SAFETY INSTRUCTIONS

! WARNING

Operator responsibility

x Any part of the machine is a potential source of danger if the machine is used in abnormal

conditions or if maintenance is not done correctly.

x Read the Manual carefully. Be familiar with the controls and their proper use. Know how to

stop the engine rapidly and how to release the ratchet strap quickly when it is used to secure

the PowerPack to a borehole.

x Use the machine only for the purpose it is intended for.

x Never allow people unfamiliar with this Manual (including the Honda Engine Manual) to use the

PowerPack. Local regulations may restrict the age of the operator.

x If you lend or resell the PowerPack to a third party, instruct him/her how to handle the product

and alert him/her to read the Manual carefully before use.

x Never use the PowerPack while user is fatigued or under medication, or if the user has

swallowed substances known to affect judgement or reactions.

x Ensure untrained people and animals are at least 5 metres away from the operator and any

assistant should be at least 2 metres from the machine. We recommend that a stop signal and

other signals between operator and assistant be decided prior to operation and that they are

used for safety during operation.

x Keep in mind that the operator or user is responsible for accidents or hazards occurring to other

people or their property.

x While operating the PowerPack always wear the following protective clothing and protective

devices:

¡ Protective clothing: wear adequate clothing, which fits closely. Do not leave sleeves and the

bottom of shirt/jacket loose. Do not wear clothes with tapes, laces and /or ribbons, necktie,

necklace etc during operation, as they could be caught in the machine. Bind your hair if it is

long and do not let your hair fall below your shoulders.

¡ Protective devices: Wear appropriate ear protection to protect your hearing from high pitched

noise; wear safety footwear with toe protectors to avoid damaging your feet by dropping the

PowerPack.

x Before each use, visually inspect the PowerPack for any damage or loose fixings.

x Never mount an incorrect part and do not tamper with the PowerPack, as this could result in

personal injury or damage to the equipment.

x Do not change the engine governor settings or over-speed the engine.

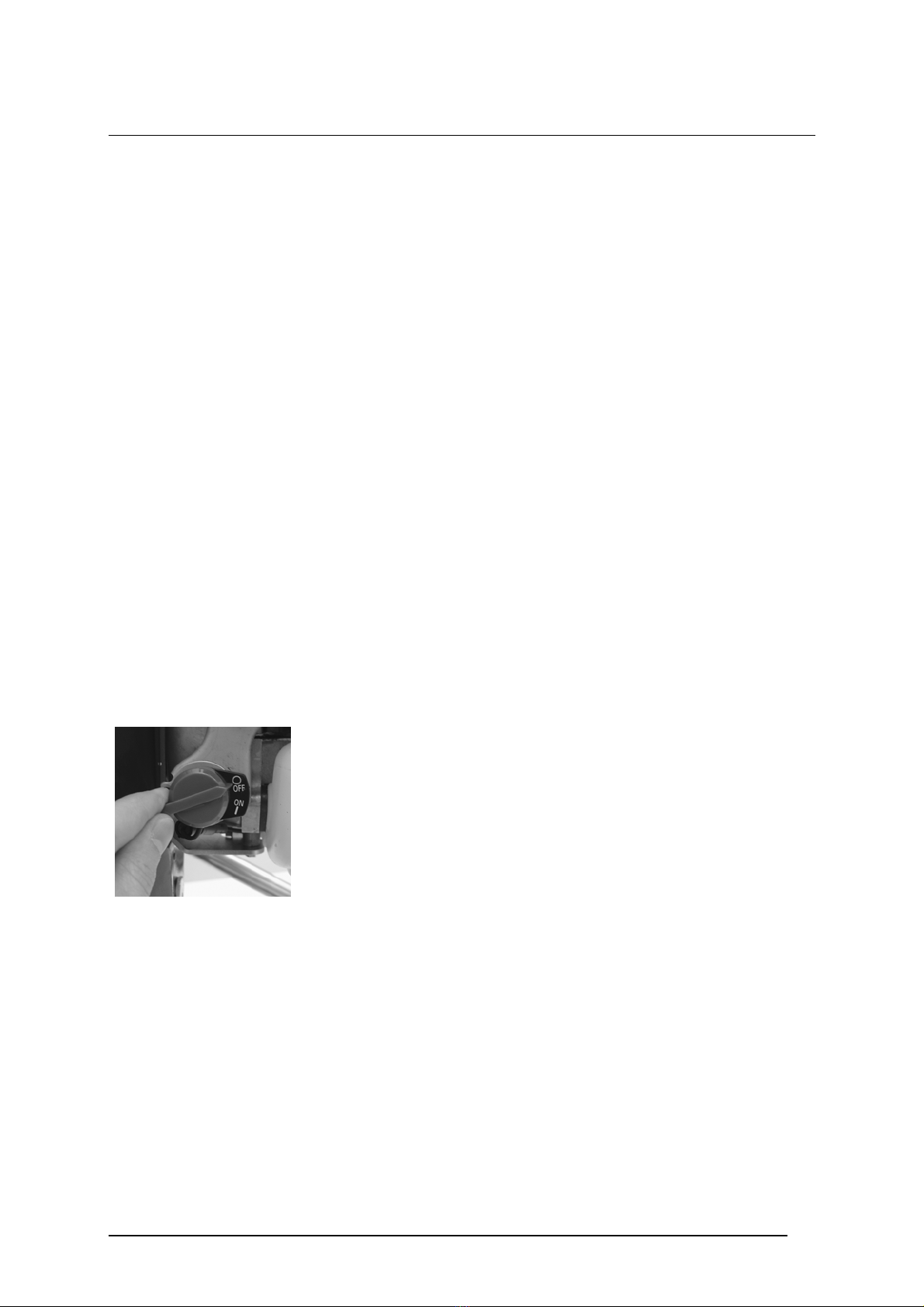

x Start the engine carefully according to the instructions.

x Never pick up or carry the PowerPack while the engine is running.

PP1

6