DOCUMENT TITLE: 150-70 / 200-100 Installation

Table of Contents

SECTION 1. MODULE OVERVIEW ........................................................................................................5

SECTION 2. INSTALLING THE CAF SYSTEM.......................................................................................6

A. Fork Lifting a CAFS..........................................................................................................................6

B. Hold Down Tabs...............................................................................................................................6

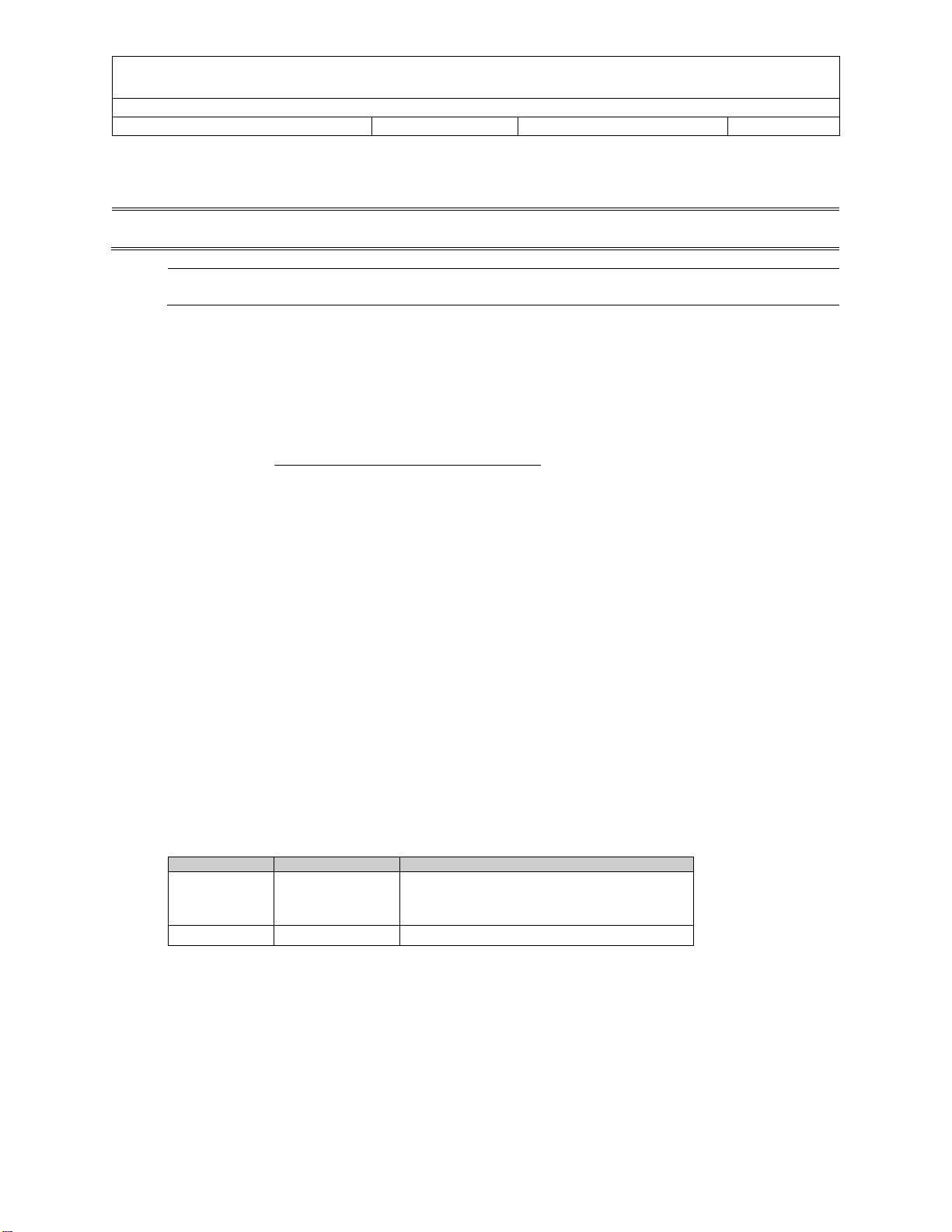

C. Engine Air Supply for Combustion and Cooling...............................................................................7

D. Battery Connections.........................................................................................................................7

