2iQUBE Installation Manual

Configuration consists of the following steps:

Define Load Cells: This is the electrical sensitivity

(mV/V output) and capacity specification of the load

cells. Load cell names and serial number can also be

specified.

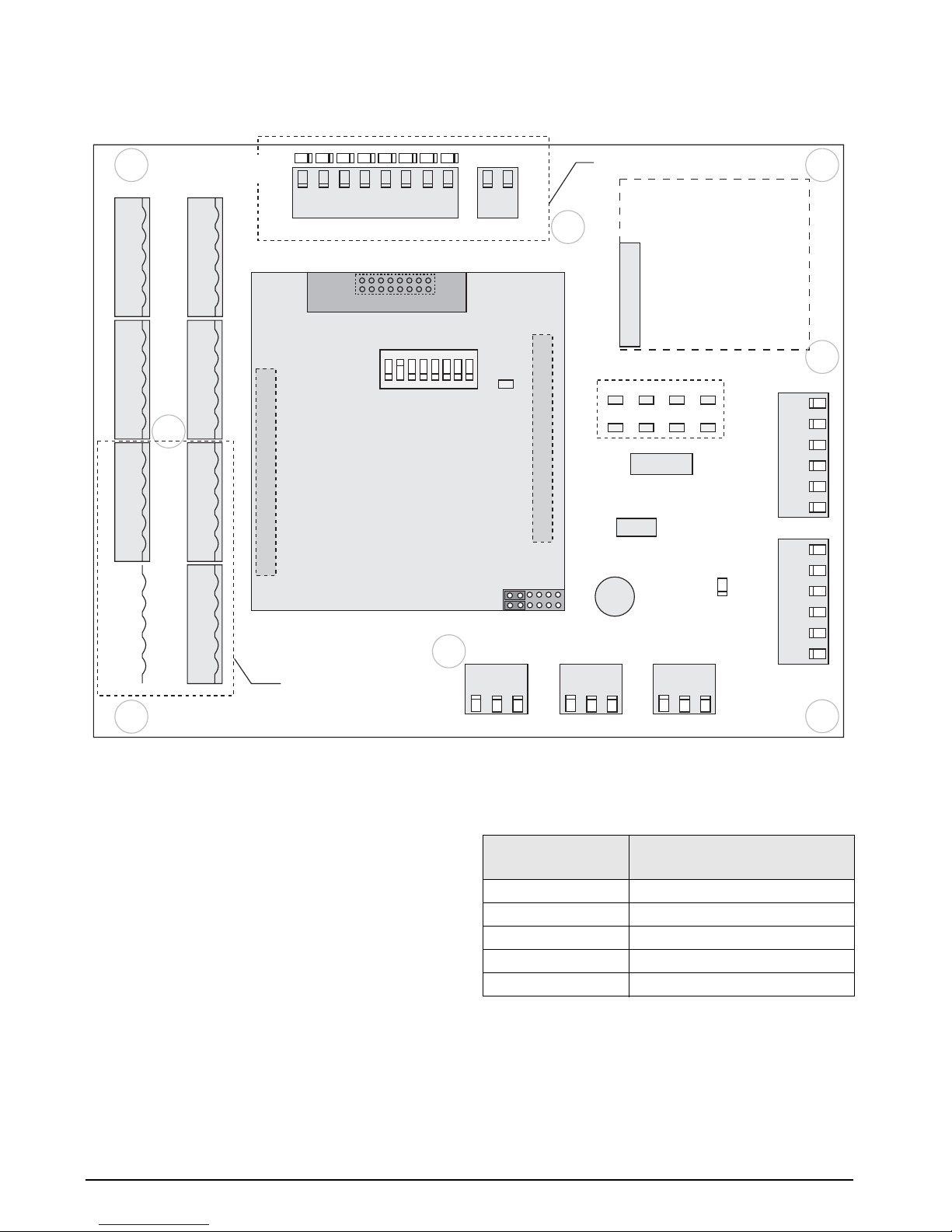

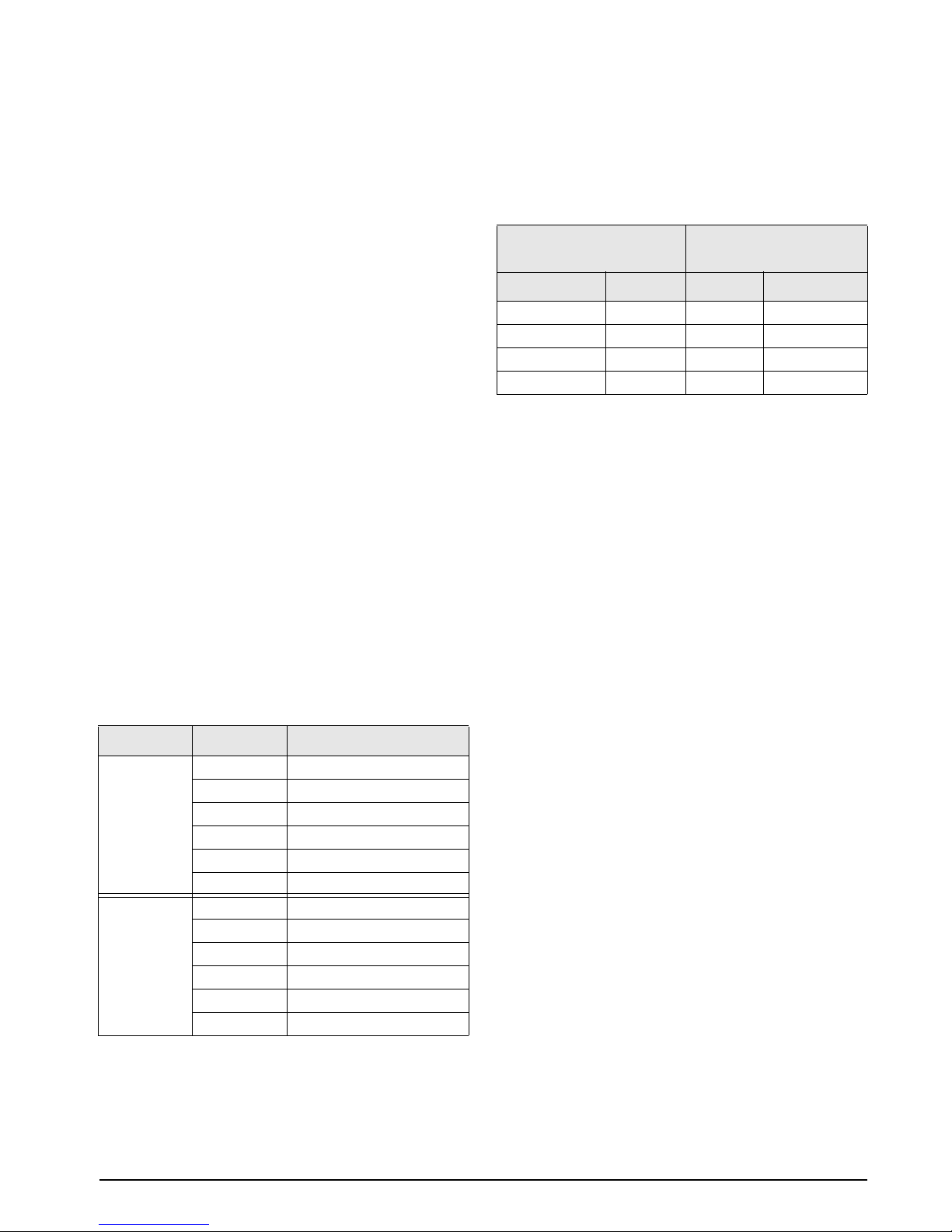

Define Platforms: Any iQUBE board can assign load

cells to two separate platforms. A maximum of four

platforms can be defined in an iQUBE system. The

relationship between load cells is also defined as a

paired or circular arrangement.

Define Systems: The platforms can be assigned to a

system. Up to four unique systems can be defined,

however the 920i will only support one system per

serial channel.

Load Cell Trimming and Calibration

Cal-Match™calibration calculates the load cell trim

based on a comparison of the signal generated by an

applied weight for each load cell to the signal

generated by all other load cells. If a known test

weight value is used, this calibration also sets the span

for the scale.

