RLH Industries Smart 8 User manual

Smart8Relay Output

User Guide

U-123 2018B-0330

RLH Industries, Inc.

!RLH Industries, Inc.!

Copyright © 2017 RLH Industries, Inc. All rights reserved.!

No part of this document may be copied or distributed without

permission.

The RLH logo may not be used for commercial purposes without the

prior written consent of RLH and may constitute trademark

infringement.

Other company and product names mentioned herein are trademarks

of their respective companies. Mention of third-party products is for

informational purposes only and constitutes neither an endorsement

nor a recommendation. RLH assumes no responsibility with regard to

the performance or use of these products.

The information contained in this document is the property of RLH

Industries, Inc. and may not be reproduced or disseminated to third

parties without the express written permission of RLH.

Every effort has been made to ensure that the information in this

manual is accurate. RLH is not responsible for printing or clerical

errors. Because we are constantly seeking ways to improve our

products, specifications and information contained in this document

are subject to change without notice.

RLH Industries, Inc.!

936 North Main Street!

Orange, CA 92867!

!

Ph. 714 532-1672!

email: info@fiberopticlink.com!

www.fiberopticlink.com

""

2

Contents

1.!Important Information

Intended Audience 5

Conventions 5

Standard Features 6

Panel Layout 7

Front Panel#7

LED Identification#7

System Alarm Contacts#8

Bottom Panel#8

Rear Panel#8

3.!Before Installing

Prepare for Installation 9

Check for shipping damage#9

Verify system contents#9

Site Requirements 9

Site selection#9

Typical installation environments#9

Required power sources#9

4.!Installation

Getting Started 10

Before starting#10

Install the Smart Relay Output#10

Connect wiring to Relay Output Contact Terminals#10

Relay Output Maximum Ratings#10

Connect Ethernet cable#10

Connect power#11

System alarm wiring#11

Start the system#11

5.!Establishing Connection to Device

General Connection 12

Default Settings#12

Assigning a Static IP Address 12

Steps for Window XP#12

Steps for Windows 7#15

6.!Device Configuration

Network Address Configuration 18

Email / SMTP Server Configuration 19

Contents 3

1.#Important Information

Relay Setup 20

Relay Control 21

System Link Configuration 22

Date/Time – NTP vs Local Time 24

SNMP Community Configuration 25

ModBus TCP 26

Function 1: Read Coil#27

Function 3: Holding Register"# 27

Function 6: Write Single Register#27

Function 16: Write Multiple Register#28

DNPv3 TCP 29

DNPv3 Device Profile#30

DNPv3 Implementation Object Table#31

DNPv3 Control Relay Output Block (CROB) Table#32

Relay Output Log 33

Administration Tasks 34

Change Password#34

Rebooting#34

Set to Factory Defaults#34

Hard Reset#35

Software Factory Reset#35

7.!Configuration Examples

Event Consolidation - Many Inputs to One Output 36

8.!Application Examples

Contact Closure over Ethernet - One to One (TCP) 37

Contact Closure over Ethernet - One to Many (UDP) 37

Event Consolidation - Many Inputs to One Output 38

Remote Relay Control 38

9.!Specifications

General Specifications 39

10.!Ordering Information

System Models 40

11.!Support

Technical Support 41

Contact Information 41

Contents4

Intended Audience

This manual is intended for use by qualified technology experts and includes references to industry standard

terminology and practices. Every effort has been made to ensure the information in this manual is accurate,

however due to constant product improvement specifications and information contained in this document is

subject to change without notice. For the most up to date information on this product you can visit

www.fiberopticlink.com.

Conventions

Symbols for notes, attention, and caution are used throughout this manual to provide readers with additional

information, advice when special attention is needed, and caution to prevent injury or equipment damage.

Notes: Helpful information to assist in installation or operation.

Attention: information essential to installation or operation.

Caution: Important information that may result in equipment damage or injury if ignored.

General Safety Practices

RLH recommends that installation and service personnel be familiar with the correct handling and use of

electrical and network equipment prior to use. RLH also recommends that installation and service personnel

follow all safety precautions including the use of protective personal equipment as required.

Caution - Severe Shock Hazard!

• Always remove source voltage using proper lockout procedures prior to installation and service.

