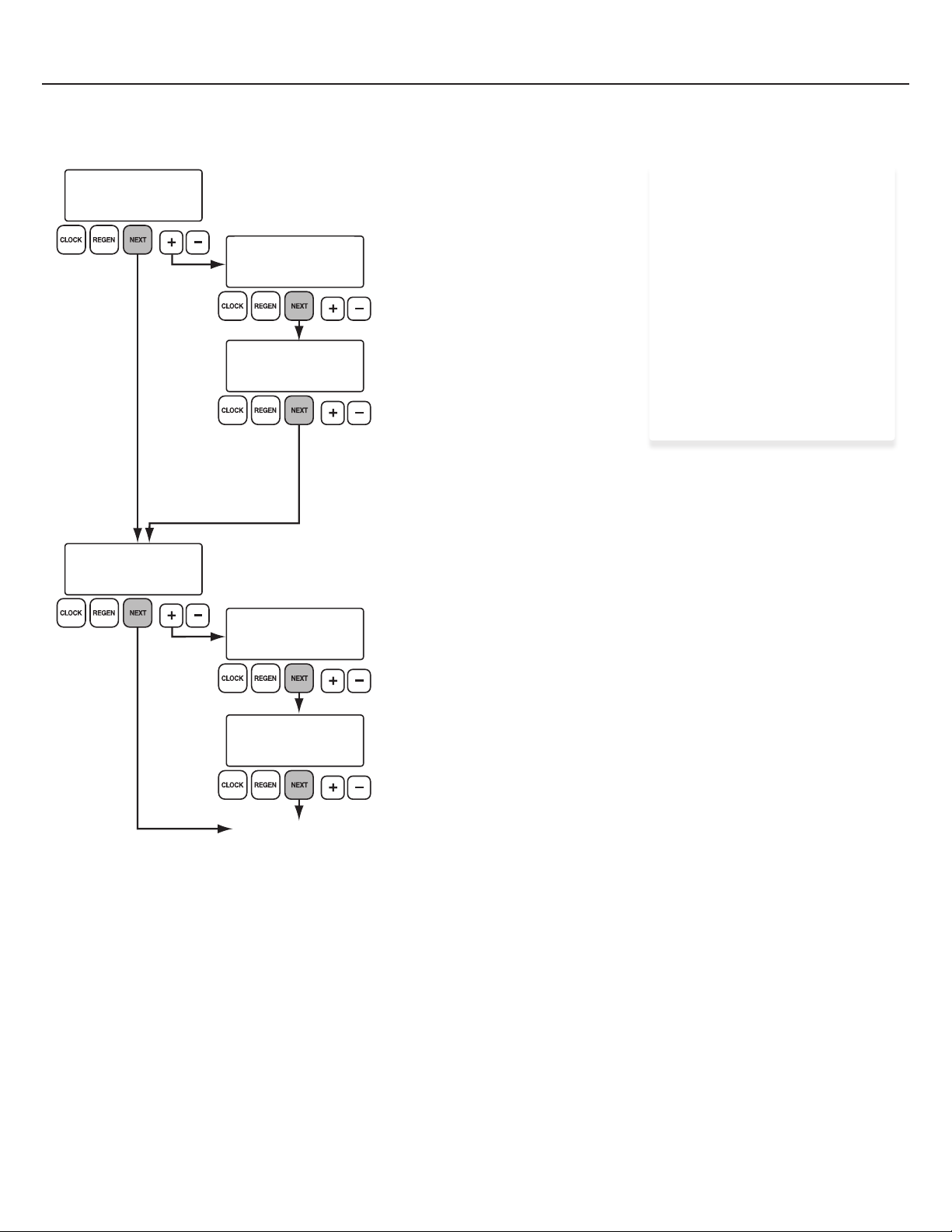

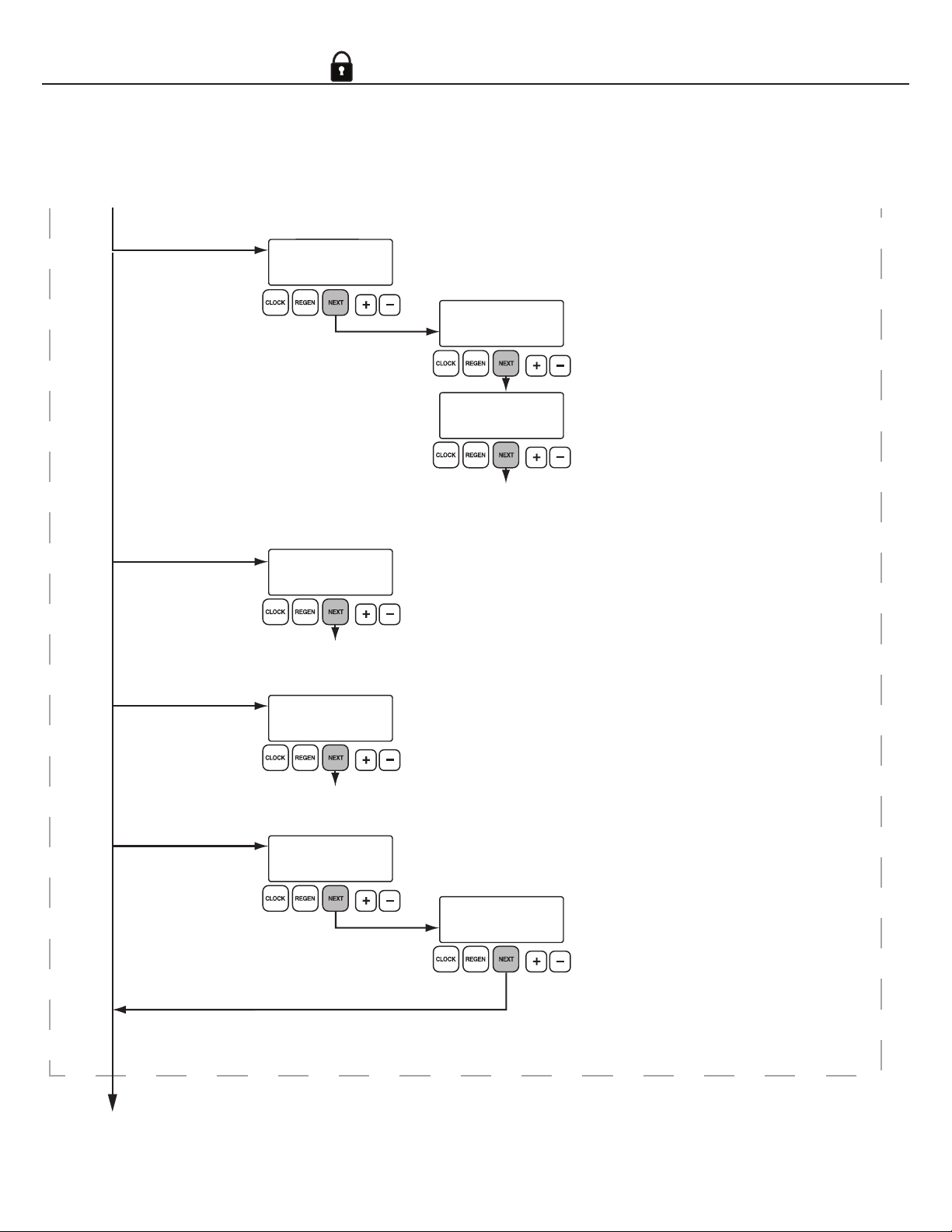

The symbol on the following pages indicates

that the screens below it will not display unless the

controller is unlocked.