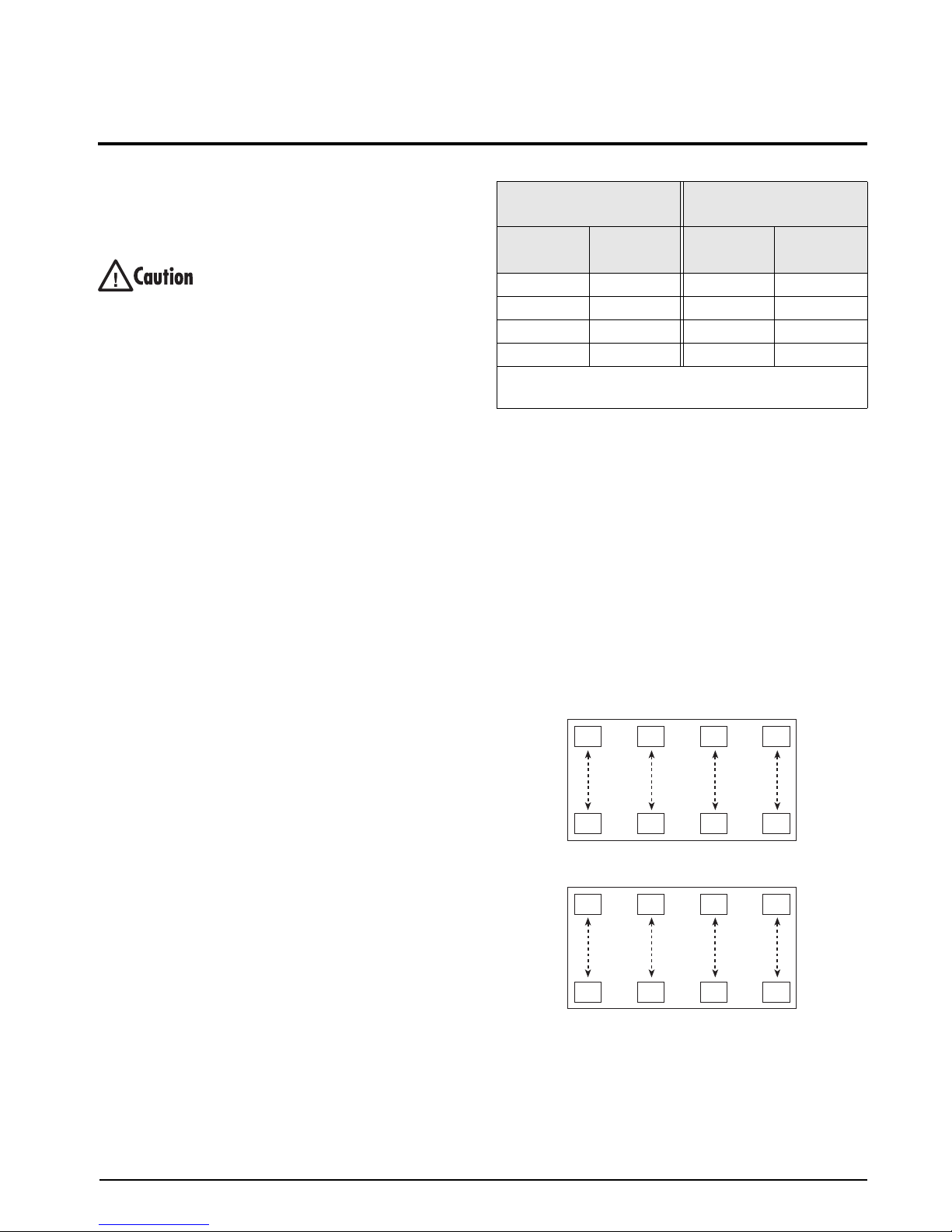

Three types of Cal-Match calibration can be

performed using the iQUBE. Each type of calibration

captures the initial dead load of the scale and provides

a means to trim the outputs of the load cells.

Theoretical calibration allows each cell to be zeroed

and trim factors calculated. Based on the cell capacity

and sensitivity, the iQUBE calculates weight values

based on the total signal from all of the cells.

Section calibration requires a weight to be placed

over each section. Trimming can be performed by

running a weight cart down the middle of the

platform, stopping for calibration of each section.

Corner calibration requires weight to be placed over

each cell individually. Corner trimming can be

performed for platforms using an even or odd number

of cells.

Diagnostics

Diagnostic functionality can be enabled for the iQUBE

to identify abnormal load cell outputs. This is based

on the reference established through cell associations.

The diagnostic conditions that can be identified for

paired configurations are open bridge or channel, zero

reference tolerance, drifting, peak-to-peak noise, and

out-of-balance conditions. Diagnostic conditions

recognized for circular configurations are limited to

open bridge or channel, drifting, and peak-to-peak

noise.

Error conditions generate a displayed error message if

connected to the 920i which, with an Ethernet card,

can be configured to e-mail the alert message to an

address. In addition, there is a visual LED indication

on the connector board to identify any load cell that

appears to have an abnormal condition.