• Never wire any relay outputs with hot (live) connections.

• Remove the terminal block when wiring.

• Check that all equipment has been properly locked out before restarting or configuring the device.

Contents 5

Ethernet I/O

The Smart Relay Output is an Ethernet device with 8 Integrated controllable relays. The device allows for web

based control of the relays and may be integrated into distributed control and network management systems to

allow those systems to control it's Relays. Each of the Relays can be individually configured to send customized

emails and notifications when an event is triggered. The device supports a wide variety of protocols it is

compatible with over Ethernet. Integration options supported are: SNMPv1,2c,3, SNMP Traps !

(SNMP 1, 2vc), Modbus TCP featuring addressable registers, and DNPv3 TCP for integration with utility and

other automation control systems.

Contact Closure Over Ethernet

The RLH Smart Relay Output may be paired with an RLH Smart Input Sensor. When using RLH's System Link

feature, the two devices become linked establishing a tunnel over an Ethernet network and will transport a

digital outputs being received by the Input Sensor through the Ethernet tunnel to the linked Relay Output

device. The System Link feature can be set up via: One to One, Many to One, and One to Many allowing for

event distribution and consolidation as needed.

Standard Features

Rugged Design - Operating temp. -40°C ~ 70°C

Intuitive embedded web interface for configuration

System Link - Pair with a Input Sensor for Alarm Transportation over Ethernet

Event Consolidation – Pair with up to 8 Input Sensors to consolidate remote alarms to one location

Alarm Distribution - Multiple output units may be paired with one Input Sensor

IGMP V2 supported to enable multicast routing in one to many configurations

Remote Control of 8 Relays

Custom email notifications for each output

Each relay supports up to 3 Amps or 60 Watts

Advanced SMTP integration allowing for SSL and TLS based authentication

Integration options include: SNMPv1, 2c, 3, SNMPv1,2c Traps, Modbus TCP, and DNPv3 TCP

Output event log with time stamps

System power ranges available: 24-48VDC, 125VDC, & 12VDC.

10/100 Fast Ethernet Port

Limited Lifetime Warranty

Made in the U.S.A."

Introduction6

•Verify or repair before continuing

Panel Layout

Front Panel

The front panel contains all the relay output terminals, LED’s, and the Ethernet port.

!

Front Panel Features

LED Identification

SERIES

Smart

1 5

LNK

ACT

2 6

3 7

4 8

10/100M

ETHERNET

PWR

STS

LNK

RLH Industries, Inc.

RELAY

OUTPUT

OUTPUTS

OUT 1 OUT 2 OUT 3 OUT 4 OUT 5 OUT 6 OUT 7 OUT 8

RX

Power LED

Status LED

System Link LED

1~8 Output LED’s

Ethernet Link LED

Ethernet Activity LED

1~8 Relay!

Outputs

Power & Alarm

Terminals

Ethernet Port

LED

Name

Color

Status

Condition

Outputs

1-8

Contact Output

Green

ON

Relay is energized

OFF

Relay is not energized

PWR

Power Failure

Green

ON

DC input power OK

OFF

DC input power failed

STS

CPU Failure

Green

Blinking

CPU operating normally

Solid (On or Off)

CPU failure

LNK

System Link

Green

ON

Paired via TCP connection

OFF

Not paired with output unit

LNK

Ethernet Link Down

Green

ON

Ethernet link is present

OFF

No Ethernet link present

ACT

Ethernet Activity

Orange

Blinking

Ethernet is active

OFF

Ethernet is not active

Introduction 7

System Alarm Contacts

• Alarms on power failure.

• Alarms when Ethernet Link Down.

• Can be configured to alarm when the system link to a paired Input Sensor is disconnected.

Bottom Panel

The bottom panel contains the power and alarm terminals.

!

Bottom Panel Features

Rear Panel

The DIN clip for mounting the system is mounted onto the rear panel. Insert a flat head screwdriver into the

release slot at the bottom of the DIN clip and pull down to remove the system from the DIN rail.

!

RESET

PWR2

PWR1

COM

NO

ALARM

NC

Alarm Terminal

Reset Button

3.9”

100mm

2.0”

51mm

Power Terminals 1 & 2

5.0”

127mm

DIN Clip

Release!