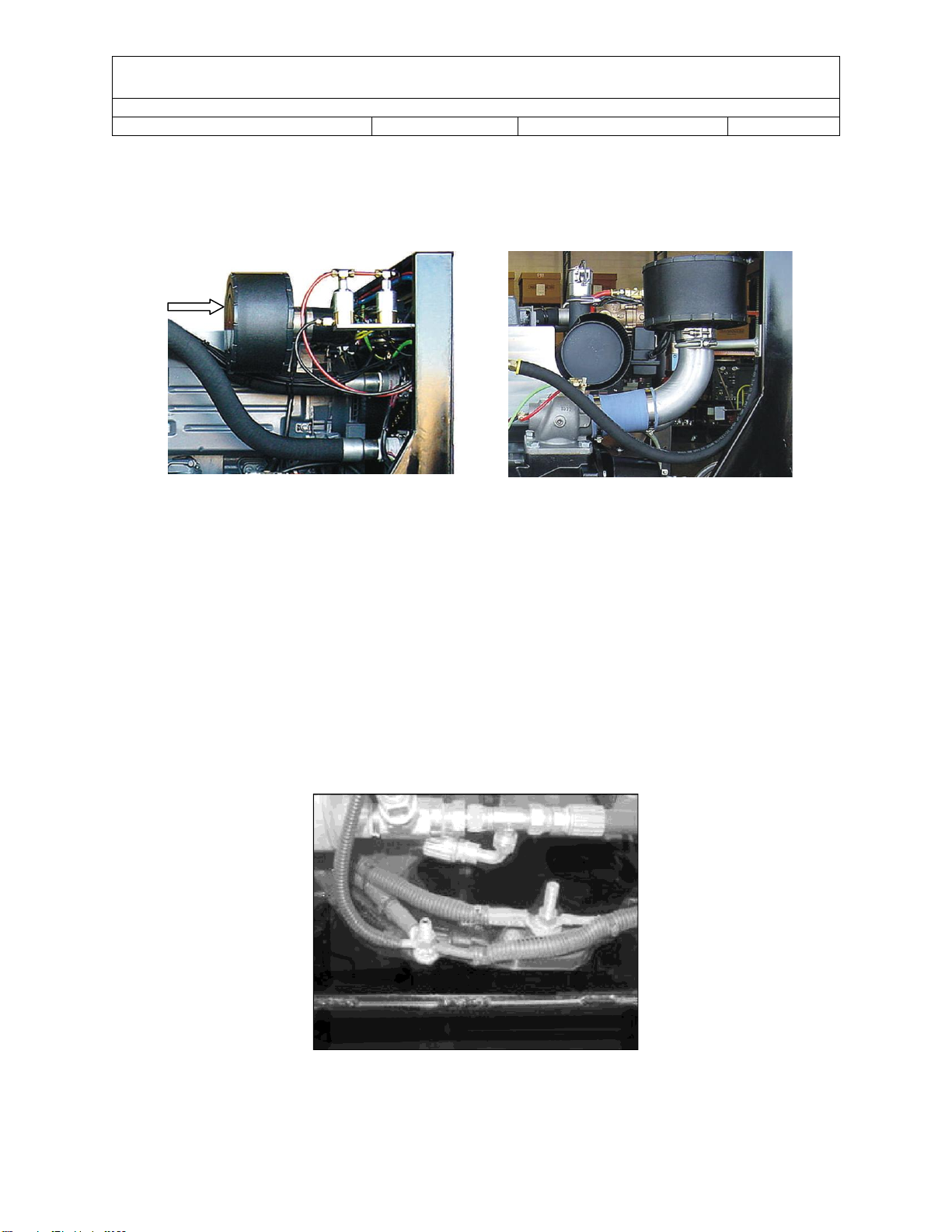

E. Fuel supply.......................................................................................................................................8

I. Fuel Filtering................................................................................................................................8

II. Fuel Tanks...................................................................................................................................8

III. Supply and Return Fuel Lines for Fuel Injection..........................................................................8

IV. Fuel line Materials........................................................................................................................8

V. Tank height offsets ......................................................................................................................9

SECTION 3. INITIAL POWERUP ..........................................................................................................11

A. Post-Installation, Pre-Power up Safety Check...............................................................................11

B. Initial Engine and Fire Pump Power up..........................................................................................11

I. Initial Compressor System Power up ........................................................................................12

SECTION 4. VERIFYING THE AUTO SYNC AIR BALANCING SYSTEM............................................13

A. UNLOAD mode verification............................................................................................................13

B. FIXED mode verification ................................................................................................................14

C. AUTO mode verification.................................................................................................................14

SECTION 5. OPTIONAL PROGRAMMABLE VALVE CONTROLLER..................................................15

A. Operation .......................................................................................................................................15

B. Programming..................................................................................................................................15

C. Wiring Harness Pin-Out .................................................................................................................15

SECTION 6. SUGGESTED THIRD-PARTY COMPONENTS ...............................................................16

A. Suggested components for CAFS discharges:..............................................................................16

B. Suggested Air and Hydraulic Hose................................................................................................16

I. Push-On.....................................................................................................................................17

II. Air Brake....................................................................................................................................17

III. Hydraulic....................................................................................................................................17

SECTION 7. TROUBLESHOOTING......................................................................................................18

A. CAFS..............................................................................................................................................19

B. Pump..............................................................................................................................................23

SECTION 8. INITIAL ADJUSTMENT OF THE AUTO-SYNC AIR BALANCING SYSTEM ...................27

A. Electric Auto-Sync Initial Setup......................................................................................................27

I. UNLOAD Mode Initial Setting....................................................................................................27

II. FIXED Mode Initial Setting.........................................................................................................29

III. AUTO Mode Initial Setting.........................................................................................................30

SECTION 9. CONDITIONAL 5-YEAR WARRANTY POLICY ...............................................................38