Cell Emulation

Cell emulation allows the output of a failed load cell

to be emulated. Automatic or manual cell emulation

can be specified (limited to one cell per scale system),

using either truck scale (Type 1) or tank/hopper/floor

scale (Type 2) emulation algorithms.

NOTE: Satisfactory results from cell emulation require the

load to be centered and the scale installation to be plumb and

level.

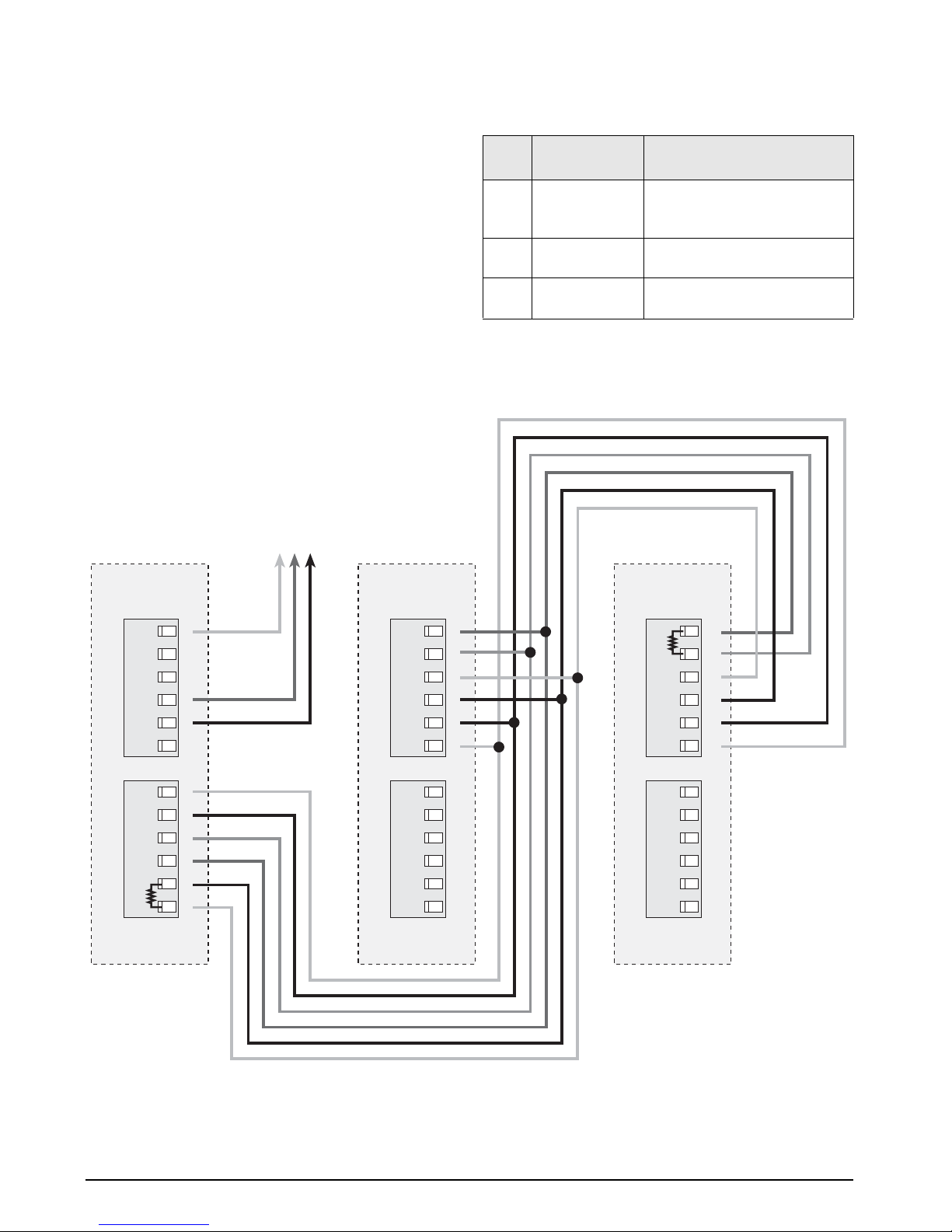

1.1 System Configurations and Options

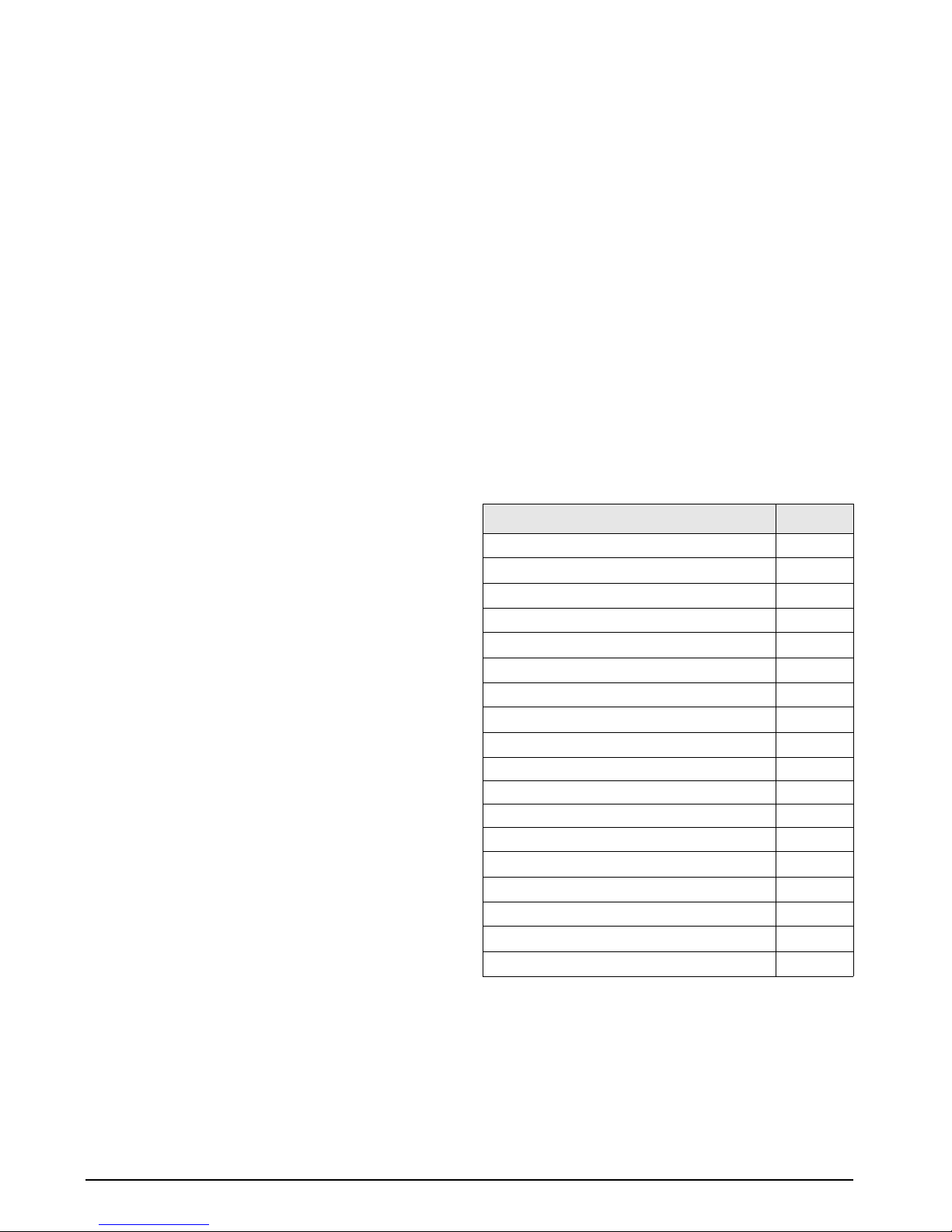

Table 1-1 lists iQUBE model and option part numbers.

920i part numbers listed are for models without A/D

cards.

Model / Option PN

4-channel iQUBE 77778

8-channel iQUBE 77148

8-channel iQUBE with digital I/O 77728

iQUBE internal power supply, 6 VDC 77531

iQUBE internal Ethernet interface 77142

iQUBE internal fiber-optic interface 77143

920i internal fiber-optic interface 77788

920i internal Ethernet communications card 71986

920i Serial expansion card 67604

Remote (external) fiber-optic interface 77789

Analog output, 0–30 mV 77146

Analog output, 4–20 mA 77797

920i universal model, 115 VAC 77790

920i universal model, 230 VAC 77791

920i panel mount model, 115 VAC 77792

920i panel mount model, 230 VAC 77793

920i wall mount model, 115 VAC 77794

920i wall mount model, 230 VAC 77795

Table 1-1. iQUBE Model and Option Part Numbers