Slot

Rear Panel Features

Smart Relay!

Output

Smart Relay!

Output

1

Hook top of

DIN clip first

2

Rotate and

snap into

position

DIN!

Rail

DIN!

Rail

DIN Rail Mounting

Introduction8

3.#Before Installing

Prepare for Installation

Check for shipping damage

Carefully unpack and inspect the device. Contact RLH immediately if any components are damaged or missing.

Verify system contents

• Smart Relay Output device

• Attached DIN Clip

• Correct model type for intended application.

Site Requirements

Site selection

Locate the Smart Relay Output to allow easy access to the equipment. Leave at least 3 inches (7.62 cm)

clearance in the front. The device is temperature hardened, but must be mounted indoors or inside an outdoor

rated enclosure.

Typical installation environments

• NEMA 4X enclosures

• RLH 19” rack mount DIN rail brackets

• Control cabinets

• T-35 DIN rail

Required power sources

The Standard RLH Smart Relay Output system accepts 24~56VDC. RLH also offers optional power

compatibility to both Low DC (12 Volts) and High DC Power (125 Volts) for enhanced compatibility with solar

and utility battery systems.

Before Installing 9

4.#Installation

Getting Started

Before starting

• Review the safety information in section 1. Important Information

• Familiarize yourself with the Smart Relay Output as described in section 2. Introduction

• Have a suitable installation environment with the correct source voltage.

Install the Smart Relay Output

• Mount the 8 Channel Relay Output to T-35 DIN rail.

Connect wiring to Relay Output Contact Terminals

• There are 8 pairs of output contact terminals located on the front panel of the 8 Channel Relay Output.

• The pluggable contact terminals may be removed if needed and will accept wire sizes 16~26 AWG.

• Fully seat the terminal block back into the connector socket before operating the system

Relay Output Maximum Ratings

RLH Recommends using a external relay for applications where voltage and amperage exceed the devices

built-in Relays specifications. Exceeding the maximum ratings may lead to premature failure or improper

operation of the Relays.

Connect Ethernet cable

• Attach the Ethernet cable to the RJ-45 Ethernet port located on the front panel of the Smart Relay Output. Verify

the Link indicators are ON to ensure you have connectivity to your network.

Relay Maximum Ratings

115VAC

1.08A

125VA

12VDC

3.00A

36 Watts

24VDC

2.50A

60 Watts

48VDC

1.25A

60 Watts

130VDC

0.46A

60 Watts

220VDC

0.27A

60 Watts

Quick Start Guide10

Connect power

The Smart Relay Output has redundant power terminals to accommodate a backup power supply in the event

of an outage. Follow these steps when attaching wires to power terminals located on the bottom of the module.

• Check that DC power source voltage matches the accepted voltage range of the device.

• Remove power from the DC power source prior to connecting to the Smart Relay Output.

• Connect the DC power cables to the terminal pairs. The power terminals are not polarity sensitive.

• Energize the power source. The PWR LED will be ON indicating that the system has power.

System alarm wiring

Connect alarm relay monitoring equipment wire pair to the alarm contact on the bottom of the device.

• Use the NO or NC contact positions as required.

• The alarm terminal block may be removed and accepts wire sizes 16~26 AWG.

• Fully seat the terminal block back into the connector before operating the system.

Start the system

Once a local power source is connected and turned on the PWR LED will turn ON. The STS LED will be

blinking to let you know the device is operating normally.. "

Installation 11

5.#Establishing Connection to Device

General Connection

To initially connect to the RLH Smart Relay Output you must access the device by its default IP address as

listed below:

Default Settings

!

In most cases you will need to assign a temporary static IP to your workstation to initially access the RLH Smart

Relay Output web page. The assigned temporary address should be within the same subnet as the default

address.

Example Client Device Address:

• IP: 192.168.2.10

• Subnet: 255.255.255.0

Now access the device via: http://192.168.2.17

Assigning a Static IP Address

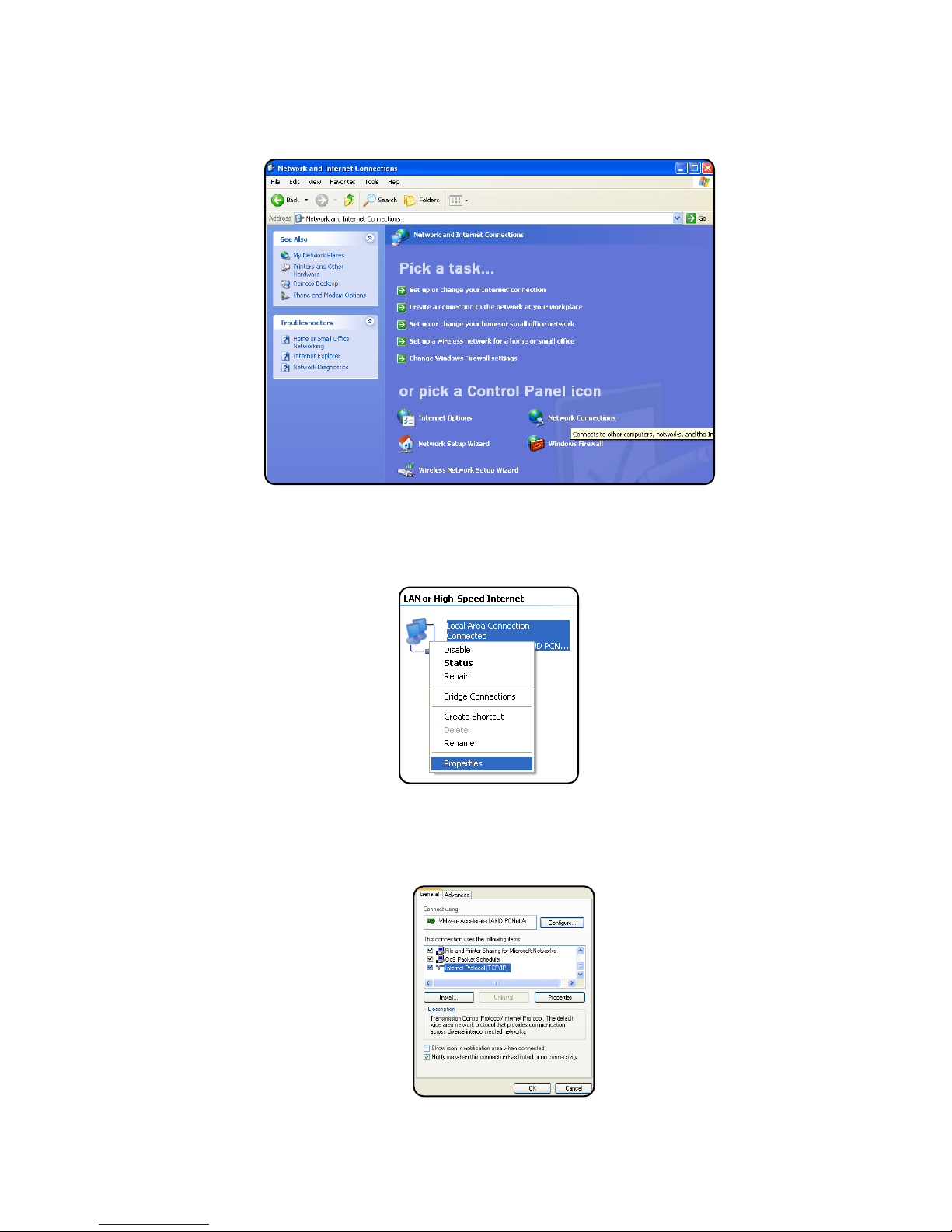

Steps for Window XP

First: Go to windows XP control panel and select Network and Internet Connections.!

!"

IP Address: 192.168.2.17

Subnet: 255.255.255.0

Username: admin

Password: admin

Default IP Address

Default Username/Password

Establishing Connection to Device12

Next: Select Network Connections

!

Next: Right-click on the adapter you want to set the IP for and select Properties.!

!

Next: Highlight"Internet Protocol (TCP/IP)"and click the Properties button.!

!

Establishing Connection to Device 13

Next: Select Network Connections

!

Next: Right-click on the adapter you want to set the IP for and select Properties.!

!

Next: Highlight"Internet Protocol (TCP/IP)"and click the Properties button.!

!

Establishing Connection to Device14

Next: Change the IP, Subnet mask, Default Gateway, and DNS Server Addresses. When you are finished

click OK.

!

Note: You will need to close out of the Network Connection Properties screen before the changes go into

effect.

Finally: Verify IP Address:

• In the Run box type in"cmd"and click OK.

• Then at the prompt type in"ipconfig"and hit Enter. This will show the IP address for the network adapter you

changed.

Steps for Windows 7

First: To a static IP address in Windows 7, type"network and sharing"into the Search box in the Start Menu and

select Network and Sharing Center when it comes up.

!

Establishing Connection to Device 15

Next: When the Network and Sharing Center opens, click on"Change adapter settings.

!

Next: Right-click on your local adapter and select Properties.

!

Next: In the Local Area Connection Properties window highlight"Internet Protocol Version 4 (TCP/IPv4)"then

click the Properties button.

!"

Establishing Connection to Device16

Finally: Now select the radio button"Use the following IP address"and enter in the correct IP, Subnet

mask, and Default gateway that corresponds with your network setup. When you’re finished click OK.

!

Note: Now you can open the command prompt and do an"ipconfig to see the network adapter settings have

been successfully changed.

Establishing Connection to Device 17

6.#Device Configuration

Network Address Configuration

!

Network Address Configuration Screen

Note: If unsure of the address to assign your device you may wish to consult your network administrator for the

correct addressing information for your network

Settings

Description

Mac Address

Read only field will display the mac-address of your device.

Host Name

Enter the host name which your DNS server will register your device as.

Enable DHCP

If checked, this option allows you to automatically obtain addressing information

from your networks DHCP server.

IP Address

Set a static IP address for which you wish to assign to the device.

Subnet Mask

Set subnet mask you wish to use.

Gateway

Set the default gateway the device will use.

Primary DNS

This will be the first server your device connects to for translating URLs and Fully

Qualified Domain Names (FQDNs).

Secondary DNS

In case of an outage in the primary DNS server the device will attempt to use the

secondary DNS as a backup.

Device Configuration18

Email / SMTP Server Configuration

!

SMTP/Email Configuration Screen

Note: SSL connections will only support up to 1024 Bit certificates.

Settings

Description

SMTP Server

Enter the FQDN or the IP address of the email server you wish to use.

Port

Set to 25 by default.

Encryption

None - No encryption will be used when communicating with SMTP server!

SSL (V2) - Encryption will be used when communicating with SMTP server

TLS (V1.1) - Encryption will be used when communicating with the SMTP server

Username

Enter in your SMTP server username.

Password

Enter your SMTP server password.

From

This will be the from address the device uses in email notifications.

To

Email Address for the To field for SMTP notifications.

CC

Email Address for the CC field for SMTP notifications.

Checkbox!

(Send Test Email)

If checked the device will send a test email when the "Save Settings" !

button is clicked.

Device Configuration 19

Relay Setup

The Relay Setup page allows you to assign names, descriptions, and enable email notifications for each relay.

!

Relay Setup Screen

Settings

Description

Name

Assign a name to each relay

Enable Email

Notifications

Enable email notifications when the relay changes state. Email notifications will

include the device Hostname, relay name, relay description, relay status, and a

time stamp if NTP is configured.

Description

Provide a description for each relay

Save Settings

Apply the new setting information by clicking the button at the bottom of the page

Device Configuration20

Table of contents

Popular Other manuals by other brands

Bosch

Bosch TR2000 Series Installation and operating instructions

Red Sea

Red Sea REEFER DLX 425 Assembly manual

Whelen Engineering Company

Whelen Engineering Company Super-LED FDCT10BR installation guide

ELWING

ELWING HALOKEE user guide

Pioneer

Pioneer MVH-X360BT owner's manual

Arregui

Arregui Supra Instruction manual and guarantee

ETAS

ETAS ES5338.1 user guide

Paradyne

Paradyne 9261 installation instructions

Beauty Works

Beauty Works Mini Microdermabrasion Instructions for use

Aquatlantis

Aquatlantis Tecatlantis EASY LED UNIVERSAL 2.0 manual

Toyotomi

Toyotomi TD-C210 operating manual

Craftwell

Craftwell Cut'n'Boss Limited Edition user manual